Influence of processing parameters on deposition characteristics of Inconel 625 superalloy fabricated by laser solid forming

来源期刊:中南大学学报(英文版)2021年第4期

论文作者:林鑫 杨海欧 张书亚 胡云龙 黄卫东

文章页码:1003 - 1014

Key words:single track clads; Inconel 625 alloy; Laves phase; residual stress; laser solid forming

Abstract: A series of single track clads of Inconel 625 alloy were fabricated by laser solid forming. To achieve the high dimensional accuracy and excellent mechanical properties, the effect of processing parameters on the geometry, the formation of Laves phase and the residual stress was investigated. The results show that laser power and scanning speed had a dramatical influence on the width and height of single-track clads. According to the columnar to equiaxed transition curve of Inconel 625, the grain morphology can be predicted during the LSF process. With the increasing laser power and the decreasing scanning speed, the segregation degree of Si, Nb, Mo, the volume fraction and size of Laves phase increased. Vickers indentation was used to demonstrate that optimizing processing parameter can achieve the minimum residual tensile stress.

Cite this article as: YANG Hai-ou, ZHANG Shu-ya, LIN Xin, HU Yun-long, HUANG Wei-dong. Influence of processing parameters on deposition characteristics of Inconel 625 superalloy fabricated by laser solid forming [J]. Journal of Central South University, 2021, 28(4): 1003-1014. DOI: https://doi.org/10.1007/s11771-021-4675-0.

J. Cent. South Univ. (2021) 28: 1003-1014

DOI: https://doi.org/10.1007/s11771-021-4675-0

YANG Hai-ou(杨海欧)1, 2, ZHANG Shu-ya(张书亚)1, 2, LIN Xin(林鑫)1, 2,HU Yun-long(胡云龙)1, 2, HUANG Wei-dong(黄卫东)1, 2

1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University,Xi’an 710072, China;

2. Key Laboratory of Metal High Performance Additive Manufacturing and Innovative Design,

MIIT, Northwestern Polytechnical University, Xi’an 710072, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: A series of single track clads of Inconel 625 alloy were fabricated by laser solid forming. To achieve the high dimensional accuracy and excellent mechanical properties, the effect of processing parameters on the geometry, the formation of Laves phase and the residual stress was investigated. The results show that laser power and scanning speed had a dramatical influence on the width and height of single-track clads. According to the columnar to equiaxed transition curve of Inconel 625, the grain morphology can be predicted during the LSF process. With the increasing laser power and the decreasing scanning speed, the segregation degree of Si, Nb, Mo, the volume fraction and size of Laves phase increased. Vickers indentation was used to demonstrate that optimizing processing parameter can achieve the minimum residual tensile stress.

Key words: single track clads; Inconel 625 alloy; Laves phase; residual stress; laser solid forming

Cite this article as: YANG Hai-ou, ZHANG Shu-ya, LIN Xin, HU Yun-long, HUANG Wei-dong. Influence of processing parameters on deposition characteristics of Inconel 625 superalloy fabricated by laser solid forming [J]. Journal of Central South University, 2021, 28(4): 1003-1014. DOI: https://doi.org/10.1007/s11771-021-4675-0.

1 Introduction

Inconel 625 alloy is a typical solid-solution-strengthened superalloy, which can be widely used in aerospace, chemical and nuclear industries, due to its excellent corrosion resistance and outstanding comprehensive mechanical properties [1, 2]. However, superalloy products generally require high dimensions and complex configuration, and traditional processing methods limit a wide range of application [3].

Laser solid forming uses a focused laser heat source [4-6] to fabricate component layer-by-layer with rapid cooling and solidification. It can achieve near-net-shape components with excellent performance and high material utilization. Laser solid forming has received extensive attention in aerospace fields [7] due to its unique advantages in material saving, process controlled and parts performance [6]. However, there are still many formation issues in the laser solid forming Inconel625 superalloy. Microcrack is discovered in large- scale products regularly and the cracks are concerned with the second phase. Owing to micro-segregation of the various elements during the laser solid forming (LSF) process, a large amount of Laves phases are formed at the end of the solidification process in the inter-dendritic region. Laves phase is detrimental for Ni-based alloy [8-11] because it is the main channels of crack initiation and propagation [12, 13]. In addition, the cracks are related to the residual stress and deformation in the forming parts due to the difference of thermal expansion coefficient [14]. Residual stress not only has an adverse effect on static load strength, fatigue strength and stress corrosion resistance, but also affects the structure dimension stability and forming precision [14, 15]. Therefore,it is very important to control the precipitation of the second phase and the residual stress in the processing of laser solid forming.

There are two ways to control the morphology of Laves phase in Inconel-625 superalloys, one is modifying the solidification conditions by changing the process parameters and the other is using post-heat treatment to make it dissoluted into the matrix. CHEN et al [16] investigated the effect of base cooling on Laves phase manufactured Inconel-718 in the deposition of water cooling sample (WCS) and air cooling sample (ACS). The results indicated that due to higher cooling rate of WCS, the volume percentage of Laves phase decreased. However, liquation cracking was generated and remained in the heat affected zone (HAZ), which deteriorated the mechanical properties of the clad mostly and with the increasing of cooling rate, the residual stress may induce the formation of cracks when its value exceeded the ultimate tensile strength of the material. HU et al [17] investigated the effect of heat-input on the cracking in LSFed DZ4125 superalloy. They found that the crack rate decreased with the increase of heat input due to the decreasing of reduced thermal stress. But higher heat input will increase the heat-affected zone and deteriorate the mechanical properties of the material. These results suggest that it is feasible for adjusting the process parameters to control the morphology of Laves phase.

Heat treatment is a typical way to modify the Laves phase and residual stress. ZHANG et al [18] obtained the effect of the temperature and time on size and contents of Laves phase during homogenization process. Furthermore, LIU et al [19] investigated the effect of residual stress on the recrystallization during solution annealing treatment. These results suggest that the microstructure after the heat treatment is related to the initial microstructure. Therefore, the morphology of Laves phase and residual stress will influence the formulation of the subsequent heat treatment system. Overall, understanding the influence of processing parameters on microstructure and residual stress in laser solid formed Inconel-625 superalloy is very important, because it has a prominent effect on the dimensional accuracy and mechanical properties of the LSFed components. In order to decrease the residual stress and the proportion of Laves phase during LSF process, the cooling rate must be controlled within a certain range. To prevent cracks appearing in the superalloy, more attention has been received on the process parameters.

However, LSF is a complicated process with multiple thermo-mechanical effects [20, 21]. Not only the laser parameters, such as the laser spot diameter or the laser power, or the scanning parameters including the scanning velocity and scanning strategy effect the process, but also the powder properties, such as the flowability or the surface roughness and environmental conditions play an important role in the process. And the single track clads are the foundation of multilayer determining the overlapping rate and increment of Z-axis in the forming process. Moreover, the geometrical shape of the single track clads is an important process characteristic to control the final part of fabrication. Therefore, the influence of processing parameters on geometry features, microstructure and residual stress of single track clads was investigated the in this work.

2 Materials and experimental procedure

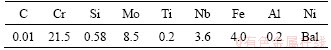

The spherical particle size range of Inconel 625 alloy powder is 50 to 150 μm. In order to homogenize the powder, clean the surface of the sheets and dislodge the absorbed water in the powder, the powders were sieved (100 mesh) and the substrate was sandblasted and then the powders were dried in a vacuum drying furnace at 120 °C for 3 h before experiment respectively. The chemical compositions of the Inconel-625 superalloy are listed in Table 1. The substrate with the dimensions of 900 mm×620 mm×140 mm was employed in this study.

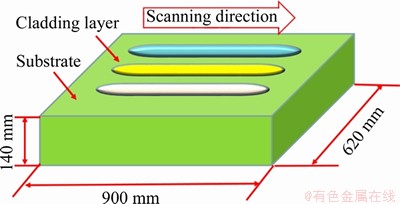

The specimens were mechanically polished and etched for 30 s in a solution of 150 mL H2O+250 mL HCl+2.5 g CrO3. Their microstructures were examined with an OLYMPUS-GX71 optical microscope (OM), TESCAN VEGA II-LMH scanning electron microscope (SEM) and SHIMADZU-1720 electron probe microanalysis technique (EPMA). Figure 1 represents that the clads of 55 mm were cladded on substrate with different processing parameters. Experiments were carried out on the laser solid formed system consisting of a 6 kW continuous-wave semiconductor laser, an inert atmosphere protection chamber, a five-axis numerical control machine tool, a powder feeder and an automatic feeding device.

Table 1 Chemical compositions of studied alloys (wt.%)

Figure 1 Schematic diagram of single-track clads

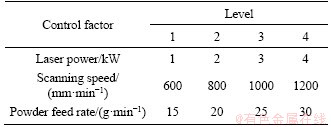

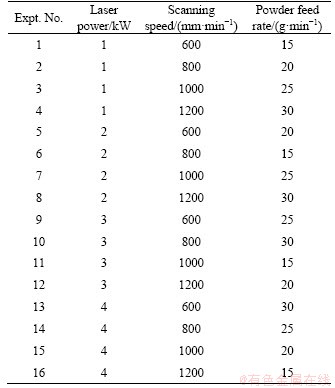

The optimization should be achieved with as little experimental work as possible, so that the orthogonal test was used in this study. Table 2 shows the levels of the control factors and the beam diameter of laser is 5 mm. 16 groups of processing parameters of the single-track clads are shown in Table 3.

Table 2 Control factors and their levels

3 Results and discussion

3.1 Geometry of single-track clads

Single track clad is the unit of LSFed Inconel-625, and the width, height and width/height ratio are the most important characteristics depending on the processing parameters. The width/height ratio cannot be too large to achieve smooth deposition surface. Considering the deposition efficiency, the optimal processing parameters can be chosen when the width/height ratio is greater than but nearly equal to 3 [22].

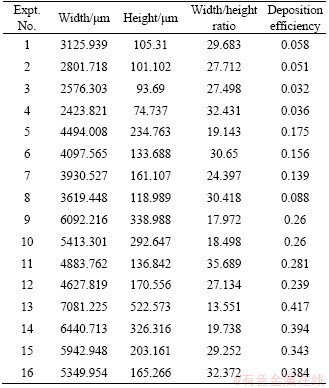

Table 3 Processing parameters for depositing single cladding tracks

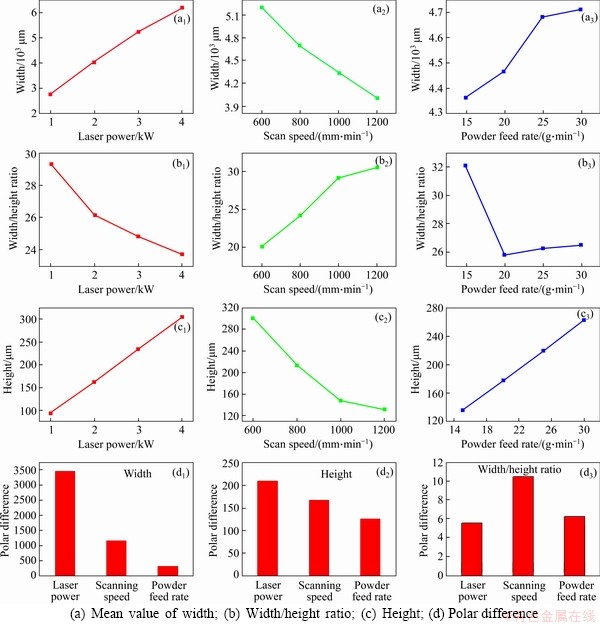

The width, height and width/height ratio of the single-track clads in 16 groups of processing parameters are shown in Table 4. Figure 2 illustrates the results that using standard procedures analyses the width, height and width/height ratio of the single-track clads. Figures 2(a) and (c) show the width and height of single-track clads perform a rise with the increase of laser power and powder feed rate or the decrease of scanning speed. However, the powder feed rate has a larger influence on the height of the single track clad. The influence of processing parameter on the width/height ratio is complicated. As shown in Figure 2(b), the weight/height ratio of a single-track clad rises with the increase of scanning speed or the decrease of laser power, but the weight/height ratio of a single-track clad decreases first and increases later with the increase of powder feed rate.

Table 4 Deposition characteristics of single-track clads

Figure 2 Range analysis results of single-track clads:

The contribution of the laser power, scanning speed and powder feed rate to the width, height and the width/height ratio is 69.26%, 23.80% and 6.90%, 41.61%, 33.20% and 25.19%, 25%, 46.88% and 28.12%, respectively. As shown in Figure 2(d), the significance of degree of processing parameters: for the width, laser power>scanning speed>powder feed rate; for the width/height ratio, scanning speed>laser power≈powder feed rate.

3.2 Microstructural evolution of single-track clads

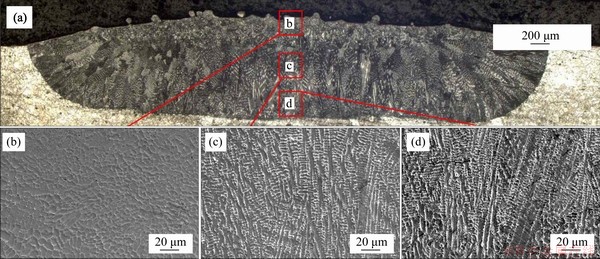

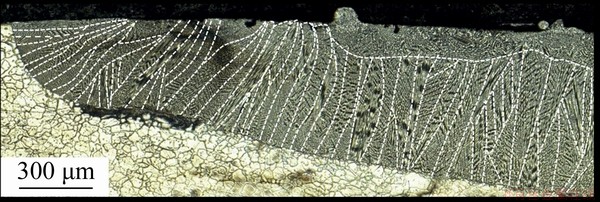

With the change of processing parameters, it is found that the equiaxed grains are formed on the top zone of molten pool with the change of processing parameters. Figure 3 shows the macrostructure in cross-sections (perpendicular to scanning speed) of Inconel-625 alloy.

In Figures 3(c) and (d), it can be observed that the bottom zone of molten pool has a typical epitaxial growth columnar grains. When the direction of temperature gradient gradually parallels to scan direction at the top zone of molten pool, a columnar to equiaxed transition (CET) forms typically shown in Figure 3(b). In order to investigate the relationship of processing parameter and grain growth, it is indispensable to comprehend CET mechanism during solidification and make sure the CET condition.

It can be found that the microstructure in the molten pool is essentially composed of elongated dendrites with different growth directions except the top zone from Figure 3(a). The microstructure is very fine and homogenous due to the high temperature gradient and solidification velocity.

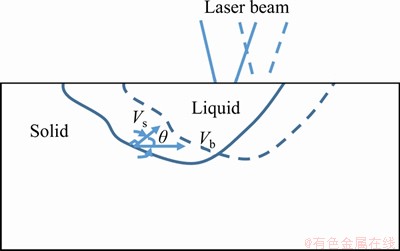

In general, the direction of the maximum temperature gradient is the normal direction Vs of the liquid-solid interface in the molten pool. As shown in Figure 4, the scanning speeds Vb and Vs satisfy the following relationship (1):

|Vs|=Vb·n=|Vb|cosθ (1)

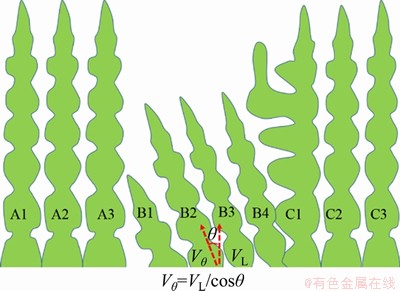

Equation (1) shows the effect of dendrites on the growth, but the influence of the preferred crystallographic directions is not taken into account during dendritic growth due to anisotropy in the crystal on the Vs. Owing to the anisotropy of properties, dendrites will grow in preferred crystallographic directions which is the most similar to heat flow direction. Figure 5 represents the grains growth in vertical-section (parallel to scanning speed). The Walton-Charmers model [23, 24] can describe the competitive growth of crystal grains as shown in Figure 6.

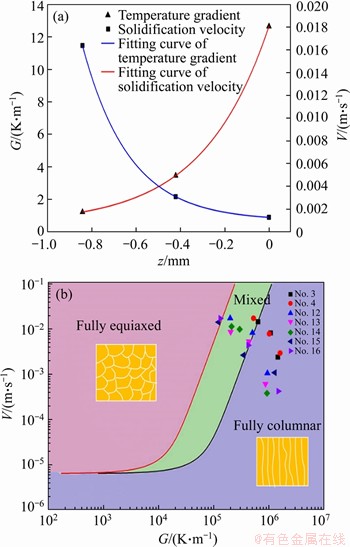

As shown in Figure 6, dendrites A and C grow with the direction of heat flow (Z), the growth direction of dendrites B deviating from the heat flow direction. Compared with other dendrites, the growth space of dendrite C1 is larger, which leads to the secondary dendrite arm more developed. Dendrite B will be eliminated with the solid-liquid interface to move forward, because the dendrite tip velocity of A and C(VL) is greater than dendrite B(Vθ). Integrated with the geometry and temperature distribution of the molten pool, the temperature gradient and the solidification velocity at the front of the solid-liquid interface can be obtained. Figure 7(a) shows the evolution the local solidification conditions of the melt pool along the solidus isotherm. It can be seen that the temperature gradient (G) decreases from the bottom of the molten pool to the top, while the solidification velocity (V) increases.

The temperature gradient and the solidification velocity determine the microstructure in solidification. Based on GAUMANN and KURZ’s modified model [25], the temperature gradient (G) and solidification velocity (R) were calculated. Under the precondition of neglecting the nucleation undercooling, the relationship between temperature gradient and solidification velocity when occurring the CET can be expressed as:

(2)

(2)

where G is the temperature gradient; R is solidification velocity; N0 is the nuclei density (2×1015/m3); a and n are material dependent constants; and is the volume fraction of the equiaxed grains.

is the volume fraction of the equiaxed grains.

Figure 3 Optical microscopy image of the as-deposited sample (a), microstructure of equiaxed dendrites in top region (b), middle zone (c) and bottom zone (d)

Figure 4 Relationship between scanning speed and solidification velocity

Figure 5 Grains growth of Inconel 625

Figure 6 Schematic diagram of Walton-Charmers model

Figure 7 gives the local solidification variables G and V in the melt pool and CET model of Inconel-625. By simulating the temperature field in the molten pool, the temperature gradient and solidification velocity of the bottom, middle and top of the molten pool were measured respectively, and the measurement results were calibrated on the CET curve. It can be indicated that with the temperature gradient decrease continuously and the solidification velocity increases gradually, CET occurs in the top region of molten pool. The model agrees well with the experimental results, so that CET model can describe the grain morphology during the LSF process.

Figure 7 (a) Local solidification variables G and V in melt pool (z=0 corresponding to the surface);(b) Modified microstructure selection map of Inconel 625 alloy by LSF

In the solidification process, the solidification velocity and the temperature gradient at the front of the liquid/solid interface are the two important factors affecting the microstructure. And at different solidification velocity, the temperature gradient is also different, so the cooling rate (G·R) plays an important role to discuss the dendritic microstructure and microscopic segregation [26, 27].

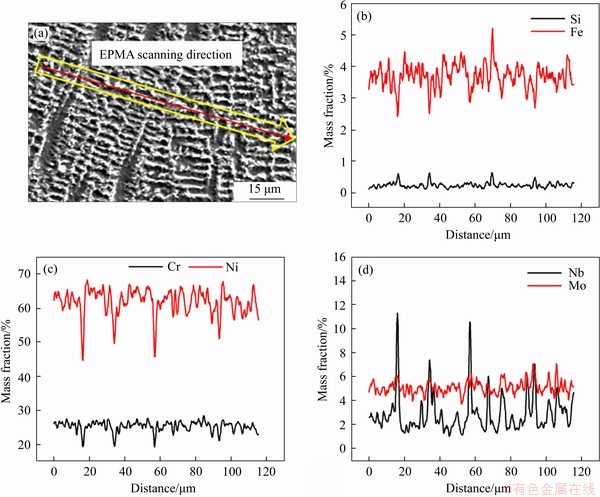

Due to the rapid cooling in the molten pool and solute redistribution during the solidification process during the LSF process, the element cannot fully diffuse between the solid and liquid phases and the solute enrichment or depletion cannot be eliminated at the front of solid/liquid interface. Therefore, micro-segregation is formed during the dendrite solidification. Figure 8 shows the distribution of elements including Cr, Ni, Si, Fe, Nb and Mo in dendritic and interdendritic region measured by EPMA.

It can be manifested that these elements enriching the dendritic region, and the segregation degree of Cr, Fe and Ni from strong to weak is: Fe>Cr>Ni. The values of k of Si, Nb and Mo are less than 1, indicating these elements enriching the inter-dendritic region in the rapid solidification, and the degree of segregation from strong to weak is: Nb>Si>Mo. Figure 8 shows the distribution of the elements was relatively uniform, and the contents of Nb, Mo and Si in the inter-dendritic were significantly higher than that of dendrites, which indicates that the formation of Laves phase is related to the enrichment of elements in this region.

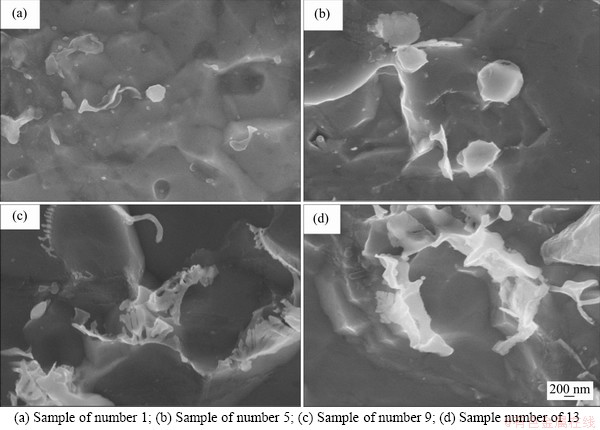

The morphology of the Laves phase in different processing parameters is presented in Figure 9. Owing to micro-segregation of the various elements during the LSF process, a large amount of Laves phases are formed at the end of the solidification process in the inter-dendritic region. The Laves phase often appears in the interdendritic region at the last solidification stage in Nb-bearing superalloys. The morphology and quantity of the Lave phase are attributed to the time and space of growth during the solidification process. Higher cooling rate plays an important role in the dendrite growth and the formation of Laves phase. In that case, it is hard to sufficiently diffuse for some elements. Because of the increasing cooling rate, some elements segregation is effectively mitigated, which makes fewer elements to form Laves phase. On no account can we ignore the changing of morphology from small particles to irregular shape and the quantity of the Laves phase in inter-dendritic region under different processing parameters.

The cooling rates of both processing parameters are higher when the laser power is 1 kW, while with the changing of processing parameters, the cooling rates are decreased quickly and the quantity of Laves phase are increased slightly. The decrease of cooling rate improves the element segregation because it provides longer time for the diffusion of elements. The value of cooling rate and the area proportion of Laves phase is opposite, and the segregation is minimized when the cooling rate is maximum. The diffusion time of the solute element in the solid solution plays a dominant role in solidification. With the cooling rate increasing and the dendrite spacing decreasing, the degree of micro-segregation is decreased. As the cooling rate increases further, the solid/liquid interface movement speed is greater than the speed of solute diffusion, which will formed non-segregation solidification. It is clear that the cooling rate determines the degree of segregation.

Figure 8 Distribution of elements in dendritic and interdendritic region measured by EPMA

Figure 9 Morphology of Laves phase in different sample:

3.3 Vickers micro-hardness and residual stress of single-track clads

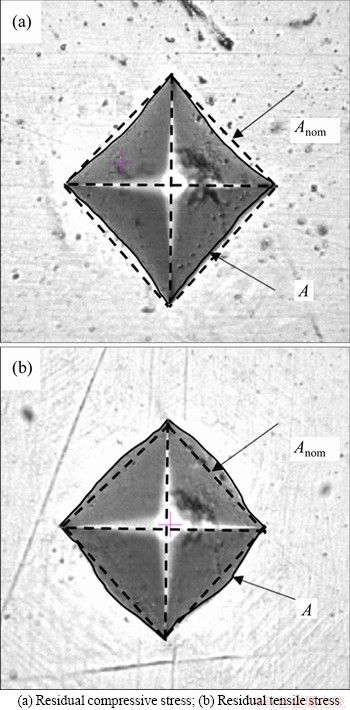

The mobile heat source of LSF is high energy laser beam. On the one hand, the laser rapidly heating and cooling in the material processing achieves the extreme non-equilibrium conditions, which makes the forming part with excellent comprehensive performance. On the other hand, the heterogeneous temperature that is generated by local heat input field will inevitably cause local heating effect, residual stress and deformation in the forming parts. As a kind of internal stress, residual stress not only has an adverse effect on static load strength, fatigue strength and stress corrosion resistance, but also affects the structure dimension stability and forming precision, and even leads to the crack defects [28]. The residual thermal stress existing in the material will induce the transformation of the coarse columnar grains to the smaller equiaxed grains and affect the distribution of the precipitated phase. Therefore, to achieve the superiority of laser solid forming and improve the integrated quality of formed parts, researching the formation mechanism of residual stress in different processing parameters has practical significance. The residual stress is calculated by Vickers indentation method [29], as shown in Figure 10. The microhardness was tested on a LECO Micro/Macro Automatic Hardness Testing System with a load of 200 g and a dwell time of 15 s.

The residual stress and the residual strain follow the following relations:

Figure 10 Schematic diagrams of indentation area:(where A is real projected contact area and Anom is nominal projected contact area)

(3)

(3)

(4)

(4)

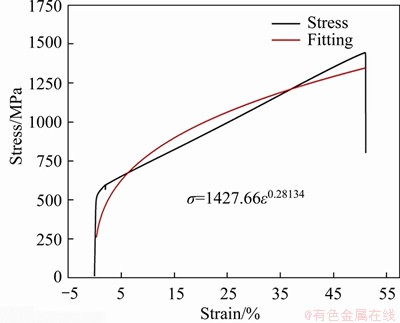

where K is the strength coefficient of the material; n is the strain hardening index of material; C is the material constant depending on the geometry of indentation. The value hardness and the ratio of area can be measured by hardness test, and the strength coefficient of material K and the index of strain hardening n is obtained by the uniaxial stress–strain curve, as shown in Figure 11. Under different processing parameters of Inconel 625 alloy, the Vickers micro-hardness fluctuates between HV 258 and HV 281.

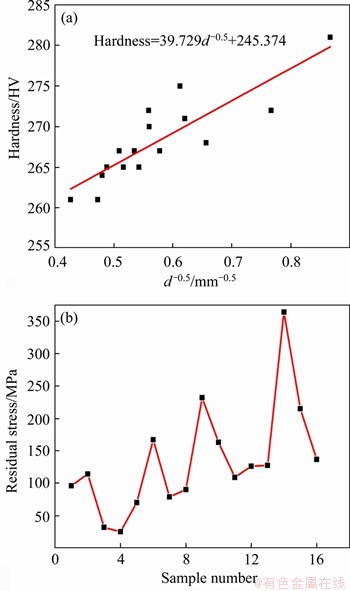

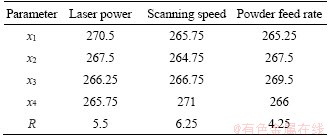

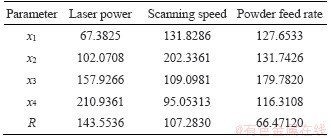

Figure 12(a) shows that the relationship of Vickers micro-hardness and grain size almost match the Hall-Petch equation. Apparently, the major contribution for the improvement of micro-hardness is grain refinement. The micro-hardness is calculated by orthogonal intuitive analysis method, as shown in Table 6, where x1, x2, x3and x4 are the average micro-hardness at different levels, and R is the difference between the maximum and the minimum. To achieve the maximum micro-hardness, the laser power, scanning speed and the powder feed rate is 1 kW, 1200 mm/s and 25 g/min, respectively. It can be seen from Figure 12(b) that the internal residual tensile stress of the different parameters of the processing parameters has a big difference, and the residual stress for the material life and mechanical properties is important, which indicated that selecting the appropriate processing parameters to minimize the damage of residual stress to the parts is important. Table 7 shows the calculation result of residual stress by orthogonal intuitive analysis. To reduce the residual stress, the laser power, scanning speed and the powder feed rate is 1 kW, 1200 mm/s and 30 g/min, respectively.

Figure 11 Tensile stress-strain curves of LSF Inconel 625 alloy

Figure 12 Relationship between Vickers microhardness and grain size (a) and residual stress in different sample (b)

Table 6 Calculation result of micro-hardness (HV) by orthogonal intuitive analysis method

Table 7 Calculation results of residual stress (MPa) by orthogonal intuitive analysis method

4 Conclusions

1) The processing parameters have a significant effect on the width and depth of single-track clads. For the width, the degree of influence of parameters is laser power>scanning speed>powder feed rate; for the width/height ratio, the degree of influence of parameters is scanning speed>laser power≈powder feed rate.

2) Dendrites will grow in preferred crystallographic directions which is the most similar to heat flow direction. The bottom zone of molten pool has a typical epitaxial growth columnar grains. Form CET curve, it can be indicated that the temperature gradient decreases continuously and the solidification velocity increases gradually from the bottom of the melt pool to the top, resulting in a columnar to equiaxed transition.

3) The formation of Laves phase is related to the enrichment of elements. The tendency of the cooling rate and the area proportion of laves phase is opposite.

4) When the laser power, scanning speed and the powder feed rate is 1 kW, 1200 mm/s and 25 g/min respectively, the maximum micro-hardness can be achieved and when the laser power, scanning speed and the powder feed rate is 1 kW, 1200 mm/s and 30 g/min respectively, the minimum residual stress can be achieved.

Contributors

YANG Hai-ou provided the concept and edited the draft of manuscript. ZHANG Shu-ya conducted the literature review and wrote the first draft of the manuscript. HU Yun-long analyzed the calculated results. LIN Xin and HUANG Wei-dong edited the draft of manuscript.

Conflict of interest

YANG Hai-ou, ZHANG Shu-ya, HU Yun-long, LIN Xin and HUANG Wei-dong declare that they have no conflict of interest.

References

[1] PAUL C P, GANESH P, MISHRA S K, BHARGAVA P, NEGI J, NATH A K. Investigating laser rapid manufacturing for Inconel-625 components [J]. Optics & Laser Technology, 2007, 39(4): 800-805. DOI: 10.1016/j.optlastec.2006.01. 008.

[2] SHOEMAKER L E. Alloys 625 and 725: Trends in properties and applications [C]// Superalloys, 718, 625, 706 and Various Derivatives, 2005. TMS, 2005. DOI: 10.7449/2005/ superalloys_2005_409_418.

[3] WANGXQ,GONGXB,CHOUK.Review on powder-bed laser additive manufacturing ofInconel 718 parts [C]// Proceedings of ASME 2015 International Manufacturing Science and Engineering Conference. Charlotte, North Carolina, USA.2015: 8-12.DOI: 10.1115/MSEC2015-9322.

[4] PAUL C P, JAIN A, GANESH P, NEGI J, NATH A K. Laser rapid manufacturing of Colmonoy-6 components [J]. Optics and Lasers in Engineering, 2006, 44(10): 1096-1109. DOI: 10.1016/j.optlaseng.2005.08.005.

[5] HERZOG D, SEYDA V, WYCISK E, EMMELMANN C. Additive manufacturing of metals [J]. Acta Materialia, 2016, 117: 371-392.DOI: 10.1016/j.actamat.2016.07.019.

[6] KHAIRALLAH S A, ANDERSON A T, RUBENCHIK A, KING W E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones [J]. Acta Materialia, 2016, 108: 36-45. DOI: 10.1016/j.actamat.2016.02.014.

[7] ENGLISH C L, TEWARIS K,ABBOTTD H. An overview of Ni base additive fabrication technologies for aerospace applications [C]// 7th International Symposium on Super Alloy 718 and Derivatives, 2010. Pittsburgh, PA: TMS and ASM, 2010,1:399-412.

[8] ZHAO Wei-wei, LIN Xin, LIU Fen-cheng, ZHAO Xiao-ming, CHEN Jing, HUANG Wei-dong. Effect of heat treatment on microstructure and mechanical properties of laser solid forming inconel 718 superalloy [J]. Chinese Journal of Lasers, 2009, 36(12): 3220. DOI: 10.3788/cjl20093612.3220. (in Chinese)

[9] MING Xian-liang, CHEN Jing, TAN Hua, YANG Hai-ou, LIN Xin. Research on persistent fracture mechanism of laser forming repaired GH4169 superalloy [J]. Chinese Journal of Lasers, 2015, 42(4): 0403005. DOI: 10.3788/cjl201542.0403 005. (in Chinese)

[10] SCHIRRA J J, CALESS R H, HATALA R W. The effect of laves phase on the mechanical properties of wrought and cast + HIP Inconel 718 [C]// Proceedings of the Conference on Superalloys 718, 625 and Various Derivatives. Warrendale, PA, The Minerals, Metals and Materials Society, 1991: 375-388.

[11] ZHANG Yao-cheng, LI Zhu-guo, NIE Pu-lin, WU Yi-xiong. Effect of precipitation on the microhardness distribution of diode laser epitaxially deposited IN718 alloy coating [J]. Journal of Materials Science & Technology, 2013, 29(4): 349-352.DOI: 10.1016/j.jmst.2013.01.002.

[12] ONO Y, YURI T, NAGASHIMA N, SUMIYOSHI H, OGATA T, NAGAO N. High-cycle fatigue properties of alloy 718 base metal and electron beam welded joint [J]. Physics Procedia, 2015, 67: 1028-1035. DOI: 10.1016/j.phpro.2015.06.196.

[13] SUI Shang, CHEN Jing, FAN En-xiang, YANG Hai-ou, LIN Xin, HUANG Wei-dong. The influence of Laves phases on the high-cycle fatigue behavior of laser additive manufactured Inconel 718 [J]. Materials Science and Engineering A, 2017, 695: 6-13. DOI: 10.1016/j.msea.2017.03.098.

[14] YANG J, HUANG W D, CHEN J, LIN X. Residual stress on the laser rapid forming metal part [J]. Applied Laser, 2004, 24(1): 5-8.

[15] MAZIASZ P J, PAYZANT E A, SCHLIENGER M E, MCHUGH K M. Residual stresses and microstructure of H13 steel formed by combining two different direct fabrication methods [J]. Scripta Materialia, 1998, 39(10): 1471-1476.

[16] CHEN Yuan, LU Feng-gui, ZHANG Ke, NIE Pu-lin, ELMI HOSSEINI S R, FENG Kai, LI Zhu-guo. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling [J]. Journal of Alloys and Compounds, 2016, 670: 312-321. DOI: 10.1016/j.jallcom.2016.01.250.

[17] HU Y L, LIN X, SONG K, JIANG X Y, YANG H O, HUANG W D. Effect of heat input on cracking in laser solid formed DZ4125 superalloy [J]. Optics & Laser Technology, 2016, 86: 1-7. DOI: 10.1016/j.optlastec.2016.06.008.

[18] ZHANG Mai-cang, CAO Guo-xin, DONG Jian-xin, ZHENG Lei, YAO Zhi-hao. Investigations on dissolution mechanism of laves phase in GH4169 alloy ingot based on classical dynamical model [J]. Acta Metallurgica Sinica, 2013, 49(3): 372-378. (in Chinese)

[19] LIU Fen-cheng, LIN Xin, YANG Gao-lin, SONG Meng-hua, CHEN Jing, HUANG Wei-dong. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy [J]. Optics & Laser Technology, 2011, 43(1): 208-213. DOI: 10.1016/j.optlastec.2010.06.015.

[20] XIAO Hui, LI Si-meng, HAN Xu, MAZUMDER J, SONG Li-jun. Laves phase control of Inconel 718 alloy using quasi-continuous-wave laser additive manufacturing [J]. Materials & Design, 2017, 122: 330-339. DOI: 10.1016/j.matdes.2017. 03.004.

[21] XIAO H, LI S M, XIAO W J, LI Y Q, CHA L M, MAZUMDER J, SONG L J. Effects of laser modes on Nb segregation and Laves phase formation during laser additive manufacturing of nickel-based superalloy [J]. Materials Letters, 2017, 188: 260-262. DOI: 10.1016/j.matlet.2016. 10.118.

[22] PICASSO M, MARSDEN C F, WAGNIERE J D, FRENK A, RAPPAZ M. A simple but realistic model for laser cladding [J]. Metallurgical and Materials Transactions B, 1994, 25(2): 281-291. DOI: 10.1007/BF02665211.

[23] RAPPAZ M, GANDIN C A. Probabilistic modelling of microstructure formation in solidification processes [J]. Acta Metallurgica et Materialia, 1993, 41(2): 345-360. DOI: 10.1016/0956-7151(93)90065-Z.

[24] GANDIN C A, RAPPAZ M. A coupled finite element-cellular automaton model for the prediction of dendritic grain structures in solidification processes [J]. Acta Metallurgica et Materialia, 1994, 42(7): 2233-2246. DOI:10.1016/0956-7151(94)90302-6.

[25] GAUMANN M, BEZENCON C, CANALIS P, KURZ W. Single-crystal laser deposition of superalloys: Processing-microstructure maps [J]. Acta Materialia, 2001, 49(6): 1051-1062. DOI: 10.1016/S1359-6454(00)00367-0.

[26] REN Y M, LIN X, FU X, TAN H, CHEN J, HUANG W D. Microstructure and deformation behavior of Ti-6Al-4V alloy by high-power laser solid forming [J]. Acta Materialia, 2017, 132: 82-95. DOI: 10.1016/j.actamat.2017.04.026.

[27] ZHENG Lei, CHELLALI R, SCHLESIGER R, BAITHER D, SCHMITZ G. Intermediate temperature embrittlement in high-purity Ni and binary Ni(Bi) alloy [J]. Scripta Materialia, 2011, 65(5): 428-431. DOI: 10.1016/j.scriptamat.2011. 05.024.

[28] HU Y L, LIN X, YU X B, XU J J, LEI M, HUANG W D. Effect of Ti addition on cracking and microhardness of Inconel 625 during the laser solid forming processing [J]. Journal of Alloys and Compounds, 2017, 711: 267-277. DOI: 10.1016/ j.jallcom.2017.03.355.

[29] XU Jian-jun, LIN Xin, GUO Peng-fei, DONG Hong-biao, WEN Xiao-li, LI Qiu-ge, XUE Lei, HUANG Wei-dong. The initiation and propagation mechanism of the overlapping zone cracking during laser solid forming of IN-738LC superalloy [J]. Journal of Alloys and Compounds, 2018, 749: 859-870. DOI: 10.1016/j.jallcom.2018.03.366.

(Edited by HE Yun-bin)

中文导读

工艺参数对激光立体成形Inconel 625合金沉积特征的影响

摘要:为达到激光立体成形技术对Inconel 625合金成形的高尺寸精度和力学性能的控制,本文通过单道单层的沉积实验研究工艺参数对熔池几何形状、Laves相的形成和残余应力的影响。结果表明,激光功率和扫描速度对熔道的宽度和高度有较大影响。根据Inconel 625合金的柱状晶―等轴晶转变曲线,可以预测成形过程中的晶粒形貌。随着激光功率的增大和扫描速度的减慢,Si、Nb、Mo等元素的偏析程度增加,Laves相的体积分数和尺寸也随之增大。采用维氏压痕法验证了优化后的工艺参数可以使溶道内的残余拉应力达到最小。

关键词:单道单层;Inconel 625 合金;Laves相;残余应力;激光立体成形

Foundation item: Project(2018YFB1105804) supported by the National Key R&D Program of China; Project(2020-TS-06) supported by the Research Fund of the State Key Laboratory of Solidification Processing (NPU), China

Received date: 2020-12-02; Accepted date: 2021-03-25

Corresponding author: LIN Xin, PhD, Professor; Tel: +86-29-88460510; E-mail: xlin@nwpu.edu.cn; ORCID: https://orcid.org/0000-0002-7491-8928