文章编号:1004-0609(2008)04-0693-05

5A12铝合金有限宽薄板钨极惰性气体焊接的数值模拟

王 蕊,刘 川,张建勋

(西安交通大学 材料科学与工程学院,西安 710049)

摘 要:针对铝合金5A12有限薄板钨极惰性气体(TIG)焊接过程存在非准稳态的特点,提出了考虑热源预热作用及移动效应的二维高斯热源修正模型,并采用修正的二维高斯热源模型对其焊接热过程、焊接残余角变形和纵向残余应力进行数值模拟及研究,同时比较数值模拟及实验结果。实验结果表明:利用修正的二维高斯模型能较好地反映有限薄板的焊接特点,所计算的接头熔合区形状、热循环曲线与实验结果吻合良好。焊接残余角变形及焊接纵向残余应力也得到了与实验值较接近的模拟结果。利用此修正的二维高斯模型可提高焊接温度场、焊接纵向残余应力与变形数值模拟的准确性。

关键词:热源模型;有限尺寸;预热;残余应力;残余变形

中图分类号:TG 456.7 文献标识码:A

Numerical simulation of tungsten inert gas welding of

5A12 aluminum alloy limited size sheet

WANG Rui, LIU Chuan, ZHANG Jian-xun

(School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049, China)

Abstract: The characteristics of the quasi-steady-state during tungsten inert gas (TIG) welding process on 5A12 aluminum alloy sheet with limited size were analyzed. The welding process, residual angular deformation and longitudinal residual stress were numerically simulated and studied using the modified two-dimonsional Gaussian heating source model. The numerical simulation results were compared with experimental results. The results show that the numerical results by the modified two-dimensional Gaussian model reflect well the limited plate welding characteristics. The shape of joint fusion zone and thermal cycle curve calculated agree well with the experimental results. And the welding residual deformation and longitudinal welding residual stress are closer with the experimental value of the simulation results. The welding temperature field, welding longitudinal residual stress and deformation can be simulated accurately using the modified two-dimensional Gaussian model.

Key words: heating source model; limited size; preheating; residual stress; residual deformation

焊接温度场不仅反映焊接过程的复杂性,还间接决定了焊接残余应力与变形,影响到熔合、裂纹、组织等与焊接质量有关的指标。采用有限元方法,在计算机上进行焊接过程的数值模拟,可以在较短的时间内获得不同参数条件下温度场分布残余应力场和残余变形,使焊接过程的准确模拟成为可能[1-2]。

对于工程实际问题,三维数值模型由于数据量大、计算周期长,而限制了其发展,许多学者仍采用二维模型进行计算,在保证计算精度的同时提高计算效 率[3-4]。作者提出采用二维广义应变模型能够有效模拟T型接头的残余应力和角变形[5],模拟了有限尺寸铝合金2024钨极氩弧焊接过程,并获得低应力无变形焊接试板[6]。ZHU等[7]采用二维模型研究了材料属性对焊接变形的影响,提出对变形影响较小的物理参数计算中可简化。UEDA等[8]采用二维有限元模型研究了局部加热、焊接顺序、初始应力和焊接间隙等因素对焊接变形的影响。ABID等[9-10]对管和法兰盘的焊接温度场、变形和残余应力进行了计算,并比较了二维和三维模型各自的优缺点。

但如何准确的通过二维模型描述瞬时移动热源,并计算相对准确的瞬时温度、应力和变形,仍然是焊接过程数值模拟重要的研究课题之一。在采用二维模型进行计算时,根据焊接的特点,热过程可以分为4个阶段:预热、加热、传热及冷却。SARKANI等[11]考虑焊接过程各主要部分的影响,寻找有效计算T型焊接接头的残余应力的方法。FERRO等[12]研究相变对SA516钢焊接残余应力的影响。提出在焊接速度较高及材料热导率较低的情况下,三维模型和二维模型的计算结果吻合更好。

1 5A12铝合金非准稳态焊接

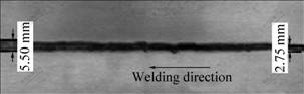

图1所示为宽度为160 mm的5A12铝合金TIG焊接试板的宏观焊缝照片。由图1可看出,当焊接规范保持不变时,焊缝上各点的宽度不同。这是由于焊接电弧对后续焊接部位的预热作用。当焊接件尺寸 很大时,这一作用会达到平衡,也就是所谓的准稳 态,但对于有限尺寸板的焊接,很难达到准稳态。

图1 预热作用对焊缝成型的影响

Fig.1 Effect of preheating on welding shaping

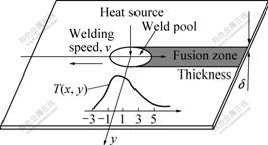

在焊接过程进入准稳态后,随热源的移动,焊接温度场及熔池形状均不随时间改变,表现为等温线的范围不再随时间增大,而只是随热源的移动而移动。图2所示为有限宽度薄板焊接二维热流分布[13]。

图2 薄板焊接二维热流分布

Fig.2 Two-dimensional heat flow distribution of thin work piece during welding

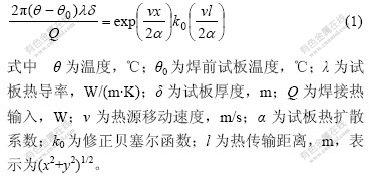

根据移动线热源传热过程计算式(1),能够计算相对于移动热源试板上任何一点p(x, y)所对应的温 度[14]。即通过假设某一等温线温度,即可求出等温线最宽点(图2所示y值)来判断试板是否进入准稳态。

根据试板焊接的实际情况,取温度为50 ℃时, θ0=20 ℃;λ=118 W/(m?K);δ=5 mm;P=560 W;v=10 cm/min;k0可查表求得;通过计算求得50 ℃等温线最宽点(x=0 mm,y=133 mm),y值大于试板半宽80 mm。由图1熔池的几何形状不均匀性及式(1)的计算结果能够说明,对于有限尺寸的铝合金薄板在焊接过程中存在非准稳态现象。

本文作者针对有限铝合金薄板的TIG焊接过程存在非准稳态现象特点,提出采用修正的二维有限元模型对焊接过程温度场、焊接残余应力和焊接残余变形进行全面的数值模拟研究,并通过对比实验来验证修正模型模拟结果的准确性。

2 计算模型

2.1 热源模型

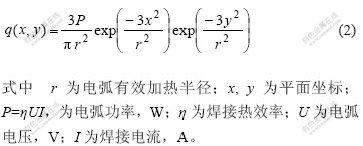

根据TIG焊接过程电弧加热的特点,采用高斯函数来描述焊接热源在一定范围内的分布。其函数表达式为:

式(2)中所建立的热源模型,在二维有限元数值模拟过程中,热源施加在垂直焊缝的中截面平面,忽略纵向热流,这种假设在有限尺寸铝合金试板,焊接速度较慢时会产生很大误差。

基于前面的分析,在有限尺寸试板上进行铝合金焊接,预热过程是焊接温度场分布的重要影响因素。为了通过二维模型准确模拟实际焊接温度场的分布情况,需对模型进行修正[11]。

修正式(3),在焊接方向上的电弧热流分布可以通过焊接速度和时间来表示。通过系数α考虑电弧移动效应以及焊接电弧对所研究平面的预热作用。

2.2 物理模型

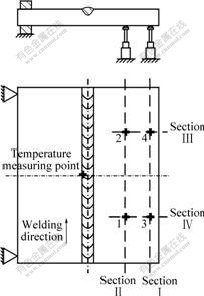

模拟计算中采用的材料为铝合金5A12,试件尺寸为200 mm×60 mm×5 mm,采用TIG焊接方法。实际模型简图如图3所示。 焊接规范参数:电流100 A;速度为10 cm/min;氩气流量为9.5 L/min;电压为14 V。

图3 实验系统布局示意图

Fig.3 Schematic diagram of experimental layout

2.3 有限元模型

本研究所建立二维平面应变模型进行温度及应力计算。材料的热物理性能参数见文献[15]。除了电弧所在的圆面加热流密度外,其他表面为对流换热表面,初始温度设定为室温20 ℃。通过式(4)[16]来确定焊接过程的对流换热系数。

(4)

(4)

式中 H为对流系数;θw为工件温度;θ c为环境温度。

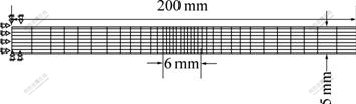

以垂直于焊缝的平面建立模型,网格模型如图4所示。采用过渡网格划分技术进行划分。为简化计算,并考虑焊接实验中焊缝宽度的最大值,取焊缝宽度为6 mm,距焊缝处10 mm宽范围内的网格比较密,而远离焊缝处的网格稀疏,逐渐实现到母材的过渡。根据实验装夹情况,在试板一侧上下表面采用位移约束。

图4 焊缝有限元网格模型

Fig.4 Finite element mesh model of welding

在模拟计算时,焊接热效率η=70%;电弧电压U=14 V;焊接电流I=100 A;电弧有效加热半径R= 3 mm;焊接速度v=10 cm/min。整个焊接过程共用 95 s完成,设置自动时间步长以保证求解的稳定性和精确性。利用ANSYS有限元分析软件进行计算。

3 结果与分析

3.1 温度场模拟结果

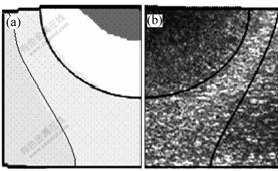

图5所示为采用修正二维高斯热源模型所建有限元计算程序获得的焊接接头温度场分布云图与焊缝接头宏观照片对比。从图5中可看出,数值模拟获得的温度场分布与焊接头温度场分布一致。熔合区形状与实验结果基本一致,与正常焊接条件下的熔化区截面形状相符。温度场模拟结果与实验结果吻合良好。

图5 温度场数值模拟与实验结果对比

Fig.5 Comparison of numerical simulation results(a) with experimental results(b) of temperature field

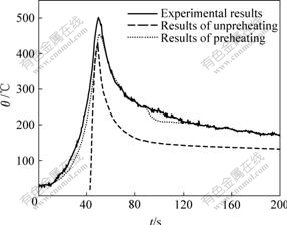

图6所示为距焊缝中心5 mm处试板底部的热循环变化曲线、数值模拟结果和实验结果对比。从图6中可看出,试板底部热循环曲线为缓升缓降过程。由于存在预热行为,温度上升较为缓慢,达到峰值 后,在外界环境作用下缓慢下降至室温,达到温度平衡。未修正二维高斯热源模型,由于未考虑热源的移动效应及焊缝周围区对焊缝的预热作用。因此,在加热阶段温度陡升。在达到峰值后,在外界环境作用下温度缓慢下降至室温达到温度平衡。

图6 距焊缝中心5 mm试板底部的热循环曲线结果比较

Fig.6 Comparison of numerical results with experimental values of temperature curves at 5 mm away from weld

采用修正模型计算距焊缝中心5 mm试板底部 获得的热循环曲线与实验测得的热循环曲线基本吻合。数值模拟热循环曲线峰值温度小于实验测得结果,在降温过程中修正后模型数值模拟结果与实验结果趋于一致。

通过对高斯热源进行修正,在二维有限元模拟过程中考虑热源的移动效应及焊接电弧对所研究平面的预热作用,能够比较准确的模拟焊接热过程,减小计算误差。

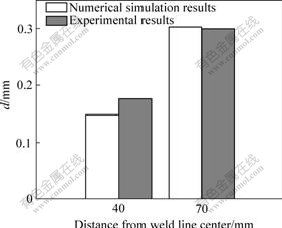

3.2 残余变形模拟结果

图7所示为焊接残余变形数值模拟结果和实验结果对比。从图7中可看出,通过修正的模型能够准确模拟焊接试板残余角变形。越靠近试板边缘测点,数值模拟结果与实验结果存在误差越小,模拟结果更加准确。

图7 残余角变形数值模拟与实验结果比较

Fig.7 Comparison of numerical simulation results and experimental results of residual angular deformation

采用二维模型和位移约束计算,残余变形计算值与测量结果符合较好。当焊接结束,由于焊缝各处的温差小,因此焊缝处的温度相对于其他区域处于高温,整个焊缝整体冷却,相互之间的收缩制约作用小,因此,二维模型残余变形计算值受其他截面的影响不大,故残余变形计算值和测量值符合较好。

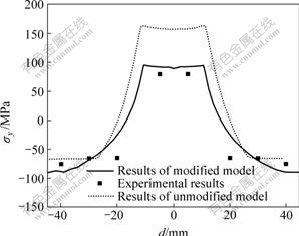

3.3 残余应力模拟结果

图8所示为垂直焊缝截面纵向应力数值模拟结果和实验结果比较。残余应力采用盲孔法测量,为简化工作,以焊缝中心为对称单向测量,并将结果沿对称中心映射。从图8中可看出,试板纵向残余应力在焊缝区存在较大拉应力,在远离焊缝区存在压应力。未进行修正的数值模拟的焊缝及熔合区拉应力分布及峰值远大于实验值。通过修正后模型垂直焊缝截面纵向残余应力峰值及分布趋势与实验值吻合较好。

图8 纵向残余应力数值模拟与实验结果比较

Fig.8 Comparison of numerical simulation results with experimental results of longitudinal residual stress

4 结论

1) 提出了考虑热源预热作用及移动效应的二维高斯热源修正模型描述有限薄板的TIG焊接热过程。

2) 采用修正的热源模型计算的焊接接头熔合区形状与热循环曲线和实验结果吻合良好。

3) 采用修正的热源模型能够比较准确地模拟焊接残余角变形及焊接纵向残余应力。

REFERENCES

[1] MICHALERIS P, SUN X. Finite element analysis of thermal tensioning techniques mitigating weld buckling distortion[J]. Welding Journal, 1997, 76(11): 451-457.

[2] 蔡志鹏, 赵海燕, 鹿安理. 结合模型试验的数值模拟方法在大型结构焊接变形控制中的应用[J]. 机械工程学报, 2002, 38(10): 100-103.

CAI Zhi-peng, ZHAO Hai-yan, LU An-li. Welding distortions of huge structures controlled accurately through the numerical method combined with model experiment[J]. Chinese Journal of Mechanical Engineering, 2002, 38(10): 100-103.

[3] 蔡洪能, 唐慕尧. TIG焊接温度场的有限元分析[J]. 机械工程学报, 1996, 32(2): 34-39.

CAI Hong-neng, TANG Mu-yao. The finite analysis of TIG welding temperature field[J]. Chinese Journal of Mechanical Engineering, 1996, 32(2): 34-39.

[4] DONG P. Residual stress analysis of a multi-pass girth weld: 3-D special shell versus axisymmetric models[J]. Journal of Pressure Vessel Technology, 2001, 123(2): 207-213.

[5] MA Ning-xu, UEDA Y, MURAKA H, MAEDA H. FEM analysis of 3-D welding residual stress and angular distortion in T-type fillet welds[J]. Transactions of the JWRI, 1995, 24(2): 115-122.

[6] PRESTON R V, SHERCLIFF H R, WITHERS P J, SMITH S D. Finite element modeling of tungsten inert gas welding of aluminium alloy 2024[J]. Science and Technology of Welding and Joining, 2003, 8(1): 10-18.

[7] ZHU X K, CHAO Y J. Effect of temperature-dependent material properties on welding simulation[J]. Computers and Structures, 2002, 80(11): 967-976.

[8] UEDA Y, MURKAWA H, GU Si-mei, OKUMOTO Y, KAMICHIKA R. Simulation of welding deformation for precision ship assembling (Report Ⅰ)—in-plane deformation of butt welded plate[J]. Transactions of the JWRI, 1992, 21(2): 265-275.

[9] ABID M, SIDDIQUE M, MUFTI R A. Prediction of welding distortions and residual stresses in a pipe–flange joint using the finite element technique[J]. Modelling and Simulation in Materials Science and Engineering, 2005, 13(3): 455-470.

[10] ABID M, SIDDIQUE M. Numerical simulation to study the effect of tack welds and root gap on welding deformations and residual stresses of a pipe-flange joint[J]. International Journal of Pressure Vessels and Piping, 2005, 82(11): 860-871.

[11] SARKANI S, TRITCHKOV V, MICHAELOV G. An efficient approach for computing residual stresses in weld joints[J]. Finite Elements in Analysis and Design, 2000, 35(3): 247-268.

[12] FERRO P, PORZNER H, TIZIANI A, BONOLLO F. The influence of phase transformations on residual stresses induced by the welding process-3D and 2D numerical models[J]. Modelling and Simulation in Materials Science and Engineering, 2006, 14(2): 117-136.

[13] KOU S. Welding metallurgy[M]. 2nd ed. Canada: A John Wiley&Sons, Inc, 2003: 49.

[14] RYKALIN N N. 焊接热过程计算[M]. 北京: 机械工业出版社, 1958.

RYKALIN N N. Computation of welding heat transfer process[M]. Beijing: Mechanical Press, 1958.

[15] 中国航空材料手册编辑委员会. 中国航空材料手册(第3卷)铝合金、镁合金系列[M]. 北京: 中国标准出版社, 2002.

China Aviation Materials Handbook Editional Board. China Aviation materials handbook (Vol. 3) Aluminum alloy, magnesium alloy series[M]. Beijing: Standards Press of China, 2002.

[16] FANG Hong-yuan, MENG Qing-guo, XU Wen-li, JI Shu-de. New general double ellipsoid heat source model[J]. Science and Technology of Welding and Joining, 2005, 10(3): 361-368.

基金项目:国家自然科学基金资助项目(50475093);现代焊接生产技术国家重点实验室基金资助项目

收稿日期:2007-07-10;修订日期:2007-12-02

通讯作者:张建勋,教授,博士;电话:029-82668807;E-mail: jxzhang@mail.xjtu.edu.cn

(编辑 李艳红)