Microstructure and properties of composite of stainless steel and partially stabilized zirconia

来源期刊:中国有色金属学报(英文版)2003年第1期

论文作者:张文泉 谢建新 杨志国 王从曾

文章页码:140 - 144

Key words:functionally gradient materials; high temperature burner; composite; stainless steel; zirconia; threshold

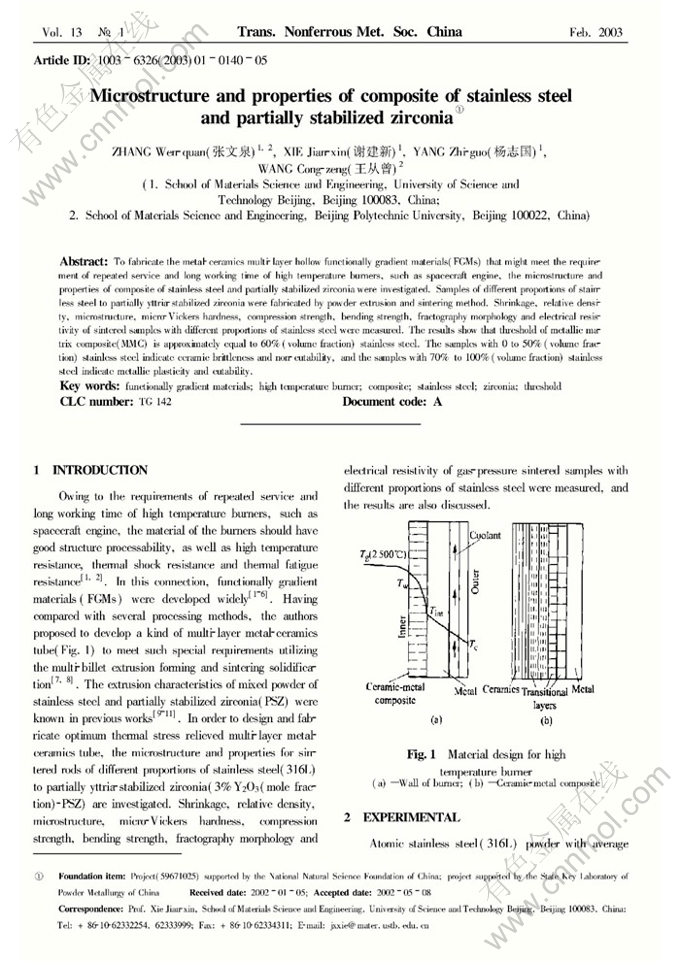

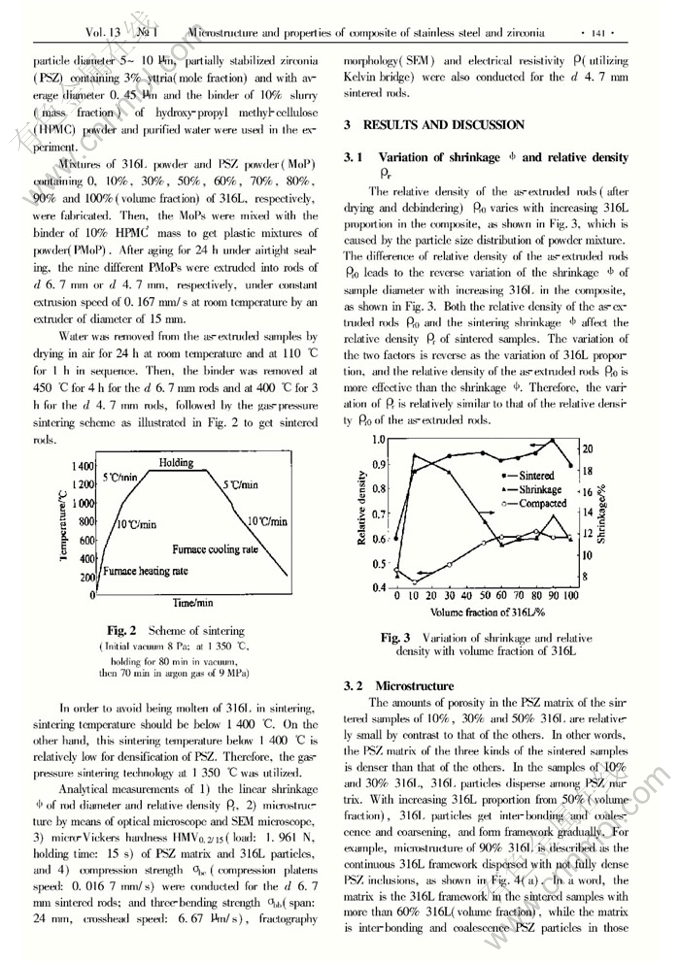

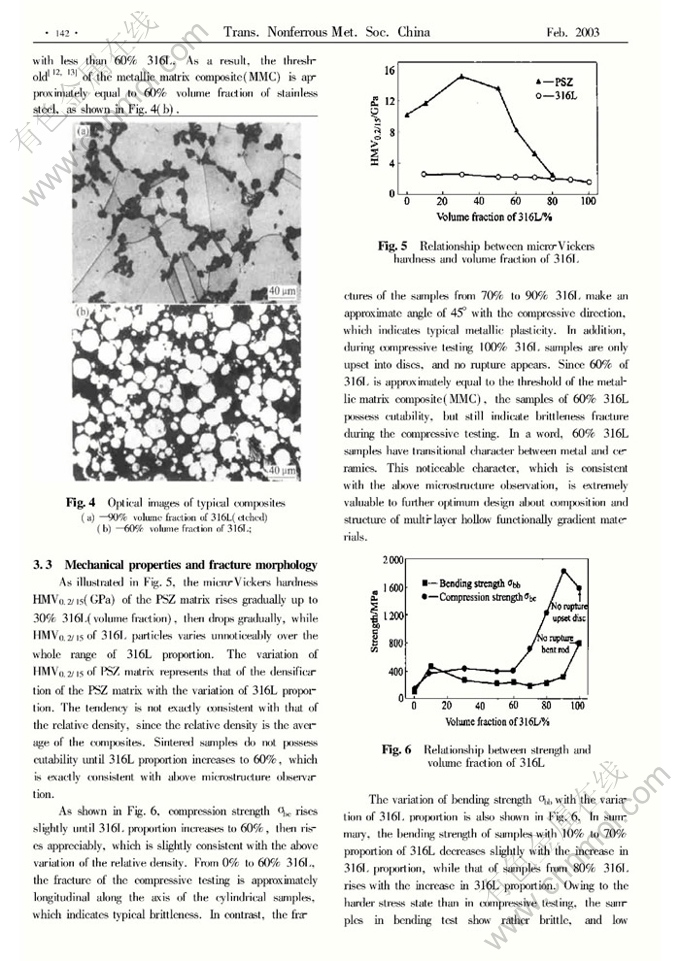

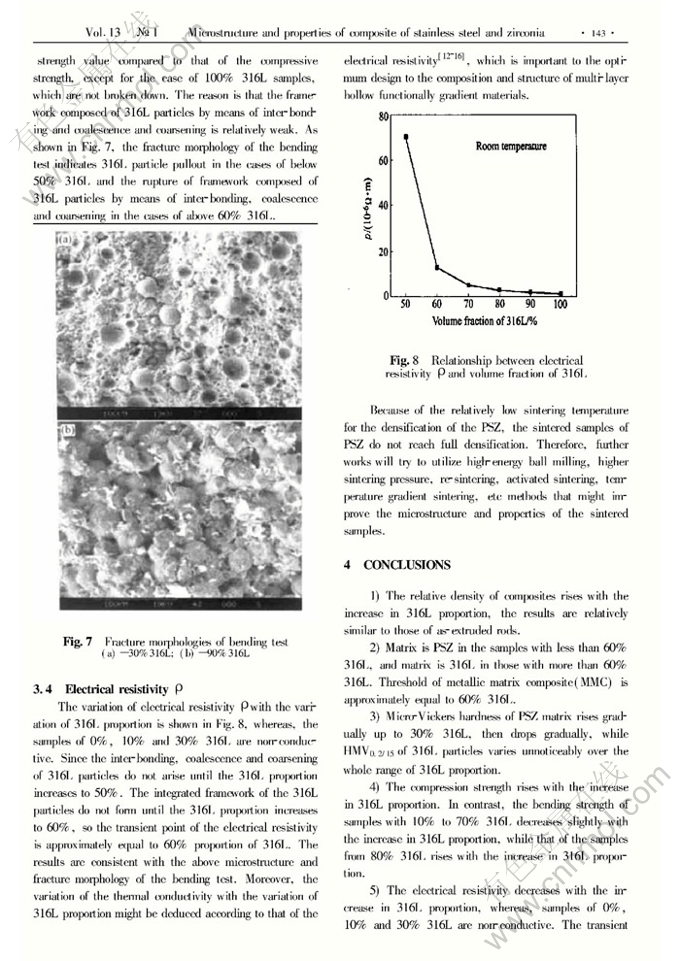

Abstract: To fabricate the metal-ceramics multi-layer hollow functionally gradient materials(FGMs) that might meet the requirement of repeated service and long working time of high temperature burners, such as spacecraft engine, the microstructure and properties of composite of stainless steel and partially stabilized zirconia were investigated. Samples of different proportions of stainless steel to partially yttria-stabilized zirconia were fabricated by powder extrusion and sintering method. Shrinkage, relative density, microstructure, micro-Vickers hardness, compression strength, bending strength, fractography morphology and electrical resistivity of sintered samples with different proportions of stainless steel were measured. The results show that threshold of metallic matrix composite(MMC) is approximately equal to 60%(volume fraction) stainless steel. The samples with 0 to 50%(volume fraction) stainless steel indicate ceramic brittleness and non-cutability, and the samples with 70% to 100%(volume fraction) stainless steel indicate metallic plasticity and cutability.