Tribological properties of hot-pressed boron carbide ceramic

来源期刊:中国有色金属学报(英文版)2001年第1期

论文作者:吴芳 王零森 张金生 樊毅 刘伯威 高游

文章页码:119 - 122

Key words:boron carbide; friction coefficient; wear; tribochemistry

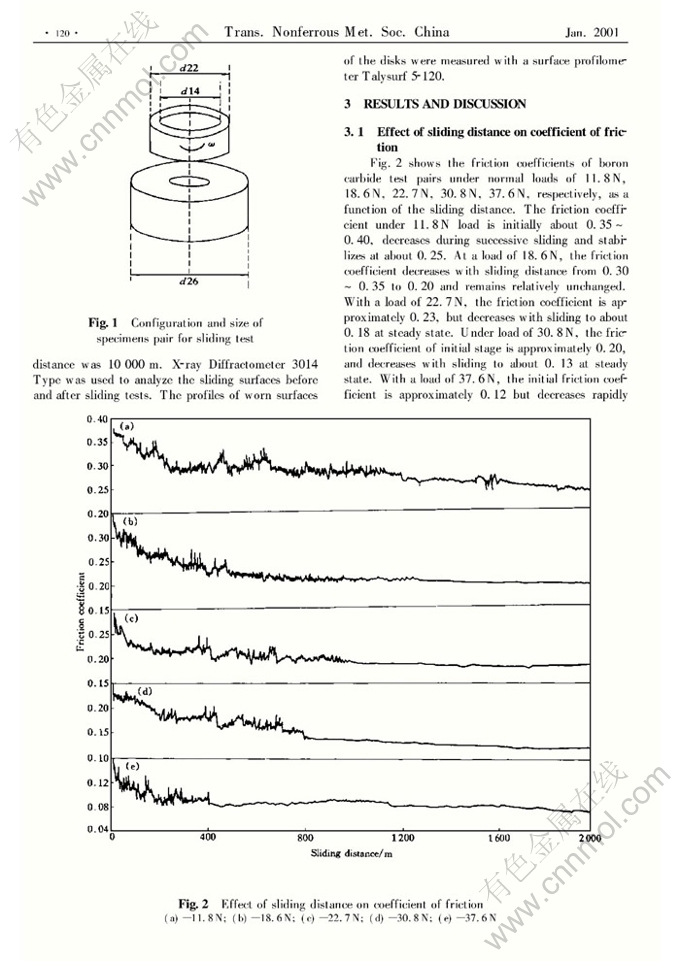

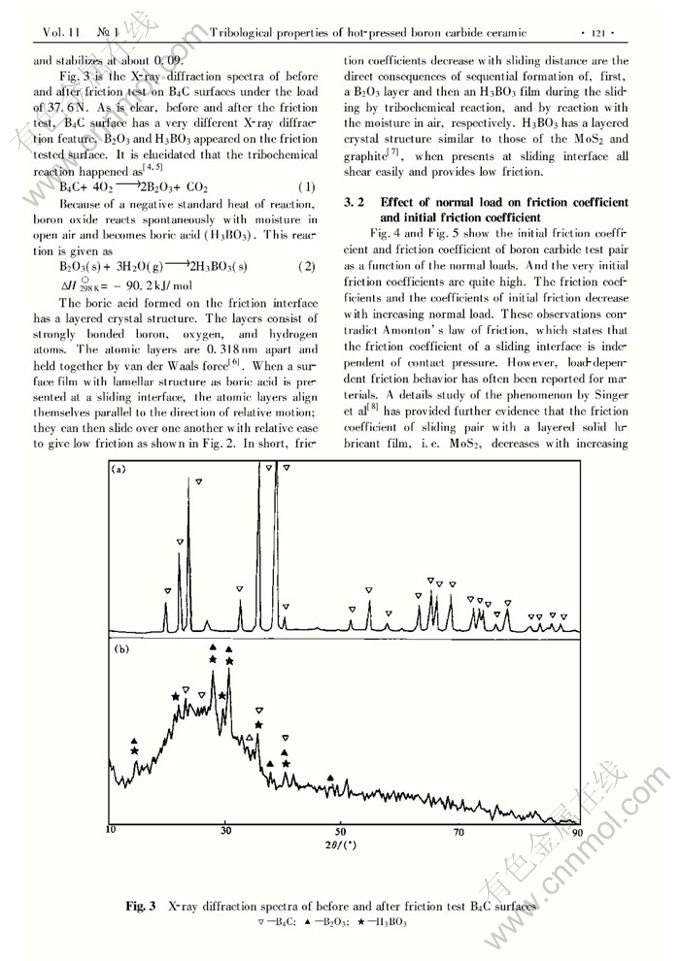

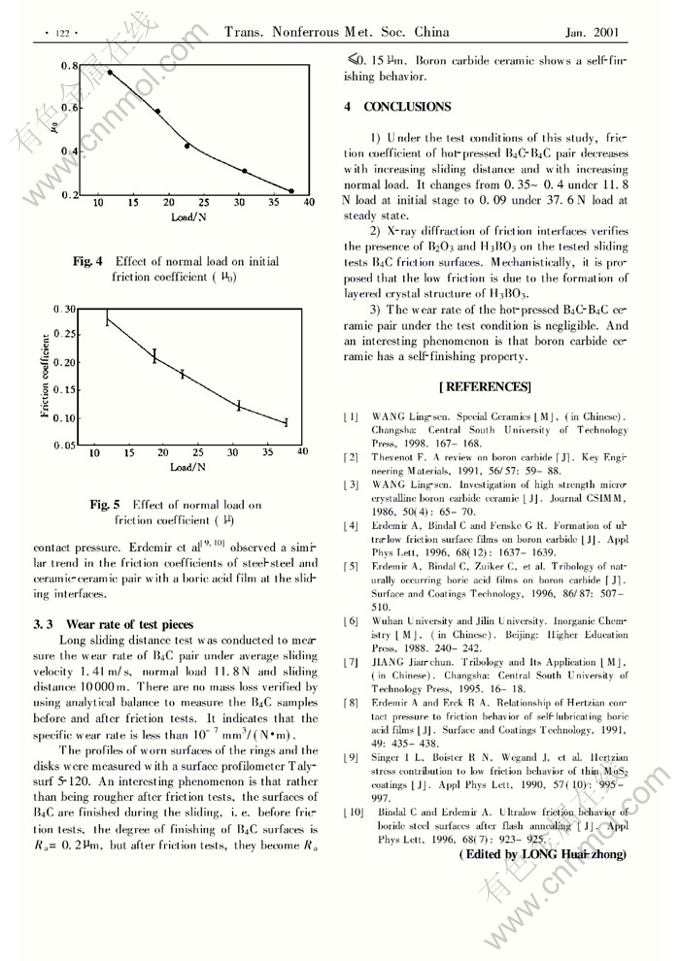

Abstract: Sliding friction experiments were conducted on hot-pressed B4C ceramic under the condition of sliding contact with themselves in air. The tests were run at average sliding velocity of 1.41 m/s and normal forces ranging from 11. 8 N to 37.6 N. The friction coefficients decrease with the increase of sliding distance and the increase of normal load. The lowest friction coefficient is as low as 0.09, compared to 0.35~0.40 as the initial friction coefficient. X-ray diffraction was used to analyze the sliding surface before and after friction tests. The results show that the tribochemical reaction between B4C and O2 produces B2O3, and B2O3 undergoes a secondary chemical reaction with moisture in the air to form H3BO3, which is responsible for the lower friction coefficients. The low-friction mechanism of boric acid is associated with its layered-triclinic-crystal structure. The atoms on each layer are closely packed and strongly bonded to each other, but the layers are widely separated and are held together by van der Waals force. Regarding the wear rate of B4C ceramics used in friction experiments, there is not any wear could be measured by using a surface profilometer.