DOI:10.11817/j.ysxb.1004.0609.2020-37777

熔融铜渣控温冷凝制备玻璃陶瓷材料研究

高鹏文1,胡建杭1, 2*,刘慧利1,王 冲3,李东波3,王 华2

(1.昆明理工大学 冶金节能减排教育部工程研究中心,云南 昆明 650093;

2.冶金化工节能环保技术国家地方联合工程研究中心,云南 昆明 650093;

3.云南铜业股份有限公司,云南 昆明 650000)

摘 要: 为了高效资源化利用铜火法冶炼过程的铜熔渣固体废弃物,本文研究了直接熔融调控+控温冷凝注模成型制备陶瓷材料的影响因素。研究得出:直接熔融炭热还原分离出铜熔渣中部分有价金属铁、并有效控制熔渣中的组分比例为熔渣陶瓷化提供了原料的基础条件,控温冷却能有效控制熔渣冷凝过程中的晶粒生长和晶粒化程度。控温冷却的速率和程序为:先以1~10 ℃/s的冷却速率快速冷却至退火温度500 ℃保温2 h,后以10 ℃/min的升温速率升温至最佳晶化温度900 ℃保温5 h,随炉温冷却至室温制得成型玻璃陶瓷;制备的成型玻璃陶瓷结构致密且平整度良好,抗弯强度可达42.5 MPa,抗压强度达到165.8 MPa。

关键词: 铜熔渣;炭热还原;控温冷凝;晶化

中图分类号: TQ174.9 文献标识码: A

铜渣是铜冶金行业中的一种主要的固体废弃物,组成极为复杂且综合利用率低[1-3]。以每产1 t铜副产2.2~3 t铜渣计算[4],2018年全国铜渣排放量近2000万t。

过去,这些铜渣通常用于制造普通水泥、铺路、制砖等;如Al-Jabri等[5]研究了利用铜渣作为细集料对水泥砂浆和混凝土性能的影响,Shi等[6]研究了铜渣在水泥和混凝土中的应用,可以减少铜渣的处置成本,并有助于保护环境,但利用技术水平相对较低。而玻璃陶瓷[7]作为一种高附加值的产品,不仅具有机械强度高、耐磨损等优点,而且具有利用固体废弃物作为生产原料的可能性。在过去的几十年里,许多类型的工业废料[8-14] (如钢渣、铝渣等),已经被研究用于制备玻璃陶瓷,而利用铜熔渣直接浇铸制备成型玻璃陶瓷没有得到很好的应用研究。

利用铜熔渣直接浇铸制造成型玻璃陶瓷不仅有利于减少工业废渣的排放、节约大量能源(高温熔融渣温度一般在1300~1450 ℃左右,其每公斤熔融渣所携带的余热在1455~1769 KJ左右[15] ),同时省去了固态铜渣所需要的粉碎作业。本研究以云南某冶炼厂铜熔渣尾渣为原料,探讨其作为成型玻璃陶瓷原料的可能性;研究了富铁矿渣玻璃陶瓷的晶化特性和性能,确定了样品的组成和热处理工艺条件,制备了能耗低、尾矿利用率高的成型玻璃陶瓷。、

1 实验

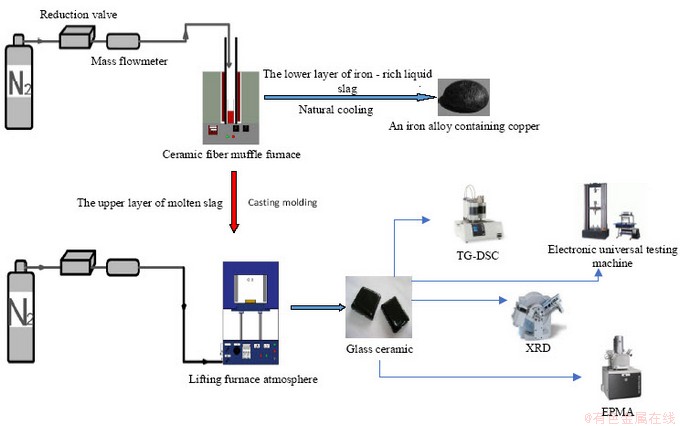

本研究利用铜熔融渣直接浇铸制备成型玻璃陶瓷的实验流程如图1所示。

图1 实验流程图

Fig. 1 Experiment flow chart

1.1 实验原料

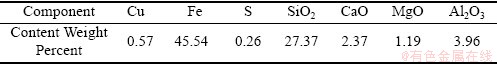

实验所用的铜熔渣尾渣为云南某冶炼厂提供,物理形貌为灰黑色固体颗粒,密度为2.7 g/cm3,粒度约100~20目(150~830 μm)。在常温下将其碾磨至200目(75 μm)进行化学分析,基本组分见表1。

表1 铜渣的主要化学成分(wt %)

Table 1 The main chemical composition of copper slag(wt %)

实验所用的CaO为阿拉丁试剂网所购买的分析纯试剂,灼烧后含量大于98%(ω)。熔融还原沉降过程中所用的还原剂为褐煤粉;该褐煤粉的固定碳含量为39.02%(ω),挥发分含量为41.62%(ω),水分含量为13.15%(ω),灰分含量为6.21%(ω),全硫含量为0.19%(ω)。

1.2 样品制备

将铜熔渣尾渣和CaO置于105 ℃的电热鼓风干燥箱中恒温干燥10小时,后将干燥过的铜熔渣尾渣和CaO以及褐煤粉分别用上海精密科学仪器有限公司生产的型号YP3001N电子天平称量100、15和30 g待用。为模拟熔融铜渣直接注模、快速冷凝成型的方法制得玻璃态陶瓷材料,将事先干燥并称量好的100 g铜渣加入到Φ70×100的刚玉坩埚中并置于型号SXW-5-17的陶瓷纤维炉中以5 ℃/min的升温速率升温至1400 ℃保温60 min;后将15 g CaO从炉膛顶部开口处加入到熔融铜渣中用于调控渣型与炉渣成分,并以100 ml/min的流速向炉膛内通入氮气;30 min后再将30 g褐煤从炉膛顶部开口处加入到熔融态铜渣中作为铁离子的还原剂反应沉降2 h,使部分铁与炉渣分离,期间陶瓷纤维炉保温温度1400 ℃保持恒定(考虑到还原反应的可能性、熔点和最终渣的粘度,还原温度可设置为1400 ℃[2,4] )。

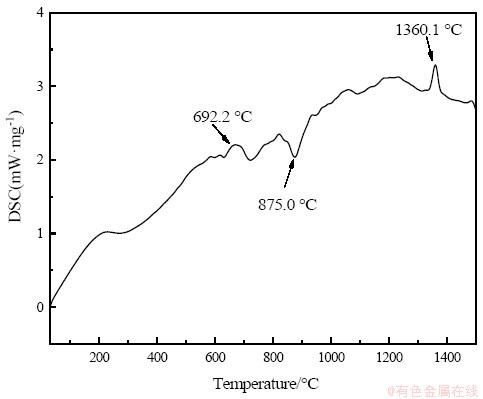

同时将不锈钢模具置于型号为TCSJ1700-2020的气氛升降炉中以10 ℃/min的速率升温至500 ℃保温。熔融铜渣反应沉降结束后,将刚玉坩埚用坩埚钳迅速从高温炉膛内取出后将熔融态铜渣上层液倒入事先于500 ℃预热的不锈钢模具中并置于升降式气氛炉中于500 ℃保温2 h后随炉温冷却至室温得到玻璃态陶瓷材料。对所得玻璃态材料进行了元素分析,主要元素的重量百分比如表2所示。

表2 材料的元素组成(wt %)

Table 2 The elemental composition of a material(wt %)

1.3 分析表征

采用同步热分析仪TG-DSC (德国耐驰 STA449F3)测定了玻璃态陶瓷材料的玻璃化转变温度(Tg)和结晶温度(Tc);具体方法为将所得玻璃态陶瓷材料用磨矿机碾磨3 min至粉末状,随后取15 mg粉末样品(50 μm以下)作DSC分析,这些样品被放置在氧化铝坩埚中,在氮气气氛下,样品升温速率为10 ℃/min,测试温度范围为30~1500 ℃。同时,利用X射线粉末衍射仪(荷兰帕纳科 X'Pert PRO MPD)对样品的结晶相进行了研究;测试范围为10 °到90 °,扫描速度为2 °/min,通过与PCPDF标准卡匹配强峰的峰位置来确定晶体的相。用电子探针仪(日本电子JXA-8230)对陶瓷材料进行了微观形貌分析;具体方法为先将样品抛光到表面1 mm以下,喷碳后,用导电胶粘在电子探针样品台上,晶体形貌清晰可见。样品的抗压强度和抗弯强度的测定方法分别参考了国家标准GB/T 4740-1999和GB/T 4741-1999,采用电子万能试验机(上海新三思CMT4202)分别进行了抗压强度和三点抗弯强度测试。

2 结果与讨论

2.1 热分析曲线

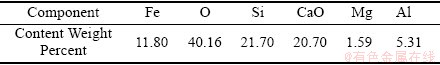

实验所得玻璃态陶瓷材料的DSC曲线如图2所示,其中有两个吸热峰和一个放热峰。第一个吸热峰出现在692.2 ℃(Tg),这是因为材料发生了玻璃化转变。在对玻璃态材料进行晶化热处理时,由于成核过程是新相的一个产生过程,由结晶学理论可知,在一个系统中,当一个新的相形成时,需要提供一定的能量,在热力学上表现为一个吸热过程[16-17]。第二个吸热峰出现在1360.1 ℃(Tm),这是由于玻璃熔化造成的。主要放热峰在875.0 ℃时达到最大,这是由于结晶相的形成引起的,因为结晶过程是一个从不稳定状态到稳定状态的转化过程,是一个放热的过程。因此,结晶温度范围可以选择在850~950 ℃范围内。

图2 玻璃态材料的DSC曲线

Fig. 2 DSC curve of glassy-state materials

2.2 晶化热处理温度对样品结晶的影响

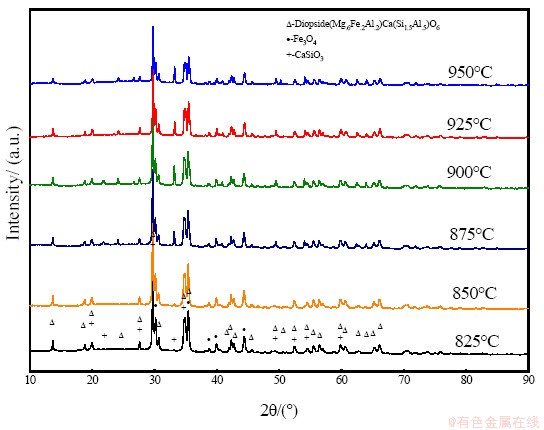

富铁矿渣玻璃陶瓷中,磁铁矿的成核速度非常快,可以在晶化热处理升温的过程中完成。如果再对材料进行进一步的形核热处理,一方面,如果形核温度过高,磁铁矿晶核可能会迅速成长为粗大的晶粒;另一方面,硅灰石晶核的形成会影响磁铁矿晶核的分布。因此,核化不利于磁铁矿晶相的生长;故无需在核化温度段进行一定时间的保温便可形核。硅灰石的核化速度较慢,需要在适宜的温度下保温一定的时间完成,但是硅灰石相可在磁铁矿晶核上生长,故无需添加晶核剂便可制备出铜尾矿渣玻璃陶瓷。为了充分研究晶化温度对铜尾矿渣玻璃陶瓷晶相含量、显微结构的影响,在825~950 ℃范围内以25 ℃为温度梯度进行了6组不同晶化温度的实验,保温时间均为3 h,升温速率均为10 ℃/min。

图3为不同晶化温度下保温3 h的样品XRD衍射图谱;可以看出,在这6组样品中,透辉石相(Mg.6Fe.2Al.2CaSi1.5Al.5O6)均被鉴定为主要的晶相。可见,在较宽的晶化热处理温度范围内均可得到透辉石相玻璃陶瓷,而透辉石相通常是矿渣玻璃陶瓷的理想相,这有利于工业化生产(透辉石基玻璃陶瓷具有良好的性能、相对简单的熔炼和陶瓷化条件以及广阔的应用前景[13])。在晶化温度为825 ℃和850 ℃时,玻璃陶瓷的两个主要的相为透辉石相和磁铁矿相(Fe3O4);随着晶化温度的提升,玻璃陶瓷中的晶相也发生了变化,在晶化热处理温度为875 ℃及以上时出现了硅灰石相(CaSiO3)。由于以磁铁矿为主晶相的玻璃陶瓷的各项物化性能均不如以硅灰石为主晶相的玻璃陶瓷[2,4,14],所以在晶化热处理的过程中应该尽量多的在磁铁矿晶核表面析出硅灰石相。

图3 不同晶化温度下的样品XRD图谱

Fig. 3 XRD mapping of samples at different crystallization temperature

同时,通过对比晶化温度为875~950 ℃这4个样品的XRD图谱,可以看出,在晶化温度为900 ℃时,硅灰石相衍射峰强度相对较高,结晶程度较好,在此温度下进行晶化热处理有利于提高陶瓷材料的综合性能。

当晶粒尺寸很小(约1~100 nm)时,由于晶粒尺寸的细小可以引起衍射线的宽化,衍射线半高峰处的线宽度B与晶粒尺寸d的关系为(Scherrer公式):d=0.89γ/Bcosθ(γ取0.154 nm)。通过Scherrer公式计算,825~950 ℃晶化温度下保温3 h后晶粒的平均粒度分别为79.3 nm、78.6 nm、49.4 nm、45.6 nm、44.7 nm、42.9 nm;由于晶粒的平均尺寸远小于可见光的波长(380~780nm),该玻璃陶瓷材料也具有一定的透光性。

2.3 晶化热处理时间对样品结晶的影响

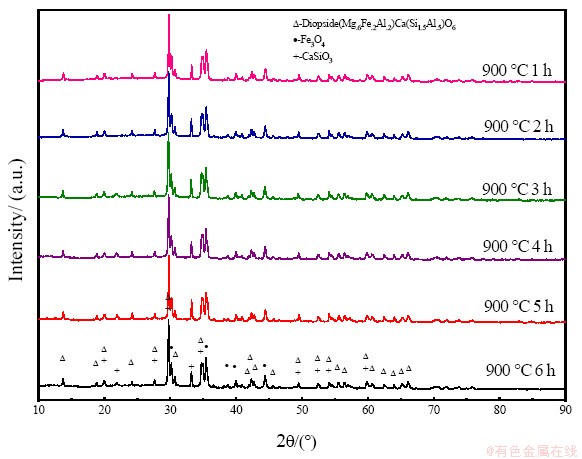

通过上一小节的分析,得到最佳晶化温度为900 ℃,而样品的性能与其内部晶相结构有密不可分的关系[18];在最佳晶化温度为900 ℃的条件下,通过改变晶化热处理时间,分别晶化热处理1、2、3、4、5和6 h,以探究不同晶化热处理时间对样品结晶的影响。不同晶化热处理时间的样品XRD衍射图谱如图4所示。

图4 晶化温度为900℃条件下不同晶化热处理时间的样品XRD图谱

Fig.4 XRD mapping of samples in different crystallization heat treatment time at 900℃

由图4可知,随着晶化热处理时间的延长,玻璃陶瓷的晶相种类没有发生变化,但是衍射峰强度有所改变,说明晶化程度有所改变;通过对比,发现晶化5 h的样品硅灰石相衍射峰较强;晶化6 h的样品较晶化5 h的样品,其它相的衍射峰强度几乎没有发生变化,硅灰石相衍射峰强度反而有所降低,说明当晶化温度由 5 h再延长时会影响硅灰石相晶体的析出,对于促进玻璃体系晶体生长并没有帮助。通过Scherrer公式计算,900 ℃晶化温度下保温1~6 h后晶粒的平均粒度分别为43.0 nm、44.9 nm、45.6 nm、44.7 nm、46.9 nm、44.3 nm;从计算结果来看,900 ℃晶化温度下保温1~6 h后晶粒尺寸的变化很小,同时也再次验证了在适宜的晶化温度下保温时间对主晶相透辉石相的影响很小。

2.4 晶化热处理过程中样品微观形貌的变化

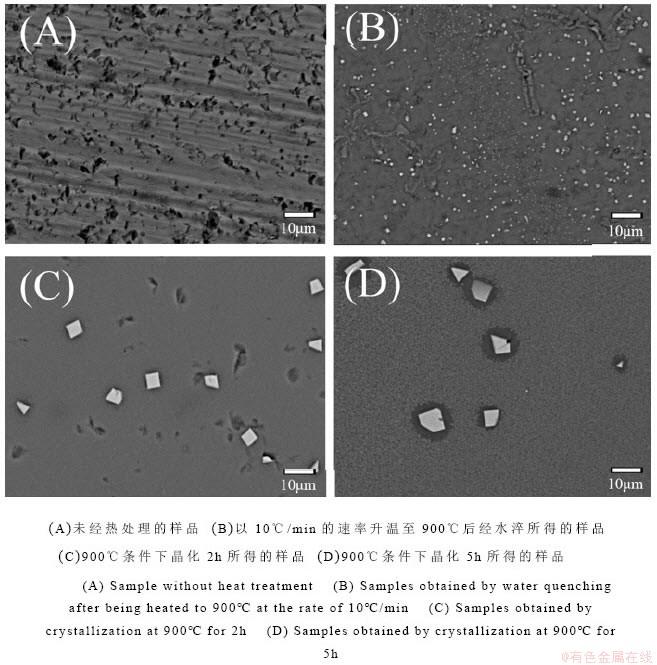

为了进一步研究玻璃态陶瓷材料样品在晶化热处理的过程中晶核形成及晶体长大的过程,选取了四个较为典型的热处理阶段,包括退火后未经晶化热处理、晶化不保温、晶化保温2 h以及晶化保温5 h,分别用字母 A、B、C及D表示。

从图5(A)中可以看到未经晶化热处理的样品没有任何晶体析出,这是由于在样品制备过程中,样品从熔点温度(Tm)有个快速降温至玻璃体转变温度(Tg)以下再于500 ℃保温的过程;因为晶核的形成是一个动力学的过程,需要有一定时间来发生,当降温速率足够快时,晶化形核的过程就来不及发生;同时也表明退火温度(500 ℃)不足以使所得玻璃态材料发生核化。

从图5(B)中可以看出以10 ℃/min的升温速率升温至900 ℃的过程中磁铁矿晶核已经均匀的在玻璃基体中析出,这是由于所制备的玻璃态材料当中铁含量较高,而铁作为一种常用的晶核剂,由于Si-O键的键能大于Fe-O键,铁离子与氧的结合破坏了硅氧四面体的网络结构,形成富铁聚集区,会使晶体更容易成核,所以在玻璃态材料升温至晶化温度的过程当中便能够形成大量的磁铁矿晶核。

图5 晶化热处理过程中不同阶段的样品的EPMA照片

Fig. 5 EPMA photos of samples in different stages during crystallization heat treatment

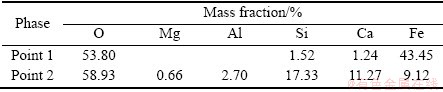

从图5(C)中可以看出在900 ℃下晶化2 h,磁铁矿晶核进一步聚集生长,同时在磁铁矿相周围聚集了一些黑色的晶体,这是由于伴生的硅灰石相晶粒也在磁铁矿相周围均匀生长。图6为试样C的电子探针图像的EDX分析,点1处为白色晶粒,主要由铁和氧元素所构成,结合之前所作的分析可知为磁铁矿;点2处为玻璃基体,主要有O、Si、Ca、Fe、Al、Mg等元素(表3)。

图6 样品C的微观结构和EDX分析

Fig. 6 microstructure and EDX analysis of sample C

表3 样品C在所选相中元素组成的EDX分析(wt %)

Table 3 EDX analysis (wt %) of elemental composition in the selected phases of sample C

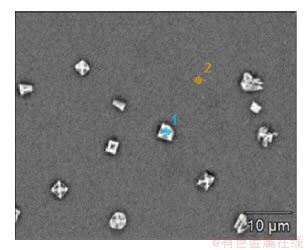

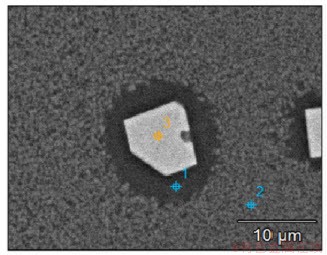

样品D的电子探针图像如图5(D)所示,主要由玻璃相、灰黑色晶相和白色晶粒所构成,为进一步确定这些晶相的元素组成,通过EPMA在玻璃样品D当中随机选取了其中一个晶粒放大并进行能谱分析,结果如图7所示。通过EDX分析可以看出白色晶粒处只有Fe和O元素,并且通过原子质量比可以大约计算出这两个元素所构成的晶粒的化学式为Fe3O4;灰黑色晶相当中的Fe、Al元素较白色晶粒及玻璃相当中的都要少,且主要由O、Si、Ca三种元素构成,经计算与硅灰石(CaSiO3)相的化学式基本吻合(表4)。通过上述分析可以看出,在900 ℃下晶化5 h,磁铁矿晶核得到了更进一步的聚集长大,同时硅灰石相也进一步得到了长大。可见富铁铜尾矿渣玻璃陶瓷的析晶机理为,在材料升温至晶化热处理温度的过程当中,玻璃网络中首先会析出磁铁矿晶核,随着材料在硅灰石相的最佳析晶温度范围下的保温时间继续延长,晶核附近的Ca,Si离子在磁铁矿相周围聚集,硅灰石相最终依托磁铁矿相形成并逐渐生长。

图7 样品D的微观结构和EDX分析

Fig. 7 microstructure and EDX analysis of sample D

表4 样品D在所选相中元素组成的EDX分析(wt %)

Table 4 EDX analysis (wt %) of elemental composition in the selected phases of sample D

2.5 晶化温度对样品力学性能的影响

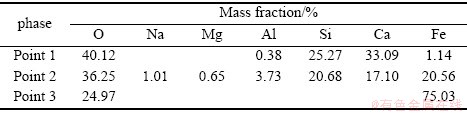

图8为成型玻璃陶瓷样品的抗弯强度和抗压强度随晶化温度的变化曲线。由图可知:在825 ℃至900 ℃区间,随着晶化温度的提高,试样的抗弯强度和抗压强度均有一个较大趋势的增强;温度为900 ℃时,强度最大,抗弯和抗压强度分别为42.5 MP和165.8 MP,随着热处理温度进一步升高,强度均有所下降。

图8 不同晶化温度下玻璃陶瓷材料的力学性能

Fig. 8 Mechanical properties of glass ceramics at different crystallization temperature

结合图3不同晶化温度下的XRD衍射图谱,在825 ℃至875 ℃区间材料的抗弯和抗压强度的增强趋势明显,是因为材料在晶化温度为875 ℃时出现了新的硅灰石相。由于玻璃陶瓷材料中仍然存在着易破碎的玻璃相组分,因此材料的机械强度在很大程度上受到了结晶相的均匀度、体积分数和颗粒大小等影响;对于多晶相的材料来说,材料的断裂破坏大多是沿着晶界发生的,因为晶界要比晶粒的内部弱;同时材料中的晶相含量越高,则其晶界就越长,裂纹的曲线迂回路程也将越长,表现为机械强度相对较高。在875 ℃至900 ℃时,随着晶化温度的提高,硅灰石相的衍射强度有所增强,这说明在此温度范围内随着晶化温度的升高样品内部的硅灰石相含量逐渐增大;说明在875 ℃时硅灰石相晶体已经开始生长,但并没有发育完全,所以此时的抗弯和抗压强度较900 ℃低,到900 ℃时硅灰石晶体已经完全长大,且分布均匀,此时抗弯和抗压强度最强。在900 ℃至950 ℃区间,随着晶化温度的进一步提升,硅灰石相的衍射强度又有所减弱,这可能是由于硅灰石相变驱动力减小,结晶率又趋于下降。

3 结论

1) 采用铜熔渣还原沉铁,控制熔渣组分中的铁氧化物、SiO2和CaO的含量,直接注模、快速冷凝成型的方法可以制得成型的玻璃陶瓷;

2) 富铁矿渣制备的玻璃陶瓷中,磁铁矿的核化可以在晶化热处理升温过程中完成,核化速度较快,所以预核化处理在富铁矿渣制备玻璃陶瓷的晶化过程中无明显作用;

3) 900 ℃作为富铁矿渣制备玻璃陶瓷的晶化温度较为适宜,晶化时间宜5 h左右,可得到抗弯强度优于大理石(抗弯强度为10~30 MPa)、花岗石(抗弯强度为20~35 MPa)等天然石材的玻璃陶瓷。

参考文献

[1] Stoyko G, Nikolay M, Yoanna k, DIANA R,DANIELA K, CHRISTINA T,GALIA G, IVAN P.Technological scheme for copper slag processing[J].International journal of mineral processing,2017,158:1-7.

[2] GUO Zheng-qi,PAN Jian,ZHU De-qing,ZHANG Feng.Green and efficient utilization of waste ferric-oxide desulfurizer to clean waste copper slag by the smelting reduction-sulfurizing process[J]. Journal of cleaner production, 2018, 199(10): 891-899.

[3] BIPRA G, R.K. J, PREMCHAND. Characteristics and utilisation of copper slag—a review[J]. Resources conservation & recycling, 2003, 39(4): 299-313.

[4] FAN Yong, Etsuro Shibata, Atsushi Iizuka, Takashi Nakamura. Review of Iron Recovery and Cleaning of Copper Slag[J]. Shigen-to-Sozai, 2014, 129(5): 177-184.

[5] Al-JABRI K S, Al-SAIDY A H, TAHA R. Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete[J]. Construction & building materials, 2011, 25(2): 933-938.

[6] SHI C, MEYER C, BEHNOOD A. Utilization of copper slag in cement and concrete[J]. Resources, Conservation and recycling, 2008, 52(10): 1115-1120.

[7] J. Deubener, M. Allix, M.J. Davis, A. Duran, T. Hoche, T. Honma, T. Komatsu, S. Krüger, I. Mitra, R. Müller, S. Nakane, M.J. Pascual, J.W.P. Schmelzer, E.D.Zanotto, S.Zhou. Updated definition of glass-ceramics[J]. Journal of non-crystalline solids, 2018, 501: 3-10.

[8] LIU Hong-yu, LU Hong-xia, CHEN De-liang, WANG Hai-long, XU Hong-liang, ZHANG Rui. Preparation and properties of glass–ceramics derived from blast-furnace slag by a ceramic-sintering process[J]. Ceramics international, 2018,35(8): 3181-3184.

[9] CHEN Hao, WU Yi-wen, ZHANG Hong,LI Zhi-cheng. Phase, magnetism and thermal conductivity of glass ceramics from iron ore tailings[J]. Journal of central south university,2014,21(9):3456-3462.

[10] LOPEZ-DELGADO A, TAYIBI H. Can hazardous waste become a raw material? The case study of an aluminium residue:a review[J]. Waste management & research, 2012, 30(5): 474-484.

[11] 史培阳, 张影, 张大勇, 王媛媛,姜茂发. 矿渣微晶玻璃的析晶行为与性能 [J]. 中国有色金属学报, 2007, 17(002): 341-347.

SHI Pei-yang, ZHANG Yi, ZHANG Da-yong,WANG Yuan-yuan, JIANG Mao-fa.Crystallization behavior and properties of glass ceramic of ferrous tailings and slag[J].The Chinese Journal of Nonferrous Metals,2007,17(002): 341-347.

[12] HE Feng, FANG Yu, XIE Jun-Lin, XIE Jun. Fabrication and characterization of glass-ceramics materials developed from steel slag waste[J]. Materials & design, 2012, 42: 198-203.

[13] Yang Zhi-Hong, LIN Qiao, LU Sheng-Chun, HE Yong, LIAO Guang-dong, KE Yi.Effect of CaO/SiO2 ratio on the preparation and crystallization of glass-ceramics from copper slag[J]. Ceramics international, 2014, 40(5): 7297-7305.

[14] Yang Zhi-Hong, LIN Qiao, LU Sheng-Chun, HE Yong, LIAO Guang-dong, KE Yi. Preparation and crystallization of glass–ceramics derived from iron-rich copper slag[J]. Journal of alloys and compounds, 2013, 574: 354-360.

[15] Zhang Kai, Liu Jiang-wen, Liu Wan-chao, YANG Jia-kuan. Preparation of glass–ceramics from molten steel slag using liquid–liquid mixing method[J]. Chemosphere, 2011, 85: 689-692.

[16] 肖汉宁, 邓春明, 彭文琴. 工艺条件对钢铁废渣玻璃陶瓷显微结构的影响[J].湖南大学学报(自然科学版), 2001, 28(1): 32-36.

XIAO Han-ning, DENG Chun-ming, PENG Wen-qin.Effects of processing conditions on the microstructures of glass-ceramics prepared from iron and steel slag[J]. Journal of hunan university, 2001, 28(1): 32-36.

[17] 杨家宽, 王梅, 何归丽, 杨述华, 肖波.FeO-Fe2O3-CaO-SiO2体系铁磁微晶玻璃的磁性及生物活性[J].功能材料, 2004, 35(增刊1): 209-213.

YANG Jia-kuan, YANG Shu-hua, HE Gui-li, WANG Mei, XIAO Bo. Magnetic properties and bioactivity of ferromagnetic glass-ceramics in the system FeO-Fe2O3-CaO-SiO2[J]. Journal of functional materlals contents, 2004, 35(Z1): 209-213.

[18] Manlika K, Kamonpan P, Uraiwan I, SUKUM E. Effects of heat treatment temperature on microstructure and mechanical properties of lithium disilicate-based glass-ceramics[J]. Ceramics international, 2018, 44: 121-124.

Preparation of glass ceramics by temperature-controlled condensation of molten copper slag

Gao Pengwen1, Hu Jianhang1,2*, Liu Huili1, Wang Chong3,Li Dongbo3, Wang Hua2

(1.Engineering Research Center of Metallurgical Energy Conservation & Emission Reduction(Kunming University of Science and Technology), Ministry of Education, Kunming 650093, China;

2. National Engineering Research Center for Metallurgical Chemical Energy Conservation and Environmental Protection Technology, Kunming 650093, China;

3. Yunnan Copper Co., Ltd., Kunming 650000, China)

Abstract: In this paper, the factors directly affecting the production of ceramic materials by melting control + temperature control condensation injection molding was studied in order to efficiently utilize the solid waste resources of copper slag in the process of copper pyrometallurgy. The results show that using directly molten carbon thermal reduction to separate valuable metal iron from copper slag, and effectively controlling the proportion of components in the slag, would provide the basic conditions for slag vitrification; temperature-controlled cooling can effectively control the growth of grain and degree of crystallization in the process of slag condensation. The tempo and steps of temperature controlled cooling were as follows: firstly, the materials were cooled to 500 ℃at the rate of 1-10 ℃/s and maintained for 2 h; the materials were heated to 900 ℃ at the rate of 10 ℃/min and maintained for 5 h, then along with the furnace temperature, the materials were cooled to room temperature and made into glass ceramic materials; The structure of the glass-ceramic materials are compact and smooth, and have a bending strength of 42.5 MPa and a compressive strength of 165.8 MPa.

Key words: copper slag; carbo thermal reduction; temperature-controlled condensation; crystallization

基金项目:国家自然科学基金联合基金项目(U1602272);国家自然科学基金项目(51966007)

Joint Funds of National Natural Science Foundation(U1602272);National Natural Science Foundation(51966007)

收稿日期:2020-07-08;修订日期:2020-09-13

通讯作者:胡建杭,男,教授,博士;电话:13529295096;E-mail: 781136652@qq.com