DOI: 10.11817/j.issn.1672-7207.2018.03.003

超声外场对SiCp/7085复合材料颗粒分布与硬度的影响

王坤1,蒋日鹏2,张立华1,李瑞卿2,李晓谦1

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 中南大学 轻合金研究院,湖南 长沙,410083)

摘要:采用半固态机械搅拌与超声施振的方法制备SiCp/7085复合材料,研究超声施振时间与超声功率对复合材料颗粒分布与布氏硬度的影响。研究结果表明:机械搅拌可实现SiC颗粒与基体的初步混合,但在搅拌过程中易形成颗粒团聚、气体夹杂等缺陷;超声施振后能够有效打散微观颗粒团聚,减少气孔夹杂等缺陷;在本实验条件下,最优超声作用时间为10 min,功率为1 kW;复合材料的布氏硬度变化规律与显微组织呈现一致性,在超声时长为10 min、功率为1 kW工况下,其硬度达到最大值131.7 N/mm2,较未施加超声时增加25.7%。

关键词:超声外场;SiCp;7085复合材料;颗粒团聚;布氏硬度

中图分类号:TG148;TB559 文献标志码:A 文章编号:1672-7207(2018)03-0529-07

Effect of ultrasonic field on particle distribution and hardness of SiCp/7085 composites

WANG Kun1, JIANG Ripeng2, ZHANG Lihua1, LI Ruiqing2, LI Xiaoqian1

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. Light Alloy Institute, Central South University, Changsha 410083, China)

Abstract: SiCp/7085 composite was prepared by semi-solid mixture and ultrasound vibrations method, and the influence of ultrasonic vibration time and power on microstructure and Brinell hardness(HBS) of the composites was studied. The results show that mechanical stirring can realize primary mix of the SiC particles and the matrix, but it is easy to form agglomeration and gas inclusions during the mixing process. Ultrasonic vibration can effectively break up the particle micro-agglomeration, improve defects such as porosity and inclusion, and the optimized time and power in this experimental condition are 10 min and 1 kW, respectively. It renders consistency between hardness and microstructure of the composites. Under work condition of 10 min and 1 kW, the HBS reaches the maximum value 131.7 N/mm2, which is 25.7% higher than that without ultrasonic field.

Key words: ultrasonic field; SiCp; 7085 composites; particle agglomeration; Brinell hardness

随着我国经济快速增长,航空航天和军工得到了迅猛发展,要求其装备结构轻量化、可靠性高、耐久性强和抗损伤容限性能强[1],传统单一材料不能同时满足既具有突出特殊性能又具有稳定性良好的综合性能的要求。颗粒增强铝基复合材料因其具有比强度和比模量高、耐磨性、阻尼性和导热性良好以及热膨胀系数小等优点,已成为实现上述目标的有效手段与技术途径[2-4]。增强体颗粒与基体之间的润湿能力差、增强体颗粒容易吸附气体夹杂、基体密度差异大等造成颗粒加入困难,颗粒在集体中分布不均匀,颗粒团聚成为缺陷源,这制约了颗粒增强铝基复合材料的发展与商业运用[5]。搅拌铸造法是最典型的颗粒增强铝基复合材料的制备方法,但在搅拌过程中产生的漩涡易吸入气体和氧化夹杂,造成复材空洞缺陷以及使气体捕获颗粒形成团聚,严重影响材料的力学性能[6]。近年来,将超声波引入熔体处理,其在熔体中传播产生的一系列非线性效应如超声空化、超声声流、超声热效应等[7]能够在处理熔体过程中分散颗粒,促进润湿[8]。运用超声波处理熔体技术可以制备出颗粒分布均匀、无气孔夹杂的良好复合材料[9],但对超声分散颗粒缺乏定量分析,为此,本文作者从超声空化角度定量分析超声分散颗粒的机制,并探讨不同超声处理时间下复合材料的硬度。

1 实验材料与方法

1.1 实验材料

以航空航天用高强7085铝合金为基体,其成分(质量分数)见表1。市售粒度为0.038 mm的磨料级绿SiC颗粒为增强体。SiC颗粒经过质量分数为5%的氢氟酸洗、超声水洗、1 000 ℃高温焙烧后(颗粒表面生成SiO2层),预热至600 ℃备用。

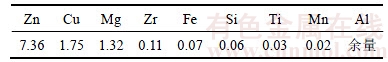

表1 实验用7085铝合金成分表(质量分数)

Table 1 Composition of aluminum alloy 7085 %

1.2 实验方法

将7085铝合金放入电阻坩埚炉中熔炼,待铝块完全融化后,将熔体温度降至625 ℃,同时将预热颗粒与熔体混合(颗粒质量分数为10%),并机械搅拌 5 min,转速为300 r/min。之后迅速升温至700 ℃,通过超声工具杆将超声直接导入熔体中(输出频率为17~22 kHz,插入深度为30 mm)。铸造设备简图见图1。用耐高温石英管将工具头下方30 mm铝熔体中直接吸取并水淬,在Automet250型自动研磨机上经粗磨、精磨、抛光后,在OLYMPUS DSX500光学显微镜下观察金相组织。在不同工况下取钢模试样并水淬至室温,得到长×宽×高为15 mm×15 mm×120 mm的长方条状样,将该试样的1对面粗磨、精磨后,采用HBS-3000型数字显示布氏硬度计测试其硬度。

图1 超声铸造实验装置

Fig. 1 Schematic diagram of ultrasonic casting experimental apparatus

2 实验结果

对SiC/7085复合材料样品金相图片中的SiC颗粒进行统计,将每张金相图片平均分成9个微区域,每个微区域内的SiC颗粒数为zi,并求出单位微区域内SiC颗粒的平均个数 ,则每张金相图片中SiC颗粒数量的相对标准偏差ζ[10]为

,则每张金相图片中SiC颗粒数量的相对标准偏差ζ[10]为

(1)

(1)

ζ 表征不同熔体位置内SiC颗粒数量的分布,其值越小,表明SiC颗粒在每个微区域内的分布数量越平均,但ζ并不能反映SiC颗粒在微区域或整个区域内偏聚的程度,因此,还需对SiC颗粒在复合材料中的偏聚现象进行准确定量分析。

从颗粒之间的最短距离出发,描述其偏聚现象。找到与每个SiC颗粒最近邻的SiC颗粒,并测量2个颗粒之间的距离xi,测量所有SiC颗粒与其最近邻颗粒的距离,求出最短距离的平均值 :

:

(2)

(2)

式中:n为测量的SiC颗粒总数。假设这n个颗粒均匀有序地在区域S中分布,计算颗粒之间的距离为x0,若SiC颗粒非完全均匀分布,则最短距离的平均值 一定小于x0。SiC颗粒分布越均匀,则

一定小于x0。SiC颗粒分布越均匀,则 越接近x0,定义表征颗粒偏聚程度的参数

越接近x0,定义表征颗粒偏聚程度的参数 如下[10]:

如下[10]:

(3)

(3)

由此可见:β越小,SiC颗粒的偏聚程度越小,其在复合材料内的分布均匀性越好。

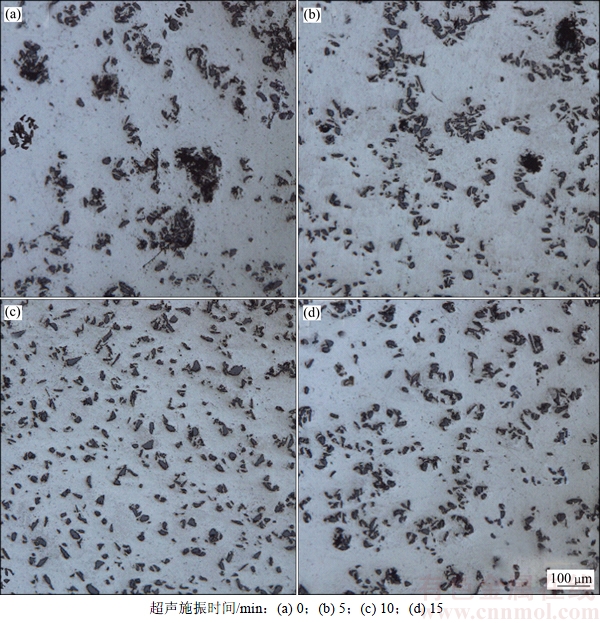

2.1 超声作用时间对颗粒微观分布的影响

图2所示为不同超声施振时间下SiCp/7085复合材料样品的微观组织。从图2(a)可见材料内部存在较多气孔缺陷,且团聚有大量碎小颗粒以及夹杂物在其周围,造成颗粒严重团聚分布不均匀。从图2(b)可见颗粒微观分布不均匀,微区内颗粒含量差异明显,形成局部颗粒团聚与分散均匀现象共存,同时,颗粒团簇中夹杂尺寸较大的气孔。从图2(c)可见微区内熔体颗粒未见明显团聚,整体呈离散状态均匀分布在熔体中,颗粒分散效果良好;此外,复合材料中没有发现气孔以及颗粒、夹杂团聚现象。由图2可知:与超声10 min所制备样品相比,颗粒团聚成簇略加剧,各微区出现轻微的颗粒分布差异,这表明超声施振存在最佳时间,延长的超声施振并不能线性提升复合材料熔体中颗粒分布的均匀程度。

图2 SiCp/7085复合材料的显微组织图像

Fig. 2 Microstructure pictures of SiC p/7085 composites

不同超声作用时间下颗粒分布的微观表征参数见表2。从表2可知:在未经超声施振的样品中,颗粒在微区内含量很不均匀,均匀性参数ζ为25;而随着超声施振时间延长,各微区之间颗粒含量不均匀现象明显减小,当超声施振持续10 min时,均匀性参数ζ低至10;继续施振,均匀性参数ζ小幅度增大。对于颗粒间间距参数β,未施振时,其值为0.93,表明颗粒间团聚严重;超声施振5 min后,β有所降低,但颗粒微观分布改善效果不明显;经过10 min超声施振, β降低到0.42,表明颗粒微观分布得到明显改善;继续延长超声施振,并不能进一步提高颗粒间间距的分散均匀度,其值有所增大。参数ζ和β的变化趋势与金相图中颗粒分布变化趋势一致,这说明所引入的参数具有代表性。

表2 不同施振时间下的微观表征参数

Table 2 Microscopic characterization parameters under different ultrasonic time

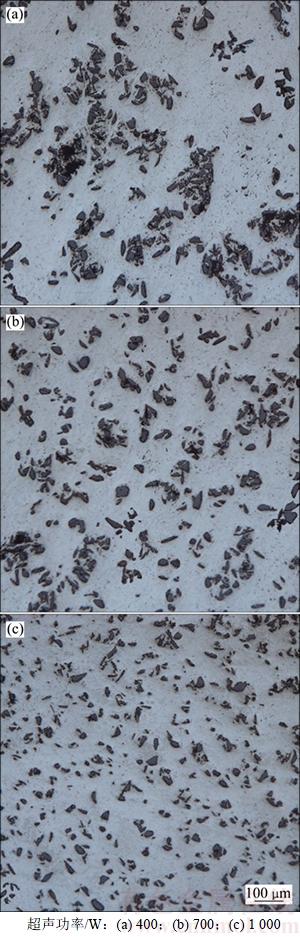

2.2 超声功率对颗粒微观分布的影响

图3所示为不同超声功率(400,700和1 000 W)施振10 min的微观组织。从图3可以看出:在超声功率为400 W时(见图3(a)),基体内夹杂较多的气体等缺陷,颗粒团聚在气体周围,形成了大量的颗粒团聚,基体内的颗粒分布不均明显;当超声功率为700 W时(见图3(b)),微区内颗粒团聚显著减少,同时气孔等缺陷明显减少;随着超声功率增加,当超声功率为1 kW时(见图3(c)),基体内无明显颗粒团聚,呈离散随机状态均匀分布在熔体中,同时未发现气孔、夹杂团聚等。

图3 SiCp/7085复合材料的显微组织图像

Fig. 3 Microstructure pictures of SiCp/7085 composites

在不同超声功率下(施振时间为10 min),颗粒分布的微观表征参数见表3。从表3可知:超声施振功率为400 W所制备样品其均匀性参数ζ为22;随着超声施振功率增加,各微区之间颗粒含量不均匀现象明显减少;当超声施振功率为700 W时,均匀性参数ζ降至12;继续增大施振功率,均匀性参数ζ继续减小至10。对于颗粒间间距参数β,当超声施振功率为400 W时,β为0.91,颗粒间团聚严重;超声功率为700 W时,β降至0.61;继续增大功率,β降低到0.42,颗粒微观分布得到明显改善。

表3 不同超声功率下的微观表征参数

Table 3 Microscopic characterization parameters under different ultrasonic time

2.3 SiCp/7085复合材料的硬度

颗粒在基体中的分布状态直接影响材料的力学性能,若基体中出现颗粒团聚分布不均匀,将导致不同区域内性能差异明显,且颗粒团聚等缺陷在材料塑性变形过程中易成为缺陷源,严重降低复合材料力学性能。因此,硬度能够反映颗粒分布状态。

图4所示为不同超声作用时间下SiCp/7085复合材料硬度分布。从图4可以看出:引入超声施振可明显提高材料硬度;随着超声时间延长,复合材料硬度呈先提高后降低的趋势。

不同施振时长复合材料硬度分布特征见表4。从表4可以看出:随超声时长增加(0 min—5 min—10 min—15 min),复合材料硬度平均值呈现先正相关增大,后在超声施振10 min处出现拐点;硬度的离散程度也是先呈正相关增加,后在超声施振10 min处出现拐点,即超声施振15 min后材料的硬度开始下降并且硬度的分布也出现较大波动,这与颗粒分布变化规律一致。超声施振10 min与未施加超声施振相比,其硬度增大26%,与施振5 min相比增大11%,与施振15 min相比增大3.1%。

图4 不同超声时间下SiCp/7085复合材料硬度分布

Fig. 4 Hardness distribution of SiCp/7085 composites at different ultrasound time

表4 不同超声时间下SiCp/7085复合材料硬度分布特征

Table 4 Characteristic of hardness distribution of SiCp/7085 composites at different ultrasonic time

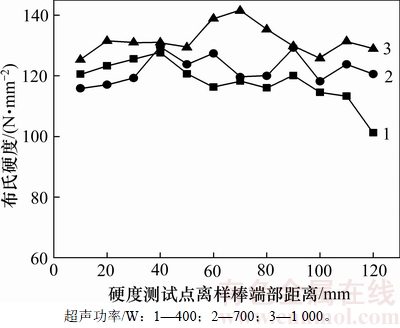

图5所示为不同超声功率下SiCp/7085复合材料硬度分布曲线。从图5可知:超声功率增大能够显著提高材料硬度,硬度与超声功率呈现正相关趋势。

不同超声功率下复合材料硬度分布特征见表5。

图5 不同超声功率下SiCp/7085复合材料硬度分布

Fig. 5 Hardness value distribution of SiCp/7085 composites at different ultrasound powers

从表5可以看出:随着超声功率增加,硬度平均值逐渐增加,同时硬度的波动程度也减小;当超声功率为1 kW时,硬度平均值最大且离散程度最小,这与复合材料显微组织变化呈现一致性;当超声功率为1 kW时,其硬度与功率为400 W时相比增大11%,与功率为700 W时相比增大8%。

表5 不同超声功率下SiCp/7085复合材料硬度分布特征

Table 5 Characteristic of hardness distribution of SiCp/7085 composites at different ultrasonic powers

3 讨论与分析

3.1 超声对颗粒分布的影响

颗粒在熔体中主要受到范德华力、毛细力、超声空化压力、超声声流作用产生液体曳力作用,经过预处理的颗粒表面静电库仑力可忽略不计,使得颗粒黏附团聚的力主要为范德华力Fww和毛细力Fm。其中,范德华力作为颗粒间分子作用力可通过下式计算[11]:

(4)

(4)

式中:Ass为HamaRer常数,Ass=8.86×10-20 [11];r1和r2分别为2个颗粒的半径,r1=r2=18.5 μm;l为颗粒间距离。经计算可得两颗粒间最大范德华力为60.7 mN。

由于存在液体张力等,熔体中颗粒与颗粒之间弯曲表面产生毛细力Fm,其计算公式为[12]

(5)

(5)

式中:θ为接触角,θ=127°; 为接触角θ函数,通常很小;σ为表面张力,σ=0.86 N/m[13]。经计算可得毛细力199.8 μN,由此可知促使颗粒颗粒聚集最大作用力为 60 899.8 μN。由空化泡产生能打破颗粒团簇的最小压力Pmin为

为接触角θ函数,通常很小;σ为表面张力,σ=0.86 N/m[13]。经计算可得毛细力199.8 μN,由此可知促使颗粒颗粒聚集最大作用力为 60 899.8 μN。由空化泡产生能打破颗粒团簇的最小压力Pmin为

×107 Pa (6)

×107 Pa (6)

式中:F为微射流冲击力;Aeffective为颗粒的有效接触面积。

据Rayleigh-Plesset公式[14]建立复合材料熔体中空化泡生长溃灭模型:

(7)

(7)

式中:R和R0分别为空化泡半径和空化泡初始半径;p0为初始压力,取105 Pa;pv和pm分别为空化泡蒸汽压和超声声压幅值;σ=0.86 N/m;K为气体多边指数,因空化泡崩溃时间很短,可假设为绝热崩溃过程,其值为4/3;w为超声波角速度。液体中半径小于100 μm的气泡或者蒸汽泡能形成超声空化泡核,而半径大于100 μm的气泡将因为浮力而上浮逸出[13],故此模型计算采用空化泡初始半径为1 μm与100 μm。经计算可得初始半径为1 μm与和100 μm的空化泡能产生高达7.86×109 Pa和7.23×107 Pa的压力,远大于所需打散颗粒最小压力。当超声在熔体中振动时,产生的高压和微射流既能瞬间打破颗粒的团簇,又能冲刷颗粒,净化其表面,增强与熔体的润湿性,减少熔体排斥推挤颗粒而造成的颗粒成团。同时,夹杂在颗粒之间的气体也在超声作用下净化出熔体,减少了因气体吸附颗粒而形成微观团簇。最终,颗粒微观团簇减少,颗粒分布均匀。

综上可见:超声空化能有效打散颗粒团聚,降低颗粒微观分布不均匀性,还能去除气体以及夹杂物达到净化熔体的效果;过短的超声施振时间不能完全达到分散颗粒和除气除杂的效果;过长的超声施振时间会引入更多的能量,造成微小颗粒热运动增加,从而使颗粒通过团聚到降低体系自由能,加剧颗粒团聚;当超声功率较小时,由于空化作用较弱且作用区域较小,不能有效打散颗粒,同时,除气效果不明显,因此,在本实验条件下,最佳超声参数如下:超声功率为1 kW、施振时间为10 min。

3.2 复合材料硬度分析

增强体加入基体合金中能大幅度提高基体合金硬度,一方面,因为所加入增强体颗粒本身具有高硬度、高熔点等特性,可通过自身高硬度性能使基体压力提高,从而提高复合材料硬度性能;另一方面,由于SiC颗粒与基体的热膨胀性、弹性模量等差异使得颗粒与基体之间结合形成大量位错,同时,SiC颗粒作为外加强化物能增大基体晶格畸变程度,从而提高复合材料抗塑性变形能力[15-17]。然而,SiC颗粒的加入对材料硬度性能的提高程度取决于颗粒在基体中的分布状态以及与熔体结合的程度,若颗粒分布不均匀,则会导致不同区域的硬度差异明显,有些区域甚至在材料塑性变形过程中首先成为缺陷源,严重降低材料力学性能。

本研究中经超声施振工艺制备的SiCp/7085复合材料硬度平均值明显比未经超声施振制备材料的高,表明超声施振对复合材料硬度提高较大。这是由于未经超声施振,基体内颗粒团簇严重,且有气孔、夹杂等缺陷。这些缺陷首先形成材料塑性变形源,降低了材料的硬度。当施振时间较短(5 min)、超声功率较小(400 W和700 W)时,不能有效分散颗粒,颗粒团簇较多,表现在其硬度较小,且离散程度较大。随着超声施振时间延长和超声功率增大,基体内微观颗粒团簇减少,颗粒分布逐渐均匀,且气孔等缺陷减少,基体的载荷能够有效传递到颗粒上,因此,其硬度显著升高且离散程度不大。当超声施振10 min、超声功率为1 kW时,基体内颗粒分散均匀且无气孔夹杂等缺陷,因此,硬度达到最大且离散程度最小;当超声施振时间过长时(15 min),基体内出现颗粒团簇,硬度略微下降且离散程度增加;硬度的变化与显微组织的变化一致,因此,复合材料不同位置间硬度的差异也能在一定程度上反映增强体颗粒的分布状况。

4 结论

1) 半固态机械搅拌能有效地使不润湿SiC颗粒与基体7085铝合金熔体混合,并能初步实现颗粒分散,但在搅拌过程中易形成颗粒团簇、颗粒与气体吸附、气孔等缺陷。

2) 超声外场能够有效减少由半固态搅拌过程所形成的气体吸附、气孔等缺陷,当超声时长和超声功率适当时,这些缺陷能得到有效控制;同时,颗粒微观团簇在超声空化作用下显著改善,逐渐分散均匀;但超声施振存在最优时间与功率,在本实验研究条件下,以时长为10 min、功率为1 kW为宜。

3) 通过机械搅拌制备样品时,存在较多颗粒团簇与气孔等缺陷,硬度较低,且分布不集中;经超声处理过后,缺陷减少,硬度明显提高,且分布更加均匀;但在较小功率下超声作用不明显,不能有效分散颗粒,过长时间的超声处理对材料硬度值分散均匀程度不利。在本实验条件下(时长为10 min、功率为1 kW),硬度达到最大,为131.7,与未施加超声相比增大25.7%。

参考文献:

[1] 张旭. 机翼结构耐久性/损伤容限与可靠性综合分析方法及应用软件研究[D]. 沈阳: 沈阳航空工业学院航空宇航工程学院, 2010: 1-30.

ZHANG Xu. A synthesis method on wing structural durability/damage and reliability and application software research[D]. Shenyang: Shenyang Institute of Aeronautical Engineering. School of Aeronautical and Astronautical Engineering, 2010: 1-30.

[2] ZCILER M, MURATOGLU M. Wear behaviour of SiC reinforced 2124 Al alloy composite in RWAT system[J]. Journal of Materials Processing Technology, 2003, 132(1/2/3): 67-72.

[3] 储双杰, 吴人洁. 金属基复合材料新型制造技术[J]. 稀有金属材料与工程, 1995, 24(6): 1-9.

CHU Shuangjie, WU Renjie. The new processing technologies of the metal matrix composites[J]. Rare Metal Materials and Engineering, 1995, 24(6): 1-9.

[4] 李涛, 郭西振, 张新馨. 颗粒增强铝基复合材料的研究与进展[J]. 黑龙江科技信息, 2014(1):41-42.

LI Tao, GUO Xizhen, ZHANG Xinxin. Research and development of particle-reinforced aluminum matrix composites[J]. Heilongjiang Science and Technology Information, 2014 (1):41-42.

[5] 孔亚茹, 郭强, 张荻. 颗粒增强铝基复合材料界面性能的研究[J]. 材料导报, 2015, 29(9): 34-43, 49.

KONG Yaru, GUO Qiang, ZHANG Di. Review on Interfacial properties of particle-reinforced aluminum matrix composites[J]. Materials Review, 2015, 29(9): 34-43, 49.

[6] 张国政, 吕栋腾, 吴治明. 碳化硅颗粒增强铝基复合材料的制备及应用的研究[J]. 新技术新工艺, 2010(11): 60-62.

ZHANG Guozheng, L Dongteng, WU Zhiming. Research of fabrication and application for SiCp particle reinforced aluminum matrix composites[J]. New Technology & New Process, 2010(11): 60-62.

Dongteng, WU Zhiming. Research of fabrication and application for SiCp particle reinforced aluminum matrix composites[J]. New Technology & New Process, 2010(11): 60-62.

[7] 蒋日鹏, 李晓谦, 李开烨, 等. 超声对铝合金凝固传热与组织形成的影响与作用机制[J]. 中南大学学报(自然科学版), 2012, 43(10): 3807-3813.

JIANG Ripeng, LI Xiaoqian, LI Kaiye, et al. Effect of ultrasonic on heat transfer and microstructure formation of aluminum alloy during solidification and its mechanism[J]. Journal of Central South University(Science and Technology), 2012, 43(10): 3807-3813.

[8] MA J, KANG J, HUANG T. Novel application of ultrasonic cavitation for fabrication of TiN/Al composites[J]. Journal of Alloys and Compounds, 2016(661): 176-181.

[9] 潘蕾, 陈锋, 吴申庆, 等. 高能超声作用下金属基复合材料的制备[J]. 机械工程材料, 2003, 27(7): 1-2.

PAN Lei, CHEN Feng, WU Shenqing, et al. Review of MMC fabrication under high intensity ultrasonic treatment[J]. Materials for Mechanical Engineering, 2003, 27(7): 1-2.

[10] 樊建中, 桑吉梅, 张永忠, 等. 铝基复合材料增强体颗粒分布均匀性的研究[J]. 金属学报, 1998, 34(11): 1200-1204.

FAN Jianzhong, SANG Jimei, ZHANG Yongzhong, et al. The spatial distribution of reinforcements in aluminium matrix composites[J]. Acta Metallurgia Sinica, 1998, 34(11): 1200-1204.

[11] 胡岳华, 徐竞, 邱冠周, 等. 细粒浮选体系中颗粒间静电及范德华相互作用[J]. 有色矿冶, 1994(2): 16-21.

HU Yuehua, XU Jing, QIU Guanzhou, et al. Fine particles in the flotation system of electrostatic and van der Waals interactions[J]. Non-Ferrous Mining and Metallurgy, 1994(2): 16-21.

[12] 阳丽, 孔令江. 微纳米球形颗粒之间的毛细力研究[J]. 广西师范大学学报(自然科学版), 2012, 30(1): 1-4.

YANG Li, KONG Lingjiang. Capillary force between microparticles[J]. Journal of Guangxi Normal University (Natural Science Edition), 2012, 30(1): 1-4.

[13] ESKIN G I. Ultrasonic treatment of light alloy melts[M]. London: CRC Press/Taylor & Francis Group, 2015: 35-60.

[14] RAE J, ASHOKKUMAR M, EULAERTS O, et al. Estimation of ultrasound induced cavitation bubble temperatures in aqueous solutions[J]. Ultrasonics Sonochemistry, 2005, 12(5): 325-329.

[15] SRIVASTAVA N, CHAUDHARI G P. Strengthening in Al alloy nano composites fabricated by ultrasound assisted solidification technique[J]. Materials Science and Engineering A, 2016(651): 241-247.

[16] VALIBEYGLOO N, AZARI KHOSROSHAHI R, TAHERZADEH MOUSAVIAN R. Microstructural and mechanical properties of Al-4.5wt% Cu reinforced with alumina nanoparticles by stir casting method[J]. International Journal of Minerals, Metallurgy, and Materials, 2013, 20(10): 978-985.

[17] 涂文斌, 柯黎明, 徐卫平. 搅拌摩擦加工制备MWCNTs/Al复合材料显微结构及硬度[J]. 复合材料学报, 2011, 28(6): 142-147.

TU Wenbin, KE Liming, XU Weiping. Microstructure and hardness of MECNTs/Al composite by friction stir processing[J]. Acta Materiae Compositae Sinica, 2011, 28(6): 142-147.

(编辑 陈灿华)

收稿日期:2017-04-12;修回日期:2017-06-16

基金项目(Foundation item):国家自然科学基金面上项目(51475840);湖南省自然科学基金青年基金资助项目(2017JJ3391) (Projects(51475840) supported by the National Natural Science Foundation of China; Project(2017JJ3391) supported by Natural Science Foundation of Hunan Province)

通信作者:蒋日鹏,博士,讲师,从事金属基复合材料超声辅助制备工艺研究;E-mail: jiangripeng@163.com