文章编号:1004-0609(2011)08-1936-08

非晶态Ni-W-P镀层退火晶化和激光晶化

组织结构的演变

刘 宏1,郭荣新2,李 莎1,宗 云1,何冰清1

(1. 山东轻工业学院 机械工程学院,轻工装备先进制造与测控技术实验室,济南 250353)

(2. 淄博市新材料研究所,淄博 255040)

摘 要:用XRD定量分析法并结合扫描电镜形貌观察,研究化学沉积高磷(13.3%)含量的Ni-W-P镀层在不同热处理条件下的晶化程度、晶粒尺寸及晶格应变等组织结构的演变规律。结果表明:高磷非晶态镀层在退火晶化过程中,Ni3P相的体积分数始终高于Ni相的,700 ℃时,两相的体积分数之差显著增大,镀层仍有残存的非晶相;在400~500 ℃之间形成的Ni3P的晶粒尺寸大于Ni的;温度为500~700 ℃时,Ni相的尺寸大于Ni3P的,但均未超过纳米级。镀层晶格应变表现为随退火温度的升高而降低,镀态时晶格应变最大。激光晶化处理的非晶态Ni-W-P镀层的显微结构特征介于400~500 ℃之间退火的镀层晶化特征。随扫描速度增加,不仅Ni3P晶粒尺寸增大,而且两相的尺寸差变大。

关键词:激光晶化;退火晶化;化学沉积Ni-W-P;晶化程度;晶粒尺寸;晶格应变

中图分类号:TQ153.2; TG156.99 文献标志码:A

Microstructures evolution of electroless amorphous Ni-W-P coating during laser and annealing crystallization

LIU Hong1, GUO Rong-xin2, LI Sha1, ZONG Yun1, HE Bing-qing1

(1. Light Industry Equipment Advanced Manufacturing and Measurement and Control Technology Laboratory,

School of Mechanical Engineering, Shandong Institute of Light Industry, Ji’nan 250353, China)

(2. Zibo Institute of New Materials, Zibo 255040, China)

Abstract: The evolution of microstructures, in terms of degree of crystallisation, grain size and lattice strain of electroless Ni-W-P coating with high phosphorous (13.3%) content during laser and furnace annealing was investigated by quantitative XRD method and morphological observation of SEM. The results show that, during the annealing crystallization of the amorphous coating, the volume fraction of Ni3P exceeds that of Ni, and the volume fraction difference between the two phases increases remarkably at 700 ℃, but the remaining amorphous phase still exists in the coating. The grain size of Ni3P is larger than that of Ni between 400 ℃ and 500 ℃, the grain size of both phases is reversed above 500-700 ℃ and are in the range of nanoscale. The lattice strain of as-plated deposit is the maximum and decreases with the increase of temperature. The characteristics of microstructures of the coating treated by laser is consistent with the deposit annealed by furnace between 400 ℃ and 500 ℃. The grain size of Ni3P and phases difference increase with the increase of the scanning velocity.

Key words: laser crystallizing; annealing crystallizing; electroless Ni-W-P; crystallisation degree; grain size; lattice strain

非晶晶化法是近年来制备纳米晶材料较为活跃的一种方法。其中,化学沉积Ni-P基合金退火晶化的研究成为热点之一[1-4]。随退火温度的升高,合金纳米晶化后表现出优于其非晶态镀层的耐磨和耐蚀性能。然而,Ni-P基合金纳米化镀层的高耐磨性和耐蚀性均出现在较高退火温度的情况下[5-6],高温退火有可能改变基体材料的组织结构,使其机械性能急剧下降。因此,对于不能承受高温的基体材料很难通过退火晶化获得性能优异的纳米晶镀层。目前,激光晶化受到关注。郑晓华等[7]和顿爱华等[8]以及王兰和邵红红[9]分别对化学沉积Ni-P-Al2O3和Ni-P-SiC复合镀层采用激光晶化手段,研究不同激光处理参数对晶化镀层组织结构、表面硬度及摩擦磨损行为的影响,并与炉内退火晶化相比,获得更高的硬度和耐磨性。初步的研究表明,无论通过退火晶化还是激光晶化都会在非晶基体中析出极细的纳米晶粒,如Ni和Ni3P纳米晶,获得非晶/纳米晶的混晶材料。这种材料与成分相同(相近)完全非晶的材料相比较,表现出优异的性能。Ni-W-P镀层晶化后耐蚀性的提高,主要缘于纳米晶的形成增加W的扩散通道,加速W向表层扩散有利于表层形成氧化钨膜[10];另一方面,耐蚀性的改变还与腐蚀过程中,Ni作为阳极相、Ni3P作为阴极相以及它们的晶粒尺寸和两相的相对量有关[11]。同样,这些因素对耐磨性也会起着重要作用。因此,退火晶化和激光晶化能否提高镀层的性能,在一定程度上取决于不同晶化法所获得的相变产物相对量比例及其晶粒尺寸是否有利于改善镀层的性能。然而,迄今为止,有关化学沉积非晶合金晶化法的相转变行为仅是针对Ni-P基合金的退火晶化[12-15],从未涉及到激光快速加热条件下镀层晶化(不熔化)热力学和动力学的研究,更缺少对其非晶/纳米晶相的定量分析,而这或许正是揭示激光晶化镀层具有优异性能的本质之关键所在。

本文作者针对化学沉积高磷(13.3%)含量的Ni-W-P合金镀层,通过XRD对激光晶化形成的Ni和Ni3P的晶粒尺寸、晶格应变及纳米化程度进行定量分析,并与退火晶化进行比较,为揭示化学沉积Ni-W-P镀层纳米化及其性能的本质提供依据。

1 实验

1.1 Ni-W-P镀层的制备、成分结构分析及形貌

镀层基体材质选用厚度为1 mm的Q235钢板,剪切成尺寸为10 mm×15 mm的试样。经除油、酸蚀及活化等一系列处理后进行化学沉积,镀液的组成如表1所列。在沉积过程中控制pH值为9~9.5,温度为90~95 ℃,得到厚度为(30±2) μm的Ni-W-P镀层。

分别将所获得的试样进行激光晶化和退火晶化处理。采用1.5 kW连续波长的diode激光器,激光束斑尺寸为2.5 mm×3.5 mm的矩形,束斑以短边在镀层上方沿试样长边在氩气保护下扫描。所用激光功率为150 W,当扫描速度为7 mm/s时,镀层表面出现熔化现象,因此,取扫描速度为8~14 mm/s。为比较,将镀态试样在马弗炉中等温加热到200~700 ℃,并在氩气保护下保温1 h。通过日本EVO50扫描电镜及能谱仪对镀层进行成分分析及形貌观察;由Philip-X射线衍射仪作结构分析,使用Cu靶,步进扫描范围10°~90°,步宽0.02°,时间常数2 s。

表1 化学沉积Ni-W-P合金镀液组成

Table 1 Compositions of plating bath for electroless Ni-W-P coatings

1.2 晶粒尺寸及晶格应变的XRD分析

一般是采用著名的Scherrer公式计算纳米晶粒尺寸[16],即:

(1)

(1)

式中:D为晶粒尺寸;θ为掠射角;λ为入射线波长;βm是仅由小晶粒尺寸引起的衍射峰的半高宽,用弧度表示;K为Scherrer常数,大约等于1。由于衍射峰的半高宽还受到晶格应变的影响,因此,目前广泛采用Pseudo-Voigt函数描述晶粒尺寸和晶格应变效应对衍射线形的影响[14]:

(2)

(2)

式中:β是包括了晶粒尺寸及晶格应变效应的衍射峰半高宽;ε为晶格应变。这种组合式函数能更好地适合衍射线形的不对称性。一般从XRD获得的镀态衍射线或者从热处理条件下析出磷化物的衍射线总是与镀态下的非晶态线形严重地重叠在一起,而晶粒尺寸的计算则要求衍射线必须与其分离。因此,对实验中获得的衍射线细化采用Philips-APD计算机软件,将重叠的衍射线分离成单一线形。根据晶化相的积分强度、衍射线位置、半高宽和积分宽度等参数,求出其晶粒尺寸和晶格应变。本研究以Ni相的(111)和(200)晶面以及Ni3P相的(312)和(141)晶面的XRD衍射数据为基础,分别计算激光晶化和退火晶化相应晶面的晶粒尺寸及晶格应变。

1.3 镀层晶化程度及相转变量的定量分析

通过粉末衍射的ICDD卡片得到含W的Ni固溶体以及Ni3P的I/Ic值分别为8.77和1.61,利用Philips-APD计算机软件得到由不同晶化法处理前后镀层各相的积分强度,并由此计算出各相所占的体积分数I /Itotal,即晶化前的非晶相、晶化后残存的非晶相、晶化产物Ni的INi /Itotal及Ni3P的INi3P/Itotal比值,从而确定镀层相应的晶化程度。

2 分析和讨论

2.1 镀层的结构和形貌特征

通过能谱分析得到镀层的化学成分为Ni-3.88%W-13.3%6P(质量分数),属于高磷镀层。图1所示为试样经两种晶化法处理前后的XRD谱。从镀态镀层显示的“馒头”状峰看似为完全非晶态结构,符合EDS分析结果。

由图1(a)可看出,退火晶化时,当加热温度在300 ℃以下,谱中没有出现其他的衍射峰,只是镀态下的“馒头”状峰变得细化,意味着只有单一Ni晶体形成;而400 ℃时,镀层中出现了Ni3P相衍射峰,但其 (321)和(222)两个晶面的衍射峰因宽化而不明显。温度继续升高达到700 ℃时,不仅(321)和(222)晶面的衍射峰逐渐加强,两相其他晶面的衍射峰也表现得越加尖锐,这说明随着热处理温度的升高,镀层的晶化程度增大,镀层由镀态时的非晶态逐渐转变成非晶态和晶态共存的混晶态。本研究中,在镀层晶化的整个温度范围,XRD谱中没有出现单一W或W的化合物峰,表明相变过程中没有W晶体或W的化合物形成,W固溶于Ni的晶胞中成为Ni的固溶体,这与XRD谱中Ni-W-P合金(111)晶面衍射峰位相对于纯Ni在同一晶面的衍射峰位向低角度漂移的现象相吻合。

图1 化学沉积Ni-W-P镀层晶化处理前后的XRD谱

Fig.1 XRD patterns of electroless Ni-W-P coatings before and after crystallization treatment: (a) Furnace; (b) Laser

由图1(b)可看出,与退火晶化相比,激光扫描速度从8~14 mm/s变化时,均发生Ni和Ni3P相的晶化反应。且随扫描速度的增加,即相当于处理温度的降低,不但Ni和Ni3P相的衍射峰强度降低,在衍射谱上,Ni(111)晶面衍射峰宽化尤为明显。这表明镀层的晶粒尺寸及晶化程度随扫描速度的增大而减小。

高磷含量的Ni-W-P镀层用不同晶化法处理前后的SEM像如图2所示。由镀态(见图2(a))、400 ℃(见图2(b))和700 ℃(见图2(c))温度下退火的表面形貌可见,在镀态下,镀层的表面形貌呈胞状凸起,胞状边缘较为清晰;且随着退火温度的升高,凸起程度减轻,达到700 ℃时,胞状边缘变得模糊。然而,激光晶化处理的镀层(见图2(d)~(f)),即使以最小的扫描速度8 mm/s,这一形貌特征也并不明显,这暗示着激光处理达到的晶化程度低于高温退火的晶化程度。

此外,当激光扫描速度为14 mm/s时,镀层表面出现微裂纹,这可能归因于激光快速加热、快速相变导致镀层具有较大的内应力所致。

图2 化学沉积Ni-W-P镀层晶化处理前后的SEM像

Fig.2 SEM images of electroless Ni-W-P coatings before and after crystallization treatment: (a) As-plated; (b) 400 ℃; (c) 700 ℃; (d) 8 mm/s; (e) 12 mm/s; (f) 14 mm/s

2.2 晶粒尺寸和晶格应变

用Philips-APD软件在掠射角为40°~55°范围,以标样Si作参照标准,计算镀层在不同晶化法处理后面心立方结构的Ni相在(111)和(200)晶面以及析出的Ni3P相在(321)和(141)晶面的晶粒尺寸和晶格应变值,然后再对Ni和Ni3P分别对应的两个晶面的晶粒尺寸和晶格应变求其平均值。图3所示为两种晶化条件下晶粒尺寸的计算结果。图3(a)中镀态的晶粒尺寸是假设镀层为不完全的非晶态结构,将(111)晶面的非晶态衍射线形分离而得到,其值小于2 nm。从图3(a)中可以看出,镀层中Ni和Ni3P相的平均晶粒尺寸随着温度的升高而增大,直至700 ℃时,两相的晶粒尺寸仍保持在纳米级;当加热温度为400~500 ℃时,Ni3P的晶粒尺寸大于Ni的;但当加热温度超过500 ℃时,两相晶粒尺寸的大小表现出相反的结果。

与退火晶化不同的是,无论扫描速度如何变化,在激光晶化过程中,Ni3P相的晶粒尺寸始终显著大于Ni的,甚至超过700 ℃退火析出的Ni3P的晶粒尺寸;且扫描速度越快,Ni3P相的晶粒尺寸越大;相反,Ni相的晶粒尺寸则变小(见图3(b))。可见激光晶化所表现出的Ni3P大Ni小的尺寸规律与400~500 ℃之间退火晶化两相的尺寸规律相同,说明它们具有相似的显微组织特征。

镀层晶格应变与温度和扫描速度的关系曲线如图4所示。从退火晶化整个温度区间的晶格应变曲线看,镀态时,镀层的晶格应变最大,这主要归因于原子排列的长程无序近程有序;加热到200~300 ℃时,晶格应变显著降低,这一现象恰好与非晶态镀层发生结构驰豫的温度相吻合,说明在此温度区间,镀层中各种缺陷的运动及湮灭、Ni晶体的形成等是引起晶格应变减小的主要原因;当温度超过300 ℃时,Ni及Ni3P相的析出及其长大,各种结构缺陷的形成与合并,这些因素综合作用的结果使晶格应变的降低幅度减小。然而,对比激光晶化过程发现,激光扫描速度从慢(8 mm/s)到快(14 mm/s)变化时,晶格应变有所增大,但增大幅度介于400~500 ℃退火的晶格应变值之间。这意味着激光晶化程度亦处在400~500 ℃退火晶化程度范围,从激光晶化获得的晶粒尺寸特点(Ni3P相晶粒大Ni相晶粒小)与400~500 ℃退火晶化的特点相同也进一步说明了这一点。

图3 化学沉积Ni-W-P镀层晶化处理前后的晶粒尺寸

Fig.3 Grain size of electroless Ni-W-P coatings before and after crystallization treatment: (a) Furnace; (b) Laser

图4 镀层晶格应变随加热温度和扫描速度的变化

Fig.4 Variation of lattice strain with temperature and scanning velocity in coating

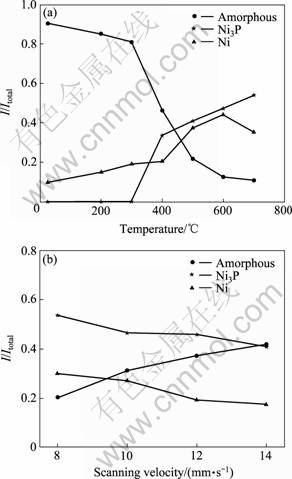

2.3 镀层的晶化程度

将不同晶化法得到的各相体积分数的计算结果I/Itotal分别绘制曲线,确定镀层在激光和退火热处理后的晶化程度,如图5所示。从图5(a)中镀态下非晶相的体积分数,即Ia/Itotal的比值0.904可以看出,镀层的非晶化程度很高,但从300 ℃到500 ℃退火晶化时,其Ia/Itotal比值锐减,说明镀层的晶化过程主要发生在这一温度范围内;从500 ℃到700 ℃,这一Ia/Itotal比值进一步降低,然而,即使加热到700 ℃,镀层也并未达到完全晶化,而是仍残留有一些非晶相(Ia/Itotal = 0.11)。化学沉积Ni-P合金采用连续加热退火在800 ℃之前不能完全晶化,这在文献[17]也有报道。此外,从400 ℃开始发生Ni3P晶化反应直至700 ℃时,镀层中Ni3P相的体积分数始终高于Ni相的体积分数,且在700 ℃时,INi/Itotal和INi3P /Itotal的比值差明显增大,表明退火温度越高,越有利于Ni3P相的析出。

图5(b)所示为非晶态Ni-W-P镀层激光晶化程度与扫描速度的变化。随扫描速度从8 mm/s增加到 14 mm/s,晶化相Ni和Ni3P各自的体积分数INi/Itotal和INi3P/Itotal均随之减小,亦即晶化程度降低,其残留的非晶相 Ia/Itotal比值在0.205~0.417之间变化,这一比值范围恰好介于400~500 ℃退火晶化的Ia/Itotal比值区间(0.462~0.216),由此证实扫描速度为8~14 mm/s时激光晶化程度略高于400~500 ℃退火的;但与之不同的是,镀层中Ni3P相的体积分数远大于Ni相的,这一现象却与INi3P /Itotal和INi/Itotal比值差增大出现在700 ℃高温退火条件下的实验结果是一致的,说明激光快速加热镀层的晶化过程发生在更高的温度下,由此进一步证实高温晶化更有利于Ni3P相的析出。此外,扫描速度为14 mm/s时,镀层表面出现显微裂纹除了受晶格应变影响,其中激光加热快速相变析出大量的尺寸相对粗大的硬化相Ni3P,使镀层比容差增大而导致其组织应力较大也是重要的影响因素。

图5 镀层中各相体积分数随加热温度和扫描速度的变化

Fig.5 Variation of volume fraction (I/Itotal) of each phase in coatings with temperature and scanning velocity: (a) Furnace annealing crystallizing; (b) Laser crystallizing

2.4 晶粒尺寸、晶化程度与温度的关系

将晶粒尺寸与镀层晶化程度随温度的变化如图6所示。由图6(a)可见,在300 ℃发生Ni3P相变之前,镀层发生结构弛豫,Ni相的晶化程度(体积分数从镀态9.6%转变为19%)较低,且尺寸(约11 nm)也小;而400~500 ℃之间,镀层的晶化特征相似,即析出的Ni3P相的体积分数高于Ni相的体积分数,意味着发生Ni3P相变的驱动力较大,说明Ni3P相的晶化反应主要发生在这一温度范围内。同时,由于Ni3P相的大量形成阻碍Ni相的长大,而Ni3P相的晶粒尺寸(33.4 nm)大于Ni相的晶粒尺寸(28.2 nm),则可能归因于在Ni3P相来不及长大的晶化温度400~500 ℃之间,其晶胞的体积远大于Ni相晶胞的体积是决定晶粒尺寸的主要因素;当退火温度达到600 ℃以上,Ni3P晶粒的聚集粗化,对Ni相长大的阻碍作用减小,于是Ni相的长大速度增加,以致其尺寸甚至大于Ni3P的。

为了理解用激光和炉子处理的显微组织特征的差异,需要考虑两种处理在温度和时间方面的受热过程。首先,激光处理的温度要比炉子高得多。本研究条件下,由于7 mm/s的激光扫描速度会使镀层表面熔化,因此,以8 mm/s扫描速度处理的表面温度应接近镀层的熔化温度。第二,加热时间,即相当于激光束和镀层表面之间的交互作用时间在178 ms和312.5 ms(由束斑短边尺寸2.5 mm/扫描速度得到)之间,比炉子保温时间1 h要短得多。因而,激光热处理是具有比炉内退火加热和冷却都快得多的过程。由于晶化温度受加热速度的影响,镀层激光处理时的晶化温度较高,因此,激光处理非晶态Ni-W-P镀层的纳米晶化发生在更高的温度下和更短的时间内。

与退火晶化相比,尽管非晶态Ni-W-P镀层激光的晶化程度、Ni3P大Ni小的晶粒尺寸特征以及晶格应变大小表现出与400~500 ℃退火晶化的特征相似,但也存在些许差别。随扫描速度降低,亦即温度升高,Ni3P的晶粒尺寸反而呈减小趋势。将激光晶化过程晶粒尺寸具有的这种演变规律与镀层晶化程度结合起来(见图6(b)),发现在激光快速扫描时(14 mm/s),镀层中Ni的INi/Itotal(0.17)比值低,Ni3P尺寸大(68 nm);而随着扫描速度降低,Ni相的INi/Itotal比值逐渐增大(8 mm/s时约0.30),Ni3P尺寸随之减小(8 mm/s时约55 nm)。显然,在激光快速加热条件下,Ni3P相的尺寸主要取决于镀层中Ni相所占的体积分数,或许正是激光相变温度高、时间短的这一特点,使镀层一旦发生Ni3P相变,于此同时形成的Ni相数量愈多愈能有效地阻止Ni3P的长大。

图6 Ni-W-P镀层晶化程度、晶粒尺寸与温度的关系

Fig.6 Relationships of phase transformation degree and grain sizes of Ni-W-P coatings with temperature: (a) Furnace; (b) Laser

值得注意的是,在400~500 ℃之间退火晶化以及激光晶化的过程中,表现出Ni3P的晶粒尺寸大于Ni的晶粒尺寸,且Ni3P所占的体积分数高于Ni的,这一显微组织特征恰好对应于以往研究的退火晶化镀层性能敏感的温度区间。热处理的Ni-P基合金加热到400 ℃时能获得最好的耐磨性[5],但耐蚀性却欠佳[6]。当加热温度超过500 ℃时,Ni的晶粒尺寸大于Ni3P的,镀层的耐蚀性得到改善。因此,热处理改变镀层的性能不仅与其纳米化有关,Ni和Ni3P两相的相对大小及相对量也是不可忽视的因素。

3 结论

1) 高P含量(13.3%,质量分数)的Ni-W-P合金镀层在退火晶化过程中,Ni3P相的体积分数始终高于Ni相的,700 ℃时,两相的体积分数之差显著增大,且镀层仍有残存的非晶相;晶粒尺寸的演变规律为在400~500 ℃之间形成的Ni3P相的晶粒尺寸比Ni相的大,加热温度超过500 ℃直至700 ℃时,Ni相的晶粒尺寸大于Ni3P相的,但两相的晶粒尺寸均未超过纳米级。镀层晶格应变表现为随退火温度升高而降低,镀态时晶格应变为最大。

2) 高P含量(13.3%)的Ni-W-P镀层激光晶化特征,如镀层晶化程度、Ni3P大Ni小的晶粒尺寸特征以及晶格应变大小均介于400~500 ℃之间的退火晶化特征。随扫描速度增加,不仅Ni3P晶粒尺寸增大,而且两相的尺寸差也变大。

致谢

本工作XRD测试及其定量分析在The University of Manchester, Material Science Center完成。在此谨向参与本工作的国外同仁Dr Z. Liu, Dr F. Viejo, Mrs. J. Shackleton和Mr G. Harrison表示真诚的感谢。

REFERENCES

[1] BALARAJU J N, JAHAN M S, JAIN A, RAJAM K S. Structure and phase transformation behavior of electroless Ni-P alloys containing tin and tungsten[J]. Journal of Alloys and Compounds, 2007, 436: 319-327.

[2] YOUNAN M M, ALY I H M, NAGEEB M T. Effect of heat treatment on electroless ternary nickel-cobalt-phosphorus alloy[J]. Journal of Applied Electrochemistry, 2002, 32: 439-446.

[3] TIEN S K, DUH J G, CHEN Y I. The influence of thermal treatment on the microstructure and hardness in electroless Ni-P-W deposit[J]. Thin Solid Films, 2004, 469/470: 333-338.

[4] MAHALLAWY N. El, BAKKAR A, SHOEIB M, PALKOWSKI H, NEUBERT V. Electroless Ni-P coating of different magnesium alloys[J]. Surface & Coatings Technology, 2008, 202: 5151-5157.

[5] PALANIAPPA M, SESHADRI S K. Friction and wear behavior of electroless Ni-P and Ni-W-P alloy coatings[J]. Wear, 2008, 265: 735-740.

[6] 曲彦平,胡 燕. 热处理温度对Ni-W-P化学镀层结构和性能的影响[J]. 材料保护, 2009, 42(8): 43-45.

QU Yan-ping, HU Yan. Effect of temperatures of heat treatment on structure and performance of electroless Ni-W-P coatings[J]. Materials Protection, 2009, 42(8): 43-45.

[7] 郑晓华, 宋仁国, 姚建华. 镍-磷-纳米氧化铝化学镀层的激光热处理及其摩擦磨损性能[J]. 中国激光, 2008, 35(4): 610-614.

ZHENG Xiao-hua, SONG Ren-guo, YAO Jian-hua. Laser heat treatment and wear resistance of electroless plating Ni-P-Nano-Al2O3 composite coatings[J]. Chinese Journal of Lasers, 2008, 39(4): 610-614.

[8] 顿爱华, 姚建华, 孔凡志, 张 伟. 激光处理Ni-P-Al2O3纳米化学复合镀层的微观组织[J]. 中国激光, 2008, 35(10): 1609-1614.

DUN Ai-hua, YAO Jian-hua, KONG Fan-zhi, ZHANG Wei. Microstructure characterization of Ni-P-Al2O3 electroless composite plating on Fe-C alloy treated by laser beam[J]. Chinese Journal of Lasers, 2008, 35 (10): 1609-1614.

[9] 王 兰, 邵红红. 化学复合镀层激光处理后基材组织与性能的研究[J]. 金属热处理, 2008, 33(9): 16-18.

WANG Lan, SHAO Hong-hong. Microstructure and performance of matrix beneath electroless composite coatings after laser treatment[J]. Heat Treatment of Metals, 2008, 33(9): 16-18.

[10] GAO Y, ZHENG Z J, ZHU M, LUO C P. Corrosion resistance of electroless deposited Ni-P and Ni-W-P alloys with various structures[J]. Materials Science and Engineering A, 2004, 381: 98-103.

[11] LIU H, VIEJO F, GUO R X, GLENDAY S, LIU Z. Microstructure and corrosion performance of laser-annealed electroless Ni-W-P coatings[J]. Surface & Coatings Technology, 2010, 204: 1549-1555.

[12] PALANIAPPA M, SESHADRI S K. Structural and phase transformation behaviour of electroless Ni-P and Ni-W-P deposits[J]. Materials Science and Engineering A, 2007, 460/461: 638-644.

[13] YONG J H, WANG T X, MENG J L, RAO Q Y. Structure and phase transformation behaviour of electroless Ni-W-P on aluminium alloy[J]. Surface & Coatings Technology, 2006, 201: 988-992.

[14] GUO Z, KEONG K G, SHA W. Crystallisation and phase transformation behaviour of electroless nickel phosphorus platings during continuous heating[J]. Journal of Alloys and Compounds, 2003, 358: 112-119.

[15] KEONG K G, SHA W. Crystallisation and phase transformation behaviour of electroless nickel-phosphorus deposits and their engineering properties[J]. Surface Engineering, 2002, 18: 329-343.

[16] DANILCHENKO S N, KUKHARENKO O G, MOSEK C E. Determination of the bone mineral crystallite size and lattice strain from diffraction line broadening[J]. Crystal Research and Technology, 2002, 37(11): 1234-11240.

[17] KEONG K G, SHA W, MALINOV S. Crystallisation kinetics and phase transformation behaviour of electroless nickel-phosphorus deposits with high phosphorus content[J]. Journal of Alloys and Compounds, 2002, 334: 192-199.

(编辑 李艳红)

基金项目:山东省自然科学基金资助项目(ZR2011EMM014)

收稿日期:2010-07-19;修订日期:2010-12-07

通信作者:刘 宏,教授,博士;电话:13953159215;E-mail: newhsx@163.com