Fe杂质对Al-15Mg2Si复合材料摩擦性能的影响

来源期刊:中国有色金属学报(英文版)2018年第6期

论文作者:A. NADIM R. TAGHIABADI A. RAZAGHIAN M. T. NOGHANI M. H. GHONCHEH

文章页码:1084 - 1093

关键词:Al-Mg2Si;原位复合材料;摩擦学;滑动磨损;摩擦

Key words:Al-Mg2Si; in-situ composite; tribology; sliding wear; friction

摘 要:研究了Fe杂质(0.2%~2%,质量分数)对Al-15Mg2Si复合材料的显微组织、干滑动磨损和摩擦性能的影响。摩擦实验采用销盘式试验机,压力分别为 0.25、0.5和1 MPa,固定滑动速度为0.13 m/s。结果显示,Fe 使初始Mg2Si颗粒从不规则枝晶状转变为多面体形状的较小颗粒,细化伪共晶结构,并导致基体中形成硬质相β-Al5FeSi片晶。尽管这些显微组织的变化提高了复合材料的硬度,但其抗干滑动磨损的能力却受到了损害。磨损表面、磨屑和下表层的SEM 结果证实了β相对摩擦学性能的不利影响。β相颗粒较易断裂,从而降低基体抗滑动应力的能力,造成摩擦层的不稳定,使其易剥离,形成大的剥落碎片。摩擦实验结果还表明,Fe降低材料的平均摩擦因数,但增加摩擦因素的波动。

Abstract: The effect of Fe-impurity (0.2%-2%, mass fraction) on the microstructure, dry sliding wear, and friction properties of Al-15Mg2Si composite was investigated using a pin-on-disk tester under the applied pressures of 0.25, 0.5 and 1 MPa at a constant sliding speed of 0.13 m/s. According to the results, Fe modified the primary Mg2Si particles from irregular dendritic form to smaller particles with polyhedral shapes, refined the pseudo-eutectic structure, and led to the formation of hard b-Al5FeSi platelets in the matrix. In spite of hardness improvement by these microstructural changes, the resistance of the composite against dry sliding wear was impaired. SEM examination of the worn surfaces, wear debris, and subsurface regions confirmed the negative effect of b-phase on the tribological properties. It was found that b-particles were fractured easily, thereby decreasing the potential of the substrate to resist against sliding stresses and giving rise to the instability and easy detachment of tribolayer as large delaminated debris. The friction results also revealed that Fe slightly decreased the average friction coefficient, but increased the fluctuation in friction.

Trans. Nonferrous Met. Soc. China 28(2018) 1084-1093

A. NADIM1, R. TAGHIABADI1, A. RAZAGHIAN1, M. T. NOGHANI1, M. H. GHONCHEH2

1. Department of Materials Science and Ceramic Engineering, Imam Khomeini International University, Qazvin, Iran;

2. School of Metallurgy and Materials Engineering, Iran University of Science and Technology, Tehran, Iran

Received 27 May 2017; accepted 1 October 2017

Abstract: The effect of Fe-impurity (0.2%-2%, mass fraction) on the microstructure, dry sliding wear, and friction properties of Al-15Mg2Si composite was investigated using a pin-on-disk tester under the applied pressures of 0.25, 0.5 and 1 MPa at a constant sliding speed of 0.13 m/s. According to the results, Fe modified the primary Mg2Si particles from irregular dendritic form to smaller particles with polyhedral shapes, refined the pseudo-eutectic structure, and led to the formation of hard b-Al5FeSi platelets in the matrix. In spite of hardness improvement by these microstructural changes, the resistance of the composite against dry sliding wear was impaired. SEM examination of the worn surfaces, wear debris, and subsurface regions confirmed the negative effect of b-phase on the tribological properties. It was found that b-particles were fractured easily, thereby decreasing the potential of the substrate to resist against sliding stresses and giving rise to the instability and easy detachment of tribolayer as large delaminated debris. The friction results also revealed that Fe slightly decreased the average friction coefficient, but increased the fluctuation in friction.

Key words: Al-Mg2Si; in-situ composite; tribology; sliding wear; friction

1 Introduction

There is no doubt that the trend towards the application of composite materials is increasing rapidly in the ongoing scenario and is likely to increase more rapidly in the future. Nowadays, Al matrix composites (AMCs) are gaining importance in the upcoming fields of engineering. These materials exhibit superior strength, hardness, corrosion resistance, fatigue strength, and creep resistance in addition to low-weight advantage of Al [1].

Recently, in-situ techniques have been developed to fabricate AMCs. These techniques involve the synthesis of composites such that desirable reinforcements, matrices and interfaces are formed during processing [2]. In-situ routes provide advantages such as uniform distribution of reinforcement, fine reinforcement particle, clear interface, and thermodynamically stable reinforcement in comparison to the conventional ex-situ processes [2,3].

In-situ Al-Mg2Si composites, comprising Mg2Si particles within an Al matrix, have been lately introduced as a new class of ultra-light materials [3-5]. Magnesium silicide (Mg2Si), as a type of in-situ reinforcement phase, exhibits high melting temperature (1085 °C), low density (1.99 g/m3), high hardness (4500 MN/m2), low CTE (7.5×10-6 K-1) and high elastic modulus (120 GPa) [6]. Such a combination of properties makes this compound a suitable candidate for reinforcing AMCs to create a new class of materials with improved specific properties and great potential for a variety of applications especially in tribological-based engineering systems. The geometrical parameters of Mg2Si reinforcements including their size, shape, distribution, and volume fraction, however, were shown to have a great influence on the final properties of Al–Mg2Si composites. In this regard, extensive efforts have been made so far to optimize these parameters through mechanical or thermo-mechanical processing [7-12], heat treatment [13-15], composition optimization, and impurity control [16-18].

Iron is one of the most troublesome impurities in Al-based cast materials. This element comes from the bauxite ore and/or Fe-based melting tools and dies. Iron also gradually accumulates through the reuse of Al alloy scrap [19-21]. During solidification due to the very low solid solubility of Fe in Al (max 0.052% (mass fraction) at 44 °C), this element promotes the formation of intermetallic phases such as AlFeSi compounds, which may damage the properties of final cast products by several mechanisms [21-23]. In this regard, several studies have been conducted to investigate and correct the effect of Fe impurity on microstructure, mechanical properties, corrosion resistance, and tribological properties of Al-based alloys. Nevertheless, most of these studies are mainly focused on Al-Si rather than other Al-based alloys like Al-Mg-Si.

In one of the more recent studies, EMAMY et al [24] investigated the effect of Fe on the microstructure and the mechanical properties of Al-15Mg2Si composite. It was found that Fe addition up to 3% (mass fraction) has improved the hardness, but its optimum amount for improving the tensile properties was determined to be 1% (mass fraction). The effect of Fe on the mechanical properties of Al-15Mg2Si composites was described by its effect on changing the morphology of primary Mg2Si particles and reducing their average size. To the best of our knowledge, however, there is no published work on the effect of Fe, as the most harmful impurity in Al-based alloys, on tribological properties of Al-15Mg2Si composites. The aim of the current work was to investigate the effect of different amounts of Fe (0.5%-2%, mass fraction) on the microstructure, mechanical properties and tribological properties of Al-15Mg2Si composites.

2 Experimental

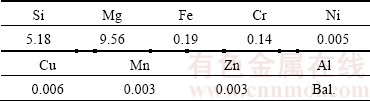

Pure Al (99.9 %), Mg (99.9 %) and Si (99.5 %) were used to prepare the primary MMC ingots. Extra Al, Si and Mg were also added to balance the oxidation loss. Aluminium ingots were melted at (750±5) °C in an electric resistance furnace. Then, the Si and Mg preheated at 300 °C were respectively added to the melt in the temperature range of 720-750 °C. The melt was regularly stirred in order to be homogenized, and then poured into a cast iron mold as primary ingots. The chemical composition of the alloy is given in Table 1.

Table 1 Chemical composition of base composite (mass fraction, %)

The primary ingots were remelted in a clay- graphite crucible using another electric resistance furnace, and heated up to a temperature of (750±10) °C. Then, different amounts of Fe in the form of 75Fe alloy compacts were added to the melt in order to achieve desired iron levels (0.5%, 1.0% and 2.0%, mass fraction). The melt was held at 750 °C for 10 min, and gently stirred to be homogenized and minimize the entrainment of any surface oxide films. Furthermore, the melt was degassed with C2Cl6 degasser, and stirred gently again before being poured. Some of the melt was poured into a preheated (250 °C) cast-iron tensile specimen mold (Fig. 1(a)) to obtain tensile samples according to ASTM B 557M-02a (Fig. 1(b)), and the rest of melt was poured into another preheated (250 °C) cast-iron mold to obtain ingots of 100 mm × 40 mm ×25 mm in size for the rest of experiments. The average cooling rate of the molds was calculated to be 3 °C/s.

Fig. 1 Schematic diagram of cast-iron mould (a) and tensile test specimens (b)

The quantitative and qualitative investigations on the morphological parameters of the solidified phases were performed to ensure that suitable Al-15Mg2Si composite has been produced. The specimens were mechanically ground, and then polished through standard routes. Each cross section was etched using 1% HF-distilled water reagent. An Olympus optical microscope and a Tescan-Vega scanning electron microscope equipped with energy dispersive X-ray spectroscopy (EDS) were used to characterize the microstructural features. Quantitative metallography was carried out using UTHSCSA image tool (Ver. 1.28).

The tensile specimens (ASTM B557M-10) were tensioned by a Zwick/Roell Z100 tensile testing machine at a constant crosshead speed of 0.5 mm/min. The average of four results was reported as the final value. The hardness of specimen was evaluated using a GNEHM  /Swiss-Rock 190 Brinell tester. The already prepared flat surface of each cast samples was indented using a 2.5 mm hardened steel ball under the applied load of about 300 N. The Vickers micro-hardness tests were conducted at the applied load of 0.10 N. The average of 10 random measurements on the surface of samples was reported as the hardness number.

/Swiss-Rock 190 Brinell tester. The already prepared flat surface of each cast samples was indented using a 2.5 mm hardened steel ball under the applied load of about 300 N. The Vickers micro-hardness tests were conducted at the applied load of 0.10 N. The average of 10 random measurements on the surface of samples was reported as the hardness number.

Pin-on-disk apparatus as per ASTM G 99-90 was used for the dry sliding wear testing. The cylindrical pins of 15 mm in height, and 9 mm in diameter were machined by wire cutting from the composite materials. The disk material is made of DIN-100Cr6 steel with a hardness of HRC 61. The average roughness (Ra) of the pin and disk surfaces was measured using a Hummel Werke-T-800 profilometer. Three roughness measure- ments were made for each surface and the Ra values were determined to be 1.72 mm and 0.45 mm for the pin and disk surfaces, respectively. The wear tests were conducted under the applied pressures of 0.25, 0.5 and 1 MPa at the constant sliding speed of 0.13 m/s with the sliding distance of 1000 m at the ambient temperature with the relative humidity controlled to be (45±10)%. The tests were repeated at least three times under the same conditions. Before each test, the specimens were rinsed ultrasonically in distilled water and immersed into acetone and cold distilled water.

3 Results and discussion

3.1 Effect of Fe-impurity on microstructure and mechanical properties of Al-15%Mg2Si composite

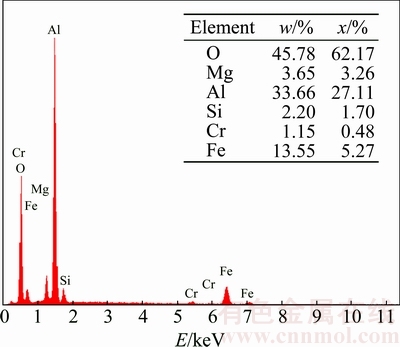

The metallographic microstructure of the base composite is shown in Fig. 2(a). As can be seen, the microstructure mainly consists of primary Mg2Si (Mg2SiP) particles by the EDS analysis shown in Fig. 2(b), within an Al-Mg2Si pseudo-eutectic matrix. As seen, the coarse Mg2SiP crystals have grown as hollow- shape particles. The emergence of this morphology is explained by the precipitation of a thick Al-rich layer in contact with the edge of growing Mg2SiP particles in such a way that their central regions cannot be exposed to Mg- and Si-rich molten Al [14]. Therefore, lack of diffusion is claimed to be responsible for the creation of cavities in Mg2Si particles. This hopper-like morphology has been shown by several researchers which adversely affects the mechanical properties [10,14,24].

The effect of Fe-impurity on the microstructure of composite has been illustrated in Fig. 3. As seen, Fe has changed the morphology of Mg2SiP particles from irregular dendritic form to polyhedral shapes, which is attributed to its poisoning effect. According to Ref. [24], Fe probably suppresses the preferred growth of the Mg2SiP crystals and accelerates their isotropic growth. The size of Mg2SiP particles has also decreased from (29.2±5.0) to (17.1±3.1) μm, as the Fe content increased from 0.2% in the base alloy to about 2% (mass fraction) (Fig. 4). Fe-impurity on the other hand has refined the Mg2Si crystals within the pseudo-eutectic matrix (Mg2SiE) (Fig. 3), but its effect on the volume fraction of the primary Mg2Si particles seems to be insignificant (Fig. 4(a)).

Fig. 2 OM microstructure of base (Al-15Mg2Si) composite, showing primary Mg2Si particles within pseudo-eutectic matrix (a), and EDS analysis result of Mg2SiP particles (b)

Regarding to the negligible solid solubility of Fe in Al, the refinement of Mg2SiE particles with Fe addition may be explained by the constitutional undercooling provided by the segregation of Fe atoms ahead of solid/liquid solidification front. The higher the Fe content, the higher the compositional undercooling is, and therefore, the finer the pseudo-eutectic matrix is. The slight change in the volume fraction of Mg2SiP particles with Fe addition may be further attributed to their density increment as transforming from the irregular hopper-like particles to the regular polyhedral [24].

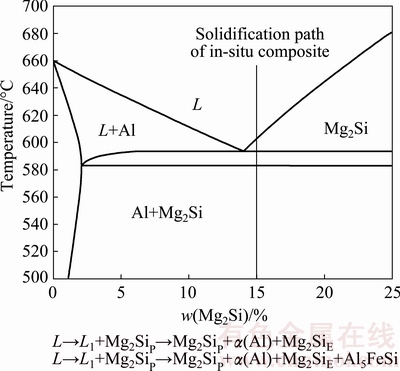

As depicted in Fig. 3, Fe-impurity has also promoted the formation of needle-like intermetallic compounds within pseudo-eutectic inter-colony regions whose average length and volume fraction increased with the Fe content (Fig. 4(b)). The EDS spectrum of Fe-needles (Fig. 3(d)) confirms that the average contents of Al, Fe and Si are consistent with the contents obtained for β-Al5FeSi phase elsewhere [25,26]. According to the equilibrium phase diagram of Al-Mg2Si (Fig. 5), solidification of Al-15%Mg2Si composite starts with the precipitation of Mg2SiP particles followed by the co-precipitation of α(Al) and Mg2SiE as eutectic colonies in the narrow phase area [27]. In the Fe-containing composites, however, as a result of successive reduction in solid solubility of Fe and Si, the inter-colony liquid becomes gradually enriched by Fe and Si, and the β-Al5FeSi needles start to precipitate there at the expense of Si and Fe. Therefore, characteristic morphology of divorced eutectic is observed in inter-colony regions comprising free a(Al) and coarse Mg2SiE.

Fig. 3 OM micrographs showing effect of Fe content on microstructure of Al-15Mg2Si composite

Fig. 4 Effect of Fe content on volume fraction and average size of Mg2SiP (a) and b-Al5FeSi (b) particles

Fig. 5 Equilibrium pseudo-binary phase diagram of Al-Mg2Si [27]

The effect of Fe-impurity on hardness and tensile properties of Al-15Mg2Si composite is presented in Table 2. As can be seen, due to the precipitation of hard β-Al5FeSi particles (HV0.1 177.81±28.44), the addition of Fe has increased the hardness. The effect of Fe on the tensile properties, however, is dependent on its content. According to tensile test results (Table 2), after a slight improvement at 0.5% Fe, both tensile strength and elongation were subsequently decreased by further addition of Fe up to 2%. The positive effect of Fe (up to 0.5%) on the tensile properties can be explained by its modification effect on the microstructure of Al-15Mg2Si composite and the precipitation of fine β-particles at inter-colony regions (Fig. 3(a)) that can act as potential barriers to dislocations motion [22,23]. Further addition of Fe up to 2%, however, has increased the size and the volume fraction of brittle β-needles thereby adversely affected the tensile properties.

Table 2 Effect of Fe addition on mechanical properties of Al-15Mg2Si composite

The negative effect of large β-particles is mainly ascribed to their brittleness and the stress concentration effects caused by their plate-like morphology which facilitates the initiation and propagation of micro-cracks within the particles themselves or through their weak interfaces with the matrix [22,23,26]. SEM examination of the fracture surfaces (Fig. 6) reveals the effect of β-Al5FeSi platelets on the premature fracture of Fe-containing samples. According to Fig. 6(a), the fracture surface of the base composite consists of some sporadic dimples which are α(Al) phase. The brittle fracture and decohesion of the coarse Mg2Si particles are also evident on the surface, indicating their decisive role in the fracture behavior. The cleavage appearance, the presence of β-Al5FeSi platelets, and β-related porosities are also the main morphological features that are obviously displayed with the fracture surface of Al-15%Mg2Si-2Fe sample (Fig. 6(b)). The formation of β-related shrinkage porosities is generally due to the physical restriction caused by these plate-like particles to the flow of compensatory liquid in interdendritic region and exerts negative effect on the mechanical properties.

3.2 Effect of Fe-impurity on tribological properties of Al-15Mg2Si composite

The effect of Fe-impurity on the sliding wear behavior of Al-15Mg2Si composite is shown in Fig. 7. It is perceived from Fig. 7 that, for the applied pressures of 0.25 and 0.5 MPa, the wear rate has increased by the Fe content. Under the applied pressure of 1.0 MPa, however, the wear rate has decreased with Fe content, passed a minimum at about 1.0% Fe, and increased again by the further increase of Fe content up to 2%.

Fig. 6 SEM images of fracture surfaces composites

Fig. 7 Variation of wear rate with Fe content for different applied pressures

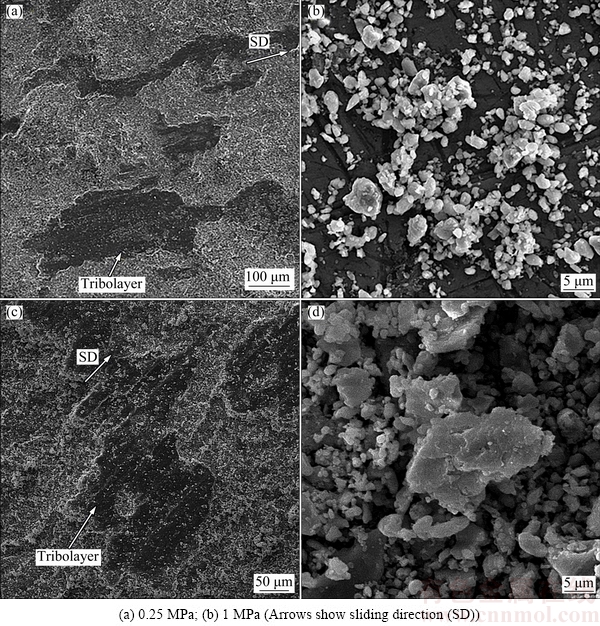

SEM micrographs taken from the worn surface and wear debris of the base composite slid under applied pressures of 0.25 and 1.0 MPa are shown in Fig. 8. Under the applied pressure of 0.25 MPa, the worn surface is covered by a rather compact stable tribolayer which experienced shallow delaminated material pickup (Fig. 8(a)). In conjunction to its high wear resistance, this morphology suggests that the wear loss in the base composite is mainly caused by the mild delamination of tribolayer. The microscopic examination of the wear debris (Fig. 8(b)) also reveals the formation of fine equiaxed particles, which is an indication of the mild wear regime.

Fig. 8 SEM micrographs showing worn surfaces and wear debris of base composite at different applied pressures

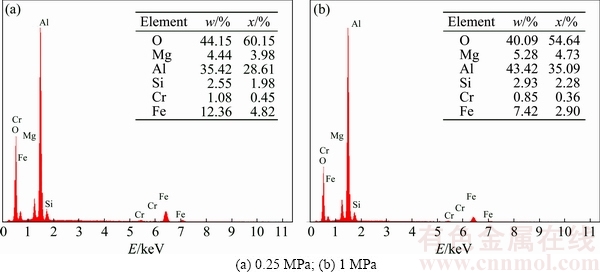

Figure 8(c) depicts the worn surface of the base composite slid under the applied pressure of 1.0 MPa. The extensive delaminated areas and localized abrasion tracks formed on the worn surface are the indications of unstable tribolayer. The instability of the tribolayer at the higher applied pressures can be explained by the extensive plastic flow of the substrate material resulting from the high frictional heat generation and the high shear stresses exerted on the surface and subsurface regions. Moreover, as shown in Figs. 9(a) and (b), the Mg2SiP reinforcing particles, located at subsurface zones, may also fracture and lose their strengthening characteristics making the tribolayer more unstable. In this case, the tribolayer is likely to be removed from the surface as large agglomerates and/or large delaminated debris (Fig. 8(d)). The corresponding EDS analyses of the worn surfaces of the base composite (Figs. 8(a) and (c)) are presented in Fig. 10. As seen, regardless of applied pressure, the high concentration of oxygen within the craters shows that delamination is most likely limited to the tribolayer (tribo-oxidative wear).

Fig. 9 Longitudinal cross-section morphologies of worn surfaces of composites at applied pressure of 1.0 MPa

Fig. 10 EDS spectra of worn surfaces of base composite at different applied pressures

Fig. 11 Variation of COF with sliding distance for base (a) and Al-15Mg2Si-2Fe composite (b) at applied pressures of 0.25 and 1 MPa

The variation of the coefficient of friction (COF) against the sliding distance for the base composite at applied pressures of 0.25 and 1 MPa is shown in Fig. 11(a). As can be seen, after an initial running-in period, which is related to the increase in the contact area, work hardening of the contact surfaces, and the change of wear mechanism from two-body to three-body because of the wear debris formed and entrapped within the sliding interface [28], the COFs, on average, are about 0.85±0.06 and 0.84±0.11, for the applied pressures of 0.25 and 1 MPa, respectively. Despite the large increase in the wear rate by increasing the applied pressure from 0.25 to 1 MPa (Fig. 7), the nearly the same average value of COF can be attributed to the instability of the tribolayer and its easy removal from the surface as may also be proven by the increasing trend and the successive break-in periods in 1 MPa plot (Fig. 11(a)). At the applied pressure of 0.25 MPa, however, after an initial stage of chaotic fluctuation (up to 400 m), the COF decreased slightly and exhibited a steady-state profile until end of the wear experiment which is consistent with the mild wear regime (Fig. 7 and Figs. 8(a) and (b)).

The SEM micrographs taken from the worn surface and wear debris of Al-15Mg2Si-2Fe alloy at applied pressures of 0.25 and 1.0 MPa are shown in Fig. 12. As seen, the worn surface of these samples is covered by a less stable tribolayer that experienced extensive delamination. In accordance to the wear results (Fig. 7), this morphology further reaffirms the negative effect of Fe on the sliding wear properties.

As already seen, Fe improves the hardness (Table 2) and exerts some refining effect on the primary and eutectic Mg2Si particles (Figs. 3 and 4(a)). Increasing of the hardness lowers the possibility of adhesion between contacting asperities and improves the substrate potential to resist against surface plastic strains and also to support the tribolayer in place. The second-phases refinement also helps to decrease the chance of microcracking in the subsurface regions. Therefore, the negative effect of Fe-impurity on the sliding wear is likely to be due to the formation of Fe-rich b-compounds.

Figures 9(c) and (d) show the subsurface microstructures of Al-15Mg2Si-2Fe composite at the applied pressure of 1 MPa. As seen, under sliding loading, the subsurface β-particles are fractured, aligned toward the surface, and gradually located into the tribolayer as relatively large discrete particles. The fractured particles lose most of their strengthening effect on the matrix, reducing its resistance against tangential stresses exerted on surface and subsurface regions and making the tribolayer more unstable. The incorporation of β-fragments into the tribolayer can also make it more porous (Fig. 9(b)) and less stable on the surface. The instability of the tribolayer can be also approved by the formation of large plate-like wear debris (Fig. 12(d)).

Fig. 12 SEM micrographs of worn surfaces and wear debris of Al-15Mg2Si-2Fe composite at different applied pressures

In conjunction to the wear results, Fig. 11(b) shows the variation of COF against the sliding distance for Al-15Mg2Si-2Fe composite at the applied pressures of 0.25 and 1 MPa. Compared with those observed in the base composite (Fig. 11(a)), the plots with lower values of average COF and the higher fluctuations are evident. The low value of COF may be explained by the lower shear strength of the tribolayer in Fe-containing composites mediated by its less compact more porous nature (Fig. 9(b)). The intense fluctuation of COF also seems to be arisen from the phenomena like intermittent asperities contact (stick-slip events), the absorption of energy during fracture of β-particles, surface-particles interactions, and the abrasion of counterface by the hard β-fragments already trapped in the tribolayer [29-31]. The high percentages of Fe and Cr elements in the tribolayer of Al-15Mg2Si-2Fe sample (Fig. 13) support the above explanation and imply that the disk material has suffered considerable amounts of wear probably due to the abrasive action of entrapped β-particles.

Fig. 13 EDS spectrum of worn surface of Al-15Mg2Si-2Fe composite at applied pressure of 1 MPa

Under the applied pressure of 1 MPa, the higher frictional heat is generated, increasing the rate of surface oxidation and accordingly the rate of tribolayer formation. The presence of high-melting point Fe-rich intermetallics [22] also helps to improve the thermal endurance of the matrix and its resistance against subsurface plastic flow. Under this circumstance, a more stable tribolayer is likely to form over the surface which is capable of higher resistance against sliding wear. Therefore, the relative improvement in the wear behaviour of 1% Fe-containing alloy at the applied pressure of 1 MPa can be explained by overcoming the rate of formation of the tribolayer on the rate at which this layer is removed from the surface by the mechanisms discussed earlier. At the higher Fe contents, however, it seems that the negative effect of higher volume fractions of large b-platelets, again makes the tribolayer unstable.

4 Conclusions

1) Fe-impurity changes the hopper-like morphology of primary Mg2Si particles within Al-15Mg2Si composite to the regular polyhedral shape, refines the pseudo-eutectic matrix, and forms β-Al5FeSi needles in the microstructure.

2) Fe-impurity increases the composite hardness, but its effect on the tensile properties depends on its content. The presence of Fe up to about 0.5% improves the UTS and elongation by almost 6% and 18%, respectively. Further addition of Fe up to 2%, however, decreases the tensile properties.

3) Despite the positive impact on hardness, Fe adversely affects the sliding wear resistance of Al-15Mg2Si composite. This negative impact can be attributed to the formation of brittle β-Al5FeSi compounds that facilitate surface/subsurface micro- cracking and make the tribolayer unstable.

4) The dominant wear mechanisms for the base and Fe-containing composites were identified as delamination and abrasive wear of the tribolayer under all applied pressure conditions.

References

[1] SRIVASTAVA A, DIXIT A R, TIWARI S. A review on fabrication and characterization of aluminium metal matrix composite (AMMC) [J]. International Journal of Advance Research and Innovation, 2014, 2: 516-521.

[2] TJONG S H, MA Z. Microstructure and mechanical characteristics of in-situ metal matrix composites [J]. Materials Science and Engineering R, 2000, 29: 49-113.

[3] ZHANG J, FAN Z, WANG Y Q, ZHOU B. Equilibrium pseudo-binary Al-Mg2Si phase diagram [J]. Materials Science and Engineering A, 2001, 17: 494-496.

[4] HUANG Z, WANG K, ZHANG Z, LI B, XUE H, YANG D. Effects of Mg content on primary Mg2Si phase in hypereutectic Al-Si alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3197-3203.

[5] LI C, WU Y, LI H, LIU X. Microstructural formation in hypereutectic Al-Mg2Si with extra Si [J]. Journal of Alloys and Compounds, 2011, 477: 212-216.

[6] MONDOLFO L F. Aluminium alloys: Structure and properties [M]. London-Boston: Butterworth, 1976.

[7] ZHANG J, ZHAO Y, XU X, LIU X. Effect of ultrasonic on morphology of primary Mg2Si in in-situ Mg2Si/Al composite [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2852-2856.

[8] BAHRAMI A, RAZAGHIAN A, EMAMY M, KHORSHIDI R. The effect of Zr on the microstructure and tensile properties of hot-extruded Al-Mg2Si composite [J]. Materials and Design, 2012, 36: 323-330.

[9] QIN Q D, ZHAO Y G, XIU K, ZHOU W, LIANG Y H. Microstructure evolution of in situ Mg2Si/Al-Si-Cu composite in semisolid remelting processing [J]. Materials Science and Engineering A, 2005, 407: 196-200.

[10] SAGHAFIAN H, SHABESTARI S G, GHONCHEH M H, SAHIHI F. Wear behavior of thixoformed Al-25 wt.% Mg2Si composite produced by slope casting method [J]. Tribology Transactions, 2015, 58: 288-299.

[11] BIAN L, LIANG W, WIE G, ZHANG W, XUE J. Enhanced ductility in an Al-Mg2Siin situcomposite processed by ECAP using a modified BCroute [J]. Materials Science and Engineering A, 2011, 528: 3463-3467.

[12] SAGHAFIAN H, SHABESTARI S G, GHADAMI S, GHONCHEH M H. Effect of iron, manganese and cooling rate on microstructure and dry sliding wear behavior of LM13 aluminum alloy [J]. Tribology Transactions, 2017, 60: 888-901.

[13] MALEKAN A, EMAMY M, RASSIZADEHGHANI J, EMAMI A R. The effect of solution temperature on the microstructure and tensile properties of Al-15 wt.% Mg2Si composite [J]. Materials and Design, 2011, 32: 2701-2709.

[14] QIN Q D, ZHAO Y G, ZHOU W, CONG P J. Effect of phosphorus on microstructure and growth manner of primary Mg2Si crystal in Mg2Si-Al [J]. Materials Science and Engineering A, 2007, 447: 186-191.

[15] REN B, LIU Z, ZHAO R, ZHANG T, LIU Z, WANG M, WENG Y. Effect of Sb on microstructure and mechanical properties of Mg2Si/Al-Si composites [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1367-1373.

[16] HADIAN R, EMAMY M, CAMPBELL J. Modification of cast Al-Mg2Si metal matrix composite by Li [J]. Metallurgical and Materials Transactions B, 2009, 40: 822-832.

[17] NORDIN N A, FARAHANY S, OURDJINI A, ABU BAKAR T A, HAMZAH E. Refinement of Mg2Si particulate reinforced Al-20%Mg2Si in-situ composite with addition of antimony [J]. Applied Mechanics and Materials, 2014, 663: 271-275.

[18] HU J, TANG C, ZHANG X, DENG Y. Modification of Mg2Si in Mg-Si alloys with neodymium [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 3161-3166.

[19] WU X, ZHANG G, WU F. Influence of Bi addition on microstructure and dry sliding wear behaviors of cast Al-Mg2Si metal matrix composite [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 1532-1542.

[20] JAFARI NODOOSHAN H R, LIU W, WU G, BAHRAMI A, PECH-CANUL M I, EMAMY M. Mechanical and tribological characterization of Al-Mg2Si composites after yttrium addition and heat treatment [J]. Journal of Materials Engineering and Performance, 2014, 23: 1146-1156.

[21] TAYLOR J A. Iron-containing intermetallic phases in Al-Si based casting alloys [J]. Procedia Materials Science, 2012, 1: 19-33.

[22] BELOV N A, AKSENOV A A, ESKIN D G. Iron in aluminium alloys: Impurity and alloying element [M]. Milton Park: Taylor and Francis, 2002.

[23] DINNIS C M, TAYLOR J A, DAHLE A K. As-cast morphology of iron-intermetallics in Al-Si foundry alloys [J]. Scripta Materialia, 2005, 53: 955-958.

[24] EMAMY M, EMAMI A R, KHORSHIDI R, GHORBANI M R. The effect of Fe-rich intermetallics on the microstructure, hardness and tensile properties of Al-Mg2Si die-cast composite [J]. Materials and Design, 2013, 46: 881-888.

[25] CAO X, CAMPBELL J. The solidification characteristics of Fe-rich intermetallics in Al-11.5Si-0.4Mg cast alloys [J]. Metallurgical and Materials Transactions A, 2004, 35: 1425-1434.

[26] TAGHIABADI R, GHASEMI H M, SHABESTARI S G. Effect of iron-rich intermetallics on the sliding wear behavior of Al-Si alloys [J]. Materials Science and Engineering A, 2008, 490: 162-170.

[27] ZHANG J, FAN Z, WANG Y Q, ZHOU B L. Microstructural development of Al-15wt.%Mg2Si in situ composite with mischmetal addition [J]. Materials Science and Engineering A, 2000, 281: 104-112.

[28] ZHAI Y, LIU C, WANG K, ZOU M, XIE Y. Characteristics of two Al based functionally gradient composites reinforced by primary Si particles and Si/in situ Mg2Si particles in centrifugal casting [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 362-370.

[29] KATO K. Wear in relation to friction-A review [J]. Wear, 2000, 241: 151-157.

[30] EBRAHIMZADEH I, ASHRAFIZADEH F. The influence of temperature on the frictional behavior of duplex-coated die steel rubbing against forging brass [J]. Journal of Materials Engineering and Performance, 2015, 24: 529-535.

[31] RABINOWICZ E. Friction fluctuations, fundamentals of friction: Macroscopic and microscopic processes [M]. Netherland: Springer Science and Business Media, 1992.

A. NADIM1, R. TAGHIABADI1, A. RAZAGHIAN1, M. T. NOGHANI1, M. H. GHONCHEH2

1. Department of Materials Science and Ceramic Engineering, Imam Khomeini International University, Qazvin, Iran;

2. School of Metallurgy and Materials Engineering, Iran University of Science and Technology, Tehran, Iran

摘 要:研究了Fe杂质(0.2%~2%,质量分数)对Al-15Mg2Si复合材料的显微组织、干滑动磨损和摩擦性能的影响。摩擦实验采用销盘式试验机,压力分别为 0.25、0.5和1 MPa,固定滑动速度为0.13 m/s。结果显示,Fe 使初始Mg2Si颗粒从不规则枝晶状转变为多面体形状的较小颗粒,细化伪共晶结构,并导致基体中形成硬质相β-Al5FeSi片晶。尽管这些显微组织的变化提高了复合材料的硬度,但其抗干滑动磨损的能力却受到了损害。磨损表面、磨屑和下表层的SEM 结果证实了β相对摩擦学性能的不利影响。β相颗粒较易断裂,从而降低基体抗滑动应力的能力,造成摩擦层的不稳定,使其易剥离,形成大的剥落碎片。摩擦实验结果还表明,Fe降低材料的平均摩擦因数,但增加摩擦因素的波动。

关键词:Al-Mg2Si;原位复合材料;摩擦学;滑动磨损;摩擦

(Edited by Bing YANG)

Corresponding author: R. TAGHIABADI; Tel/Fax: +98-28-33901156; E-mail: taghiabadi@ikiu.ac.ir

DOI: 10.1016/S1003-6326(18)64744-2