文章编号:1004-0609(2011)08-1967-07

化学气相沉积硬质合金TiN/TiCN/Al2O3/TiN

多层涂层的抗氧化性能

陈响明1, 2,易丹青1,黄道远1,李秀萍2,刘会群1,吴春萍1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 株洲钻石切削刀具股份公司,株洲 412007)

摘 要:对化学气相沉积(CVD)法制备的硬质合金TiN/TiCN/Al2O3/TiN多层涂层试样在600~950 ℃温度范围内进行了氧化质量增加试验,采用X射线衍射(XRD)和扫描电子显微镜(SEM)分析试样氧化前后相组成及微观组织。结果表明:复合涂层最外层为α-Al2O3时,涂层具有最佳的抗氧化能力;增加TiN/TiCN/κ-Al2O3/TiN复合涂层中TiCN和κ-Al2O3的厚度能大大提高涂层高温抗氧化性。TiN和TiCN涂层经600 ℃以上氧化后,产物均为金红石结构的TiO2,氧化后TiN/TiCN间的界面消失;经900 ℃以上氧化时,κ-Al2O3转变为α-Al2O3。

关键词:硬质合金;化学气相沉积多层涂层;抗氧化性

中图分类号:TG135.5;TG115.5 文献标志码:A

Thermal oxidation resistance of TiN/TiCN/Al2O3/TiN multilayer coatings on cemented carbide by chemical vapor deposition

CHEN Xiang-ming1, 2, YI Dan-qing1, HUANG Dao-yuan1, LI Xiu-ping2, LIU Hui-qun1, WU Chun-ping1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Zhuzhou Cemented Cutting Tools Co., Ltd., Zhuzhou 412007, China)

Abstract: The oxidation mass gain test at the temperature range of 650-950 ℃ in different times were carried out on the cemented carbide coated by multilayer TiN/TiCN/Al2O3/TiN coating prepared by chemical vapor deposition (CVD) method. The phase component and microstructure of coating samples were investigated by X-ray diffraction (XRD) and scanning electron microscopy (SEM). The results show that, when the outset layer is α-Al2O3, the sample exhibits excellent oxidation resistance. The oxidation resistance of TiN/TiCN/κ-Al2O3/TiN multilayer coating sample is improved with the increase of the thickness of TiCN and κ-Al2O3. The oxidation product of TiN and TiCN layer is rutile TiO2 when the temperature is higher than 600 ℃, and the interface of TiN/TiCN disappears. The κ-Al2O3 transforms to α-Al2O3 when the oxidation temperature is above 900 ℃.

Key words: tungsten carbide; chemical vapor deposition multilayer coatings; oxidation resistance

硬质合金材料由于其具有较高的强度、红硬性和耐磨性,在矿山开采和机械加工等领域得到广泛应用。随着机械加工技术的不断进步,切削速度不断提高,尤其是近年来干式切削技术的飞速发展,硬质合金刀具的使用温度越来越高,对合金的高温性能尤其是抗氧化性提出了新的要求。

对硬质合金抗氧化性的研究,目前主要集中在硬质合金基体和单层涂层方面,BASU和SARIM[1]的研究发现,600 ℃以下,纯WC-Co硬质合金的氧化几乎可以忽略,随着温度升高,合金氧化速度明显上升,氧化后产物为WO3和CoWO4。CASAS等[2]对WC-Co硬质合金氧化动力学曲线进行测定,发现其氧化质量增加随时间呈线性增长。一些研究工作者[3-6]研究表明,硬质合金上涂覆AlSiTiN和AlSiCrN涂层后,氧化过程中,涂层中的Al和Si元素与O作用将形成致密的氧化层,阻止合金继续氧化,大大提高合金的抗氧化能力。另一些研究者[7-10]研究发现,硬质合金在涂覆10 μm厚的TiN后,其抗氧化能力比无涂层合金的提高10倍以上。但随着切削速度和温度的提高,无涂层或单层涂层硬质合金已经不能满足高速切削的需要,硬质合金多层复合涂层的出现使合金耐磨性和抗氧化能力大大提升,成为目前应用最广的硬质合金涂层。但对硬质合金用多层复合涂层抗氧化性能和抗氧化机理报道较少,这严重阻碍硬质合金材料的进一步向前发展,有必要开展这方面的研究工作。

本文作者对有代表性的4种CVD多层涂层硬质合金试样进行氧化质量增加试验,同时借助SEM和XRD对氧化前后试样的表面形貌和物相进行分析,探讨不同组合结构涂层的抗氧化机理,为新型硬质合金抗氧化涂层的设计提供有用指导。

1 实验

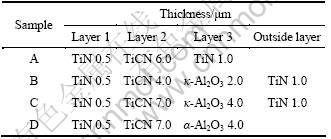

本研究制备了4种CVD涂层试样,样品规格为10 mm×10 mm×3 mm块体,其涂层体系及各层厚度见表1,基体材料为WC-5.5(Ti,Ta,Nb)C-6Co硬质合金。

表1 试验所用的CVD涂层样品

Table 1 Composite of specimen used

氧化试验在SX2-8-10箱式电阻炉中进行,试验温度为600、700、800、900、950 ℃,氧化时间分别为30、60、90、120 min。采用TG 328A型分析天平称量氧化前后样品的质量,用D/max 2000 X射线衍射仪和LEO 1525场发射扫描电镜对样品进行物相和微观组织分析。

2 结果与讨论

2.1 不同涂层试样的氧化动力学分析

几种涂层试样在不同温度下氧化质量的增加随时间的变化如图1所示。由图1可以看出,几种涂层样品氧化质量的增加随时间都呈现出近抛物线增长,在氧化初期,质量增加速度较快;随着氧化时间增长,质量增加速度减缓。当氧化温度为600 ℃时,几种样品的质量增加速度都较低,且差别不大,氧化120 min后,其质量增加量都小于0.01%。氧化温度为700 ℃时,几种样品质量增加的速度有所加快,试样A、B和C氧化质量的增加十分接近,氧化120 min后,质量增加在0.013%到0.015%之间,由于试样D的最外层为Al2O3,试样表面不能继续氧化,表现出良好的抗氧化性,氧化120 min后,质量增加还不到0.005%。氧化温度为800 ℃时,氧化质量增加速度明显加快,几种涂层的氧化速度从大到小依次为试样A、C、B和D,且差别较大。当氧化温度为900 ℃时,氧化速度急剧增加,试样A氧化60 min后,即发生整体剥落导致涂层失效,试样B氧化60 min后,表面也部分失效,质量增加速度加快,120 min后,质量增加超过0.1%,较600 ℃时提高了约10倍。而此时试样D的氧化质量增加仍低于0.006%,与600 ℃时的氧化质量增加几乎相同。当氧化温度为950 ℃时,氧化30 min后,试样A和B即发生剥落失效,而试样C和D仍具有较好的抗氧化性能;氧化120 min后,氧化质量增加分别为0.025%和0.008%。

2.2 不同涂层试样氧化后的XRD分析

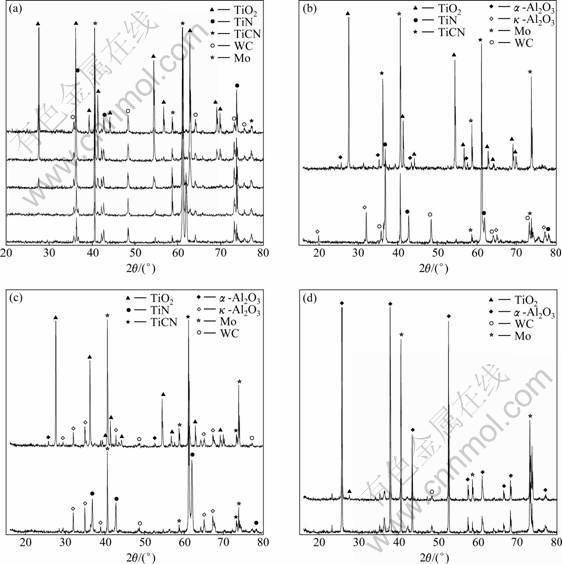

几种涂层试样氧化前后的XRD谱如图2所 示。由图2可以看出,试样A经600 ℃氧化后,表面TiN涂层出现轻微氧化,衍射谱中出现强度很低金红石结构的TiO2峰[11];经700 ℃氧化后,TiO2峰衍射强度增加,而TiCN峰强度基本保持不变,说明此时仅表层TiN涂层发生氧化,而内层TiCN涂层没有氧化;800 ℃时,内层TiCN也开始氧化,其衍射峰强度明显下降;经900 ℃氧化60 min后,TiCN氧化完全,其衍射峰基本观测不到(见图2(a))。

试样B经900 ℃氧化120 min后,除了出现强度很高的TiO2峰外,涂层中原有的κ-Al2O3也发生相变转变为α-Al2O3(见图2(b)),由于此相变过程中,Al2O3单胞体积将减少8%,这将导致涂层崩溃[12-13]。外层Al2O3崩溃失效后,内层TiCN将迅速氧化,涂层的氧化速度急剧增加,这与氧化质量增加结果(见图1(d))相符。

试样C经950 ℃氧化120 min后,氧化产物中出现了TiO2,但与试样B的不同,大部分Al2O3保持原有κ型晶体结构,只有少量Al2O3发生κ晶型到α-Al2O3的转变(见图2(c)),从而保持Al2O3涂层的完整性,导致高温下试样C的抗氧化能力高于试样B的。

图1 不同温度下涂层样品的氧化动力学曲线

Fig.1 Oxidation kinetics of coating samples at different temperatures: (a) 600 ℃; (b) 700 ℃; (c) 800 ℃; (d) 900 ℃; (e) 950 ℃

试样D经950 ℃氧化120 min后,仅出现了十分微弱的TiO2峰(见图2(d)),说明该涂层在高温下仍具有很好的稳定性。

2.3 不同涂层试样氧化后的组织形貌分析

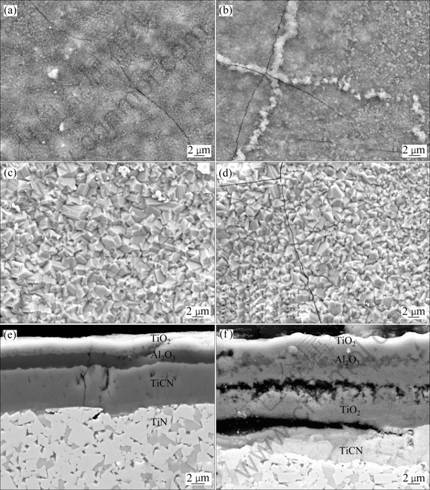

2.3.1 试样A涂层微观组织结构变化

试样A在氧化前的表面TiN晶粒边角明锐,为规整的多面体(见图3(a)),涂层表面有少量热裂纹存 在[14-15],氧化后,涂层表面变得平滑,晶粒边界变得模糊(见图3(b)),表面裂纹宽度也有所增加。对其进行截面组织(见图3(c)和(d))观察,氧化层和原始涂层界面清晰,氧化后涂层的厚度随着氧化时间变长而增厚。由于TiCN和TiN氧化后,C和N元素以气体形式沿裂纹逸出,仅留下相同的固态产物TiO2,因此,涂层氧化后,TiCN/TiN层间的界面消失。

2.3.2 试样B涂层微观组织结构变化

图4所示为试样B在不同氧化条件下的SEM像。由图4可以看出,经800 ℃氧化30 min后,各个晶粒发生融合,涂层表面变得十分平滑。经900 ℃氧化30 min后,表面出现大量细小TiO2晶粒,并且在表面沿裂纹处出现絮状堆积物, 这是因为内层TiCN氧化后生成TiO2,体积发生膨胀沿裂纹发生迁移而形成的。随着氧化温度升高和氧化时间的增长,表面TiO2晶粒发生长大,形成规整的多面体晶粒。对其截面组织观察可发现,经800 ℃氧化30 min后,表面的TiN涂层已全部转化为TiO2,而内部涂层没有发生氧化(见图4(e))。而经900 ℃氧化120 min后,内层TiCN涂层全部氧化,基体也出现局部氧化;Al2O3涂层由κ型转变为α型,由于体积效应Al2O3发生破碎变成细小颗粒包裹在TiO2中[16],导致涂层崩溃;同时,各氧化物间出现了较宽的裂纹和孔隙(见图4(f))。

图2 几种试样氧化前后XRD谱

Fig.2 XRD patterns of coating samples under different oxidation conditions: (a) Sample A after oxidation for 60 min; (b) Sample B after oxidation for 120 min at 900 ℃; (c) Sample C after oxidation for 120 min at 950 ℃; (d) Sample D after oxidation for 120 min at 950 ℃

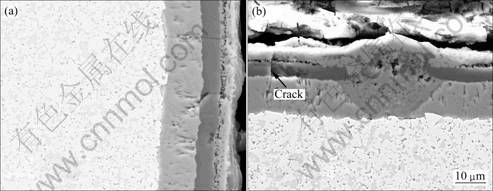

2.3.3 试样C涂层微观组织结构变化

图5所示为试样C经950 ℃氧化120 min后的截面形貌。与试样B不同,仅在裂纹附近区域,Al2O3涂层和内层TiCN遭到破坏(见图5(b)),而其它区域仍保持完好(见图5(a))。分析其原因:O进入内层后,TiCN与其反应有两种途径,一是通过涂层中的热裂纹直接进入;第二种是穿过Al2O3层与TiCN发生反应,当中间Al2O3涂层较薄时(如涂层试样B),上述两种方式都将起作用,从而内层TiCN能与O较为均匀地发生反应;当中间层Al2O3较厚时(如涂层试样C),O穿过Al2O3层进入TiCN层的扩散变得十分困难,O只能通过热裂纹进入,因此只有在裂纹附近区域TiCN才能发生反应,氧化不均匀不连续。

图3 试样A在氧化前后的显微组织

Fig.3 Microstructures of sample A: (a) Before oxidation; (b) After oxidation at 800 ℃ for 30 min; (c) Cross-section after oxidation at 800 ℃ for 30 min; (d) Cross-section after oxidation at 800 ℃ for 120 min

图4 试样B在不同氧化条件下的SEM像

Fig.4 SEM images of sample B under different oxidation conditions: (a) 800 ℃, 30 min; (b) 900℃, 30 min; (c) 900 ℃, 120 min; (d) 950 ℃, 30 min; (e) Cross-section morphology after oxidation at 800 ℃ for 30 min; (f) Cross-section morphology after oxidation at 900 ℃ for 120 min

图5 试样C经950 ℃氧化120 min后的截面形貌

Fig.15 Cross-section morphologies of sample C oxidated at 950 ℃ for 120 min: (a) Without oxidation in inner; (b) Part oxidation at crack in inner

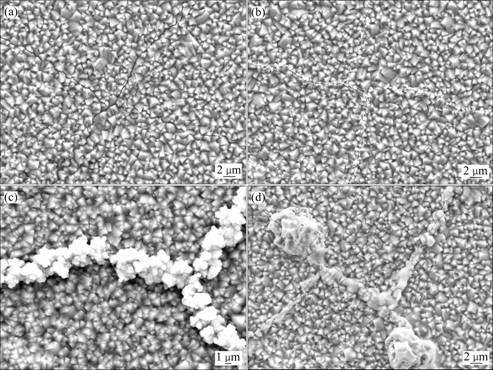

图6 试样D在不同氧化条件下的SEM像

Fig.6 SEM images of sample D under different oxidation conditions: (a) 800 ℃, 30 min; (b) 800 ℃, 120 min; (c) 900 ℃, 120 min; (d) 950 ℃, 120 min

2.3.4 试样D涂层微观组织结构变化

图6所示为试样D在氧化后的SEM像。由图6可看出,由于试样D最外层为Al2O3,不能被继续氧化,因此,氧化后其形貌基本不变。和试样B类似,试样D氧化后在表面裂纹处也出现了TiO2絮状堆积物,且随着氧化时间和温度的升高,堆积物晶粒发生长大。

3 结论

1) 最外层为α-Al2O3结构的涂层在950 ℃时仍具有很好的高温稳定性,其抗氧化能力远高于最外层为TiN的涂层的抗氧化能力。

2) 对于TiN/TiCN/κ-Al2O3/TiN复合涂层,增加TiCN和κ-Al2O3层的厚度能大幅度提高涂层样品的抗高温氧化性能。

3) TiN和TiCN涂层氧化后生成TiO2导致其原有界面消失,在高于900 ℃时,Al2O3将发生晶型转变由k-Al2O3转变为α-Al2O3。

REFERENCES

[1] BASU S N, SARIM V K. Oxidation behavior of WC-Co[J]. Materials Science and Engineering A, 1996, 209(1/2): 206-212.

[2] CASAS B, RAMIS X, ANGLADA M, SALLA J M, LLANES L. Oxidation-induced strength degradation of WC-Co hardmetals[J]. International Journal of Refractory Metals and Hard Materials, 2001, 19(4/6): 303-309.

[3] BARDI U, CHENAKIN S P, GHEZZI F. High-temperature oxidation of CrN/AlN multilayer coatings[J]. Applied Surface Science, 2005, 252(5): 1339-1349.

[4] SETTINERI L, FAGA M G, GAUTIER G, PERUCCA M. Evaluation of wear resistance of AlSiTiN and AlSiCrN nanocomposite coatings for cutting tools[J]. CIRP Annals—Manufacturing Technology, 2008, 57(1): 575-578.

[5] FAGA M G, GAUTIER G, CALZAVARINI R,PERUCCA M, AIMO BOOT E, CARTASEGNA F, SETTINERI L. AlSiTiN nanocomposite coatings developed via Arc Cathodic PVD: Evaluation of wear resistance via tribological analysis and high speed machining operations[J]. Wear, 2007, 263(7/12): 1306-1314.

[6] LIN J, MISHRA B, MOORE J J, SPROUL W D. A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analyses[J]. Surface and Coatings Technology, 2008, 202(14/15): 3272-3283.

[7] ZHANG W H, HSIEH J H. Tribological behavior of TiN and CrN coatings sliding against an epoxy molding compound[J]. Surface and Coatings Technology, 2000, 130(2/3): 240-247.

[8] MILOSEV I, STREHBLOW H H, NAVINSEK B. XPS in the study of high-temperature oxidation of CrN and TiN hard coatings[J]. Surface and Coatings Technology, 1995, 74/75(2): 897-902.

[9] JIANG Wen-ping, MORE A S. A cBN-TiN composite coating for carbide inserts: Coating characterization and its applications for finish hard turning[J]. Surface and Coatings Technology, 2006, 201(6): 2443-2449.

[10] KAMIYA S, HANYU H, AMAKI S. Statistical evaluation of the strength of wear-resistant hard coatings[J]. Surface and Coatings Technology, 2007, 202(4/7): 1154-1159.

[11] YAO S H, SU Y L, KAO W H. Tribology and oxidation behavior of TiN/AlN nano-multilayer films[J]. Tribology International, 2006, 39: 332-341.

[12] CHANG Pei-ling, WU Yu-chun, LAI Su-jung. Size effects on c- to a-Al2O3 phase transformation[J]. Journal of the European Ceramic Society, 2009, 29: 3341-3348.

[13] RUPPI S, LARSSON A, FLINK A. Nanoindentation hardness, texture and microstructure of a-Al2O3 and k-Al2O3 coatings[J]. Thin Solid Films, 2008, 516: 5959-5966.

[14] KIM B J, KIM Y C, NAH J W, LEE J J. High temperature oxidation of (Ti1-xAlx)N coatings made by plasma enhanced chemical vapor deposition[J]. Journal of Vacuum Science & Technology A, 1999, 17: 133-137.

[15] PIERSON H O. Handbook of chemical vapor deposition[M]. New York: Noyes Publications, 1999: 286.

[16] BAI L J, ZHU X D, XIAO J M, HE J W. Study on thermal stability of CrTiAlN coating for dry drilling[J]. Surface and Coatings Technology, 2007, 201(9/11): 5257-5260.

(编辑 李艳红)

基金项目:科技重大专项资助项目(2009ZX04012-021)

收稿日期:2010-09-10;修订日期:2010-12-11

通信作者:陈响明;电话:0731-88830263;E-mail: 645383213@qq.com