Trans. Nonferrous Met. Soc. China 26(2016) 722-728

Thermal deformation behavior and mechanism of intermetallic alloy Ti2AlNb

Qin-chai ZHANG1, Ming-he CHEN1, Hui WANG1, Ning WANG1, Jin-dong OUYANG2, Xin-xiao LI3

1. College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. Jiangxi Hongdu Aviation Industry Group Co., Ltd., Nanchang 330024, China;

3. Xi’an Aero Engine (Group) Co., Ltd., Xi’an 710021, China

Received 22 April 2015; accepted 26 October 2015

Abstract: The deformation behavior and mechanism of Ti2AlNb-based alloy were experimentally investigated at elevated temperatures. Firstly, the stress-strain relationships at different temperatures and strain rates were investigated via uniaxial tensile testing. Then, formability data, as determined by examining the deep drawing and bending abilities, were obtained through limiting draw ratio (LDR) and bending tests. Finally, metallographic experiments and fracture morphology investigations were conducted to examine the thermal deformation mechanism of the alloy. The results showed that as the temperature increased, the total elongation increased from 13.58% to 97.82% and the yield strength decreased from 788 to 80 MPa over the temperature range from 750 to 950 °C at a strain rate 0.001 s-1. When the temperature reached 950 °C, the strain rate was found to have a great influence on the deformation properties. The plastic formability of the sheet metal was significantly improved and a microstructural transformation of O to B2 and α2 occurred in this temperature region, revealing the deformation mechanism of its plasticity.

Key words: Ti2AlNb-based alloy; deformation behavior; deformation mechanism; formability

1 Introduction

With the light-mass requirements for the development of aero-engines and for improving the flight speed, light quality and high temperature resistant materials need to be used in the fabrication of critical components of aviation engines [1,2]. Ti2AlNb-based alloy, a new high temperature structural material with low density, high modulus of elasticity, and excellent high temperature strength, has been widely developed in recent years. Such an alloy may be used to replace high temperature titanium alloy and nickel-based superalloy components [3], such as low-pressure turbine blades and high-pressure compressor blades, in aviation engines. As a result, it has generated widespread interest at home and abroad in the field of aeronautics [4,5].

Although there are broad prospects for the application of Ti2AlNb-based alloy, its brittleness and poor formability at room temperature [6], as well as the harsh conditions required for deformation, mean that the alloy has very limited applications in the aviation industry until now [7]. Super plastic forming (SPF) processing is a feasible method of processing to fabricate Ti2AlNb-based alloy components with complex shapes [8-10]. However, this technique requires precise control of the process parameters, alloys with small equiaxed grains (<10 μm) as well as perfect thermal stability. The as-cast microstructure of Ti2AlNb alloy is bulky, and its SPF processing is very complicated [11], which has become one of the difficulties associated with the research on Ti2AlNb forming. Hot forming is an important technology that is associated with sheet metal forming. Unlike the SPF process that has interval stain rates ranging from 1×10-4 to 1×10-2 s-1, the strain rate used for this procedure is greater than or equal to 1×10-2 s-1 [12]. Thus, a study on the thermal deformation behavior and plastic forming mechanism of Ti2AlNb-based alloy under different deformation conditions is of great significance for the optimization of the forming process.

XU et al [13] investigated the characteristics of the flow stress in a Ti-22Al-25Nb alloy via Gleeble thermal simulation experiments over a range of deformation temperatures from 940 to 1000 °C and strain rates from 1×10-2 to 50 s-1 as well as the maximum deformation degree of 50%. The results show that the flow stress decreases with the strain rate decreasing or temperature increasing, and that flow softening is attributed to the increased temperature and microstructural changes. SHEN and FENG [14] studied advances in the means to control the microstructure, crystal structure and phase transformations of Ti2AlNb-based alloy. Current studies have focused on the key element influencing the deformation behavior, which is the transformation of the alloy’s microstructure by increasing temperature. Thus, it is critical that the effect of the hot forming temperature on the microstructural evolution and deformation properties should be studied. In this work, the deformation behavior and mechanism of Ti2AlNb-based alloy under different hot forming conditions were experimentally examined, including the stress-strain relationship, yield strength and elongation as the temperature increased, deep drawing and bending formability under hot forming conditions, and metallographic experiments and fracture morphology analysis at different temperatures.

2 Experimental

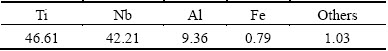

The composition of the Ti2AlNb-based alloy used in these experiments is shown in Table 1. The specimens were machined from a rolled sheet with a thickness of 1 mm.

Table 1 Chemical composition of Ti2AlNb-based alloy (mass fraction, %)

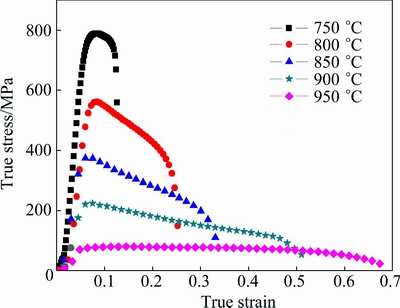

2.1 Tensile test

Tensile testing was conducted at different temperatures and strain rates using a RG2000 microcomputer-controlled electronic testing machine. The tensile specimens of the Ti2AlNb-bsaed alloy, as shown in Fig. 1, were processed into standard sub-size dog bone sizes using fine electric spark line cutting. Sprayed boron nitride was coated on the surface to prevent oxidation. Then, specimens were placed inside an environmental chamber and allowed to reach a pre-specified temperature before the tests were started. The tensile tests were conducted at five different temperatures ranging from 750 to 950 °C at intervals of 50 °C. The strain rates at different temperatures were 0.1, 0.01 and 0.001 s-1. Finally, the true stress-strain curves were obtained by computer calculations after recording all of the data from the force and displacement sensors.

Fig. 1 Dimensions of tensile test specimens (unit: mm)

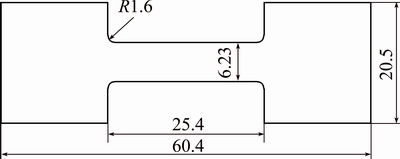

2.2 Deep drawing and bending test

Deep drawing and bending testing were performed to investigate the forming performance of the Ti2AlNb sheet alloy.

A schematic diagram of tooling geometry for the deep drawing test is shown in Fig. 2(a). The punch diameter used was 50 mm, and the punch speed was controlled at 5 mm/s. The blank holder force is critical and must be controlled so that it is low enough to allow the sheet alloy to flow past the plates, but not so low as to slide past the binder and wrinkle around the punch. A part was deemed to form if it did not fail (splitting, cracking, etc.) or did not display any evidence of serious wrinkling. In this experiment, post test drawing cups were used to determine limiting draw ratio (LDR) of the material [15]. The ratio of the diameter of the largest blank to be successfully formed to the punch diameter was then defined as its LDR value, which is based on GBT 15825.3-2008.

Fig. 2 Equipment for hot forming formability test

A bending test, which is a stamping processing procedure for the common sheet metal, is a method of bending sheets into certain shapes and angles. The dimensions of the bending test tool used in this work are shown in Fig. 2(b). According to GBT 15825.5-2008 sheet metal forming performance and test method, a test method for bending test, the deformation zone on the lateral surface of the samples was checked after bending. After determining that there were no cracks or significant depressions, testing was performed to evaluate the bending properties.

2.3 Metallographic experiment and observation of surface morphology

There are three phases in Ti2AlNb-based alloys: an α2-phase with a close-packed hexagonal structure, a B2-phase with a body-centered cubic structure and an O-phase with an ordered orthorhombic structure. The organizational structure of the three types of phases is complex. When different grains with different volume fractions and shapes (equiaxed or lath shaped) are present, there are many differences in the mechanical properties and deformation mechanisms. Thus, it is necessary to carry out observations and analyses on the phase transformation and surface morphology of Ti2AlNb-based alloys during thermal deformation.

The etchant used was Kroll’s reagent, consisting of HF, HNO3 and H2O, with a volume ratio for each component of V(HF):V(HNO3):V(H2O)=1:3:7. Etching was performed for 15 s. After cleaning, the microstructures of the specimens were observed using a Leica DVM-5000 optical microscope. The surface morphology of the Ti2AlNb-based alloy after tensile fracture was observed using an FEI Quanta 200FEG field emission electron microscope.

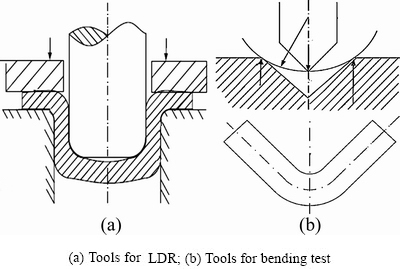

Fig. 3 True stress-true strain curves for specimens at elevated temperatures (Tensile axis is parallel to rolling direction and strain rate is 0.001 s-1)

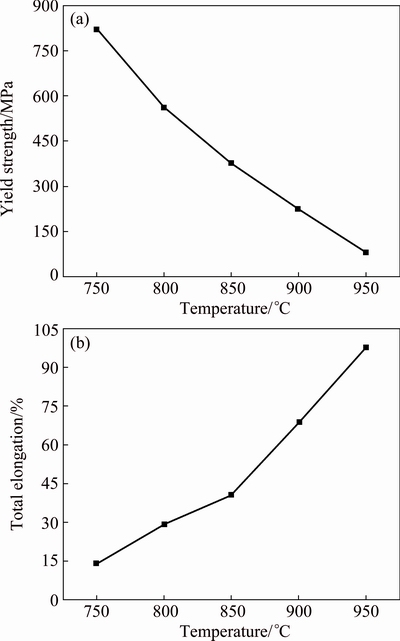

Fig. 4 Effect of temperature on yield strength (a) and total elongation (b) of specimens

3 Results and discussion

3.1 Stress-strain relationship

3.1.1 Effect of temperature on strength and ductility

Figure 3 shows the true stress-true strain relationship for a Ti2AlNb-based alloy at several elevated temperatures. The results show that the curves vary greatly at different temperatures. The tensile strength decreases as the temperature increases. Figure 4(a) shows that the yield strength at 950 °C is nearly 10% that at 750 °C. Meanwhile, the total elongation increases with temperature increasing, which rises from 13.58% to 97.82% at temperatures ranging from 750 to 950 °C, as shown in Fig. 4(b). Overall, during stretching, exposure at different temperatures has a great influence on the deformation characteristics of Ti2AlNb-based alloy, which can result in significant changes in the mechanical properties.

3.1.2 Strain rate sensitivity at different temperatures

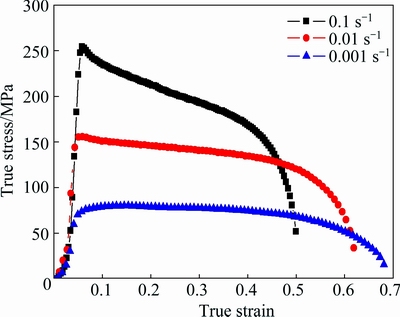

Strain rate sensitivity is a very important property during hot forming of Ti2AlNb-based alloy. For a constant temperature, the stress-strain relationship can be adjusted using the strain rate. Figure 5 shows that the true stress-true strain relationship varies remarkably for different strain rates at 950 °C. As the strain rate decreases, the peak flow stress decreases by 68.5% and the total elongation increases by 50.9%. This may be explained by two parts: firstly, the dynamic softening rate is greater than initial work hardening, minimizing the effect of material work hardening; secondly, as the strain rate decreases, the deforming time increases and more grains circumrotate to align with the deformation direction, which is favorable for multiple slip systems to start up, so metal plasticity gets better and the deformation resistance reduces.

The strain rate sensitivity (m) may be evaluated by

(1)

(1)

where σ is the stress, and  is the strain rate.

is the strain rate.

According to the Grosman model, in the plastic region, there exists

(2)

(2)

where C is the strength coefficient, n and n1 are strain hardening exponents. This implies a relationship of the form:

(3)

(3)

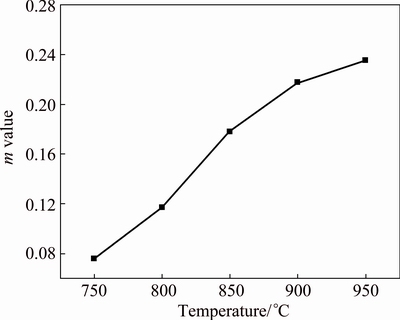

The results in Fig. 6 show that m value increases at 750-950 °C, suggesting that as the temperature increases, the changes in the strain rates have greater effects on the plastic properties of the Ti2AlNb-based alloy.

Fig. 5 True stress-true strain curves of Ti2AlNb-based alloy at 950 °C and different strain rates

Fig. 6 m value as function of temperature for Ti2AlNb-based alloy

3.2 Limiting draw ratio (LDR) and bending properties

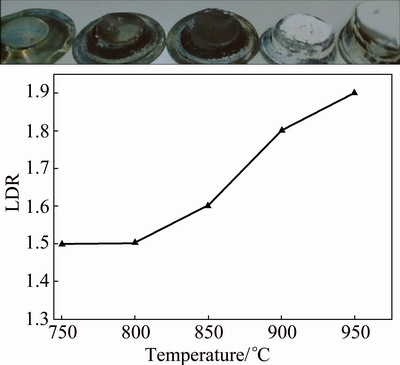

The relationship of the LDR value as a function of temperature is shown in Fig. 7. The results show that temperature has a significant influence on the deep drawing ability of the Ti2AlNb-based alloy. When the temperature is lower than 800 °C, the deep drawing formability is poor and the sheet is too hard and brittle to be formed. However, as the temperature exceeds 850 °C, the LDR value increases significantly. At 950 °C, the LDR value exceeds 1.9 and the formability is greatly improved over that at 800 °C.

Fig. 7 Results of deep drawing tests and relationship between LDR value and temperature

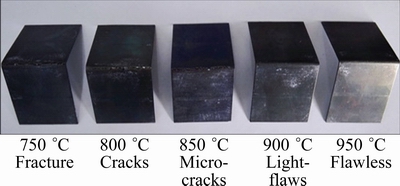

Figure 8 shows the experimental results of the bending test. We adopted a punch-nose radius of 3 mm to better reflect the effect of temperature on the bending properties of the Ti2AlNb-based alloy. Similar to the deep drawing test results, when the temperature is lower than 800 °C, brittle fractures occur in the bending area and the material brittleness clearly decreases at temperatures above 850 °C. The ductility and bending properties are improved at 950 °C.

Fig. 8 Results of bending tests with change of temperature

3.3 Microstructure and fracture analysis

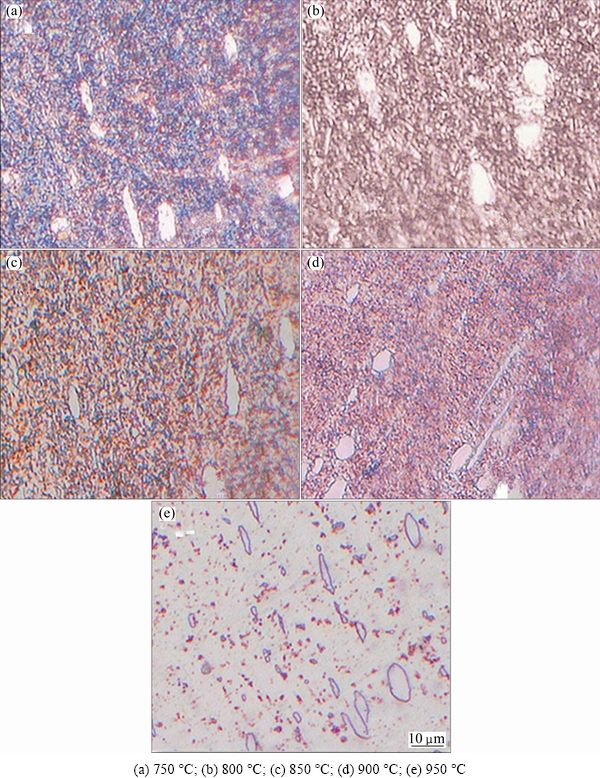

Figure 9 shows the microstructures of the Ti2AlNb- based alloy at different temperatures. When the temperature is 750 °C, the alloy is composed of a two-phase microstructure with an O-phase (white) and B2-phase (gray), as shown in Fig. 9(a). Although the O and adjacent B2 phases have good compatibility, which is conducive to improve intermetallic compound plasticity [16], the amount of the B2-phase is relatively small, and the O-phase takes over as the ordered phase. The atomic mobility is poor, and the alloy has high strength and hardness at this temperature. When the temperature is increased from 800 to 900 °C, the B2-phase content increases as the content of the O-phase decreases. There are large amounts of acicular B2 and bulk phases separating out from the O phase at this point, and as the temperature continues to be increased to 900 °C, the equiaxed α2-phase appears. This indicates that there is a phase transition from O to B2 and that α2 occurs over this temperature interval. Just as the true stress-true strain curves of the tensile test specimens shown in Fig. 3, the yield strength of the Ti2AlNb-based alloy exhibits a significant decline over this temperature range, which decreases from 561 to 224 MPa. When the temperature reaches 950 °C, the acicular B2 phase disappears, resulting in a continuous matrix phase in the material [17]. The alloy turns into a dual-phase material composed of B2-phase and a small amount of α2-phase due to higher content of plastic B2 phase. Its ductility increases, providing a demonstration of the results for the drawing tests and bending tests to certain extent, at this temperature.

Fig. 9 Microstructures of Ti2AlNb-based alloy at elevated temperatures

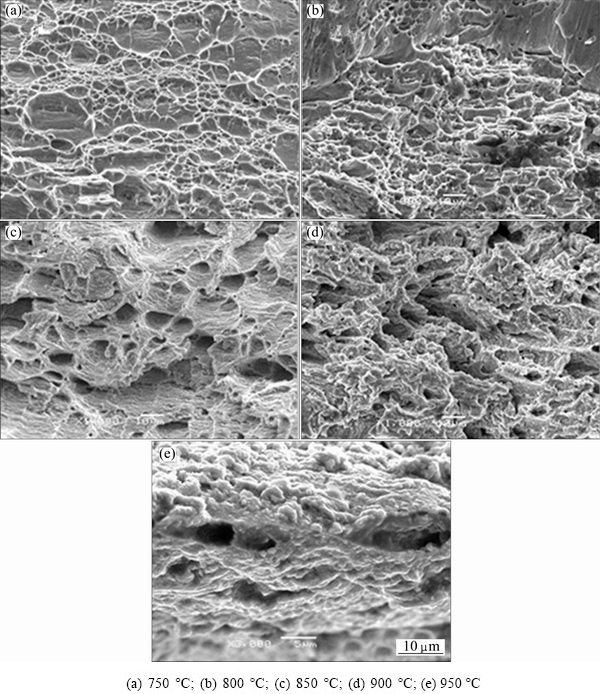

To further investigate the deformation mechanism in the Ti2AlNb-based alloy, the fracture morphologies of the tensile test specimens using the same strain rate ( =0.001 s-1) were observed by SEM. Figure 10 shows microscopic fracture photographs of the samples over a temperature range from 750 to 950 °C. At temperatures of 750 to 800 °C, the fracture is identified as a quasi- cleavage fracture, which is a transitional fracture that forms between the cleavage fracture and dimple fracture. The macro fracture appears flush and brightly colored, which is the characteristic of a brittle fracture. However, there are also many small, shallow dimples distributed in the micro fracture, specifically the appearance of parabolic dimples, as shown at the top of Fig. 9(b). This is because in the process of forming micro holes, shear stress plays a dominative role in deformation, which makes micro holes have the fastest growth rate in the direction of the shear stress, elongating the micro holes. Thus, materials with parabolic form dimples possess good plasticity [18]. This indicates that there is a transition from brittleness to ductility over this temperature range. When the temperature increases from 850 to 900 °C, the size of the dimples and depth of the micro holes increase significantly. Although there is serious fracture oxidation on the surface, these are clearly ductile fracture features. This demonstrates that the hot ductility of the Ti2AlNb-based alloy is confirmed, which corresponds to the change in the O-B2 phase, leading to a great increase in the plastic phase B2, which is based on the analysis of the microstructures above. When the temperature reaches 950 °C, there is remarkable section shrinkage at the fracture and necking in the macroscopic fracture is obvious. The plasticity of the alloy is confirmed to be further improved at this point, which agrees with the conclusions obtained from the tensile tests.

=0.001 s-1) were observed by SEM. Figure 10 shows microscopic fracture photographs of the samples over a temperature range from 750 to 950 °C. At temperatures of 750 to 800 °C, the fracture is identified as a quasi- cleavage fracture, which is a transitional fracture that forms between the cleavage fracture and dimple fracture. The macro fracture appears flush and brightly colored, which is the characteristic of a brittle fracture. However, there are also many small, shallow dimples distributed in the micro fracture, specifically the appearance of parabolic dimples, as shown at the top of Fig. 9(b). This is because in the process of forming micro holes, shear stress plays a dominative role in deformation, which makes micro holes have the fastest growth rate in the direction of the shear stress, elongating the micro holes. Thus, materials with parabolic form dimples possess good plasticity [18]. This indicates that there is a transition from brittleness to ductility over this temperature range. When the temperature increases from 850 to 900 °C, the size of the dimples and depth of the micro holes increase significantly. Although there is serious fracture oxidation on the surface, these are clearly ductile fracture features. This demonstrates that the hot ductility of the Ti2AlNb-based alloy is confirmed, which corresponds to the change in the O-B2 phase, leading to a great increase in the plastic phase B2, which is based on the analysis of the microstructures above. When the temperature reaches 950 °C, there is remarkable section shrinkage at the fracture and necking in the macroscopic fracture is obvious. The plasticity of the alloy is confirmed to be further improved at this point, which agrees with the conclusions obtained from the tensile tests.

Fig. 10 Fracture photographs of Ti2AlNb-based alloy at different temperatures

4 Conclusions

1) Tensile testing indicates that temperature has a significant effect on the plastic properties of the Ti2AlNb-based alloy. The yield strength decreased from 788 to 80 MPa and the total elongation increased from 13.58% to 97.82% comparing 750 °C with 950 °C. At the same time, strain rate plays an important role in test with higher sensitivity factor (m-value) as temperature increases.

2) The LDR and bending property results show that deep drawing and bending formability are poor when the forming temperature is lower than 800 °C and the alloy exhibits hard and brittle intermetallic characteristics. However, there is an obvious increase in the formability when the temperature is higher than 850 °C. The results indicate that the practical forming temperature would be between 900 and 950 °C.

3) The results of the microstructural evolution and fracture morphology demonstrate that Ti2AlNb is mainly an O-based intermetallic at low temperatures, where the alloy exhibits brittle and hard deforming characteristics. When the temperature exceeds 900 °C, the O-phase transition to the B2- and α2-phases and the plasticity of the alloy are significantly improved.

References

[1] SONG Hui, WANG Zhong-jin, HE Xiao-dong. Improving in plasticity of orthorhombic Ti2A1Nb based alloys sheet by high density electro pulsing [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 32-37.

[2] WU Hong-yan, ZHANG Ping-ze, CHEN Wei, WANG Ling, ZHAO Hao-feng, XU Zhong. High-temperature tribological behaviors of Ti2AlNb-based alloys by plasma surface duplex treatment [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1121-1125.

[3] LI Shi-qiong, ZHANG Jian-wei, CHENG Yun-jun, LIANG Xiao-bo. Current status on development of Ti3Al and Ti2AlNb intermetallic structural material [J]. Rare Metal Materials and Engineering, 2005, 34(3): 104-109.

[4] KAZANTSEVA N V, DEMAKOV S L, POPOV A A. Microstructure and plastic deformation of orthorhombic titanium aluminides Ti2AlNb. III: Formation of transformation twins upon the B2 to O phase transformation [J]. The Physics of Metals and Metallography, 2007, 103(4): 378-387.

[5] SHI Ke, LIU Yang, WU Zeng-chen, LI Bao-yong, FAN Xiao-long. Research on hot forming process of Ti2A1Nb alloy thin-walled component [J]. Materials Science and Technology, 2013, 21(5): 40-44. (in Chinese)

[6] QIN Chun, YAO Ze-kun, LI Yu-zhi, NING Yong-quan, GUO Hong-zhen. Effect of hot working on microstructure and mechanical properties of TC11/Ti2AlNb dual-alloy joint welded by electron beam welding process [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3500-3508.

[7] FENG Ai-han, LI Bo-bo, SHEN Jun. Recent advances on Ti2A1Nb-based alloys [J]. Journal of Materials and Metallurgy, 2011, 10(1): 30-38. (in Chinese)

[8] GERMANN L, BANERJEE D, GUEDOU J Y, STRUDEL J L. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide [J]. Intermetallic, 2005, 13(9): 920-924.

[9] KAMAT S V, GOGIA A K, BANERJEE D. Effect of alloying elements and the heat treatment on the fracture toughness of Ti2AlNb alloys [J]. Acta Materialia, 1998, 46(1): 239-251.

[10] PENG Ji-hua, MAO Yong, LI Shi-qiong, SUN Xun-fang. Tensile properties and fracture behavior of Ti2AlNb based alloys at room temperature [J]. Transactions of Nonferrous Metals Society of China, 2000, 10(3): 378-381.

[11] DANIEL G S, MAMIDALA R. Examination of superplastic forming combined with diffusion bonding for titanium: Perspective from experience [J]. Journal of Materials Engineering and Performance, 2004, 13(6): 744-752.

[12] SAJADIFAR S V, YAPICI G G, KETABCHI M. High temperature deformation behavior of 4340 steel: Activation energy calculation and modeling of flow response [J]. Journal of Iron and Steel Research (International), 2013, 20(12): 133-139.

[13] XU Bin, ZENG Wei-dong, HE De-hua, ZHOU Yi-gang, LIANG Xiao-bo, LI Shi-qiong. Study on hot deformation behavior of Ti-22Al-25Nb alloy [J]. Hot Working Technology, 2007, 36(1): 1-4. (in Chinese)

[14] SHEN Jun, FENG Ai-han. Recent advances on microstructural controlling and hot forming of Ti2AlNb-based alloy [J]. Acta Metallurgica Sinica, 2013, 49(11): 1286-1294. (in Chinese)

[15] WANG H, LUO Y B, FRIEDMAN P, CHEN M H, GAO L. Warm forming behavior of high strength aluminum alloy AA7075 [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 1-7.

[16] LIN Peng, HE Zhu-bin, YUAN Shi-jian, SHEN Jun, HUANG Yong-jiang, LIANG Xiao-bo. Instability of the O-phase in Ti-22Al-25Nb alloy during elevated-temperature deformation [J]. Journal of Alloys and Compounds, 2013, 578: 96-102.

[17] WANG Kai-xuan, ZENG Wei-dong, ZHAO Yong-qing, SHAO Yi-tao, ZHOU Jian-hua, WANG Xiao-ying, ZHOU Yi-gang. Quantitative analysis on microstructural evolution of lamellar alpha-phase in titanium alloy during hot working [J]. Rare Metal Materials and Engineering, 2010, 39(4): 565-569.

[18] MICHEL J F, PICARD P. Size effects on the constitutive behavior for brass in sheet metal forming [J]. Journal of Materials Processing Technology, 2003, 141: 439-446.

金属间化合物Ti2AlNb的高温变形行为和变形机理

张钦差1,陈明和1,王 辉1,王 宁1,欧阳金栋2,李新孝3

1. 南京航空航天大学 机电工程学院,南京 210016;

2. 江西 洪都航空工业有限公司,南昌 330024;

3. 西安航空发动机(集团)有限公司,西安 710021

摘 要:对金属间化合物Ti2AlNb基合金在加热状态下的变形行为和变形机理进行研究。首先,利用单向拉伸试验得到不同温度和应变速率下合金的真应力-应变关系;然后,通过拉深和弯曲试样得到合金的极限拉深比(LDR)及弯曲性能参数;最后,通过金相实验和断口形貌分析研究Ti2AlNb基合金在不同加热条件下的高温变形机制。结果表明:在750~950 °C、应变速率0.001 s-1的条件下,随着温度的升高,合金的伸长率从13.58%增大至97.82%,屈服强度从788 MPa降低至80 MPa;当温度达到950 °C时,应变速率对合金的变形性能有明显影响。同时,在该温度范围内,材料发生由O相向B2和α2相的组织转变,从微观组织演变揭示了Ti2AlNb基合金塑性提高的变形机理。

关键词:Ti2AlNb基合金;变形行为;变形机制;成形性能

(Edited by Wei-ping CHEN)

Foundation item: Project (XAEP-KIZ-KIB-1309-0063) supported by the Fundamental Research for General Armament Department, China

Corresponding author: Min-he CHEN; Tel: +86-13951809276; E-mail: meemhchen@126.com

DOI: 10.1016/S1003-6326(16)64162-6