文章编号:1004-0609(2010)S1-s0852-05

Ti-5553合金的高温变形行为

周 伟,葛 鹏,赵永庆,李 倩,冯 亮,杨 义

(西北有色金属研究院 钛合金研究所,西安 710016)

摘 要:在Gleeble-1500热模拟试验机上,当应变速率为0.1~10 s-1,变形温度为800~860 ℃时,采用高温压缩试验对Ti-5553钛合金热压缩变形中流变应力行为进行研究。研究结果表明:应变速率和变形温度的变化显著地影响合金流变应力的大小,流变应力随着变形温度的升高而降低,随应变速率的提高而增大,当流变应力达到峰值后趋于平稳。热变形过程的流变应力可采用双曲正弦本构关系来描述,平均激活能为611 kJ/mol。

关键词:钛合金;热压缩;应力;激活能

中图分类号:TG456.3 文献标志码:A

Hot deformation behavior of Ti-5553 alloy

ZHOU Wei, GE Peng, ZHAO Yong-qing, LI Qian, FENG Liang, YANG Yi

(Titanium Alloy Research Center, Northwest Institute for Non-ferrous Metal Research, Xi’an 710016, China)

Abstract: The flow stress behavior of Ti-5553 Titanium alloy during hot compression deformation was studied by thermal simulation test at the deformation temperature of 800-860 ℃ and the strain rate of 0.1-10 s-1 on the Gleeble-1500 thermal and mechanical simulator. The results show that the flow stress is controlled by both strain rate and deforming temperature. The flow stress decreases with the increase of deforming temperature, and increases with the increase of strain rate until the flow stress reaches the peak value, then the flow stress remains constant. The flow behaviors are described by the hyperbolic sine constitutive equation, and the average activation energy calculated is 611 kJ/mol.

Key words: titanium alloy; hot compression deformation; flow stress; activation energy

Ti-5553(Ti-5Al-5Mo-5V-3Cr-0.5Fe)合金是从俄罗斯合金VT-22发展而来的一种新型亚稳定β钛合金,与Ti-1023合金相比,该合金具有对偏析不太敏感,淬透性好,强度优异和断裂韧性较高等优点,特别适合制造必须承受巨大应力的零部件,例如结构件和起落架,在航空航天工业中日益受到青睐[1-3]。

高温下,钛合金的流动应力及组织性能不仅与合金的化学成分和显微组织等因素密切相关,而且还强烈地受热工艺参数 —— 变形温度、变形程度和应变速率的影响。目前,对Ti-5553钛合金热加工流变应力行为研究的报道较少,为制定合理的热加工提供技术依据,本文作者对该合金进行热压缩变形试验,测试合金高温热变形性能以及应变速率、温度和压缩屈服应力间的关系。

1 实验

试验用材料采用经3次真空自耗电弧熔炼制备的铸锭,其化学成分(质量分数,%)为:5.14 Al,5.38 Mo,5.06 V,3.02 Cr,0.43 Fe,0.027 C,0.009 N,0.002 H,0.009 O,其余为Ti。合金(α+β)/β相变温度为 (860±5) ℃。合金锻棒经900 ℃,2 h AC(空冷)处理后,机械加工成d 8 mm×12 mm的热模拟试样。热模拟压缩试验在Gleeble-1500热模拟机上进行。变形温度为800、820、840和860 ℃,应变速率分别为0.1、l和10 s-1,设计变形量为60%。

2 结果与讨论

2.1 真应力—真应变曲线特征

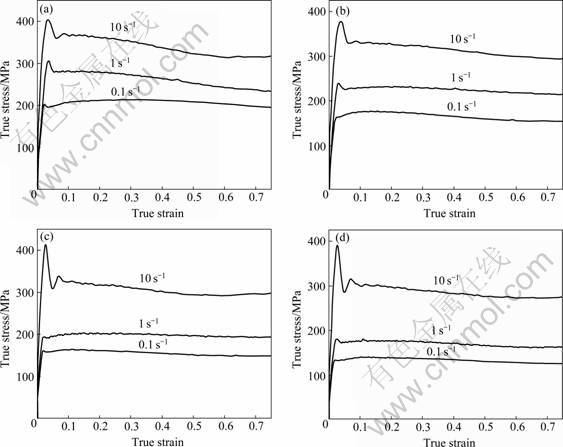

在800~860 ℃变形温度时,不同应变速率下的Ti-5553合金的真应力—真应变曲线如图1所示。由图1可以看出,应变速率为0.1 s-1时,应力随着应变增加到峰值后基本保持恒定,没有明显的软化过程,真应力—真应变曲线均接近于稳态流动型。稳态流动的实质是位错增殖引起的应变硬化和位错的相互销毁及重排引起的软化之间达到动态平衡[4]。应变速率提高到0.1和10 s-1,应力达到峰值后,随着应变的增加,出现不同程度的软化,应力曲线出现锯齿状波动现象,随后逐渐趋于稳定状态,应力值基本保持恒定。流变应力变化主要取决于两个方面[5]:位错增值引起的加工硬化和由于变形及高温的作用导致的动态软化。两者在热加工过程中同时进行、互相竞争。一般认为由于变形速率较大,原子扩散受阻,变形产生的位错塞积来不及通过动态回复松弛,随着变形量的增加,位错蓄积越来越严重,在一定情况下产生孪晶变形,并改变晶粒取向,使合金在有利的方向上继续变形,如此反复形成应力的上下波动[6]。

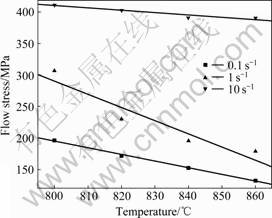

对应力—应变曲线进行归纳总结,通过提取每一温度和应变速率下材料所对应的最大流变应力,绘制成如图2所示的最大流变应力与变形速率和温度之间的关系图。

由图2可以看出,在同一应变速率下,流变应力随温度的升高而降低。因为随温度的升高,热激活的作用增强,原子间的动能增大,原子间的临界剪切应力减弱,此外动态回复及动态再结晶引起的软化程度也随温度的升高而增大,从而导致合金的应力水平降低[7]。但是当变形速率增加到10 s-1时,温度在变形过

图l Ti-5553合金在不同温度下的真应力—真应变曲线

Fig.1 True stress—true strain curves of Ti-5553 all0y at different temperatures: (a) 800 ℃; (b) 820 ℃; (c) 840 ℃; (d) 860 ℃

程中引起的软化作用不明显,这是由于当应变速率增大时,单位变形时间缩短, 动态再结晶提供的软化过程缩短太大,使得动态回复和动态再结晶不能充分进行。在同一变形温度下,材料的流动应力随应变速率的增大而显著提高,这说明该合金在该实验条件下具有较正的应变速率敏感性。随着变形速率的增加,使得位错增殖率显著增大,加工硬化作用更加明显,材料的流动应力增大[8]。实际锻造时,金属处于稳态流动状态,且变形抗力小,并且对变形温度、应变速率和变形程度的敏感性要低,因此,仅从热力参数对流动应力的影响特点来看。合金在α+β两相区进行常规锻造时,宜选择较低的应变速率。

图2 变形温度和变形速率对流动应力的影响

Fig.2 Effects of deformation temperature and strain rate on flow stress

2.2 变形机制分析

在热变形过程中,材料在任何应变或稳态下的高温流变应力σ取决于变形温度T和应变速率 ,为了准确地反映其流变应力同变形温度、变形速率和变形程度的关系,许多研究表明[9-11],采用双曲正弦模型来描述流变应力与变形温度和应变速率的关系能较好地描述压缩、扭转、挤压等常规的热加工变形。

,为了准确地反映其流变应力同变形温度、变形速率和变形程度的关系,许多研究表明[9-11],采用双曲正弦模型来描述流变应力与变形温度和应变速率的关系能较好地描述压缩、扭转、挤压等常规的热加工变形。

(1)

(1)

式中:σ为高温流变应力; 为应变速率;T为热力学温度;n为应力指数;A为材料常数;R为摩尔气体常数;Q为热变形激活能;a为应力水平参数(mm2·N-1)。

为应变速率;T为热力学温度;n为应力指数;A为材料常数;R为摩尔气体常数;Q为热变形激活能;a为应力水平参数(mm2·N-1)。

材料的指数关系模型和幂指数关系模型如下:

(2)

(2)

(3)

(3)

式中:A1和A2是常数;n1和β是材料常数。

对式(2)和(3)两边取对数得:

(4)

(4)

(5)

(5)

考虑到峰值应力均出现在应变较小的时刻,为方便计算,取相应 、T条件下的真实峰值应力,分别以

、T条件下的真实峰值应力,分别以 和

和 、σ和

、σ和 为坐标作图,如图3所示。由式(4)和(5)可知,n1和β分别为

为坐标作图,如图3所示。由式(4)和(5)可知,n1和β分别为 —

— 和

和 —

— 曲线的斜率的倒数。采用最小二乘法线性回归,n1取图3(a)中峰值应力较低的4条直线(即变形温度为860、840、820和800 ℃)斜率倒数的平均值为6.9;β取图3(b)中峰值应力较高的4 条直线斜率倒数的平均值为0.028 44;利用σ=β/n1,求得α为0.004 121 7。

曲线的斜率的倒数。采用最小二乘法线性回归,n1取图3(a)中峰值应力较低的4条直线(即变形温度为860、840、820和800 ℃)斜率倒数的平均值为6.9;β取图3(b)中峰值应力较高的4 条直线斜率倒数的平均值为0.028 44;利用σ=β/n1,求得α为0.004 121 7。

图3 在不同温度下流变应力与应变速率的关系

Fig.3 Relationships between strain rate and flow stress at different temperatures: (a)  —

— ; (b)

; (b)  —

—

在热变形过程中,高温峰值应力取决于T和 ,其相互关系可用Zener-Hollomon因子表示[12]:

,其相互关系可用Zener-Hollomon因子表示[12]:

(6)

(6)

将式(6)代入式(1)得

(7)

(7)

对式(1)两边取偏导得

(8)

(8)

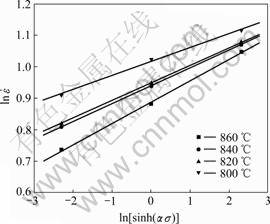

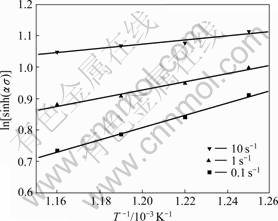

同样采用线性回归处理,绘制出相应的 —

— 关系曲线如图4所示。并同样绘制出

关系曲线如图4所示。并同样绘制出 —1/T关系曲线,其结果如图5所示。将其斜率值代入式(8),可求得不同温度和不同应变速率下的变形激活能Q,取其平均值为611 kJ/mol。Ti-5553合金在(α+β)两相区的变形激活能远高于纯钛α、β相的自扩散激活能[13](Qα=204 kJ/mol,Qβ=166 kJ/mol),意味着变形是扩散以外的其他机制起主导作用。

—1/T关系曲线,其结果如图5所示。将其斜率值代入式(8),可求得不同温度和不同应变速率下的变形激活能Q,取其平均值为611 kJ/mol。Ti-5553合金在(α+β)两相区的变形激活能远高于纯钛α、β相的自扩散激活能[13](Qα=204 kJ/mol,Qβ=166 kJ/mol),意味着变形是扩散以外的其他机制起主导作用。

图4 在不同温度下应变速率与流变应力的关系

Fig.4 Relationships between strain rate and flow stress at different temperatures

图5 在不同应变速率下流变应力与温度的关系

Fig.5 Relationships between flow stress and deformation temperature at different strain rates

对式(7)两边取对数得

(9)

(9)

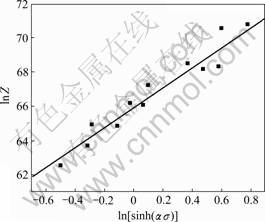

式中:ln A为直线 —

— 的截距。取一定的

的截距。取一定的 、Q与T,求得对应的ln Z值。取ln Z和对应的

、Q与T,求得对应的ln Z值。取ln Z和对应的 ,采用最小二乘法线性回归法绘制相应的

,采用最小二乘法线性回归法绘制相应的 —

— 曲线(见图6),得 ln A=65.851 55。

曲线(见图6),得 ln A=65.851 55。

将所求得的参数代入式(1)可得实验合金的应 力—应变关系方程为

图6 流变应力与参数Z的关系

Fig.6 Relationship between flow stress and Z parameter

3 结论

1) 以Ti-5553钛合金的热模拟压缩实验结果为基础,获得了变形工艺参数(变形温度、变形程度和应变速率)对流动应力的影响规律。流动应力随应变的增加而迅速增加,当应变超过一定值后,流动应力开始下降并逐渐趋于稳定,出现稳态流动特征;变形温度升高和应变速率增大应力曲线出现锯齿状波动现象。

2) 合金的峰值应力随变形温度的升高而降低,随应变速率的增大而提高,具有正应变速率的敏感性。

3) Ti-5553钛合金高温流变应力σ与变形温度T、应变速率 之间满足关系

之间满足关系

,其中变形激活能Q=611 kJ/mol。

,其中变形激活能Q=611 kJ/mol。

REFERENCES

[1] WAGNER V, BAILI M, DESSEIN G, LALLEMENT D. Experimental characterization of behavior laws for titanium alloys: Application to Ti5553[J]. Engineering Materials, 2010, 446: 147-155.

[2] WARCHOMICKA F, STOCKINGER M, DEGISCHER H P. Flow behaviour and microstructure during hot deformation of Ti-5Al-5Mo-5V-3Cr-1Zr[C]//Ti-2007 Science and Technology. Japan, 2007: 511-514.

[3] JONES N, JACKSON M, DYE D, DASHWOOD R. Comparing the hot working behaviour of high strength beta alloys Ti-5Al-5Mo-5V-3Cr with that of Ti-10V-2Fe-3Al[C]//Ti-2007 Science and Technology. Japan, 2007: 1005-1008.

[4] 王克鲁, 鲁世强, 李 鑫, 董显娟. 应变速率对TC11钛合金α+β相区变形行为的影响[J]. 热加工工艺, 2009, 38(8): 13-16.

WANG Ke-lu, LU Shi-qiang, LI Xin, DONG Xian-juan. Effect of strain rate on deformation behavior in a+b phase field of titanium alloy TC11[J]. Material and Heat Treatment, 2009, 38(8): 13-16.

[5] 毛柏平, 郭胜利, 沈 建. Ti-5523钛合金热变形流变行为的研究[J]. 稀有金属, 2008, 32(5): 674-678.

MAO Bo-ping, GUO Sheng-li, SHEN Jian. Study on hot deformation behavior of Ti-5523 titanium alloy[J]. Chinese Journal of Rare Metals, 2008, 32(5): 674-678.

[6] 张效宁, 宋 杰, 范志国. Beta Ti-9.8Mo-3.9Nb-2V-3.11Al合金的热压缩变形行为研究[J]. 郑州大学学报: 工学版, 2009, 30(1): 10-13.

ZHANG Xiao-ning, SONG Jie, FAN Zhi-guo. Hot compressive deformation behavior of Ti-9.8Mo-3.9Nb-2V-3.1Al alloy[J]. Journal of Zhengzhou University: Engineering Science, 2009, 30(1): 10-13.

[7] 曲银化, 孙建科, 孟祥军. TC4钛合金高温压缩变形行为的研究[J]. 材料开发与应用, 2006, 21(2): 24-29.

QU Yin-hua, SUN Jian-ke, MENG Xiang-jun. An investigation on mechanic behavior of TC4 alloy during hot compression deformation[J]. Development and Application of Materials, 2006, 21(2): 24-29.

[8] 徐文臣, 单德彬, 李春峰, 吕 炎. TA15钛合金的动态热压缩行为及其机理研究[J]. 航空材料学报, 2005, 25(4): 10-19.

XU Wen-chen, SHAN De-bin, LI Chun-feng, L? Yan. Study on the dynamic hot compression behavior and deformation mechanism of TA15 titanium alloy[J]. Journal of Aeronautical Materials, 2005, 25(4): 10-19.

[9] 李慧中, 李 洲, 刘 咏, 张 伟, 王海军. TiAl 基合金的高温塑性变形行为[J]. 中国有色金属学报, 2010, 20(1): 79-85.

LI Hui-zhong, LI Zhou, LIU Yong, ZHANG Wei, WANG Hai-jun. Plastic deformation behavior of TiAl based alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 79-85.

[10] 寇琳媛, 金能萍, 张 辉, 韩 逸, 吴文祥, 李落星. 7150 铝合金高温热压缩变形流变应力行为[J]. 中国有色金属学报, 2010, 20(1): 43-48.

KOU Lin-yuan, JIN Neng-ping, ZHANG Hui, HAN Yi, WU Wen-xiang, LI Luo-xing. Flow stress behavior of 7150 aluminum alloy during hot compression deformation at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 43-48.

[11] 王蕊宁, 奚正平, 赵永庆, 戚运连, 杜 宇. Ti53311S钛合金的热变形和加工图[J]. 热加工工艺, 2007, 36(22): 14-17.

WANG Rui-ning, XI Zheng-ping, ZHAO Yong-qing, QI Yun-lian, DU Yu. Hot deformation behaviors of Ti53311S alloy and its processing map[J]. Material and Heat Treatment, 2007, 36(22): 14-17.

[12] JONAS J J, SELLARS C M, MC W J. Strength and structure under hot working conditions[J]. Tegart Int Metal Reviews, 1996, 14(2): 1-24.

[13] 曾卫东, 周义刚, 俞汉青. 应用Zener-Hollomon因子Ti-17的高温压缩行为[J]. 西北工业大学学报, 1996, 14(2): 166-168.

ZENG Wei-dong, ZHOU Yi-gang, YU Han-qing. On mechanism underlying high temperature compressive behavior of Ti-17 alloy[J]. Journal of Northwestern Polytechnical University, 1996, 14(2): 166-168.

(编辑 杨幼平)

基金项目:国家重点基础研究发展计划资助项目(2007CB613805);国家科技支撑计划项目(2007BAE07B03)

通信作者:周 伟;电话:029-86231078-401;E-mail: zhouwei2002563@163.com