文章编号:1004-0609(2013)05-1323-08

多孔Pb合金阳极在电积制备铜粉中的应用特性

于枭影1,李艳红1,蒋良兴1, 2,赖延清1, 2,李 劼1, 2,刘业翔1

(1. 中南大学 冶金科学与工程学院,长沙 410083;

2. 中南大学 难冶有色金属资源高效利用国家工程实验室,长沙 410083)

摘 要:为了降低电积法生产铜粉的能耗,减小阳极腐蚀率,提高阴极铜粉品质,采用反重力渗流技术制备不同合金成分、不同孔径的多孔Pb合金阳极,并与平板阳极在阳极电位、阳极腐蚀率、阳极氧化膜的形貌与组成、阴极铜粉的纯度和形貌等方面进行对比。结果表明:多孔阳极可以降低阳极真实电流密度,从而降低析氧过电位,如孔径1.0~1.25 mm的Pb-Ag多孔阳极的析氧过电位比同样合金成分平板阳极的降低了131 mV,可以显著降低铜粉电积过程的能耗。另外,多孔阳极表面氧化膜由疏松的粉末状变为致密、平整的片状,提高了阳极的耐腐蚀性能,可以降低阴极铜粉中的Pb含量,有利于提升产品品质。

关键词:电积铜粉;多孔阳极;Pb合金;阳极电位;腐蚀率

中图分类号:TF811 文献标志码:A

Application characteristics of Pb-alloy porous anode in copper powder electrowinning

YU Xiao-ying1, LI Yan-hong1, JIANG Liang-xing1, 2, LAI Yan-qing1, 2, LI Jie1, 2, LIU Ye-xiang1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. National Engineering Laboratory for Efficient Utilization of Refractory Nonferrous Metals Resources,

Central South University, Changsha 410083, China)

Abstract: In order to reduce the energy consumption of copper powder electrowinning, enhance the corrosion resistance of anode and improve the product quality, the Pb-based porous anodes with different pore sizes and various Ag and Ca contents were prepared by counter- gravity infiltration, and compared with plate anodes in following aspects: anodic potential, anodic corrosion rate, morphology and composition of the anodic oxidation film, purity and morphology of cathodic product. The results show that the porous anode can reduce the real anodic current density and decrease anodic oxygen evolution overpotential. For example, the oxygen evolution overpotential of Pb-Ag porous anode (pore diameter of 1.0-1.25 mm) is 131 mV lower than that of Pb-Ag plate anode, which can significantly decrease the energy consumption. Besides, the anodic oxidation film of porous anode changes from loose, powdery form into denser, flatter flaky form, which can enhance the anodic corrosion resistance, reduce the Pb content of copper powder and then improve the product quality.

Key words: copper powder electrowinning; porous anode; Pb-alloy; anodic potential; corrosion rate

铜粉是重要的金属粉末材料。近年来,铜粉以其优异的导电导热性能、耐腐蚀性能、无磁性等特点,广泛地应用在冶金、化工、医药等领域[1-2]。铜粉的制备方法主要有氧化还原法[3]、雾化法[4]和电化学法等[5]。其中,电化学法生产的铜粉由于具有表面洁净、成形性好、生坯强度高等特点,在一些高端行业或特殊行业一直无法被其他工艺制备的铜粉所替代[6]。

电化学法制备铜粉根据电解液中Cu2+来源的不同,又分为电解法和电积法。电解法采用可溶性精铜阳极,通过铜阳极的溶解补充电解液中的Cu2+,并在阴极沉积金属铜粉。电积法采用不溶性阳极,阳极主要发生O2的析出反应,通过电解液的循环来维持Cu2+浓度的稳定。目前,国内外普遍采用电解法制备铜粉,但其具有生产成本高、杂质富集后的电解液处理难度大、工艺流程长等缺点。而电积法作为一种新发展的方法,具有无需Cu阳极浇铸、无残极产生、劳动强度小、工艺流程短等优点,且由于采用硫酸铜为原料,可以为阴极铜生产企业加快变现中间物料的速度以及铜矿石堆浸-萃取除杂后的硫酸铜溶液直接制备铜粉提供了一种工艺途径,因而越来越受到重视[7-8]。

然而,电积法采用Pb合金平板阳极,生产时电流密度在1 000 A/m2以上。由于析氧电势与电流密度成正比,铜粉电积时阳极过电位达1.5 V以上,每生产1 t铜粉时无用电耗近2 000 kW·h。此外,高电流密度导致阳极严重腐蚀,腐蚀产物会污染阴极铜粉,影响产品品质。以上缺陷严重制约了电积法生产铜粉的工业化应用。

前期研究表明[9-10],在锌电积过程中,多孔阳极由于具有较大的比表面积,可在高表观电流强度下获得低的阳极真实电流密度,减小阳极极化的程度,从而达到降低能耗、提高阳极抗腐蚀能力及阴极产品质量的目的。本文作者将多孔Pb合金阳极引入电积铜粉的生产过程,采用反重力渗流技术制备了不同成分和不同孔径的Pb合金多孔阳极,从阳极电位、腐蚀率、表面氧化膜形貌以及阴极铜粉品质等方面与传统平板阳极的应用特性进行对比。

1 实验

1.1 多孔阳极的制备

采用反重力渗流法[11]制备不同合金成分(Pb-0.24%Ag-0.1%Ca(质量分数)和Pb-0.8%Ag)、不同孔径范围(0.8~1.0 mm、1.0~1.25 mm、1.25~1.43 mm、1.43~1.6 mm、1.6~2.0 mm和2.0~2.5 mm)的多孔合金。将多孔材料线切割成10 mm×10 mm×10 mm的立方体,焊接铜导线后用环氧树脂密封,获得几何面积为10 mm×10 mm的测试电极。

1.2 电化学测试与分析

测试前,多孔阳极在碱性除油、有机除油等预处理后,用煮沸的糖碱溶液(20 g葡萄糖、100 g NaOH溶于1 000 mL 蒸馏水中配制而成)去除表面的铅氧化膜,用去离子水清洗。而用于对比的平板阳极用金相磨样机磨平、抛光后,进行除油处理。另外,进行电化学测试前,预先将测试电极在-10 mA/cm2的电流密度下极化10 min,以充分去除电极表面的氧化物,露出新鲜基底。

整个电化学测试在玻璃三电极体系内进行,测试电极为Pb合金多孔阳极和平板阳极,对电极为10 mm×10 mm的Cu电极,参比电极为双盐桥饱和甘汞电极(SCE)(若无特别说明,本研究所有的阳极电位均是与SCE的相对值)。测试所用电解液为CuSO4-H2SO4体系(Cu2+ 15 g/L,H2SO4 140 g/L),电解液体积为1000 mL,电解液温度利用 HH-1型热恒温水浴锅保持在(35±0.5) ℃。电积时利用GPS-18300恒流源控制电流密度为1 800 A/m2,剥粉周期为30 min[12]。

分别从以下几个方面评价多孔阳极在铜粉电积过程中的应用性能,并与平板阳极进行对比。

1) 阳极电位

阳极析氧电位反应了阳极能耗[13],是电积过程中的重要参数。利用万用表读取整个阳极极化过程的阳极电位,并与电脑连接自动记录数据,数据采集间隔为1 min。

2) 阳极腐蚀率

腐蚀使阳极具有一定的使用寿命,而且从阳极表面脱落下来的PbO2部分在电解液中溶解并在阴极放电析出,或悬浮在电解液中并输运至阴极表面夹杂于阴极沉积物中,造成阴极铜粉中的Pb含量升高。因此,阳极腐蚀率是评价阳极的另一个重要指标,腐蚀率越低,阳极的使用寿命越长,阴极铜粉中的Pb含量随之降低,从而提高阴极产品的合格率。用ICP光谱仪检测电解液中Pb含量变化,并通过以下计算公式阳极腐蚀率:

(1)

(1)

式中:Ccorr为阳极腐蚀率,mg/(cm2·h);ΔcPb为电解液中Pb2+浓度的变化量,mg/L;V为电解液总体积,L;wPb为阴极铜粉中的Pb含量,%;mc为阴极铜粉的产量,g;A为阳极的表观面积,cm2;t为电解时间,h。

3) 阳极表面氧化膜形貌

电解完成后,迅速将测试电极取出,去离子水清洗干净后用冷风吹干,获得干燥、清洁的样品。利用扫描电子显微镜(日本JEOL公司,JSM-6360LV型)观察并对比电积后阳极表面氧化膜的微观形貌。

4) 阴极铜粉

采用ICP光谱仪检测铜粉中的Pb含量;采用扫描电子显微镜对产物进行形貌分析。

2 结果与讨论

2.1 阳极电位

图1所示为不同成分和不同孔径的多孔阳极在CuSO4-H2SO4电解液中及1 800 A/m2电流密度下的恒流极化曲线。从图1可以看出,各阳极电位在极化初期时从一个较高值迅速降低,然后随着时间的延长变化减缓,最终稳定。衷水平[14]认为,恒电流极化条件下Pb基阳极表面氧化膜成分为β-PbO2以及PbSO4。电解初期PbSO4迅速形成,此时阳极的膜电阻大,阳极析氧过电位高。随着电解的进行,PbSO4逐渐向PbO2转变,氧化膜的阻抗降低,析氧电催化活性增强,阳极电位从较高的位置逐渐下降。当电解液溶解、阳极气体冲刷等作用使膜减少的量与阳极表面膜生成量达到动态平衡时,膜结构便相对稳定。此时,氧化膜各组分的相对含量也基本稳定,析氧过电位、膜电阻都不再有大的变化,阳极电位趋于稳定。最终趋于稳定的阳极电位数值被称为稳定阳极电位。由于铜粉电积过程中阳极电位绝大部分时间都在稳定阳极电位附近波动,故稳定阳极电位是阳极能耗的直接反应。稳定阳极电位越低,阳极反应能耗越小。从图1可以看出,Pb-Ag-Ca阳极的阳极电位在电解400 min后才基本达到稳定(见图1(a)),而Pb-Ag阳极的稳定时间只需200 min左右(见图1(b)),阳极电位的快速稳定有利于电解系统的维护,也说明Pb-Ag多孔阳极表面氧化膜更容易趋向稳定,有利于阳极腐蚀率的降低。

从图1还可以看出,对于各种孔径的多孔阳极,阳极电位均随时间的变化会有轻微的波动,而平板电极没有这种现象。在铜粉电积过程中,阳极主要发生的反应为O2的析出。多孔阳极为一种三维电极,电极内部也同时发生着电化学反应。由于孔径有一定的大小,且电极内部到外部的路径是弯曲的,电极内部生成的O2必须长大到一定的体积后才能从通道挤出。这种气泡逸出的不均匀性会造成阳极表面积的变化,从而使电极表面电流密度不稳定,导致阳极电位的波动。

图1 不同成分和不同孔径的多孔阳极电位随时间的变化曲线

Fig. 1 Anodic potential-time curves of porous anodes with different Ag and Ca contents and various

表1 各阳极在铜粉电积条件下的稳定阳极电位

Table 1 Stable anodic potential of anodes for copper powder electrowinning

读取各阳极的稳定阳极电位,其结果列于表1。从表1以看出,各多孔阳极的稳定阳极电位均比相同合金成分的平板阳极的稳定阳极电位低,且同合金成分多孔阳极的稳定阳极电位随着孔径的增大呈先降低后升高的趋势。如Pb-Ag多孔阳极的稳定阳极电位在孔径为1.0~1.25 mm时取得最小值,比多孔阳极的最大值(孔径为2.0~2.5 mm时)降低了45 mV,比平板阳极的稳定阳极电位降低了131 mV。一方面,多孔阳极由于具有比平板阳极大得多的比表面积,使其表面的真实电流密度降低,减轻了电极表面的极化程度,因而具有比平板阳极更低的稳定阳极电位。另一方面,多孔阳极的阳极电位还受O2的逸出阻力和阳极孔径的共同影响:孔径越小,阳极的比表面积越大,电极表面的真实电流密度越低,阳极电位降低;但孔径越小,O2的逸出阻力越大,将有更多的O2滞留在电极内部,造成阳极孔洞利用率下降,又会使阳极电位有所上升。因此,铜粉电积过程存在一个最优化的阳极孔径。从表1中可以看出,Pb-Ag多孔阳极和Pb-Ag-Ca多孔阳极的稳定阳极电位均在孔径为1.0~1.25 mm时取得最小值。

从表1还可以看出,Pb-Ag合金阳极的稳定阳极电位比Pb-Ag-Ca合金阳极的稳定阳极电位低得多,且前者阳极电位降低的幅度更大。如Pb-Ag合金平板阳极与Pb-Ag-Ca合金平板阳极相比,前者的稳定阳极电位降低了57 mV;当孔径为1.0~1.25 mm时,Pb-Ag合金和Pb-Ag-Ca合金多孔阳极的稳定阳极电位分别比同合金成分的传统平板阳极的稳定阳极电位降低了131和90 mV。这是由于合金元素Ag可以提高Pb基合金析氧电催化活性,且Ag含量越高,阳极过电位越低。二元合金中Ag含量为0.8%,而三元合金中Ag的含量只有0.24%,因此,Pb-Ag阳极表现出更好的析氧电催化能力。在电流密度相同的情况下,阳极电位越低,单位质量铜粉的能耗越低,电能效率越高,这对铜粉的电积法生产过程的节能降耗具有重要意义。

2.2 阳极腐蚀率

在电解过程中,Pb合金表面最终会生成一层稳定的PbO2氧化膜,对金属基体起保护作用,并提供电化学反应的场所。一方面,阳极表面O2的大量析出对氧化膜层具有冲刷作用,使得阳极表层组织结构疏松的PbO2剥离、脱落,造成了阳极的腐蚀;另一方面,电解液及新生O可以穿过氧化膜渗入Pb基体,进一步腐蚀阳极,但同时也不断修补外层氧化膜,保持氧化膜厚度和成分等达到动态稳定。对于多孔电极来说,由于其表面积的增大减小了电极工作时的真实电流密度,使氧化膜层趋于致密,从而减缓阳极的电化学腐蚀速率[13]。但同时,表面积的增大也增大了O2的冲刷面积和电解液的侵蚀,对降低腐蚀率不利。

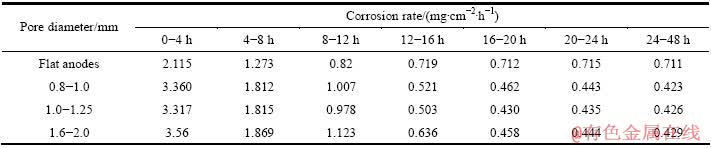

表2所列为Pb-Ag合金和Pb-Ag-Ca合金阳极在1 800 A/m2的电流密度下极化48 h后的平均腐蚀率。从表2可以看出,极化48 h后,Pb-Ag-Ca多孔阳极的平均腐蚀率与同合金成分的平板阳极的相当,而Pb-Ag多孔阳极的平均腐蚀率比同合金成分的平板阳极的稍小。虽然Pb-Ag合金阳极的Ag含量较高,其腐蚀率比Pb-Ag-Ca阳极的要低,但与传统平板阳极相比,其优势并不明显。

表2 各阳极在铜粉电积条件下电解48 h的平均腐蚀率

Table 2 Average corrosion rate of anodes for 48 h copper powder electrowinning

为了更直观地了解阳极腐蚀速率随着极化时间的变化趋势,在48 h的极化过程中,每隔一定时间对电解液取一次样,检测溶液中的Pb2+浓度,从而计算出相邻时间点之间的平均腐蚀速率。表3所列为Pb-Ag-Ca合金阳极在1 800 A/m2的电流密度下极化48 h时,各时间段的阳极腐蚀率结果。从表3可以看出,各阳极的即时腐蚀率均随着极化时间的延长先迅速降低而后基本保持稳定。在极化初期,Pb合金基体与电解液直接接触而溶解,腐蚀率较高。随着极化的进行,电极逐渐生成PbO2氧化膜,对基底起保护作用,阳极腐蚀率迅速降低。当氧化膜达到稳定状态时,氧化膜的腐蚀速率与生成速度达到一个动态平衡,膜层厚度基体不变,阳极腐蚀率也维持在一个较低的水平。

同时,从表3还可以发现,多孔阳极的腐蚀率在电解初期比平板阳极的还高,只有当极化到一定时间后(16 h),多孔阳极的即时腐蚀速率才低于平板阳极的。这是由于多孔阳极是一种三维电极,孔与孔之间的孔壁和孔棱上有许多的突起和尖锐的边角,这些地方容易发生电力线的集中,使局部腐蚀加剧;再加上其表面积大,在氧化膜未完全覆盖表面时,基体溶解引起的化学腐蚀更加严重。经过16 h极化,PbO2氧化膜对基体形成保护,多孔阳极由于真实电流密度小,极化程度低,其即时腐蚀速率比平板阳极的低。

比较表2和3的数据可知,虽然多孔阳极比平板阳极有更大的即时腐蚀速率降幅,但由于极化初期多孔阳极腐蚀的累积效应,其在48 h内的平均腐蚀速率与平板阳极的平均腐蚀速率的差值变小。可以预见的是,随着极化时间的延长,多孔阳极的平均腐蚀率还将进一步降低。

表3 Pb-Ag-Ca阳极在不同时间段的阳极腐蚀率

Table 3 Anodic corrosion rate of Pb-Ag-Ca anodes in various time quantum

图2 Pb-Ag-Ca平板阳极和多孔阳极的表面氧化膜形貌

Fig. 2 Morphologies of surface oxidation film of Pb-Ag-Ca plate anode and porous anode

2.3 阳极氧化膜形貌

图2所示为Pb-Ag-Ca多孔阳极和平板阳极在极化48 h后的表面氧化膜形貌。从图2可以看出,Pb-Ag-Ca多孔阳极与Pb-Ag-Ca平板阳极在微观形貌上有很大区别。多孔阳极由于可降低表面的真实电流密度,生成的氧化膜致密、平整,而平板阳极的氧化膜疏松、多孔,在O2的冲刷下容易脱落,这应当是造成传统平板阳极在极化后期的即时腐蚀率较多孔阳极高的原因之一。但疏松多孔的表面氧化膜结构使电极的比表面积增大,有利于降低阳极析氧过电位,从而造成Pb-Ag-Ca多孔阳极的阳极电位降低幅度较Pb-Ag多孔阳极的小。

图3所示为Pb-Ag多孔阳极和平板阳极的表面氧化膜形貌。从低倍率放大图(见图3(a)和(c))上看,两种阳极的表面氧化膜都比较致密,这是Pb-Ag阳极的腐蚀率比Pb-Ag-Ca阳极的腐蚀率低的原因。但从高倍率放大图(见图3(b)和(d))上看,两者的微观形貌差异较大:与Pb-Ag-Ca多孔阳极类似,Pb-Ag多孔阳极表面氧化膜的晶粒为不规则的片状,而平板阳极的为疏松粉末状。这种微观结构的差异可能使平板阳极的表面氧化膜耐O2的冲刷能力较差,因而后期的即时腐蚀率较大。

综合图2和3的结果可知,多孔结构对阳极氧化膜的微观形貌影响较大。平板阳极由于电流密度大,表面电化学极化严重,生成的氧化物晶粒较小,但氧化膜为一层粉末状的PbO2,不能经受O2的长时间冲刷。多孔阳极表面生成的氧化物虽然晶粒较大,形状不规则,但晶粒与晶粒之间结合紧密,没有裂纹,反而不容易脱落,使电极的耐腐蚀性能有所提高。

2.4 阴极铜粉

2.4.1 铜粉中杂质Pb元素的含量

在金属活动性顺序表中,元素Pb较Cu活泼,且电解液中Cu2+的浓度比Pb2+的浓度大得多,故Pb2+的沉积电位比Cu2+的负,阴极优先发生Cu2+的析出。但是由于电流密度较大,电积过程在溶液中Cu2+的极限电流密度下进行,电极表面 趋向于0,这增加了Pb2+放电的可能性。再加上阳极表面的PbO2颗粒在O2冲刷下会进入溶液,而阴极铜粉比表面积大,PbO2颗粒容易夹杂、包裹在铜粉中,从而对铜粉造成污染。

趋向于0,这增加了Pb2+放电的可能性。再加上阳极表面的PbO2颗粒在O2冲刷下会进入溶液,而阴极铜粉比表面积大,PbO2颗粒容易夹杂、包裹在铜粉中,从而对铜粉造成污染。

图3 Pb-Ag平板阳极和多孔阳极的表面氧化膜形貌

Fig. 3 Morphologies of surface oxidation film of Pb-Ag plate anode and porous anode

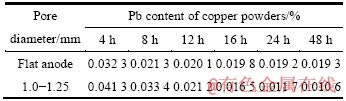

将Pb-Ag-Ca阳极在电沉积4、8、12、16、24和48 h时的铜粉分别取样,处理后对各样品的Pb含量进行ICP分析,其结果如表4所列。从表4可以看出,随着电积时间的延长,各时间段收集的阴极铜粉中的Pb含量在电积初期迅速减小,而后趋于稳定。在电积初期,多孔阳极上的铜粉品质比平板阳极上的铜粉品质要差,因为前者的铅含量较高,但经过一定时间之后,多孔阳极上的铜粉品质反而比平板阳极上的铜粉品质更好。这与Pb-Ag-Ca阳极在各时间段的即时腐蚀率的变化规律一致,说明阳极腐蚀率是影响阴极铜粉中Pb含量的主要因素。

目前电积铜粉采用与电解铜粉相同的牌号与标准,国标GB/T 5246—2007规定,牌号为FTD1的电解铜粉中杂质元素Pb含量不大于0.04%。多孔阳极经过48 h的极化后,铜粉中的Pb含量满足FTD1牌号标准。

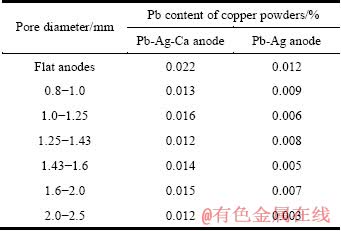

将不同孔径和不同合金成分的多孔阳极电积48 h所得的阴极铜粉收集在一起并混合均匀后,测试铜粉的Pb含量,其结果如表5所列。从表5可以看出,各阳极所生产的阴极铜粉的Pb含量均低于0.04%,满足国标对FTD1号电解铜粉的要求。同时,由于金属Ag可降低阳极的腐蚀率,采用Pb-Ag阳极所获得的铜粉的品质较好。多孔阳极也由于比表面积的增大,使其阳极腐蚀率较平板阳极的有所降低,进而降低了阴极铜粉中的Pb含量。

表4 Pb-Ag-Ca阳极在不同时间生产的铜粉的Pb含量

Table 4 Pb content of copper powders prepared with Pb-Ag-Ca anode different times

表5 各阳极电沉积48 h所得铜粉中的铅含量

Table 5 Pb content of copper powders after 48 h electrowinning

图4 采用平板阳极和多孔阳极制备的铜粉的微观形貌

Fig. 4 Morphologies of copper powders prepared by Pb-Ag plate anode and porous anode

2.4.2 铜粉的微观形貌

图4 所示分别为采用多孔阳极和平板阳极所得的阴极铜粉的表面形貌。从图4可以看出,阳极的形状对阴极铜粉的形貌的影响基本可以忽略。两类阳极所得阴极铜粉的形貌相同,基本为菜花状,偶见树枝状结晶。从高倍率图像(见图4(b)和(d))中可以看出,铜粉晶粒呈不规则球状,这与 [15]的研究结果一致。要想得到树枝状铜粉,阴极电流密度还需要进一步提高到2 000 A/m2左右。

[15]的研究结果一致。要想得到树枝状铜粉,阴极电流密度还需要进一步提高到2 000 A/m2左右。

4 结论

1) 采用多孔阳极可以在高的表观电流强度下,获得较低的阳极真实电流密度,减小阳极极化的程度,从而有效降低阳极析氧过电位。多孔阳极的孔径大小对阳极电位有影响,当孔径为1.0~1.25 mm时,阳极电位达到最小值,其中Pb-Ag多孔阳极的析氧过电位较同样合金成分的平板阳极降低了131 mV,这对电积铜粉生产降低能耗有重要意义。

2) 多孔阳极可降低表面的真实电流密度,生成致密、平整的氧化膜,其结构由细小的粉末状变成较大的片状,耐腐蚀性能优于平板阳极的。16 h极化后,多孔阳极的即时腐蚀速率比平板阳极的低。腐蚀率的降低,有利于延长阳极使用寿命,提升阴极铜粉品质。采多孔阳极制备的阴极铜粉中的Pb含量较低,可满足FTD1电解铜粉标准。

3) 采用多孔阳极对阴极铜粉的形貌没有影响,所得铜粉呈菜花状,为立方晶系结构,结晶度良好。

4) 与现行铜粉电积工业上广泛采用的 Pb基平板阳极相比,多孔阳极可以降低析氧过电位、阳极腐蚀率和铜粉中的Pb含量,适合替代平板阳极用作电积铜粉用阳极。

REFERENCES

[1] 万新梁. 全球铜及铜合金粉末的生产现状及应用发展趋势[J]. 新材料产业, 2009(4): 28-36.

WAN Xin-liang. Production status and application trend of global copper and copper powders[J]. Advanced Materials Industry, 2009(4): 28-36.

[2] 楚 广, 唐永建, 刘 伟, 罗江山, 黎 军, 杨天足. 纳米铜粉的制备及其应用[J]. 金属功能材料, 2005, 12(3): 18-21.

CHU Guang, TANG Yong-jian, LIU Wei, LUO Jiang-shan, LI Jun, YANG Tian-zu. The preparation technology and application of nanocrystalline copper powder[J]. Metallic Functional Materials, 2005, 12(3): 18-21.

[3] WU Song-ping, MENG Shu-yuan. Preparation of micron size copper powder with chemical reduction method[J]. Materials Letters, 2006, 60: 2438-2442.

[4] 李占荣, 汪礼敏, 万新梁. 低松装密度水雾化铜粉工艺的研究[J]. 粉末冶金工业, 2003, 13(1): 5-7.

LI Zhan-rong, WANG Li-min, WAN Xin-liang. Study on production process of copper powders with low apparent density[J]. Powder Metallurgy industry, 2003, 13(1): 5-7.

[5] 徐纯芳, 张 丽, 廖元杭, 鲁 军. 电解铜粉生产工艺的研究[J]. 粉末冶金工业, 2006, 16(5): 17-19.

XU Chun-fang, ZHANG Li, LIAO Yuan-hang, LU Jun. Research on production of electrolytic copper powder[J]. Powder Metallurgy Industry, 2006, 16(5): 17-19.

[6] 汪锦瑞, 段建军. 影响电积法生产铜粉的电耗因素及对策[J]. 粉末冶金工业, 2010, 20(4): 6-9.

WANG Jin-rui, DUAN Jian-jun. The measures reducing the electricity consumption in copper powder production with electrowinning[J]. Powder Metallurgy Industry, 2010, 20(4): 6-9.

[7] 刘有源, 陈白珍, 孙锡良, 杨喜云, 周晓源. 浸出-电沉积法从多金属低品位矿制备铜粉的研究[J]. 湖南有色金属, 2008, 24(2): 28-31.

LIU You-yuan, CHEN Bai-zhen, SUN Xi-liang, YANG Xi-yun, ZHOU Xiao-yuan. Technology of preparation for sponge copper powder by leaching-electrowinning from the complex multi-metal and low metal grade ores[J]. Hunan Nonferrous Metallurgy, 2008, 24(2): 28-31.

[8] 陈自江. 电积法生产铜粉的开发与研制[J]. 中国有色冶金, 2010, 39(4): 59-64.

CHEN Zi-jiang. Preparation of copper powder with electrowinning[J]. China Nonferrous Metallurgy, 2010, 39(4): 59-64.

[9] LAI Yan-qing, JIANG Liang-xing, LI Jie, ZHONG Shui-ping, LV Xiao-jun, PENG Hong-jian, LIU Ye-xiang. A novel porous Pb-Ag anode for energy-saving in zinc electrowinning: Part II: Preparation and pilot plant tests of large size anode[J]. Hydrometallurgy, 2010, 102(4): 81-86.

[10] LAI Yan-qing, JIANG Liang-xing, LI Jie, ZHONG Shui-ping, LV Xiao-jun, PENG Hong-jian, LIU Ye-xiang. A novel porous Pb-Ag anode for energy-saving in zinc electro-winning: Part I: Laboratory preparation and properties[J]. Hydrometallurgy, 2010, 102(4): 73-80.

[11] 蒋良兴, 吕晓军, 李 渊, 彭红建, 赖延清, 李 劼, 刘业翔. 锌电积用“反三明治”结构铅基复合多孔阳极[J]. 中南大学学报: 自然科学版, 2011, 42(4): 871-875.

JIANG Liang xing,  Xiao jun, LI Yuan, PENG Hong jian, LAI Yan qing, LI Jie, LIU Ye xiang. Anti sandwich structure lead based composite porous anode for zinc electrowinning[J]. Journal of Central South University: Science and Technology, 2011, 42(4): 871-875.

Xiao jun, LI Yuan, PENG Hong jian, LAI Yan qing, LI Jie, LIU Ye xiang. Anti sandwich structure lead based composite porous anode for zinc electrowinning[J]. Journal of Central South University: Science and Technology, 2011, 42(4): 871-875.

[12] 郭学益, 陈胜利, 梁永宣, 田庆华. 工艺条件对电积法制备铜粉的影响[J]. 北京科技大学学报, 2011, 33(2): 182-187.

GUO Xue-yi, CHEN Sheng-li, LIANG Yong-xuan, TIAN Qing-hua. Effect of process conditions on the preparation of copper powders by electro-deposition[J]. Journal of University of Science and Technology Beijing, 2011, 33(2): 182-187.

[13] 蒋良兴, 衷水平, 赖延清, 吕晓军, 洪 波, 彭红建, 周向阳, 李 劼, 刘业翔. 电流密度对锌电积用Pb-Ag平板阳极电化学行为的影响[J]. 物理化学学报, 2010, 26(9): 2369-2374.

JIANG Liang-xing, ZHONG Shui-ping, LAI Yan-qing,  Xiao-jun, HONG Bo, PENG Hong-jian, ZHOU Xiang-yang, LI Jie, LIU Ye-xiang. Effect of current densities on the electrochemical behavior of a flat plate Pb-Ag anode for zinc electrowinning[J]. Acta Phys Chim Sin, 2010, 26(9): 2369-2374.

Xiao-jun, HONG Bo, PENG Hong-jian, ZHOU Xiang-yang, LI Jie, LIU Ye-xiang. Effect of current densities on the electrochemical behavior of a flat plate Pb-Ag anode for zinc electrowinning[J]. Acta Phys Chim Sin, 2010, 26(9): 2369-2374.

[14] 衷水平. 锌电积铅基多孔节能阳极的制备、表征与工程化试验[D]. 长沙: 中南大学, 2009: 77-94.

ZHONG Shui-ping. Preparation, characterization and pilot scale tests of lead based porous anode for energy-saving in zinc electrowinning[D]. Changsha: Central South University, 2009: 77-94.

[15]  H. Effect of electrolysis parameters on the morphologies of copper powder obtained in a rotating cylinder electrode cell[J]. Powder Technology, 2010, 201: 57-63.

H. Effect of electrolysis parameters on the morphologies of copper powder obtained in a rotating cylinder electrode cell[J]. Powder Technology, 2010, 201: 57-63.

(编辑 何学锋)

基金项目:国家“十二五”科技支撑计划课题(2012BAA03B04);国家自然科学基金项目(51204208)

收稿日期:2012-07-17;修订日期:2013-03-20

通信作者:蒋良兴,讲师,博士;电话:0731-88830649;E-mail:lxjiang@csu.edu.cn