文章编号:1004-0609(2008)09-1590-06

AZ91D镁合金恒定小电流密度微弧氧化工艺

吕维玲1,陈体军1,马 颖1,徐卫军1, 2,王 伟1,郝 远1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 甘肃联合大学 理工学院,兰州 730000)

摘 要:研究硅酸盐体系中AZ91D镁合金恒定小电流密度微弧氧化工艺。采用在相同工作电压下增大处理面积的原理来提高生产效率和提高微弧氧化膜层的性能。利用TT230数字式涂层测厚仪、JSM?6700F扫描电子显微镜、2206型表面粗糙度测量仪(E34?001)和W?92涂层附着力划痕实验机等研究其微观结构和CHI660C电化学工作站和UMT?2MT型球-块往复式摩擦实验机进行耐蚀性和耐磨性的评定。结果表明,此工艺稳定,可达到提高工作效率的目的,其微观结构有利于大幅度提高膜层的耐蚀性和耐磨性。

关键词:AZ91D镁合金;金属型铸造;微弧氧化;电流密度;耐蚀性;耐磨性

中图分类号:TG 174 文献标识码:A

Invariable small current density process of micro-arc oxidation of magnesium alloy AZ91D

L? Wei-ling1, CHEN Ti-jun1, MA Ying1, XU Wei-jun1, 2, WANG Wei1, HAO Yuan1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology,

Lanzhou 730050, China;

2. College of Science and Technology, Gansu Lianhe University, Lanzhou 730000, China)

Abstract: The invariable small current density process of micro-arc oxidation of magnesium alloy AZ91D were investigated in silicate electrolyte. The work efficiency was enhanced feasibly by the principle of increasing its processing area in the same operating voltage, and the properties of the micro-oxidation coating were enhanced. The microstructures were studied by means of TT230 digital coating thickness gauge, JSM?6700F scanning electron microscope (SEM), 2206 surface roughness measuring instrument (E34?001), W?92 coating adhesion scratch test machine etc, and the corrosion and wear resistance were assessed by CHI660C electrochemistry workstation and UMT?2MT ball-block reciprocating friction tester. The results show that this process is stable and can enhance the work efficiency, the microstructures are advantageous to the significant enhancement of corrosion and wear resistance.

Key words: AZ91D Mg alloy; permanent mould casting; micro-arc oxidation; current density; corrosion resistance; wear resistance

镁合金具有密度小、比刚度和比强度高、能量衰减系数大及良好的电磁屏蔽性等优点,广泛地应用于航空、航天、交通工具、3C产品、体育用品、纺织和印刷行业等,但其自身的电极电位较低,表面易腐蚀且形成的氧化膜疏松多孔,无自保护功能以及其总的耐磨性较差,这些都制约了镁合金的广泛应用,使得必须对其进行适当的表面防腐处理后才能使用[1?3]。镁合金表面处理的方法很多,有化学处理、阳极氧化、微弧氧化和金属镀层,这些均可与有机涂层配合使用。其中,化学处理和阳极氧化工艺最成熟,但存在着膜层薄、耐蚀性差及因铬酐加入污染环境等问题,难以满足防腐和环保的要求[4]。

微弧氧化技术是近年来兴起的一种新表面处理技术,成为国内外研究的热点[5?7],且该技术电解液无污染、生成膜层与基体的结合力强、尺寸变化小,使得镁合金耐磨损、耐腐蚀、抗热冲击及绝缘性能都得到了很大改善,这有利于镁合金的进一步推广应用。国内外相关文献表明,关于镁合金微弧氧化膜层的研究主要集中在电解液配方、电参数等工艺参数与微弧氧化膜的结构、成分及其性能的相互关系和规律的探讨上[8?10]。

本文作者着重研究了AZ91D镁合金恒定小电流密杜微弧氧化工艺,以期达到节约能源,利用在相同的工作电压下增大处理面积的原理来提高生产效率和提高微弧氧化膜层的性能。

1 实验

1.1 镁合金试样的制备

实验用合金为商用AZ91D镁合金锭。将一定量的镁合金放入电阻坩埚炉中熔炼,覆盖剂为RJ2,熔化后当温度达到680 ℃时用C2Cl6精炼、拔渣,升温至710 ℃浇入室温的金属型,得到直径为55 mm的圆棒。将圆棒加工成直径为40 mm、厚8 mm、表面积约为0.35 dm2的圆饼作为微弧氧化试样。所有试样使用前均先用1200#砂纸打磨,然后用去离子水清洗,最后用丙酮经超声清洗后用热风吹干。

1.2 微弧氧化及微弧氧化膜的性能检测

本研究在已优化过的硅酸盐体系电解液中进行微弧氧化处理[11]。大幅度的减小微弧氧化过程中的电流密度(从原来的10 A/dm2减小到1 A/dm2,甚至更小),并用手动加压的方式使其在微弧氧化的过程中保持不变,具体的实验方案为:时间为20 min(不变),电流值依次为0.15、0.25、0.35、0.45和0.55 A,对应的电流密度依次约为0.42、0.71、1.0、1.29和1.58 A/dm2。

采用TT230数字式涂层测厚仪、2206型表面粗糙度测量仪(E34?001)和W?92涂层附着力划痕实验机测量了膜层厚度、粗糙度和膜层的结合力。采用JSM?6700F扫描电子显微镜进行试样的表面的观察,并对膜层的表面质量和孔隙率做定性比较。采用DT2000通用图像分析软件测表面孔隙率,微观形貌观察到的孔隙区所占总表面积的比率为该试样的表面孔隙率。采用 CHI600电化学工作站测量样品在 3.5%的NaCl 水溶液中浸泡48 h时Tafel曲线以评价其腐蚀行为;用UMT?2MT型球-块往复式摩擦实验机测量其耐磨性,加载为2 N,频率为1 Hz,时间为30 min。

2 结果与分析

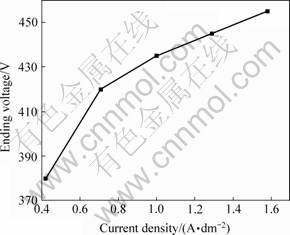

2.1 电流密度对终止电压的影响

图1所示为终止电压与电流密度的关系曲线。由图1可看出,终止电压随着电流密度的增大而增大,在反应结束后终止电压都小于460 V,但增大速率却明显减小。这说明维持恒定小电流密度所需要增加的电压不同,随着电流密度的增大所需要增加的电压增大,其能耗也会增大。因此,恒定小电流密度微弧氧化工艺有利于节约能源,且当功率相同时,恒定小电流密度微弧氧化工艺可以通过增大单位时间处理表面积的原理来提高工作效率。

图1 终止电压与电流密度的关系

Fig.1 Relationship between ending voltage of MAO films and current density

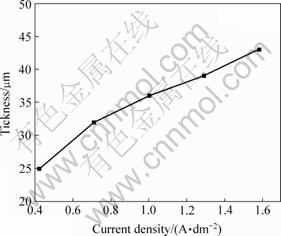

2.2 电流密度对膜层厚度的影响

图2所示为微弧氧化膜层厚度与电流密度的关系。由图2可看出,微弧氧化处理20 min后,膜层厚度均可以达到25 μm以上(可以满足现在生产所需),且膜层的厚度随着电流密度的增大而增厚,其增厚速率先增大后减小,说明恒定小电流密度决定膜层的增厚率,膜层的总体厚度由反应的终止电压来决定,这与文献[12]的研究结论一致。因此,可以通过增大电流密度的方法提高膜层的增厚率,在相同时间提高了反应的终止电压,从而得到较厚的膜层。

图2 微弧氧化膜层厚度与电流密度的关系

Fig.2 Relationship between thickness of MAO films and current density

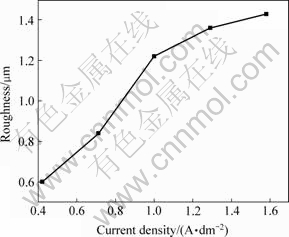

2.3 电流密度对膜层粗糙度的影响

图3所示为微弧氧化膜层粗糙度与电流密度的关系。由图3可看出,微弧氧化膜层的粗糙度随着电流密度的增大而增大,但由于电流密度都很小,因此,总的粗糙度值也都很小。这是由于在微弧氧化的过程中,电流密度较小时,反应的放气量较小,且放气阻力也小,形成的气孔也较小。因此,可以通过增大电流密度的方法增大膜层的粗糙度,可增加膜层后续处理的涂挂性,也可以通过减小电流密度的方法减小膜层的粗糙度,使得膜层耐磨、耐蚀和耐疲劳等性能更好[13]。

图3 微弧氧化膜层粗糙度与电流密度的关系

Fig.3 Relationship of roughness of MAO films and current density

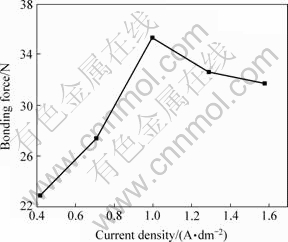

2.4 电流密度对膜层结合力的影响

图4所示为微弧氧化膜层结合力与电流密度的关系。由图4可看出,微弧氧化膜层的结合力均大于 22 N,且随着电流密度的增大呈现出先增大后减小的趋势,在1.0 A/dm2时,结合力出现最大值。这主要是由于当电流密度大于1.0 A/dm2时,由于膜层的增厚使得弧光密度减小,因而随着电流密度的增大,单个弧光的强度增强,反应时间也延长,膜层致密度下降,其膜层内部的聚合力下降,导致其结合力也下降。

图4 微弧氧化膜层结合力与电流密度的关系

Fig.4 Relationship between bonding force of MAO films and current density

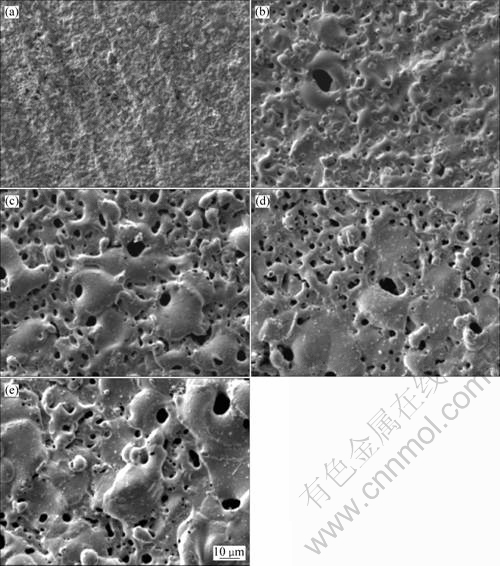

2.5 氧化膜层的表面形貌及孔隙率分析

图5所示为不同电流密度时微弧氧化膜层表面形貌。由图5可看出,膜层致密,表面平整,具有良好的仿形性,表面具有细小的棒状熔融物。这是由于在电流密度较小时,冷却比较及时,反应比较缓慢(膜层生长速度为1.25 μm/min),孔隙尺寸远小于1 μm。膜层表面熔融物为块状,且出现了10 μm的孔隙,但大孔隙的数量较少,膜层表面的熔融物为颗粒状且依次增大,孔隙尺寸普遍增大且这种大孔隙数量也增多,但总体数量却减少。因此,随着微弧氧化电流密度的增大,镁合金微弧氧化膜层表面熔融物颗粒增大(这也是造成粗糙度增加的原因),孔隙也迅速增大,大孔隙数目呈出现增多—减少的变化趋势(由于在微弧氧化电流密度增大时,弧光变大,而后变大并变稀所致)。与文献[14]中的相比,该工艺所得的微弧氧化膜层没有出现裂纹,这是由于小电流足以提供微弧氧化的热力学及动力学条件[15],过大的电流会导致裂纹的产生。

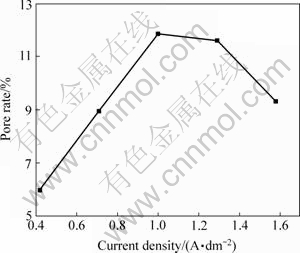

从上述分析可知,膜层表面孔隙的尺寸和数量随加压幅度的变化而变化。图6所示为微弧氧化膜层孔隙率与电流密度关系。由图6可看出,随着电流密度的增大,微弧氧化表面的孔隙率呈先增大后减小的趋势,且在电流密度为1 A/dm2时,孔隙率出现最大值。这主要是由于当电流密度大于1 A/dm2时,微弧氧化膜层生长过程中的弧光变大、变稀,导致孔隙尺寸变大,但微弧氧化孔隙的数目减少所导致的,这与图5所示的规律相同。

图5 不同电流密度时微弧氧化膜层的表面形貌

Fig.5 Surface morphologies of MAO coatings formed under different current densities: (a) 0.42 A/dm2; (b) 0.71 A/dm2; (c) 1.0 A/dm2; (d) 1.29 A/dm2; (e) 1.58 A/dm2

图6 微弧氧化膜层孔隙率与电流密度的关系

Fig.6 Relationship between pore rate of MAO films and current density

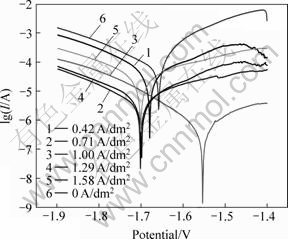

2.6 电流密度对膜层耐蚀性的影响

图7所示为微弧氧化膜层腐蚀48 h时Tafel曲线与制备电流密度的关系。由图7可看出,与基体相比,微弧氧化膜层的腐蚀电位大部分都是呈现出负移趋势,但腐蚀电流都明显小于基体,说明其耐腐蚀能力均有提高,但电流密度为1 A/dm2时,腐蚀电位却正移(约105 mV)和腐蚀电流显著减小(3个数量级),其耐腐蚀能力显著提高。因此,随着电流密度的增大,耐腐蚀能力呈现先增大后减小的趋势,当电流密度为1 A/dm2时,耐腐蚀能力最强。主要是由于在微弧氧化过程中,随着电流密度的增加,膜层厚度增加,因此耐蚀性增强;但如果电流密度过高,会出现较剧烈放电,产生大的弧光,且大的弧光放电时间会延长,膜层孔隙变大, 使得其致密性下降,导致膜层的耐蚀性下降。

图7 微弧氧化膜层Tafel曲线与制备电流密度的关系(48 h)

Fig.7 Relationships between Tafel curves of MAO films and current density(48 h)

2.7 电流密度对膜层耐磨性的影响

图8所示为AZ91D镁合金微弧氧化膜与Si3N4球对磨时的摩擦因数和磨损率与电流密度的关系。由图8可以看出,随电流密度的增大,摩擦因数呈先增大后减小的趋势,这与微弧氧化膜层表面的微观结构有关。当电流密度为0.42 A/dm2时,主要是由于表面粗糙度和孔隙率很小,其表面与基体形貌相仿,表面颗粒很细小,导致其摩擦因数与基体相比变化不大;当电流密度增大到0.71 A/dm2时,摩擦因数迅速增大,主要是由于表面粗糙度和孔隙率都迅速增大,其表面颗粒物变为块状;当电流密度增大到1 A/dm2时,摩擦因数缓慢增大,主要是由于表面粗糙度和孔隙率增大,且其表面颗粒物变为大颗粒。由于其表面粗糙度的进一步增大,孔隙率反而减小以及表面颗粒物变的更大使得摩擦因数减小,但很缓慢。由电流密度的变化曲线可以看出,随着电流密度的增大,膜层的磨损率与基体相比迅速减小,开始膜层的磨损率比基体降低了近1个数量级,当电流密度增大到1 A/dm2时,膜层的磨损率比基体降低了近2个数量级;当电流密度大于1 A/dm2时,磨损率减小不明显,主要是由于膜层厚度的增加提高了其耐磨性能。这说明恒定小电流密度工艺制备的微弧氧化膜层的结构致密、均匀且硬度高,具有良好的耐磨性。

图8 微弧氧化膜层摩擦因数(a)和磨损率(b)与电流密度的关系

Fig.8 Relationships among friction coefficient(a) and wear rate(b) of MAO films and current density

3 结论

1) 硅酸盐体系中AZ91D镁合金恒定小电流密度微弧氧化工艺稳定,利用在相同的工作电压下增大处理面积的原理来提高生产效率可行。

2) 随着电流密度的增大,微弧氧化反应的终止电压、微弧氧化膜层的厚度和粗糙度都呈增大趋势;微弧氧化膜层的结合力和孔隙率呈现先增大后减小的趋势,在1.0 A/dm2时都出现最大值。观察其表面形貌,发现表面熔融物颗粒增大,大孔隙数目呈出现增多—减少的变化趋势,表面均没有出现裂纹。

3) 随着电流密度的增大,耐腐蚀能力和摩擦因数呈先增大后减小的趋势,在1.0 A/dm2时,都出现最大值,这与微弧氧化膜层表面的微观结构有关。膜层的磨损率与基体相比迅速减小。这说明恒定小电流密度工艺制备的微弧氧化膜层的结构致密、均匀且硬度高,具有良好的耐蚀性和耐磨性。

REFERENCES

[1] GRAY J E, LUAN B. Protective coatings on magnesium and its alloys—A critical review[J]. Journal of Alloys and Compounds, 2002, 336(1/2): 88?113.

[2] YEROKHIN A L, NIE X, LEYLAND A, MATTHEWS A, DOWEY S J. Plasma electrolysis for surface engineering[J]. Surf Coat Tech, 1999, 122(2): 73?93.

[3] MORDIKE B L, EBERT T. Magnesium properties-applications- potential[J]. Mater Sci Eng A, 2001, 302(1): 37?45.

[4] 张荣发, 单大勇, 韩恩厚, 曾志良. 镁合金阳极氧化的研究进展与展望[J]. 中国有色金属学报, 2006, 16(7): 1136?1148.

ZHANG Rong-fa, SHAN Da-yong, HAN En-hou, ZENG Zhi-liang. Status and prospect of anodization on magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1136?1148.

[5] 蒋百灵, 张淑芬, 吴国建, 雷廷权. 镁合金微弧氧化陶瓷层纤维缺陷与相组成及耐蚀性[J]. 中国有色金属学报, 2002, 12(3): 454?457.

JIANG Bai-ling, ZHANG Shu-fen, WU Guo-jian, LEI Ting-quan. Micro-flaw and phases constitution of ceramic coating formed by micro-arc oxidation on magnesium alloys and their influence on corrosion resistance[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 454?457.

[6] 郝建民, 陈 宏, 张荣军, 蒋百灵. 镁合金微弧氧化陶瓷层的耐蚀性[J]. 中国有色金属学报, 2003, 13(4): 988?991.

HAO Jian-min, CHEN Hong, ZHANG Rong-jun, JIANG Bai-ling. Corrosion resistance of magnesium alloys micro-arc oxidation ceramic coating[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 988?991.

[7] RAMS K L, SOMARAJU K R C, SUNDARARAJU G. The tribological performance of ultra-hard ceramic composite coatings obtained through microarc oxidation[J]. Surface and Coatings Technology, 2003, 163: 484?490.

[8] HAN I, CHOI J H, ZHO BAO-HONG, BAIK H K, LEE I S. Micro-arc oxidation in various concentration of KOH and structural change by different cut off potential[J]. Current Applied Physics, 2007, 7(S1): 23?27.

[9] 张荣发, 李明升, 龙小丽, 何向明, 单大勇, 韩恩厚. 电参数对镁合金阳极氧化膜性能影响的研究进展[J]. 中国有色金属学报, 2006, 16(11): 1829?1837.

ZHANG Rong-fa, LI Ming-sheng, LONG Xiao-li, HE Xiang-ming, SHAN Da-yong, HAN En-hou. Research progress in effects of electric parameters on properties of anodic coatings on magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1829?1837.

[10] CHEN Fei, ZHOU Hai, YAO Bin, QIN Zhen, ZHANG Qing-feng. Corrosion resistance property of the ceramic coating obtained through microarc oxidation on the AZ31 magnesium alloy surfaces[J]. Surface and Coating Technology, 2007, 201(9/11): 4905?4908.

[11] 梁永政. 镁合金表面微弧氧化工艺的研究[D]. 兰州: 兰州理工大学, 2004.

LIANG Yong-zheng. Study on Micro-arc of magnesium alloy surfaces[D]. Lanzhou: Lanzhou University of Technology, 2004.

[12] 陈 宏, 郝建民, 王利捷. 镁合金微弧氧化处理电压对陶瓷层的影响[J]. 表面技术, 2004, 33(3): 17?18.

CHEN Hong, HAO Jian-min, WANG Li-jie. Influences of Mg alloy micro-arc oxidization voltage on ceramic layer[J]. Surface Technologe, 2004, 33(3): 17?18.

[13] 表面粗糙度[BO/OL]. http://baike.baidu.com/view/55599.htm, 2006?08?09.

Surface roughness[BO/OL]. http://baike.baidu.com/view/55599. htm, 2006?08?09.

[14] 蒋百灵, 张先锋. 镁合金微弧氧化陶瓷层的生长过程及其耐蚀性[J]. 中国腐蚀与防护学报, 2005, 25(2): 97?101.

JIANG Bai-ling, ZHANG Xian-feng. Growth process and corrosion resistance of ceramic coatings formed by micro-arc oxidation on magnesium alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(2): 97?101.

[15] 陈显明, 罗承萍, 刘江文, 李文芳. 镁合金微弧氧化热力学和动力学分析[J]. 兵器材料科学与工程, 2006, 29(3): 17?20.

CHEN Xian-ming, LUO Cheng-ping, LIU Jiang-wen, LI Wen-fang. Thermodynamic and kinetic analysis of micro-arc oxidation on magnesium alloy[J]. Ordnance Material Science and Engineering, 2006, 29(3): 17?20.

基金项目:国家重点基础研究发展计划资助项目(2007CB613700);甘肃省科技重大专项资助项目(0702GKDA024);省际国际科技合作计划资助项目(0708WCGA151);教育部春晖计划资助项目(Z2006-1-62002)

收稿日期:2007-09-21;修订日期:2008-04-12

通讯作者:陈体军,教授,博士;电话:0931-2976578;E-mail: chentj@lut.cn

(编辑 李艳红)