DOI: 10.11817/j.ysxb.1004.0609.2021-36632

叠层缝合结构C/C-SiC复合材料微观结构与弯曲性能

赵向坤1,王雅雷1,熊 翔1,杜鹏程1,叶志勇1,刘聪聪1,刘宇峰2

(1. 中南大学 粉末冶金研究院,长沙 410083;

2. 航天材料及工艺研究所 先进功能复合材料技术重点实验室,北京 100076)

摘 要:为了满足高超音速飞行器热结构部件材料的需求,采用化学气相沉积法(CVD)和反应熔渗法(RMI)混合工艺制备了叠层缝合C/C-SiC复合材料,研究C/C多孔体密度和熔渗温度对C/C-SiC复合材料微观结构和弯曲性能的影响。结果表明:C/C多孔体孔径呈双峰分布,孔体积随C/C多孔体密度增加而降低。C/C-SiC 复合材料由 SiC、C 及残余 Si 相组成。C/C-SiC复合材料弯曲强度随熔渗温度的升高而增加;1650 ℃制备的C/C-SiC复合材料弯曲强度随C/C多孔体密度升高先增加后略有减小,而1750 ℃制备C/C-SiC复合材料弯曲强度随C/C多孔体密度升高而升高。当C/C多孔体密度为1.55 g/cm3,熔渗温度为1750 ℃时,制备的C/C-SiC复合材料弯曲强度最高为253 MPa。在弯曲载荷作用下,C/C-SiC复合材料的位移-载荷曲线呈现“阶梯型”断裂行为。

关键词:C/C-SiC;叠层缝合结构;熔渗温度;C/C多孔体密度;弯曲强度

文章编号:1004-0609(2021)-07-1869-10 中图分类号:TB332 文献标志码:A

引文格式:赵向坤, 王雅雷, 熊 翔, 等. 叠层缝合结构C/C-SiC复合材料微观结构与弯曲性能[J]. 中国有色金属学报, 2021, 31(7): 1869-1878. DOI: 10.11817/j.ysxb.1004.0609.2021-36632

ZHAO Xiang-kun, WANG Ya-lei, XIONG Xiang, et al. Microstructure and flexural properties of laminated suture structure C/C-SiC composites[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1869-1878. DOI: 10.11817/j.ysxb.1004.0609.2021-36632

高超音速飞行器在大气中飞行时会承受严峻的气热和动热环境,为保证飞行器在高空中安全飞行,其热结构部件需满足耐高温、抗氧化和高强度等特点[1-2]。C/C-SiC复合材料具有耐高温、抗氧化及高温力学性能优异等特性,是飞行器热结构部件的理想材料[3-7]。碳纤维预制体是制备C/C-SiC复合材料的关键,决定了复合材料的性能。相比正交三向和碳布穿刺织物无法实现异构件仿形编织及针刺织物制备的复合材料力学性能偏低的特点,叠层缝合预制体不但使制备的复合材料力学性能优异,且具有较强的结构设计性和异形曲面的适应性,作为高超音速飞行器热结构部件具有优异的承载特性[8-10]。

目前,国内外学者已对叠层缝合C/C-SiC复合材料进行了一些研究。如:SURESH等[11]对缝合C/C预制体内部孔结构进行了表征,指出熔体渗透速率与孔径有关,当孔径在4.3 μm时渗透速率最佳。张兆杭等[12]采用三维随机碰撞算法对缎纹编织C/C-SiC复合材料的孔隙缺陷分布进行了建模分析,并探讨了孔隙缺陷的尺寸和分布形式对材料拉伸性能的影响。张根西等[13]研究表明加卸载行为会消耗缝合式三维编织C/SiC复合材料内部能量,对纤维与基体间的界面造成损伤,最终降低材料的承载能力。MEI等[14]研究表明,高缝合密度的叠层缝合预制体会严重损伤纤维,使基体产生大量的微裂纹。NIE等[15]研究表明,缝合线的存在能够小幅减少C/SiC复合材料的弯曲性能,但能显著提高材料的剪切性能,当缝合密度为5 mm/针时材料的性能最佳。而目前鲜有关于C/C多孔体密度和溶渗温度对叠层缝合C/C-SiC复合材料微观结构与弯曲性能内在联系的报道,尤其是弯曲性能作为复合材料在实际应用的必检指标,研究C/C多孔体密度和溶渗温度对C/C-SiC复合材料微观结构和弯曲性能的影响具有重要意义。

本文作者通过化学气相沉积法(CVD)在预制体内部引入热解碳(PyC),制备了3种不同密度的C/C多孔体,然后采用反应熔渗法(RMI)制备了叠层缝合C/C-SiC复合材料。研究了C/C多孔体密度和溶渗温度对C/C-SiC复合材料微观结构和弯曲性能的影响;研究C/C-SiC复合材料的断裂失效行为,探讨C/C-SiC复合材料弯曲性能的内在影响因素。

1 实验

1.1 C/C多孔体的制备

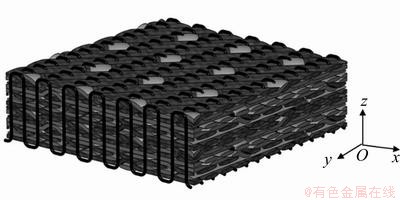

采用密度为0.9 g/cm3,碳纤维体积分数为47%的叠层缝合预制体作为增强体。其中预制体碳布为八枚缎纹布(MT300-3K)按0°、45°、90°、-45°周期性层间铺层,然后利用Z向缝合(MT300-3K)纤维将叠层密实后的碳布层施加连接,图1所示为叠层缝合预制体结构模型示意图。

图1 叠层缝合预制体结构模型示意图

Fig. 1 Structure model schematic diagram of laminated suture preform

以丙烯和氮气作为碳源气体和稀释气体,通过CVD法将PyC引入到预制体碳纤维上。其中丙烯与氮气流量比为3:1,沉积压力为 0.6~0.8 kPa,沉积温度为950 ℃,控制沉积时间为150 h、200 h、250 h制备出3种不同密度的C/C多孔体,对应编号为C/C1,C/C2,C/C3。根据CVD后预制体密度的变化,可以计算出C/C多孔体中PyC含量,如下式所示[16]:

(1)

(1)

式中: 、

、 和

和 分别为C/C多孔体的密度、预制体密度以及PyC的密度;

分别为C/C多孔体的密度、预制体密度以及PyC的密度; 为0.9 g/cm3,

为0.9 g/cm3, 为1.98 g/cm3。

为1.98 g/cm3。

1.2 C/C-SiC复合材料制备

采用平均粒度47 μm、纯度99.99%的Si粉为原料,将包埋后的C/C多孔体置于真空反应炉中,在氩气保护气氛下加热到1650 ℃和1750 ℃进行熔渗实验,保温时间均为4 h。本文所制备的C/C-SiC复合材料用C/Sn-T,其中n代表C/C多孔体型,T代表熔渗温度(如C/S1-1650、C/S1-1750、C/S2-1650、C/S2-1750、C/S3-1650和C/S3-1750分别代表C/S1、C/S2、C/S3在1650 ℃和1750 ℃时的C/C-SiC复合材料)。

1.3 性能表征

根据Archimedes排水法测量C/C和C/C-SiC复合材料的密度和开孔率;采用AutoPore IV 9510压汞仪测试C/C多孔体的孔径如下式所示[17]。

(2)

(2)

式中:dp为孔径,mm;p为外压力,Pa; 为表面张力,N;θ为接触角,(°)。

为表面张力,N;θ为接触角,(°)。

将C/C-SiC复合材料切割成2 mm×2 mm×2 mm尺寸规格,每个样品取12个。采用硝酸和氢氟酸体积分数比为4:1混合溶液浸泡腐蚀48 h,通过测量浸泡前后的样品质量变化来确定复合材料中残余Si含量,残余Si含量如下式所示:

(3)

(3)

式中:m1为样品浸泡前质量;m2为样品浸泡干燥后的质量;wSi为对应样品残余硅质量分数。此方法的反应原理是根据方程式:

3Si+4HNO3→3SiO2+4NO↑+2H2O (4)

SiO2+4HF→SiF4+2H2O (5)

SiF4+2HF→H2SiF6 (6)

在德国布鲁克生产的F07002型X 射线衍射光谱仪上对C/C-SiC复合材料进行物相分析,辐射源为Cu靶,Kα1单色光辐射,扫描速度为8 (°)/min,工作电压是32 kV,电流为50 mA,扫描角度为10°~80°。在美国FEI公司生产的Nova NanoSEM230场发射扫描电子显微镜观察C/C多孔体和C/C-SiC复合材料的微观结构以及基体相分布。

1.4 弯曲性能表征

在美国Instron 3369材料力学试验机上进行C/C-SiC复合材料弯曲性能测试,测试方向平行于x轴方向。采用三点弯曲法按照GB/T 1449—2005测试标准测量C/C-SiC复合材料的弯曲强度,样品规格为80 mm×10 mm×4 mm,跨距为70 mm,加载速率为0.5 mm/min,测试结果取6个样品的平均值。

2 结果与讨论

2.1 叠层缝合C/C多孔体微观结构

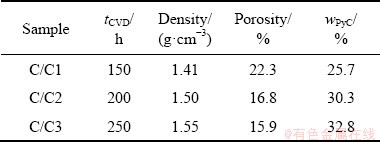

表1所示为叠层缝合C/C多孔体的物理参数。

表1 叠层缝合C/C多孔体物理参数

Table 1 Physical parameters of laminated suture C/C porous composite

由表1可知,CVD时间越长,C/C多孔体密度越高,开孔率越低,其中C/C3沉积250 h后密度可达1.55 g/cm3。根据式(1)和C/C多孔体的密度可以计算出PyC体积含量,由PyC含量变化可知,C/C1到C/C3的密度增速会降低。

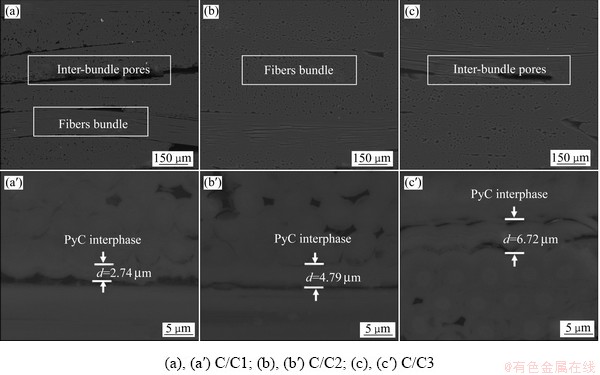

图2所示为叠层缝合C/C多孔体微观形貌的SEM像。由图2可见,纤维束相互交错排布,在纤维束相交的区域会发生弯曲并产生孔隙。孔隙结构可分成三类:碳纤维束内孔、碳纤维束间孔以及碳纤维层间孔。纤维束内孔的尺寸较小,碳纤维束间孔和纤维层间孔的尺寸较大。由图2(a′)、(b′)、(c′)可见,在纤维束间孔和层间孔的碳纤维上分布着层状环绕的PyC,PyC与碳纤维紧密结合形成界面。随着沉积时间从150 h延长到250 h,纤维外层PyC厚度从2.74 μm增长到6.72 μm,且发现处于纤维层间纤维PyC厚度明显大于纤维束内PyC的厚度。这是因为在CVD的初始阶段,预制体的孔隙率和孔径较大,PyC迅速沉积到碳纤维上。随着沉积时间的延长,靠近外层的碳纤维因为PyC的附着,预制体孔径尺寸会变小甚至发生闭孔,这会限制碳源气体向内扩散,使预制体束内纤维难以接触到碳源气体,沉积效率降低。在图2(c′)中的有些碳纤维表面的热解碳出现脱黏现象,这是在制样过程中磨削导致。

图2 叠层缝合C/C多孔体微观形貌的SEM像

Fig. 2 SEM images of micrographs of laminated suture C/C porous composites

2.2 叠层缝合C/C多孔体孔隙结构

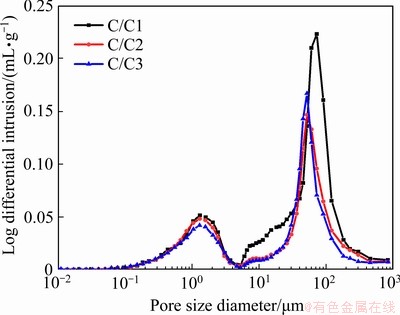

图3所示为叠层缝合C/C多孔体的孔径分布。由图3可见,C/C多孔体孔径均呈双峰分布,孔体积随多孔体密度增加而降低。C/C1孔径分布在0.5~3 μm和5~200 μm之间,孔径分布在5~200 μm约占孔体积的80%;C/C2与C/C3孔径分布在0.5~3 μm和30~200 μm之间,孔径分布在30~200 μm约占孔体积的70%。C/C1的最可几孔径为100 μm,而C/C2和C/C3的最可几孔径为50 μm,说明提高PyC含量在一定程度上降低了预制体的孔隙尺寸。在C/C多孔体内部也存在少量孔径在0.5 μm附近的小孔,结合图2不难发现,这是纤维束内的小孔。孔隙尺寸是影响熔渗反应效果的重要因素,研究证明孔隙尺寸在10~1300 μm范围内的C/C多孔体有利于熔融Si的渗入[18],本实验的C/C多孔体适合于熔渗反应。

图3 叠层缝合C/C多孔体孔径分布

Fig. 3 Pore size distributions of laminated suture C/C

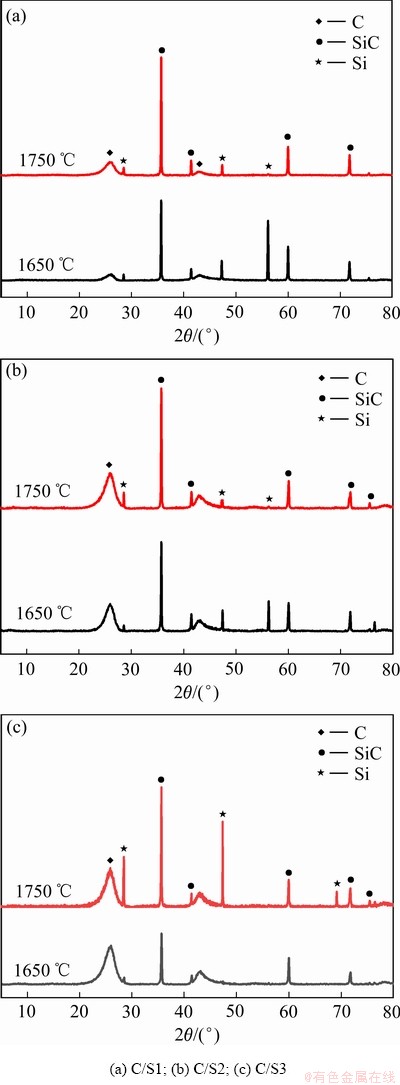

图4所示为叠层C/C-SiC复合材料XRD谱。由图4可见,在1650 ℃和1750 ℃熔渗反应下制备的C/C-SiC复合材料物相组成是一致的,包括C相、SiC相和未完全反应的残余Si相。其中C/C-SiC复合材料主要成分是SiC相,其衍射峰强度最高。在C/C-SiC复合材料中,C/S1的PyC含量最低,C/S3的PyC含量最高,对应在XRD谱上C/S1的C峰强度低,C/S3的C峰强度高,且1750 ℃制备的C/C-SiC复合材料SiC相衍射峰强度明显高于1650 ℃ SiC衍射峰强度。

图4 叠层缝合C/C-SiC复合材料XRD谱

Fig. 4 XRD patterns of laminated suture C/C-SiC composites

表2所示为叠层缝合C/C-SiC复合材料物理参数。由表2可知,1750 ℃制备的C/C-SiC复合材料密度高于1650 ℃制备的复合材料密度。相同熔渗温度制备的C/C-SiC复合材料密度随C/C多孔体密度的增加而降低。这是由于C/C多孔体密度低时孔隙率高,多孔体内部可填充更多的SiC基体,但同时进入材料内部Si也多,残余量就高。经检测残余Si含量表明,C/S1-1650最高为14.51%,C/S3-1650残余Si含量最低为4.66%。

表2 叠层缝合C/C-SiC复合材料物理参数

Table 2 Physical parameters of laminated suture C/C-SiC composites

结合图4和表2可知,总体来说熔渗温度和C/C多孔体密度升高,残余Si含量减少。JIANG等[19]研究表明,在1400~1800 ℃范围内,当熔渗时间相同时,熔渗的高度随熔渗温度的升高而增加,这会促进更多的Si原子反应,从而降低材料内部残余Si含量。但在图4(c)中发现C/S3-1750内部残余Si含量要高于C/S3-1650残余Si含量,这是因为C/C3孔径尺寸最小,温度升高会提高反应速率和Si的渗入速率,Si的渗入速率更大,这样温度升高生成的SiC相很容易封闭孔隙,导致C原子与Si原子接触面积降低,相应的Si原子就会留在复合材料内部,这与我们残余Si含量的测量结果是一致的。

2.3 叠层缝合C/C-SiC复合材料微观形貌

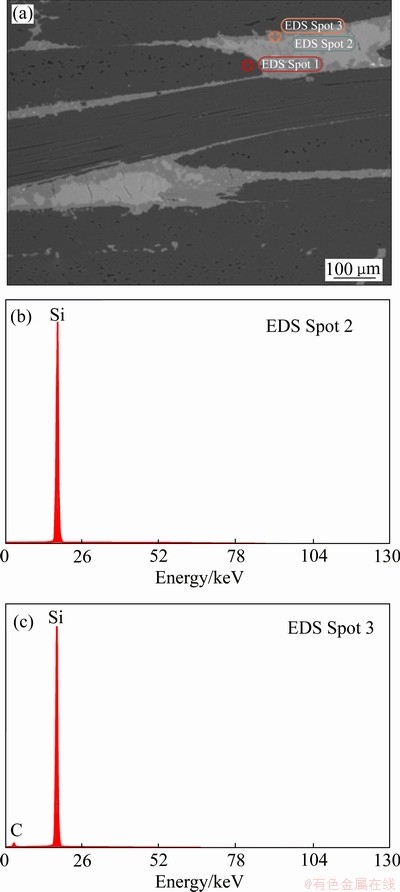

图5 叠层缝合C/C-SiC复合材料的形貌和EDS谱

Fig. 5 Morphology of laminated suture C/C-SiC composites(a) and EDS spectra of corresponding spots((b), (c))

图5所示为叠层缝合C/C-SiC复合材料的EDS谱。由图5可见黑色区域为碳纤维,灰色区域为SiC,白色区域为残余Si。图6所示为叠层缝合C/C-SiC复合材料微观形貌的SEM像。由图6可见,SiC基体在碳布层和纤维束间的孔隙中呈连续分布状态。在图6(a)、(b)发现,少量SiC基体也分布在纤维束内孔中,可以看到纤维束内孔有些区域的PyC被消耗完后碳纤维也发生了反应,如图6(g)所示,但在图6(d)、(f)纤维束内部并没有看到SiC基体。在纤维束内的SiC基体不再是连续分布,而是呈块状分布,这是因为C/C1密度较低,孔隙尺寸相对较大,虽然熔体Si不能直接流入纤维束内孔,但在高温下可通过Si蒸汽扩散进入,Si蒸汽进入纤维束内后立即与PyC反应生成SiC填充在这些孔隙通道中,生成的SiC会阻止Si蒸汽进一步扩散,SiC晶粒无法长大,故纤维束内的SiC基体以块状分布。而C/C2和C/C3的PyC含量高、密度大,孔径尺寸相对C/C1的较小,熔渗反应时熔体Si和Si蒸汽都难以进入到这些孔隙中。另外在图6(e)、(f)中有乳白色相存在,这是在制样时留下的杂质。

图6 叠层缝合C/C-SiC复合材料微观形貌的SEM像

Fig. 6 SEM image of micrographs of laminated suture C/C-SiC composites

由图6可见,在C/C-SiC复合材料内部有沿纤维轴向扩展的微裂纹。微裂纹是由于复合材料内部残余热应力造成的,热解碳的热膨胀系数要大于碳纤维的热膨胀系数。在轴向上,拉伸热残余应力在热解碳产生,压缩热残余应力在碳纤维产生,碳纤维和热解碳的热膨胀系数不匹配会导致应力集中,进而产生沿碳纤维轴向的裂纹[20],这些裂纹可能会成为失效源,降低材料力学性能。

2.4 叠层缝合C/C-SiC复合材料的弯曲强度

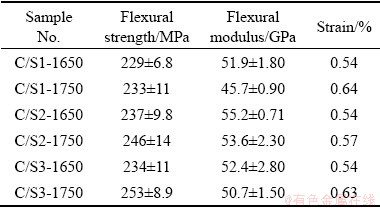

表3所示为叠层缝合C/C-SiC复合材料弯曲性能。由表3可知,1650 ℃制备的叠层C/C-SiC复合材料弯曲强度和断裂应变要低于1750 ℃制备的复合材料弯曲强度和断裂应变,其中C/S3-1750弯曲强度最高为253 MPa,但1650 ℃制备的复合材料弯曲模量更高,最高为55.2 GPa。1650 ℃制备的C/C-SiC复合材料弯曲强度随C/C多孔体密度升高先增加后降低,由于此时C/S2致密度最高,缺陷最少,弯曲强度最高为237 MPa;1750 ℃制备的复合材料弯曲强度随C/C多孔体密度升高而升高,而断裂应变与多孔体密度无关。

表3 叠层缝合C/C-SiC复合材料弯曲性能

Table 3 Flexural properties of laminated suture C/C-SiC composites

2.4.1 C/C多孔体密度的影响

PyC含量会影响界面结合强度与碳纤维的损伤程度。C/C1密度较低,包裹纤维的PyC层薄,虽然C/S1致密度最高,但有些纤维被熔体Si腐蚀导致其弯曲强度降低。C/S2和C/S3致密度较低,但PyC含量较高,减少了熔渗过程中碳纤维的损伤,纤维很好地发挥了增强增韧效果。另一方面,CAO等[21]研究表明,PyC含量增加会降低界面结合强度,从而导致纤维的韧性增加,纤维与界面之间容易分离,复合材料加载时会消耗更多的能量,所以C/S3弯曲强大于C/S1弯曲强度。

2.4.2 熔渗温度的影响

熔渗温度会影响原子渗入过程、扩散过程和反应过程。熔渗温度升高可以降低熔体Si的黏度,也就是需克服Si黏度带来的阻力减小,并且降低Si与C的润湿角。YANG等[22]通过计算得到了理论熔渗高度,如下式所示。

(6)

(6)

式中:C为曲率因子; 为Si的表面张力;θ为熔融Si与C的润湿角;t为熔渗时间;R0是t=0时刻毛细管半径;η为熔融Si的黏度。

为Si的表面张力;θ为熔融Si与C的润湿角;t为熔渗时间;R0是t=0时刻毛细管半径;η为熔融Si的黏度。

由式(6)可知,熔渗温度升高,Si的熔渗高度增加,且温度升高原子的扩散速率加快。硅碳反应的吉布斯自由能在高于1450 ℃时远小于0,随着熔渗温度的升高,反应的驱动力增大,反应速率加快,促使反应朝着生成物的方向进行,C/C-SiC复合材料内SiC基体增多而残余Si含量减少,材料致密度增加,热残余应力会逐渐释放,基体内微裂纹数量减少,故在1750 ℃下制备的C/C-SiC复合材料弯曲性能较1650 ℃的弯曲性能更为优异[20]。

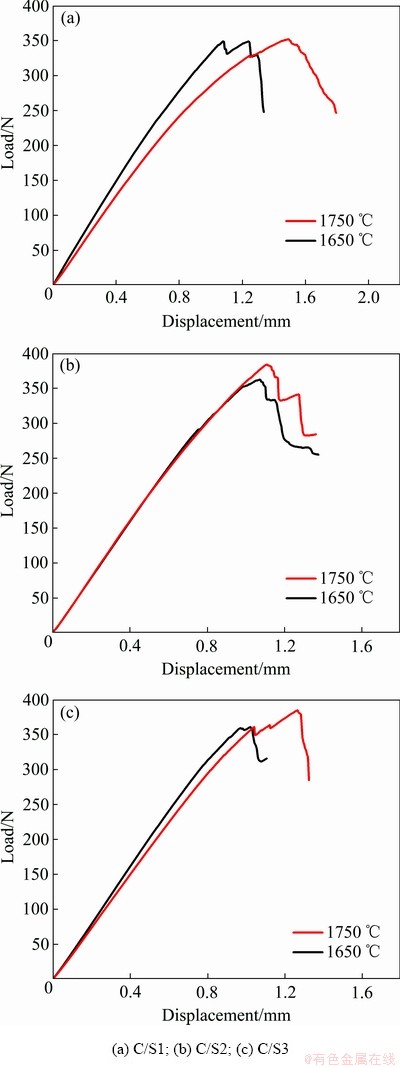

2.5 叠层缝合C/C-SiC复合材料的弯曲失效行为

图7所示为叠层缝合C/C-SiC复合材料弯曲载荷-位移曲线。由图7可见,弯曲载荷-位移曲线可以分为三个阶段。在加载初始阶段:载荷-位移曲线呈线性变化,此时C/C-SiC复合材料处于弹性变形阶段,基体和纤维共同承担载荷,基体模量小于纤维,基体首先开裂,内部产生新的裂纹。在第二阶段:载荷-位移曲线呈现非线性变化,此时基体裂纹增大、扩展并达到饱和。在第三个阶段:复合材料基体与纤维、基体与界面发生分离和脱粘,裂纹延伸到另一端,随着纤维断裂,最终导致复合材料的“假塑性”断裂破坏[23]。在不同的熔渗温度时,C/C-SiC复合材料在1750 ℃下的载荷位移更大,断裂应变更高。

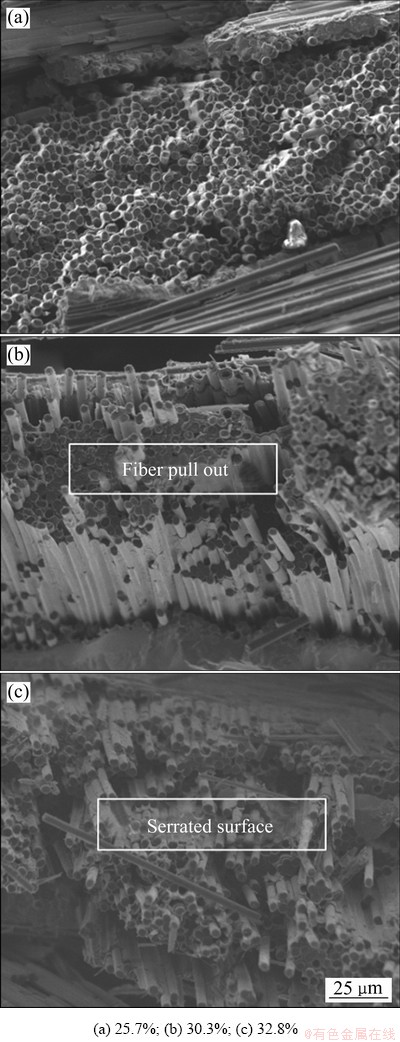

图8所示为不同PyC含量下弯曲破坏纤维的SEM像。由图8可见,弯曲断口在PyC含量不同时呈现不同的变化特征。在PyC含量为25.7%时,纤维拔出长度较短,只有少量纤维拔出,但随着C/C-SiC复合材料PyC含量增加,纤维束拔出的数量越来越多,且纤维拔出长度也相应增加。在PyC含量为32.8%时,复合材料断口出现锯齿状表面。结合图7可知,这受纤维与PyC界面强度的影响,C/S1加载后呈现缓慢的断裂方式,而C/S3在载荷达到最大值后曲线相对陡峭,这是因为PyC含量增加导致界面变弱的原因,界面结合强度越低,纤维更容易拔出。

图7 叠层缝合C/C-SiC复合材料弯曲载荷-位移曲线

Fig. 7 Flexural load-displacement curves of laminated suture C/C-SiC composites

图8 不同PyC含量下弯曲破坏纤维的SEM像

Fig. 8 SEM images of failed fibers after flexural test at different PyC contents

3 结论

1) 以叠层缝合预制体为增强体,经气相法引入热解碳,制备了3种不同密度的C/C多孔体。其中C/C多孔体孔径分布在5~200 μm的纤维束间孔和层间孔占孔体积的70%~80%,分布在0.5~3 μm的纤维束内孔占孔体积的20%~30%。

2) 热解碳含量对C/C-SiC复合材料弯曲性能有显著影响。其中热解碳含量增加减少了碳纤维的损伤,降低了界面结合强度,纤维拔出增多,且提高了C/C-SiC复合材料的弯曲强度和弯曲模量,但对断裂应变无明显影响。

3) 熔渗温度是影响C/C-SiC复合材料弯曲强度的关键因素。熔渗温度升高,熔体Si黏度降低,反应驱动力增强,促使反应生成更多的陶瓷基体。1650 ℃制备的叠层缝合C/C-SiC复合材料弯曲强度和断裂应变要低于1750 ℃制备的复合材料弯曲强度和断裂应变,但1650 ℃制备的复合材料弯曲模量更高。C/C-SiC复合材料的弯曲载荷-位移曲线呈现“阶梯型”断裂行为。

REFERENCES

[1] 王 璐, 王友利. 高超声速飞行器热防护技术研究进展和趋势分析[J]. 宇航材料工艺, 2016, 44(1): 1-6.

WANG Lu, WANG You-li. Research progress and trend analysis of hypersonic vehicle thermal protection technology[J]. Aerospace Materials & Technology, 2016, 44(1): 1-6.

[2] 李贺军, 史小红, 沈庆凉, 等. 国内C/C复合材料研究进展[J]. 中国有色金属学报, 2019, 29(9): 2142-2154.

LI He-jun, SHI Xiao-hong, SHEN Qing-liang, et al. Research and development of C/C composites in China[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 2142-2154.

[3] 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨[J]. 复合材料学报, 2007, 24(2): 1-6.

ZHANG Li-tong, CHENG Lai-fei. Discussion on strategies of sustainable development of continuous fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica, 2007, 24(2): 1-6.

[4] 刘小冲, 成飞来, 张立同, 等. C/SiC复合材料在空间环境中的性能研究进展[J]. 材料导报, 2013, 27(9): 127-130.

LIU Xiao-chong, CHENG Lai-fei, ZHANG Li-tong, et al. Research progresses on properties of the C/SiC composites under the space environment[J]. Materials Review, 2013, 27(9): 127-130.

[5] JAYASEELAND D, XIN Y, VANDEPERRE L. Development of multilayered thermal protection system (TPS) for aerospace applications[J]. Composites Part B: Engineering, 2015, 79(15): 392-405.

[6] CHEN Guan-yi, LI Zhuan, XIAO Peng, et al. Tribological properties and thermal-stress analysis of C/C-SiC composites during braking[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(1): 123-131.

[7] PADTURE N P. Advanced structural ceramics in aerospace propulsion[J]. Nature Materials, 2016, 15(8): 804-809.

[8] 堵同亮. 碳纤维编织复合材料冲压成形实验与仿真分析[J]. 功能材料, 2013, 44(16): 2401-2405.

DU Tong-liang. Experimental and numerical stamping of carbon woven fabrics[J]. Journal of Functional Materials, 2013, 44(16): 2401-2405.

[9] GARCIA-CARPINTERO A, HERRAEZ M, XU J, et al. A multi material shell model for the mechanical analysis of triaxial braided composites[J]. Applied Composite Materials, 2017, 24(6): 1425-1445.

[10] 田 俊, 周储伟. 纺织复合材料和结构多尺度耦合的数值分析[J]. 计算力学学报, 2010, 27(6): 1022-1028.

TIAN Jun, ZHOU Chu-wei. Multi-scale coupled numrical analysis of textile composites and structures[J]. Chinese Journal of Computational Mechanics, 2010, 27(6): 1022-1028.

[11] SURESH K, ANIL K, ROHINI D, et al. Capillary infiltration studies of liquids into 3D-stitched C-C preforms: Part A: Internal pore characterization by solvent infiltration, mercury porosimetry, and permeability studies[J]. Journal of the European Ceramic Society, 2009, 29(12): 2651-2657.

[12] 张兆杭, 崔少康, 谭志勇, 等. C/C-SiC缎纹编织复合材料孔隙缺陷的建模及其拉伸性能仿真[J]. 复合材料学报, 2020, 37(8): 1969-1980.

ZHANG Zhao-hang, CUI Shao-kang, TAN Zhi-yong, et al. Modeling of void defects in C/C-SiC satin weave composites and simulation of their tensile properties[J]. Acta Materiae Compositae Sinica, 2020, 37(8): 1969-1980.

[13] 张根西, 张培伟, 李彦斌, 等. 缝合式三维编织 C/SiC拉伸加卸载力学行为[J]. 复合材料学报, 2019, 36(12): 2894-2901.

ZHANG Gen-xi, ZHANG Pei-wei, LI Yan-bin, et al. Analysis of mechanical behavior of sutured 3D-C/SiC braided composite under cycle tensile loading[J]. Acta Materiae Compositae Sinica, 2019, 36(12): 2894-2901.

[14] MEI H, YU C K, XU H R, et al. The effects of stitched density on low-velocity impact damage of cross-woven carbon fiber reinforced silicon carbide composites[J]. Ceramics International, 2016, 42(1): 1762-1768.

[15] NIE J J, XU Y D, ZHANG L T, et al. Effect of stitch spacing on mechanical properties of carbon/silicon carbide composites[J]. Composites Science and Technology, 2008, 68(12): 2425-2432.

[16] LI K Z, JING X, FU Q G, et al. Effects of porous C/C density on the densification behavior and ablation property of C/C-ZrC-SiC composites[J]. Carbon, 2013, 57: 161-168.

[17] 田志宏, 张秀华, 梅鸣华, 等. 压汞法测试耐火材料孔结构的原理与方法[J]. 理化检验, 2013, 49(9): 615-617.

TIAN Zhi-hong, ZHANG Xiu-hua, MEI Min-ghua, et al. Principle and method of refractory pore structure measurement by mercury intrusion method[J]. Physical Testing and Chemical Analysis, 2013, 49(9): 615-617.

[18] 王林山, 熊 翔, 肖 鹏, 等. 多孔体制备工艺对C/C-SiC复合材料弯曲性能的影响[J]. 中国有色金属学报, 2003, 13(5): 1191-1201.

WANG Lin-shan, XIONG Xiang, XIAO Peng, et al. Effect of manufacturing techniques of performs on properties and fracture modes of C/C-SiC composites[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1191-1201.

[19] JIANG S Z, XIONG X, CHEN Z K, et al. Influence factors of C/C-SiC dual matrix composites prepared by reactive melt infiltration[J]. Materials and Design, 2009, 30(9): 3738-3742.

[20] YAN K F, ZHANG C Y, QIAO S R, et al. Failure and strength of 2D-C/SiC composite under in-plane shear loading at elevated temperatures[J]. Materials and Design, 2011, 32(6): 3504-3508.

[21] CAO X Y, YIN X W, FAN X M, et al. Effect of PyC interphase thickness on mechanical behaviors of SiBC matrix modified C/SiC composites fabricated by reactive melt infiltration[J]. Carbon, 2014, 77: 886-895.

[22] YANG J, LLRGBUSI O J. Kinetics of silicon-metal alloy infiltration into porous carbon[J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(6): 617-625.

[23] 管国阳, 矫桂琼, 张增光.2D-C/SiC复合材料的宏观拉压特性和失效模式[J]. 复合材料学报, 2005, 22(4): 81-85.

GUAN Guo-yang, JIAO Gui-qiong, ZHANG Zeng-guang,. Uniaxial macro-mechanical property and failure mode of a 2D-woven C/SiC composite[J]. Acta Materiae Compositae Sinica, 2005, 22(4): 81-85.

Microstructure and flexural properties of laminated suture structure C/C-SiC composites

ZHAO Xiang-kun1, WANG Ya-lei1, XIONG Xiang1, DU Peng-cheng1, YE Zhi-yong1, LIU Cong-cong1, LIU Yu-feng2

(1. Powder Metallurgy Research Institute, Central South University, Changsha 410083, China;

2. Science and Technology of Advanced Functional Composite Materials Laboratory, Aerospace Research Institute of Materials and Processing Technology, Beijing 100076, China)

Abstract: In order to meet the requirements of materials for hypersonic aircraft thermal structure components, the laminated suture structure C/C-SiC composites were prepared by mixed process of chemical vapor deposition (CVD) and reactive melt infiltration (RMI), the influence of C/C porous bodies density and infiltration temperature on the microstructure and flexural properties of C/C-SiC composites was investigated. The results show that the pore size of the C/C porous bodies has a bimodal distribution, and the pore volume decreases with the increase of the density of the porous bodies. C/C-SiC composites are composed of SiC, C and residual Si phases. The flexural strengths of C/C-SiC composites increase with the increase of infiltration temperature. The flexural strength of C/C-SiC composites prepared at 1650 ℃ firstly increases and then decreases slightly with the raise of C/C porous bodies density. At 1750 ℃, the flexural strength increases as the density of the C/C porous bodies increases. The maximum flexural strength of C/C-SiC composites is 253 MPa when the density of C/C porous is 1.55 g/cm3 and the infiltration temperature is 1750 ℃. Under the flexural loads, the displacement-load curves of C/C-SiC composites show a “stepped” fracture behavior.

Key words: C/C-SiC; laminated suture structure; infiltration temperature; C/C porous bodies density; flexural strength

Foundation item: Project supported by National Defense Basic Scientific Research Program of China

Received date: 2020-10-23; Accepted date: 2021-01-18

Corresponding author: WANG Ya-lei; Tel: +86-13007496215; E-mail: yaleipm@csu.edu.cn

(编辑 李艳红)

基金项目:国防实验室稳定支持(国防基础科研项目)

收稿日期:2020-10-23;修订日期:2021-01-18

通信作者:王雅雷,副研究员,博士;电话:13007496215:E-mail:yaleipm@csu.edu.cn