文章编号:1004-0609(2014)08-2181-07

微波加热与常规加热时高碳铬铁粉固相脱碳动力学对比研究

李晓光1,陈 津1,郝赳赳1,韩培德1,刘金营2

(1. 太原理工大学 材料科学与工程学院,太原 030024;

2. 中国电子科技集团公司 第十二研究所,北京 100016)

摘 要:以内配碳酸钙高碳铬铁粉为研究对象,对不同加热方式下固相脱碳的动力学行为和活化能进行研究。内配碳酸钙高碳铬铁粉在微波加热场和常规加热场分别加热到900、1000、1100和1200 ℃,并分别保温脱碳0、20、40和60 min。结果表明,随着脱碳温度的升高和脱碳保温时间的延长,微波加热场和常规加热场中的脱碳物料的脱碳率都提高,在相同的脱碳温度和脱碳保温时间下,微波加热场中脱碳物料的脱碳率远高于常规加热场中的。微波加热场中固相脱碳反应的表观活化能为109.76 kJ/mol;常规加热场中固相脱碳反应的表观活化能为169.65 kJ/mol。微波加热场能改善固相脱碳的动力学条件,提高内配碳酸钙高碳铬铁粉固相脱碳反应速率,促进碳在高碳铬铁粉中的扩散,降低脱碳反应的活化能。

关键词:高碳铬铁粉;固相脱碳;微波加热场;常规加热场;动力学

中图分类号:TF641 文献标志码:A

Comparative research on solid state decarburization kinetics of high-carbon ferrochrome powder by microwave heating and conventional heating

LI Xiao-guang1, CHEN Jin1, HAO Jiu-jiu1, HAN Pei-de1, LIU Jin-ying2

(1. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. 12th Research Institute, China Electronics Technology Group Company, Beijing 100016, China)

Abstract: Taking the high-carbon ferrochrome powder containing calcium carbonate as the research object, the kinetics behavior and activation energy of solid phase decarburization under different heating methods were studied. Microwave oven and muffle furnace respective were used to heat high-carbon ferrochrome powder containing calcium carbonate to 900, 1000, 1100 and 1200 ℃, preserve heat and keep decarburization for 0, 20, 40 and 60 min. The results show that with the rising of heating temperature and holding time, the decarburization rates in microwave heating field and conventional heating field increase, when the heating temperature and holding time are the same, the decarburization rate in microwave heating field is significantly higher than that in conventional heating field. The apparent activation energy of solid phase decarburization reaction in microwave field is 109.76 kJ/mol; the apparent activation energy of solid phase decarburization reaction in conventional heating field is 169.65 kJ/mol. Microwave heating field can improve the kinetics condition of solid phase decarburization, increase the reaction rate of solid phase decarburization of high-carbon ferrochrome powder containing calcium carbonate, promote the diffusion of carbon in high-carbon ferrochrome powder, and reduce the activation energy of decarburization reaction.

Key words: high-carbon ferrochrome powder; solid phase decarburization; microwave heating field; conventional heating field; kinetics

中低碳铬铁主要用于生产中低碳结构钢、铬钢、合金结构钢。近年来,随着钢铁产品在种类上的细化,对中低碳铬铁的需求也越来越大[1]。采用固相反应使高碳铬铁脱碳,反应温度要求相对较低,工艺流程简便,铬回收率高,对环境污染小,因此,高碳铬铁粉的固相脱碳日益受到关注。

按加热方式的不同,物料加热可以分为两种类型[2-4]:一种是面积型加热,即通常所说的常规加热,其加热机理是依靠热量转递的方式进行物料加热,尽管传导、对流、辐射3种传递热量的形式有所不同,但均依靠温度梯度由表及里地加热物料;另一种是体积型加热,即微波加热,其加热机理是依靠能量转换的方式进行物料加热,物料加热过程不依赖于温度梯度,而是通过组成物料的分子或离子与微波场的相互作用将微波能转变为热能,使物料中的每个质点同时产生热量[5]。微波属于“超高频电磁波”,当具有分子或离子的物料置于微波场中,物料中的分子或离子会在微波场中变形和极化,并随微波场进行转向和排列,在这个过程中,物料的分子或离子必须克服原来的热运动和分子间的相互引力作用,产生类似于摩擦的作用,电磁能通过物质分子的运动和介电损耗转换为热能[6],物料温度升高。相比于常规加热,微波加热有其独特的特点[7-10]:微波加热是体加热,升温过程中物料的内外部不会产生明显的温差,可以避免出现冷中心的现象;微波加热速度快,且可以对物料进行选择性加热;微波加热是靠能量的转移而不是热量的传递;微波加热属于非接触式加热,便于开始温度和结束温度的控制。

微波可以对粉状物料进行选择性加热[11],且大部分的含碳材料都对微波有着良好的吸收特性[12-13]。本文作者采用微波加热法和常规加热法对内配碳酸钙高碳铬铁粉进行固相脱碳对比实验,研究在微波加热和常规加热条件下内配碳酸钙高碳铬铁粉固相脱碳在动力学上的差异。

1 实验

1.1 实验材料

实验原料为广西中信大锰矿业有限责任公司提供的块状高碳铬铁,用球磨机将块状高碳铬铁制成粒度小于300 μm的粉状物料,并将45 μm以下的粉料筛除,粒度分布见表1,高碳铬铁粉的化学成分如表2所列。由于物料的吸波性能与其化学组成及其结构有关,故同时给出了高碳铬铁粉的XRD谱,如图1所示,可以看出高碳铬铁物相中有Cr7C3、Cr23C6、CrFe、Fe3C、Cr3Si以及游离的石墨相。固体脱碳剂为工业碳酸钙粉,粒度小于0.045 mm,主要组成如表3所列。

1.2 实验方法

图2所示为自行研制的微波加热冶金实验炉,工作电压为220 V,加热频率为2.450 GHz,加热功率设定为10 kW。高碳铬铁粉中的碳和碳酸钙粉完全分解后分别产生的CO2的量的比值称为脱碳摩尔比,按脱碳摩尔比1:1.4称取经过烘干处理的高碳铬铁粉510 g和工业碳酸钙粉490 g混合均匀,自然装入由轻质耐火砖制成的直径为12 mm、高为36 mm的圆柱状坩埚中。随后一同放入微波加热炉内,在大气压且无保护气氛条件下分别加热物料到900、1000、1100和1200 ℃,并分别保温0、20、40和60 min。

表1 高碳铬铁粉的粒度分布

Table 1 Particle size distribution of high-carbon ferrochrome powders

表2 高碳铬铁粉的化学成分

Table 2 Chemical composition of high-carbon ferrochrome powders (mass fraction, %)

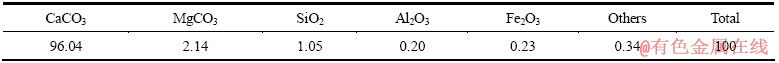

表3 碳酸钙粉的化学成分

Table 3 Chemical compositions of calcium carbonate powders (mass fraction, %)

图1 高碳铬铁的XRD谱

Fig. 1 XRD diagram of high-carbon ferrochrome

常规加热所用的加热设备是马弗炉,工作电压为220 V,加热功率设定为10 kW,按脱碳摩尔比1:1.4称取高碳铬铁粉510 g、工业碳酸钙粉490 g混合均匀,自然装入与微波加热时相同的轻质耐火砖坩埚内,然后再放入马弗炉中,分别将物料加热到900、1000、1100和1200 ℃,并分别保温0、20、40、60和80 min。

图2 微波加热实验装置结构示意图

Fig. 2 Schematic diagram of microwave heating device

实验结束后,待物料自然冷却到室温,取少量物料用气体容量法测定混合物料中的碳含量,测定仪器为NXQ-2D型碳硫分析仪。最后计算反应后高碳铬 铁中的碳含量,计算公式如下:

(1)

(1)

式中:w为反应后高碳铬铁粉的碳含量,%;w1为仪器测定的物料的碳含量,%;m1为反应后物料的质量,g;m2为碳酸钙粉完全分解后CaO的质量,g。

2 结果与讨论

2.1 微波加热和马弗炉加热脱碳物料反应阶段升温特性对比

图3所示为内配碳酸钙高碳铬铁粉在无保护气氛条件下的DSC-TG曲线,样品的升温速率为10 ℃/min。在800 ℃左右DSC线出现一个明显的吸热 峰,且热重线大幅下降,表明样品发生吸热反应且质量减小,可判断出这是由于物料中的碳酸钙受热分解,生成CaO和CO2并吸收热量。在800 ℃以后,随着温度的上升,TG线呈上升趋势,这是因为高碳铬铁粉与CO2发生脱碳反应并和空气中的氧气缓慢氧化,在1100 ℃左右差热线出现一个放热峰,表明脱碳反应在该温度下反应剧烈。

图3 内配碳酸钙高碳铬铁粉的DSC-TG曲线

Fig. 3 DSC-TG curve of high-carbon ferrochrome powder containing calcium carbonate

微波加热与常规加热的原理不同,微波加热所具有的一些特点可能会使物料在反应阶段的升温特性与常规加热存在差异,故绘制反应阶段物料分别在微波加热和常规加热情况下的升温曲线,如图4所示。可以看出微波加热到850 ℃左右升温速率逐渐减小,经过10 min左右,升温速率又开始增大,这是因为碳酸钙粉的吸波性能较差,微波不能将碳酸钙粉加热到较高温度,这时主要是高碳铬铁粉将热量传递给碳酸钙粉使其升温,这在一定程度上延缓了碳酸钙粉的分解,由于体加热的特点,当温度达到890 ℃左右时碳酸钙大量分解吸热导致升温速率下降。当碳酸钙粉分解趋于完全,生成的氧化钙的吸波性能优于碳酸钙的,故升温速率又逐渐增大。而在常规加热情况下,物料在反应阶段的升温过程是一个升温速率逐渐减小的过程,不同于微波的体加热,在常规加热场下,物料的升温是一个由表及里的过程,由于温度梯度的存在,碳酸钙粉不能在较短的时间内分解完全,故不会出现分解反应大量吸热导致升温速率急剧减小的阶段。微波体加热的特点使碳酸钙粉在900 ℃左右较短的时间内分解完全,产生充足的CO2气体,有利于高碳铬铁粉在相对较低的温度下脱碳。

图4 微波加热和常规加热内配碳酸钙高碳铬铁粉的升温曲线对比图

Fig. 4 Heating curves of high-carbon ferrochrome powders containing calcium carbonate by microwave heating and muffle furnace heating

2.2 微波加热和马弗炉加热物料固相脱碳效果对比研究

马弗炉加热和微波加热时碳酸钙高碳铬铁粉中碳含量如表4和5所列。由表可知,随着脱碳温度的升高和脱碳保温时间的延长,微波加热和马弗炉加热时脱碳物料中碳含量都呈下降趋势,即脱碳率均逐渐升高,但在相同的加热温度和相同的保温时间下,微波加热中脱碳物料的脱碳率均高于马弗炉加热脱碳物料的脱碳率。在加热到1200 ℃保温60 min时,微波加热的最高脱碳率可达到82.97%;马弗炉加热时脱碳率为71.32%,说明微波加热能改善反应的动力学条件,使反应速率比马弗炉加热时的快[14]。微波加热可以使能量在分子水平上传递,分子结构将影响微波和材料的相互作用和能量传递,同时碳对微波具有很好的吸收作用,当用微波加热内配碳酸钙高碳铬铁粉时,高碳铬铁粉中的碳可以产生局部的高温,使脱碳反应优先发生,促进高碳铬铁粉的脱碳,从而加快了反应速率。

表4 马弗炉加热时内配碳酸钙高碳铬铁粉中碳含量

Table 4 Carbon content of high-carbon ferrochrome powder containing calcium carbonate by muffle furnace heating

表5 微波加热时内配碳酸钙高碳铬铁粉中碳含量

Table 5 Carbon content of high-carbon ferrochrome powder containing calcium carbonate by microwave heating

在加热到900和1000 ℃保温0 min的情况下,马弗炉加热的碳含量分别为8.03%和7.98%,脱碳率为1.59%和2.21%,脱碳反应近乎没发生;微波加热的碳含量分别为7.10%和5.43%,脱碳率分别为12.99%和33.46%,明显高于马弗炉加热的脱碳率。微波加热是依靠物料自身的介电性质转换微波能量[15],体加热的特点使物料的受热比较均匀,脱碳反应在物料的各个部位可同时发生。而马弗炉加热则是通过热传递的方式使热量由外而内传递,由于内部物料升温较慢,内外产生温差,物料内部温度达不到反应温度,使得脱碳反应只能在外部发生,影响内部脱碳。另外在加热到900 ℃时,随着保温时间的增加,马弗炉加热的脱碳率增长不明显,在保温80 min时脱碳率仅为9.07%,而微波加热的脱碳率在保温60 min时已经达到了37.99%,从热力学上分析,在900 ℃时,高碳铬铁粉中的C3Cr7和C6Cr23还没有达到与CO2发生化学反应的温度,此时脱碳反应主要是高碳铬铁粉中含有的少量石墨与CO2反应,这与在马弗炉加热下物料随着保温时间的延长脱碳率始终较低相一致,但是在微波加热下,随着保温时间的延长,物料的脱碳率已经较高,说明在900 ℃下的脱碳反应不只是石墨与CO2 的反应,C3Cr7或C6Cr23也与CO2发生了反应,表明微波加热能促进脱碳物料在温度相对较低时发生反应。

2.3 微波加热和马弗炉加热时内配碳酸钙高碳铬铁粉固相脱碳活化能对比研究

内配碳酸钙高碳铬铁粉在加热过程中发生脱碳反应,其实质是碳酸钙粉分解出的二氧化碳气体和致密的高碳铬铁粉之间发生的气-固反应。化学反应从固相物的表面开始,逐渐向颗粒内部推进,高温条件下固体生成物包裹在高碳铬铁粉颗粒的表面,二氧化碳则需要透过固态产物层,扩散到反应界面继续进行反应。

假设高碳铬铁粉颗粒为致密的球形颗粒,且反应前后体积无明显变化,则根据气-固未反应核模型,内配碳酸钙高碳铬铁粉的脱碳反应过程一般由以下环节组成:二氧化碳在固体物外边界层的外扩散,二氧化碳通过固相产物层到达反应物界面的内扩散和二氧化碳与高碳铬铁粉的界面化学反应。脱碳过程速度最慢的环节为控速环节。而当某一环节为控速环节时,脱碳率与脱碳时间关系如下[16]。

1) 外扩散控制时,脱碳率α与反应时间t的关系为α=kt。

2) 气体通过固体产物层的内扩散控制时,脱碳率α与反应时间t的关系为1+2(1-α)-3(1-α)2/3=kt。

3) 界面化学反应控制时,脱碳率α与反应时间t的关系为:1-(1-α)1/3=kt。

根据以上原理,将脱碳率代入并与反应时间作图,如果脱碳反应是上述某一环节控速时,1-(1-α)与时间应呈线性函数关系。

分别将微波加热和马弗炉加热下不同温度的高碳铬铁粉的脱碳率对时间作图(见图5),结果显示在微波加热下1+2(1-α)-3(1-α)2/3与时间t呈较好的线性关系,说明在1173 K到1473 K之间在微波场中内配碳酸钙高碳铬铁粉脱碳反应的控速环节为内扩散;在马弗炉加热下1-(1-α)1/3与时间t呈较好的直线关系,说明马弗炉加热内配碳酸钙高碳铬铁粉的脱碳反应的控速环节是界面化学反应。

图5 不同温度下不同动力学控制模型函数与时间之间的关系

Fig. 5 Relationship between different model functions and decarburization time at different temperatures

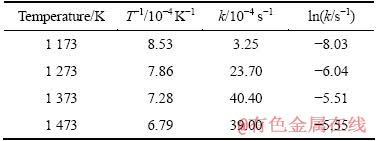

由图5中直线的斜率可求出各温度下脱碳反应的表观速率常数k,如表6和表7所列。根据不同脱碳温度下脱碳反应的表观速率常数,由Arrhenius公式可求得脱碳反应的活化能:

(2)

(2)

式中:k为表观反应速率常数;E为表观活化能;R为摩尔气体常数,R=8.314 J/min;A是指前因子。

在加热到1200 ℃时,由于物料出现明显烧结,物料体积收缩,对计算结果影响较大,故回归拟合时采用了3个温度点,将不同脱碳温度下的表观反应速率常数的对数ln k对T -1作图,如图6所示,可求得微波加热下脱碳反应的表观活化能为E为109.76 kJ/mol,马弗炉加热下脱碳反应的活化能为169.65 kJ/mol。

表6 马弗炉加热内配碳酸钙高碳铬铁粉时不同脱碳温度的表观反应速率常数k

Table 6 Apparent reaction rate constant k of high-carbon ferrochrome powder containing calcium carbonate at different decarburization temperatures by muffle furnace heating

表7 微波加热内配碳酸钙热高碳铬铁粉时不同脱碳温度的表观反应速率常数k

Table 7 Apparent reaction rate constant of high-carbon ferrochrome powder containing calcium carbonate in different decarburization temperature by microwave heating

以气-固反应的未反应核模型分析内配碳酸钙高碳铬铁粉固相脱碳反应的活化能,在用马弗炉加热时,反应的控速环节为界面化学反应,微波加热时,反应的控速环节为CO2的内扩散,而在相同实验条件下,微波加热物料的脱碳速率要快于马弗炉的,说明微波加热可以促进界面化学反应的发生。与常规加热相比,微波加热具有增强固相反应离子扩散的作用,有效促进了高碳铬铁粉中碳向反应界面的扩散,加快反应速率[17-18]。在微波加热场中,由于受到交变电磁场的作用,偶极子随着电磁场的方向进行极快的转向,反应物分子随着电场方向重新排列,形成取向效应,分子在同轴线上的运动会增加,使得分子的有效碰撞增加,加快了反应速度。微波加热条件下脱碳反应的表观活化能要比马弗炉加热的表观活化能低,微波能转换为热能的过程,增加了分子中化学键的振动能级和非简谐振动系数[19],使电子的能量增加,由于微波的辐照能量要低于一般化学键的键能,不会造成化学键的断裂,但是微波的频率与分子转动的频率相差不大,用微波进行加热时,分子中储存的微波能量与分子平动能量自由交换,通过改变分子排列等焓或熵效应,降低了反应的活化能[6, 20],加快了反应的进程。

图6 微波加热和常规加热时表观反应速率常数与温度的关系

Fig. 6 Relationship between apparent reaction rate constant and temperature with microwave heating(a) and conventional heating(b)

3 结论

1) 微波加热使碳酸钙粉在900 ℃左右较短的时间内分解完全,产生充足的CO2气体,有利于高碳铬铁粉在相对较低的温度下脱碳。在反应阶段,随着温度的升高,微波加热场中混合物料的升温速率先降低然后升高,常规加热场中物料的升温速率逐渐下降。

2) 随着加热温度的升高和保温时间的延长微波加热和马弗炉加热的脱碳率都会增加,在相同实验条件下,微波加热的脱碳率要高于马弗炉加热的脱碳率,微波加热的反应速率高于马弗炉加热的反应速率,微波加热可以提高内配碳酸钙高碳铬铁粉固相脱碳的脱碳率。微波加热的最高脱碳率为82.97%,马弗炉加热的最高脱碳率为79.78%。微波加热能促进内配碳酸钙高碳铬铁粉在温度相对较低的情况下发生反应。

3) 在微波加热场中,脱碳反应的控速环节为内扩散,在常规加热场中,反应的控速环节是界面化学反应,微波可以促进界面化学反应的发生。微波加热内配碳酸钙高碳铬铁粉固相脱碳的活化能为109.76 kJ/mol,马弗炉加热的活化能为169.65 kJ/mol,微波加热场降低了反应的活化能,使脱碳反应更容易进行。

REFERENCES

[1] 王海娟, 张 烽, 汪晓今,  . 转炉吹炼引入水蒸气冶炼中低碳锰铁和中低碳铬铁[J]. 铁合金, 2012, 43(2): 1-4.

. 转炉吹炼引入水蒸气冶炼中低碳锰铁和中低碳铬铁[J]. 铁合金, 2012, 43(2): 1-4.

WANG Hai-juan, ZHANG Feng, WANG Xiao-jin,  . Refining of M-LCFeMn and M-LCFeCr by introducing steam in converter process[J]. Ferro-Alloys, 2012, 43(2): 1-4.

. Refining of M-LCFeMn and M-LCFeCr by introducing steam in converter process[J]. Ferro-Alloys, 2012, 43(2): 1-4.

[2] THOSTENSON E T, CHOU T W. Microwave processing: Fundamentals and applications[J]. Composites: Part A, 1999, 30(9): 1055-1071.

[3] 陈 津, 张 猛, 赵 晶, 石巨岩, 周剑雄. 含碳铬矿粉微波加热体还原显微矿相结构的研究[J]. 电子显微学报, 2008, 27(1): 26-33.

CHEN Jin, ZHANG Meng, ZHAO Jing, SHI Ju-yan, ZHOU Jian-xiong. Microstructure study of voluminal reduction on chromite ore fines containing coal heated by microwave[J]. Journal of Chinese Electron Microscopy Society, 2008, 27(1): 26-33.

[4] 孙宏飞, 陈 津, 张 猛, 赵 晶. 微波场中高碳锰铁粉及固相脱碳物料的电磁性能[J]. 钢铁研究学报, 2012, 24(8): 12-15.

SUN Hong-fei, CHEN Jin, ZHANG Meng, ZHAO Jing. Electromagnetic properties of solid phase decarburization of high carbon ferromanganese powders[J]. Journal of Iron and Steel Research, 2012, 24(8): 12-15.

[5] MOSHTAGHIOUN B M, POYATO R, CUMBRERA F L, de BERNARDI-MARTIN S, MONSHI A, ABBASI M H, KARIMZADEH F, DOMINGUEZ-RODRIGUEZ A. Rapid carbothermic synthesis of silicon carbide nano powders by using microwave heating[J]. Journal of the European Ceramic Society, 2012, 32(8): 1787-1794.

[6] OLIVER KAPPE A. Controlled microwave heating in modern organic synthesis[J]. Angewandte Chemie, 2004, 43(46): 6250-6284.

[7] IDRIS A, KHALID K, OMAR W. Drying of silica sludge using microwave heating[J]. Applied Thermal Engineering, 2004, 24(5/6): 905-918.

[8] JONES D A, LELYVELD T P, MAVROFIDIS S D, KINGMAN S W, MILES N J. Microwave heating applications in environmental engineering—A review[J]. Resources, Conservation and Recycling, 2002, 34(2): 75-90.

[9] HAQUE K E. Microwave energy for mineral treatment processes—A brief review[J]. International Journal of Mineral Processing, 1999, 57(1): 1-24.

[10] NANTHAKUMAR B, PICKLES C A, KELEBEK S. Microwave pretreatment of a double refractory gold ore[J]. Minerals Engineering, 2007, 20(11): 1109-1119.

[11] 陈 津, 潘小娟, 张 猛, 赵 晶, 林原生. 含碳氧化锰矿粉微波加热升温特性研究[J]. 材料导报, 2007, 21(11): 81-84.

CHEN Jin, PAN Xiao-juan, ZHANG Meng, ZHAO Jing, LIN Yuan-sheng. Heating characteristics of manganese oxide ore fines containing coal under microwave irradiation[J]. Meterials Review, 2007, 21(11): 81-84.

[12]  Microwave heating processes involving carbon materials[J]. Fuel Processing Technology, 2010, 91(1): 1-8.

Microwave heating processes involving carbon materials[J]. Fuel Processing Technology, 2010, 91(1): 1-8.

[13] GUO Sheng-hui, LI Wei, PENG Jin-hui, NIU Hao, HUANG Meng-yang, ZHANG Li-bo. Microwave-absorbing characteristics of mixtures of different carbonaceous reducing agents and oxidized ilmenite[J]. International Journal of Mineral Processing, 2009, 93(3/4): 289-293.

[14] 陈建铭, 宋云华, 付纪文, 任鹏飞, 陈建峰. 微波加热制备低水硼酸锌(ZB2335)的研究[J]. 材料科学与工艺, 2004, 12(5): 529-531.

CHEN Jian-ming, SONG Yun-hua, FU Ji-wen, REN Peng-fei, CHEN Jian-feng. The synthesis of zinc borates(ZB2335) powder by microwave heating[J]. Materials Science & Technology, 2004, 12(5): 529-531.

[15] 陈 津, 刘 浏, 曾加庆, 任瑞刚, 刘金营. 微波加热还原含碳铁矿粉实验研究[J]. 钢铁, 2004, 39(6): 1-5.

CHEN Jin, LIU Liu, ZENG Jia-qing, REN Rui-gang, LIU Jin-ying. Experimental research of microwave heating on iron ore concentrates containing coal and lime[J]. Iron and Steel, 2004, 39(6): 1-5.

[16] 李小斌, 齐天贵, 彭志宏, 刘桂华, 周秋生. 铬铁矿氧化焙烧动力学[J]. 中国有色金属学报, 2010, 20(9): 1822-1828.

LI Xiao-bin, QI Tian-gui, PENG Zhi-hong, LIU Gui-hua, ZHOU Qiu-sheng. Kinetics of chromite ore in oxidation roasting process[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1822-1828.

[17] 石蔼如, 贾云发. 微波固相反应的扩散增强机理[J]. 青岛大学学报, 1998, 11(1): 64-67.

SHI Ai-ru, JIA Yun-fa. Mechanism of enhanced diffusion in microwave solid state reaction[J]. Journal of Qingdao University, 1998, 11(1): 64-67.

[18] KUNIHIRO F, KEIJI K, MANABU K, TETSUYA Y, HIDETO Y. Synthesis of indium tin oxide powder by solid-phase reaction with microwave heating[J]. Advanced Powder Technology, 2009, 20(5): 488-492

[19] PAVLE S, JELENA J, BORIVOJ A. Unique effects of microwave heating on polymerization kinetics of poly(methyl methacrylate) composites[J]. Materials Chemistry and Physics, 2013, 141(2/3): 882-890.

[20] 张先如, 徐政. 微波技术在材料化学中的原理及其应用进展[J]. 辐射研究与辐射工艺学报, 2005, 23(4): 196-200.

ZHANG Xian-ru, XU Zheng. Principle of microwave chemistry and application of microwave technique in material chemistry[J]. Journal of Radiation Research and Radiation Processing, 2005, 23(4): 196-200.

(编辑 龙怀中)

基金项目:钢铁联合研究基金—国家自然科学基金委员会与上海宝山钢铁集团公司联合资助(51174252)

收稿日期:2013-09-10;修订日期:2014-03-15

通信作者:陈 津,教授;电话:13111009379;E-mail: chenjinty@sohu.com