文章编号:1004-0609(2016)02-0423-07

破碎方式对低品位金矿石全泥氰化的影响

唐 远,印万忠,迟晓鹏

(福州大学 紫金矿业学院,福州 350116)

摘 要:在常规颚式破碎和高压辊磨两种不同破碎方式下进行细粒级金矿石的全泥氰化浸出试验,探究两种破碎方式对低品位金矿浸出效果的影响,并结合颗粒表面检测结果及扫描电镜技术,进一步研究高压辊磨机在金矿石处理中的作用机理。结果表明:高压辊磨机产品的粒度较常规颚式破碎机产品的更细,但分布不均匀;相同浸出条件下,粒径小于0.15 mm的细粒级部分金浸出率提高3.7%~6.6%。两种破碎方式产生的颗粒裂纹的数量和尺寸存在差异,高压辊磨机能产生更加丰富的微裂纹,有助于浸出剂通过裂纹的渗透,增加颗粒的比表面积和孔隙度,有利于浸出剂与目的金矿物的接触。同时,在理论上揭示破碎方式对金矿浸出效果影响的机制。

关键词:高压辊磨机;微裂纹;比表面积;孔隙度;全泥氰化;金矿石

中图分类号:TF111 文献标志码:A

破碎和磨矿在各类选厂都是最主要的耗能工段,占总能耗的60%~80%[1-2]。目前,金矿石品位逐渐下降、解离难度大、要求细磨或超细磨,破磨成本逐年增加,制约金矿企业的发展[3]。氰化浸金仍是大部分黄金矿山所沿用的选冶技术,该技术已相当成熟,对提高企业效益贡献不大,“多碎少磨”概念的提出,对于提高磨矿系统的处理能力和降低能源消耗显得尤为重要,该方针顺理成章地成为黄金企业降耗增效所优先考虑的途径[4]。高压辊磨机是一种新型高效的破碎设备,具有单位破碎能耗低、处理能力大、占地面积和钢耗少等特点[5-7]。目前,已作为铁精矿球团前的细磨设备,黑色、有色金属和无机非金属矿山的细碎或超细碎设备,以及贵金属矿石粉碎设备等加以应用[8-10]。

PATZELT等[11]以石英脉型和矽卡岩型金矿石破碎产品的粒度分布及邦德(Bond)球磨功指数为切入点,指出与对辊破碎机相比,高压辊磨机产品中小于0.074 mm含量高出10%(质量分数),邦德(Bond)球磨功指数下降约3.1 (kW·h)/t,KLINGMANN等[12]通过比较两种不同金矿石经过不同破碎方式破碎后的浸出效果,认为高压辊磨机明显增加了金的解离,可使金浸出率提高7.7%~10.7%,二者均只从破碎后的产品细度方面分析了高压辊磨机的作用效果。谢洪珍等[13]通过对不同破碎方式产品细磨后的浸出试验,简要分析了单体解离度和产品微裂纹的作用,对颗粒裂纹的微观特性研究未详细描述。鉴于此,本文作者针对某低品位金矿石,采用常规颚式破碎机和不同辊面压力下的高压辊磨机进行粉碎处理,对粉碎后的物料特性进行分析,再对不同破碎方式细粒级产品的浸出效果进行对比研究,结合比表面、孔隙度以及显微分析技术,就破碎方式对低品位金矿石的全泥氰化浸出效果的影响机理进行研究。

1 实验

原试样取自闽西某地,矿石中金属矿物以褐铁矿、黄铁矿为主,还有少量铜蓝和蓝辉铜矿;脉石矿物绝大多数为石英,还有少量地开石、明矾石,SiO2的质量分数约为92%,矿石含泥量高,有用矿物金含量仅为0.34 g/t,主要以颗粒金形式存在,适宜通过氰化浸出法处理。对原试样采用PEX-150×250、XPC- 60×100两种型号的颚式破碎机及20 mm圆孔筛组成的闭路破碎流程进行粗碎和中碎,再分别采用CLM-25-10型高压辊磨机和PEF-60×100型颚式破碎机进行全开路细碎,高压辊磨机的辊面压力分别为3.5 N/mm2和5.5 N/mm2,工作辊间距4~7 mm,辊子转速0.4 m/s,颚式破碎机排矿口宽度与高压辊磨机的两辊间距相同,破碎产品中小于0.15 mm粒级作为全泥氰化试样。

全泥氰化浸出实验在3 L浸出搅拌槽内进行,分别取200 g不同破碎方式下试样到搅拌槽内,加入一定量的自来水到合适矿浆浓度,用石灰调整pH为10.5~11,加入适量浓度为10%的NaCN溶液,最后用JJ-1型精密增力电动调速搅拌器进行搅拌浸出。浸出完成后,过滤出富液化验,渣样清洗3次烘干制样送检。

2 结果与讨论

2.1 破碎产品粒度特性

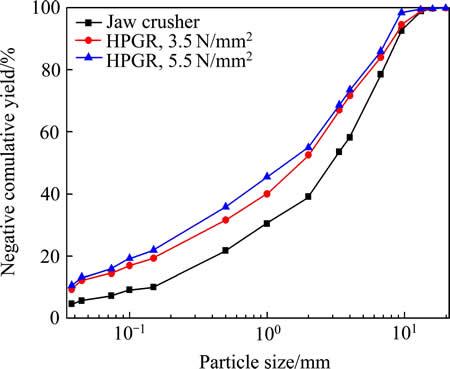

对高压辊磨机和常规颚式破碎机的3种开路破碎产品进行粒度筛分分析,其结果如图1所示。

图1 不同破碎方式产品粒度分布

Fig. 1 Particle size distributions of products crushed by different comminuting methods

由图1可看出,辊面压力为3.5 N/mm2时,高压辊磨机粉碎产品中小于0.15 mm的细粒级含量较常规颚式破碎机产品高9.32%,其中小于0.074 mm粒级含量增加了7.23%。当辊面压力增大到5.5 N/mm2时,两辊对矿石的作用力加大,粗颗粒得到进一步破碎,产品中细粒级含量随之增加。为进一步描述破碎产品的粒度特性,采用加权算术平均粒度D表示物料的平均大小、偏差系数 K 描述物料的均匀程度[14],二者计算公式如式(1)和(2)所示:

(1)

(1)

(2)

(2)

式中:D 为加权平均粒度,mm;K 为偏差系数,%;wi为各粒级质量分数,%;di 为各粒级平均直径,mm;σ 为标准差。

根据式(1)计算得常规颚式破碎产品平均粒度 Dc=3.91 mm,在3.5 N/mm2和5.5 N/mm2两种辊面压力下的高压辊磨产品的平均粒度分别为 Dm=2.99 mm和 Dh=2.69 mm,由式(2)计算得常规颚式破碎机的偏差系数 Kc=90.26%,比两种压力下高压辊磨机产品的偏差系数小16.46%~19.54%,表明经高压辊磨机破碎后的产品中细粒级含量较高,颗粒尺寸主要集中于细粒级和中间粒级,且随着辊面压力的增大,偏差系数减小,物料的均匀程度转好。

矿物经粉碎后的颗粒性质与其粒度大小有着直接的关系,试样中金主要分布在小于0.038 mm和0.045~0.074 mm的微细粒部分,粒度越细,越有利于金的浸出。通过比较图1中3种破碎产品的P80所对应的粒度可知,高压辊磨机产品的P80均较常规颚式破碎机的小,说明高压辊磨机的破碎比更大,粉碎效率更高。

2.2 细粒级产品表面及微孔特性

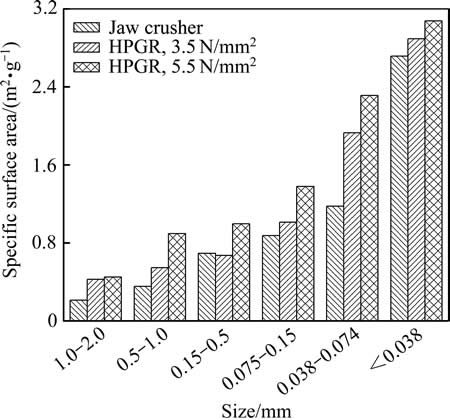

高压辊磨机内颗粒受到来自周围其他各方颗粒的挤压应力,理论上由此产生的单位体积的应力形变更加丰富。为了进一步描述破碎方式对颗粒产品产生应力形变效果的影响,选择上述不同破碎方式下不同粒级的产品,采用美国康塔仪器生产的6站全自动比表面及孔隙度分析仪,测定在特定粒级下产品的BET比表面积和BJH孔隙度差异,表征颗粒内部的性质,从而获得产品较细观的信息,比表面积和孔隙度的测定结果分别如图2和3所示。

由图2结果可看出,3种破碎产品的比表面积均随粒度的减小而增加,且图2中高压辊磨机各粒级产品比表面积几乎全都高于常规颚式破碎机,两种压力下高压辊磨机产品的平均BET比表面积分别为1.24 m2/g和1.52 m2/g,分别较常规颚式破碎机产品提高24.50%和51.39%,且在0.038~0.074 mm粒级比表面积增加最多,表明该粒级高压辊磨产品颗粒表面粗糙、内部裂纹更加丰富且粒度更细。两种破碎方式产品小于0.038 mm粒级的比表面积仅相差0.2 m2/g左右,说明颗粒内部微裂纹的差异减少,过细颗粒的形状渐趋于规则。因此,若将全泥氰化浸出的金矿石试样进一步细磨,则破碎方式对浸出效果的影响就不明显。

图2 不同破碎方式下各粒级颗粒比表面积

Fig. 2 Specific surface area of individual size in different comminuting methods

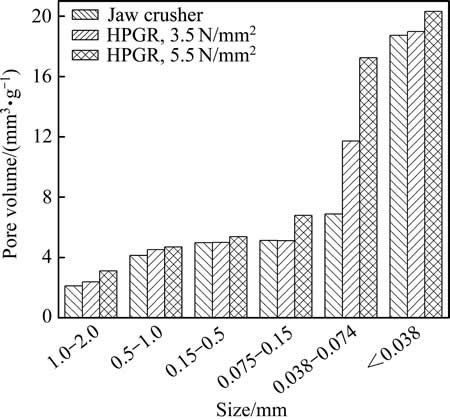

图3 不同破碎方式下各粒级颗粒单位孔体积

Fig. 3 Pore volumes of individual size in different comminuting methods

图3中用单位孔体积大小来表征颗粒的BJH孔隙

度,结果表明:产品孔隙度随粒度的减小而增大,且图3中高压辊磨机各粒级产品孔体积也几乎全都高于常规颚式破碎方式产品,两种压力下高压辊磨机产品的平均BJH孔隙度为7.95 mm3/g和9.59 mm3/g,分别较常规颚式破碎机产品的提高13.73%和37.20%,且0.038~0.074 mm粒级孔隙度的差异最明显,与图2中比表面积测定结论相同,但在0.15~1.0 mm和小于0.038 mm粒级则差别不大,表明高压辊磨机对0.038~0.074 mm粒级部分颗粒表面的孔隙性质影响最大,对过细或过粗粒级颗粒的影响减小,高压辊磨机产品的孔隙率越大越有利于后续粉碎,破碎需要克服的压力变小,可以减小设备磨损,提高生产效率。

2.3 破碎产品全泥氰化浸出效果

针对矿浆pH值、初始NaCN浓度、矿浆浓度和浸出时间等主要影响因素[15-16],采用一次一因素法对常规颚式破碎产品中小于0.15 mm细粒级产品的最佳浸出条件进行探索,在确定的最佳综合条件(石灰用量1.5 kg/t、初始NaCN浓度1.5 g/L、矿浆浓度40%、浸出时间24 h、搅拌器转速500 r/min)下进行不同破碎方式产品的浸出对比实验。全泥氰化试样中,常规颚式破碎机试样小于0.074 mm粒级含量为71.94%,仅较两种压力高压辊磨试样小于0.074 mm粒级含量低1.4%~2.2%,可认为三试样用小于0.074 mm含量表征的产品细度相差不大。

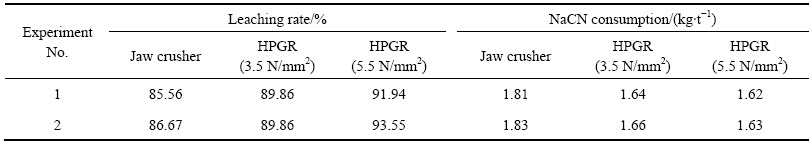

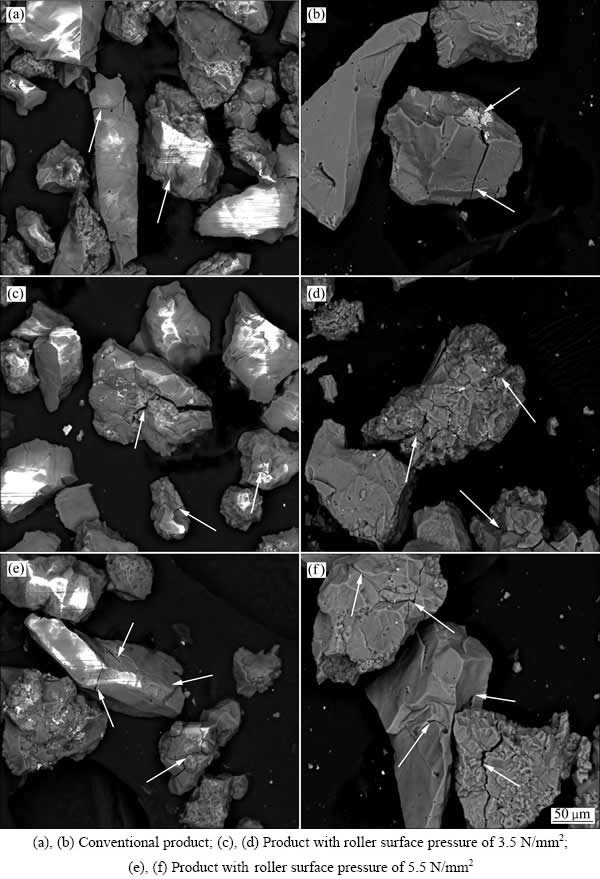

设置两组同条件的重复浸出实验,金的浸出率均以浸出渣的金品位来计算,实验结果列于表1,并借助显微镜分析技术,对0.074~0.15 mm和小于0.074 mm两个粒级颗粒微观表面结构进行观察分析,从而进一步分析破碎方式对金浸出率的影响机理,扫描电子显微镜观测结果如图4所示。

由表1结果可知,高压辊磨机试样在辊面压力3.5 N/mm2和5.5 N/mm2时的平均金浸出率分别为89.86%和92.75%,比常规颚式破碎机试样的浸出率高出约3.7%~6.6%,即在相同浸出条件下,高压辊磨机产品较常规颚式破碎机的细粒级产品的浸出效果好,同时测得的浸出剂耗量减少了约0.2 kg/t。

表1 综合条件试验结果

Table 1 Result of overall conditional test

图4 不同破碎方式下小于0.074 mm和0.074~0.15 mm粒级颗粒扫描电子显微镜图

Fig. 4 SEM images of particles with grain size less than 0.074 mm((a), (c), (e)) and 0.074-0.15 mm((b), (d), (f)) in different comminuting methods

从图4中可看出,在小于0.074 mm和0.074~ 0.15mm粒级,图4(c)~(f)中高压辊磨机产品的颗粒表面微裂纹数量较图4(a)和(b)中常规颚式破碎机产品的多,当辊面压力由3.5 N/mm2增大到5.5 N/mm2时,裂纹数量也明显增多。常规颚式破碎机小于0.074 mm粒级产品在扫描电镜的多个视野中很难找到较明显的裂纹,在0.074~0.15 mm粒级微裂纹数量稍增,由此可知,对于已经产生裂纹的较粗颗粒,在破碎机内进一步受到机械力的作用,会使该颗粒沿着强度较低的裂纹方向产生应力形变而破碎解离变细。因此,在粒度越细的颗粒表面,可观察的微裂纹数量就越少。同时,通过对上述两个粒级颗粒群中裂纹尺寸的统计测量发现,两种破碎方式小于0.074 mm粒级产品的微裂纹平均尺寸大都集中在500~650 nm的范围内,差别不明显,但在0.074~0.15 mm的粒级中,高压辊磨机产品的裂纹尺寸集中在680~950 nm的范围内,偶见1500 nm以上的颗粒裂纹,比常规颚式破碎机产品的裂纹尺寸略小。在全泥氰化过程中,颗粒在矿浆中可看成是固体颗粒完全浸入到液体的浸湿过程,浸湿过程是将气固界面变成固液界面,多孔性固体表面会发生与毛细现象有关的渗透过程[17]。以含有长为l,宽为r(宽度一般是变化的)的裂纹的单个固体颗粒为研究对象,将裂纹顺着开裂长度方向垂直分割成l/r个较小的单元,由于r值很小,因此,沿着裂纹深度方向可近似看成l/r个直径为r的毛细微管。为了研究含有浸出剂的液体渗透进入裂纹的难易度,以每一个毛细微管为研究对象,发生渗透的动力为液体产生的附加压力△p的表达式如式(3)所示:

(3)

(3)

式中:r为毛细微管直径;γgl为气液界面张力;θ为接触角,试样主要由石英、褐铁矿等矿物组成,故0≤θ≤90°;△p向着裂纹深度方向的气体一方。在接触角和气液界面张力一定的情况下,r越小,产生的附加压力越大,液体自发渗透到裂纹深部的能力就越强,即浸出剂更易进入到颗粒裂纹内部,而与金矿物直接接触发生溶解反应。因此,高压辊磨机破碎方式产生的大量尺寸略小的裂纹,对浸出过程更有利。

另一方面,正是由于高压辊磨机在颗粒内部产生丰富的应力裂纹,验证了图2和3中颗粒比表面积和孔隙度的检测结果,使颗粒的比表面积和单位孔体积均显著增加,可以加大浸出过程中浸出剂与颗粒的接触面积,提高浸出剂和金矿物的接触机率,使氰化浸出反应更快或者能从多个方向同时进行,避免或减少与其他矿物的络合反应,从而降低浸出剂的消耗,对提高浸出效果、降低药耗均有利。

因此,在金矿破碎的过程中,高压辊磨机采用的静压粉碎(或料层粉碎)机理,使机械挤压应力在作用区间内的颗粒间相互传递,整个料层颗粒都受到不同程度的粉碎,这种全粒级粉碎使辊压后的颗粒表面能产生大量的细粒、微细粒及颗粒内部微裂纹。综上所述,可以获得以下规律:1)较粗颗粒的表面微裂纹数量要大于较细颗粒;2)对于较细颗粒,两种破碎方式产生的裂纹尺寸相近,但高压辊磨机的裂纹在数量上有优势;3)对于试样中较粗颗粒,高压辊磨机的裂纹不仅数量多且尺寸略小、均匀,更利于液体的自发渗透,对提高金浸出率有利。

3 结论

1) 高压辊磨机与常规颚式破碎机相比,具有破碎比大、破碎效率高等特点,粉碎产品细粒级含量较高,其中小于0.074 mm粒级含量高出7.23%,但整体粒度分布的均匀性略差,随着辊面压力的增大,粒度分布均匀性转好。

2) 高压辊磨机产品各粒级产品的比表面积和孔隙度,几乎均高于常规颚式破碎机产品的测定结果,说明高压辊磨机在相同粒级下的产品粒度更细,且能在颗粒内部形成了更多的微裂纹,同时颗粒的力学性能下降,将对进一步粉碎能耗的降低发挥重要作用。

3) 对比两种不同破碎方式下小于0.15 mm细粒级产品的全泥氰化浸出效果,表明试样经高压辊磨机处理后对金的浸出有利,最终比常规颚破产品的浸出率提高约3.7%~6.6%,浸出剂减少约9%~10%,利于实现降耗增效的目标。

4)对两种破碎方式试样0.074~0.15 mm和小于0.074 mm两个粒级产品的SEM分析结果表明,高压辊磨机产品的裂纹在数量上占优,且颗粒越细,产生的裂纹数量越少。微细颗粒的裂纹尺寸接近,较粗颗粒中高压辊磨机产品的裂纹尺寸略小,更利于液体自发的渗透,对提高金浸出率有利。

REFERENCES

[1] 李丽匣, 袁致涛, 郭小飞, 谢琪春. 高压辊磨超细碎对攀西钒钛磁铁矿分选的影响[J]. 东北大学学报(自然科学版), 2013, 34(9): 1335-1338.

LI Li-xia, YUAN Zhi-tao, GUO Xiao-fei, XIE Qi-chun. Influence of ultra-fine comminution by HPGR on separation of V-Ti magnetite in Panxi[J]. Journal of Northeastern University (Natural Science), 2013, 34(9): 1335-1338.

[2] 侯 英, 丁亚卓, 印万忠, 姚 金, 罗溪梅, 王余莲, 孙大勇. 邦铺钼铜矿石高压辊磨后物料的特性[J]. 中南大学学报(自然科学版), 2013, 44(12): 4781-4786.

HOU Ying, DING Ya-zhuo, YIN Wan-zhong, YAO Jin, LUO Xi-mei, WANG Yu-lian, SUN Da-yong. Product characteristics of Mo-Cu ore from bangpu by high pressure grinding rolls[J]. Journal of Central South University (Science and Technology), 2013, 44(12): 4781-4786.

[3] SARAMAK D, KRAWCZYKOWSKA A, MLYNARCZYKOWSKA A. Effects of high pressure ORE grinding on the efficiency of flotation operations[J]. Archives of Mining Sciences, 2014, 59(3): 731-740.

[4] 张清波, 张梅岭. 多碎少磨是增加黄金产量提高企业经济效益的最有效途径[J]. 黄金, 1995(1): 48-49.

ZHANG Qing-bo, ZHANG Mei-ling. More crushing and less grinding is the most effective way to increase gold production and improve the economic efficiency of enterprises[J]. Gold, 1995(1): 48-49.

[5] ALTUN O, BENZER H, DUNDAR H. Comparison of open and closed circuit HPGR application on dry grinding circuit performance[J]. Minerals Engineering, 2011, 24(3): 267-275.

[6] 高 航, 方存光, 杨晓明, 徐小荷. 高压辊磨技术的发展及其在选矿业的应用前景[J]. 中国有色金属学报, 1998, 8(S2): s623-s626.

GAO Hang, FANG Cun-guang, YANG Xiao-ming, XU Xiao-he. Developments of high pressure grinding technology and its application prospects in mineral processing[J]. The Chinese Journal of Nonferrous Metals, 1998, 8 (S2): s623-s626.

[7] FAN Jian-jun, QIU Guan-zhou, JIANG Tao, GUO Yu-feng, HAO Hai-zheng, YANG Yong-bin. Mechanism of high pressure roll grinding on compression strength of oxidized hematite pellets[J]. Journal of Central South University, 2012, 19(9): 2611-2619.

[8] 印万忠, 侯 英, 丁亚卓, 姚 金, 王余莲, 罗溪梅, 孙大勇. 破碎方式对邦铺钼铜矿石可磨性及钼浮选的影响[J]. 金属矿山, 2013(2): 86-89.

YIN Wan-zhong, HOU Ying, DING Ya-zhuo, YAO Jin, WANG Yu-lian, LUO Xi-mei, SUN Da-yong. Effect of different comminuting process on grindability and molybdenum flotation of Bangpu Mo-Cu ore[J]. Metal Mine, 2013(2): 86-89.

[9] VAN F P, MAPHOSA W. High pressure grinding moving ahead in copper, iron, and gold processing[J].Journal of the Southern African Institute of Mining and Metallurgy, 2012(6): 637-648.

[10] 刘建远, 黄瑛彩. 高压辊磨机在矿物加工领域的应用[J]. 金属矿山, 2010(6): 1-8.

LIU Jian-yuan, HUANG Ying-cai. Applications of high-pressure grinding rolls in mineral processing[J]. Metal Mine, 2010(6): 1-8.

[11] PATZELT N, KNECHT H, BAUM W. Case made for high-pressure roll-grinding in gold plants[J]. Mining Engineering, 1995, 47(6): 524-529.

[12] KINGMANN H L. HPGR benefits at golden queen soledad mountain gold heap leaching project[R]. Perth: Randol Innovative Metallurgy Forum, 2005.

[13] 谢洪珍, 胡杰华, 阴 菡. 高压辊磨对矿石中金浸出影响试验研究[J]. 黄金科学技术, 2013(5): 145-148.

XIE Hong-zhen, HU Jie-hua, YIN Han. Experimental study on the effect of leaching of gold ore by high pressure roller mill[J]. Gold Science and Technology, 2013(5): 145-148.

[14] 段希祥. 碎矿与磨矿[M]. 3版. 北京: 冶金工业出版社, 2013: 135-136.

DUAN Xi-xiang. Crushing and grinding[M]. 3rd ed. Beijing: Metallurgical Industry Press, 2013: 135-136.

[15] 温胜来, 周 源. 浙江某金矿全泥氰化浸出试验研究[J]. 湿法冶金, 2012, 31(2): 103-105.

WEN Sheng-lai, ZHOU Yuan. Test research on full-slime cyanidation leaching of certain gold concentrate in Zhejiang[J]. Hydrometallurgy of China, 2012, 31(2): 103-105.

[16] 余忠宝, 陈建华, 魏宗武, 陈 晔. 广西某低品位金矿的浸出试验研究[J]. 矿产保护与利用, 2011(1): 44-45.

YU Zhong-bao, CHEN Jian-hua, WEI Zong-wu, CHEN Ye. Study on leaching of a low grade gold ore in Guangxi Province[J]. Conservation and Utilization of Mineral Resources, 2011(1): 44-45.

[17] 颜肖慈, 罗明道. 界面化学[M]. 北京: 化学工业出版社, 2004: 162-165.

YAN Xiao-ci, LUO Ming-dao. Interfacial chemistry[M]. Beijing: Chemical Industry Press, 2004: 162-165.

Influence of comminuting methods on full-slime cyaniding of low grade gold ore

TANG Yuan, YIN Wan-zhong, CHI Xiao-peng

(College of Zijin Mining, Fuzhou University, Fuzhou 350116, China)

Abstract: The full-slime cyaniding leaching experiments of fine particles products crushed by conventional jaw crusher and high pressure grinding rolls (HPGR) were conducted, the influences of two different comminuting processes on the leaching rate of low grade gold ore processed were studied. Combined with the particle surface test results and scanning electron microscopy, the mechanism of HPGR in the treatment process of gold ore was studied furthermore. The result shows that the products of HPGR are finer but not more uniform than that of conventional jaw crusher. The gold leaching rate of less than 0.15 mm part under the same conditions can be increased by 3.7%-6.6%. The number and size of micro-cracks from this two comminuting process become obvious difference. HPGR can produce richer micro-cracks through the quasi-static pressure, which contributes to the penetration of leaching reagents through the cracks. On the other hand, the specific surface area and porosity of particles increase, which will be beneficial to the contact of gold and leaching reagents. So the mechanism of influences on the gold leaching rate of different comminuting process in theory can be revealed.

Key words:high pressure grinding rolls; micro-cracks; specific surface area; porosity; full-slime cyaniding; gold ores

Foundation item: Project(51374079) supported by the National Natural Science Foundation of China

Received date: 2015-07-08; Accepted date: 2015-10-24

Corresponding author: YIN Wan-zhong; Tel: +86-0591-22866519; E-mail: yinwanzhong@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51374079)

收稿日期:2015-07-08;修订日期:2015-10-24

通信作者:印万忠,教授,博士;电话:0591-22866519;E-mail: yinwanzhong@163.com