DOI:10.11817/j.ysxb.1004.0609.2020-39480

退火对新型锆合金组织与性能的影响

张福全1, 2,黄阳正1, 2,周惦武2,刘金水1,王 练3

(1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

3. 国核宝钛锆业股份公司,宝鸡 721013)

摘 要:采用扫描电镜(SEM)、电子背散射衍射(EBSD)、X射线衍射(XRD)、透射电镜(TEM)和万能试验机等,研究真空退火对新型Zr-Nb-O-Cu锆合金微观组织与力学性能的影响。结果表明:在580 ℃、3 h退火条件下,合金的平均晶粒尺寸为2.5 μm,晶粒为等轴晶,退火前后均存在{0001} 和{0001}

和{0001} 两种织构,但基面织构强度有所降低。第二相颗粒在晶内和晶界呈弥散分布,为体心立方(BCC)结构的β-Nb相与密排六方(HCP)结构的Zr-Nb-Fe相,尺寸集中在30~150 nm之间。相对于原材,退火后合金沿轧制方向(RD)和垂直方向(TD)的屈服强度(σs)及抗拉强度(σb)均下降,试样均韧性断裂。3个方向的应变硬化指数(n)与塑性应变比(r)差异明显。晶粒与第二相的尺寸、织构等因素对力学性能有重要影响。

两种织构,但基面织构强度有所降低。第二相颗粒在晶内和晶界呈弥散分布,为体心立方(BCC)结构的β-Nb相与密排六方(HCP)结构的Zr-Nb-Fe相,尺寸集中在30~150 nm之间。相对于原材,退火后合金沿轧制方向(RD)和垂直方向(TD)的屈服强度(σs)及抗拉强度(σb)均下降,试样均韧性断裂。3个方向的应变硬化指数(n)与塑性应变比(r)差异明显。晶粒与第二相的尺寸、织构等因素对力学性能有重要影响。

关键词:新型锆合金;织构;第二相;力学性能;退火

文章编号:1004-0609(2020)-01-0140-10 中图分类号:TG146.4 文献标志码:A

锆具有低的热中子俘获截面,其合金耐腐蚀性能优异、且辐照条件下力学性能优良,因此,在核反应堆关键核心元件中具有十分重要的应用[1-2]。锆合金通常用作核反应堆中的包壳和结构材料,其研究当前主要集中在合金元素配比与加工工艺改进等方面。为满足苛刻的应用需求,各国研究人员开发出许多新型锆合金,如ZIRLOTM、M5 、HANA等[3-5],Zr-Nb-O-Cu合金是在它们的基础上研制并得到应用的一种新型锆合金。合金成分一定时,锆合金的力学性能与轧制之后退火形成的显微组织关联密切[6]。再结晶退火充分的锆合金具备较好的塑性,有利于后续加工。从Zr-Nb合金二元相图可得出,Zr-1.0Nb合金的包析温度为610 ℃左右[7]。工业化生产中,为防止β-Zr的生成退火温度一般低于该温度[8]。此外,织构、第二相也对锆合金的力学性能产生影响。栾佰峰等[9]对轧制过程中纯锆的织构进行了研究,发现其为基面平行于轧面的基面双峰织构,主要为

、HANA等[3-5],Zr-Nb-O-Cu合金是在它们的基础上研制并得到应用的一种新型锆合金。合金成分一定时,锆合金的力学性能与轧制之后退火形成的显微组织关联密切[6]。再结晶退火充分的锆合金具备较好的塑性,有利于后续加工。从Zr-Nb合金二元相图可得出,Zr-1.0Nb合金的包析温度为610 ℃左右[7]。工业化生产中,为防止β-Zr的生成退火温度一般低于该温度[8]。此外,织构、第二相也对锆合金的力学性能产生影响。栾佰峰等[9]对轧制过程中纯锆的织构进行了研究,发现其为基面平行于轧面的基面双峰织构,主要为 //RD和

//RD和 //RD两种织构。锆合金的织构类型也与此相似[6]。合金力学性能与其第二相的成分、形态和分布紧密相关。对商业化的Zr-Nb合金而言,根据合金成分和加工工艺的不同,Zr-Nb合金存在α-Zr、β-Zr、β-Nb和三元Zr-Nb-Fe等相。在不同的温度范围热处理,可得到不同的相组成。Zr-Nb合金在高温淬火之后存在α-Zr与亚稳态的β-Zr,在包析反应温度以下退火,β-Zr会最终分解为α-Zr与β-Nb[10]。

//RD两种织构。锆合金的织构类型也与此相似[6]。合金力学性能与其第二相的成分、形态和分布紧密相关。对商业化的Zr-Nb合金而言,根据合金成分和加工工艺的不同,Zr-Nb合金存在α-Zr、β-Zr、β-Nb和三元Zr-Nb-Fe等相。在不同的温度范围热处理,可得到不同的相组成。Zr-Nb合金在高温淬火之后存在α-Zr与亚稳态的β-Zr,在包析反应温度以下退火,β-Zr会最终分解为α-Zr与β-Nb[10]。

核反应堆中的关键核心元件,部分是由锆合金带材冲压成型而成的内、外条带组成。锆合金的应变硬化指数(n)、塑性应变比(r)等与冲压关联密切的力学性能指标与制造工艺中的轧制与退火工艺相关。为此,本文选择新型Zr-Nb-O-Cu锆合金为对象,研究了真空退火对其微观组织与力学性能的影响,研究结果有望为优化锆合金力学性能提供理论依据,并为推进核反应堆用新型锆合金带材的国产化提供有益的理论参考。

1 实验

实验所用材料为一种新型Zr-Nb-O-Cu合金带材,厚度为0.46 mm。其化学成分(质量分数,%):Nb 1.0、O 0.1~0.2、Cu 0.05~0.2、其余为Zr。将各组样品分别在真空炉中加热至560 ℃、580 ℃、600 ℃、620 ℃进行退火处理,保温时间均为3 h,研究真空退火工艺对合金微观组织与力学性能的影响。

晶粒与织构的检测在装有EBSD组件的QUANTA-200扫描电子显微镜上进行,实验样品采用电解抛光制备。显微组织观察在JSM-6700F 场发射扫描电子显微镜上进行,腐蚀剂为HNO3、H2O和HF的混和液(HNO3、H2O和HF的体积比9:9:1)。实验所用的透射电镜为JEM-3010与Tecnai-F20,透射试样在10%HClO4+90%C2H5OH的电解双喷液中进行电解处理,温度为-25 ℃,电流为40 mA。XRD物相分析在D5000型衍射仪上进行:Cu靶、扫描角度范围为10°~90°、扫描速度3 (°)/min。将材料沿轧制方向(RD)、与RD呈45°方向(45°)以及与RD垂直方向(TD)加工成标距为30 mm的拉伸试样,拉伸实验在MTS-810万能试验机上进行,拉伸速率为2 mm/min。

2 结果与讨论

2.1 微观组织和织构

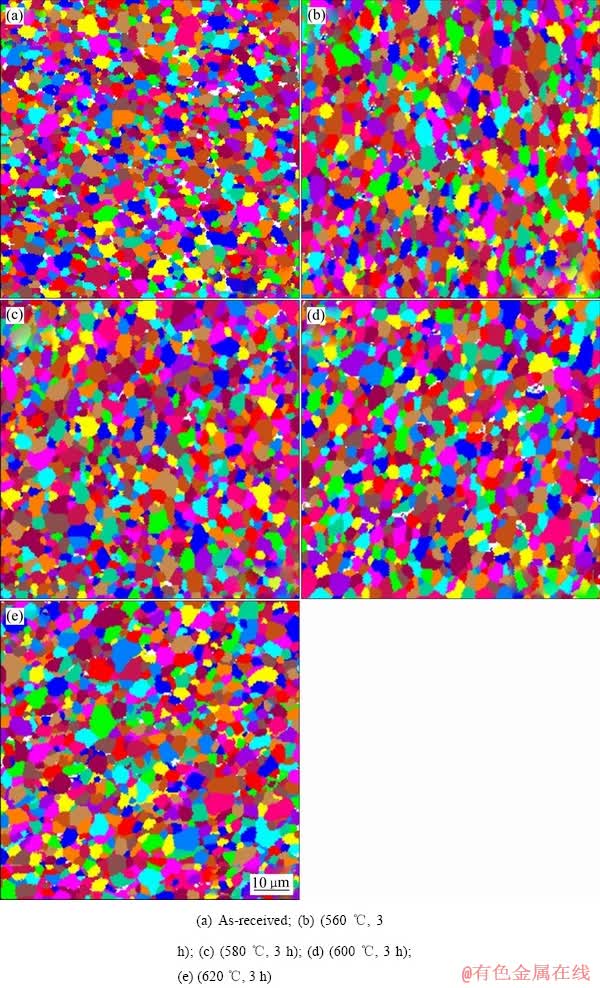

通过对不同样品RD-TD面区域内采集的EBSD信息进行分析处理,得到如图1所示的晶粒图。由图1可知,样品主要组织由较大的等轴晶粒与未充分长大的细小等轴晶粒组成,平均晶粒尺寸约为2.3 μm(见图1(a));经560 ℃、3 h退火处理后,样品中平均晶粒尺寸变化较小(见图1(b));经580 ℃、3 h退火处理后,样品中的平均晶粒尺寸约为2.5 μm,尺寸小于1 μm的晶粒所占比例最小(见图1(c));经600 ℃、3 h退火处理后,样品中的平均晶粒尺寸最大约为2.8 μm(见图1(d));经620 ℃、3 h退火处理后,样品中晶粒尺寸相对于600 ℃、3 h退火处理的变化不大(见图1(e))。各工艺条件下的平均晶粒尺寸在2.3~2.8 μm之间。在不同温度保温3 h退火条件下,细小晶粒在退火处理之后继续长大,导致晶粒平均尺寸变化。随着退火温度的升高,更多细小的晶粒得以长大。但是弥散的第二相粒子会对晶粒的长大起阻碍作用[11],因此在不同的温度退火平均晶粒尺寸变化不明显。本实验在580 ℃保温3 h退火较为理想,尺寸小于1 μm的细小晶粒所占的比例最少,晶粒主要呈等轴的再结晶态,从而有利于后续成型加工[8]。

图1 不同工艺条件样品的EBSD晶粒图

Fig. 1 Grain maps of samples by EBSD

图2所示为不同工艺条件下的极图与反极图。从图2中极图中可以看出晶粒存在明显的取向,且多数晶粒的c轴集中在试样的ND(法向)方向附近。大多数晶粒的c轴未完全平行于ND方向,而是与ND方向存在一定的夹角。相关研究表明轧制形成的难变形晶粒多为晶粒c轴平行于ND[12]。各组实验样品中均存在基面双峰织构,其中 方向在试样的ND-TD平面内,并向TD方向倾斜,不同退火温度下倾斜的角度差别不大。一部分晶粒的

方向在试样的ND-TD平面内,并向TD方向倾斜,不同退火温度下倾斜的角度差别不大。一部分晶粒的 平行于RD方向,另一部分晶粒的

平行于RD方向,另一部分晶粒的 平行于RD方向。从图2中还可以得出,图2(a)原材的基面织构强度最高;而经580 ℃退火处理3 h得到的基面织构强度最低为6.14。

平行于RD方向。从图2中还可以得出,图2(a)原材的基面织构强度最高;而经580 ℃退火处理3 h得到的基面织构强度最低为6.14。

图2中反极图的结果进一步表明,材料中存在 //RD和

//RD和 //RD两种织构。图2(a)中

//RD两种织构。图2(a)中 // RD与

// RD与 //RD织构强度最低。随着退火温度的变化,部分晶粒的取向发生改变,织构会发生转变,因而不同的工艺得到的反极图存在差异。相对于原材料,经560 ℃退火处理3 h的试样中

//RD织构强度最低。随着退火温度的变化,部分晶粒的取向发生改变,织构会发生转变,因而不同的工艺得到的反极图存在差异。相对于原材料,经560 ℃退火处理3 h的试样中 //RD织构强度更高;而经580 ℃退火处理3 h与经600 ℃退火处理3 h材料的织构类型与织构强度变化不大;经620 ℃退火处理3 h时,材料中

//RD织构强度更高;而经580 ℃退火处理3 h与经600 ℃退火处理3 h材料的织构类型与织构强度变化不大;经620 ℃退火处理3 h时,材料中 //RD织构强度有所降低,

//RD织构强度有所降低, //RD织构部分转变为

//RD织构部分转变为 //RD织构。SAXENA K等[13]的研究表明,

//RD织构。SAXENA K等[13]的研究表明, 取向的织构是在热轧过程中形成的,并且织构的强度随热轧温度升高而增大。刘二伟等[14]的研究表明,锆合金在冷轧加工后大多数晶粒中

取向的织构是在热轧过程中形成的,并且织构的强度随热轧温度升高而增大。刘二伟等[14]的研究表明,锆合金在冷轧加工后大多数晶粒中 //RD,再结晶退火后晶粒会绕c轴旋转30°左右,形成角度为30°的{0001}

//RD,再结晶退火后晶粒会绕c轴旋转30°左右,形成角度为30°的{0001} 、{0001}

、{0001} 两种织构。本文的锆合金中弥散分布的第二相粒子作为晶界迁移的障碍[11],导致退火后晶粒长大不明显,两种类型的织构在不同工艺下均存在。

两种织构。本文的锆合金中弥散分布的第二相粒子作为晶界迁移的障碍[11],导致退火后晶粒长大不明显,两种类型的织构在不同工艺下均存在。

图2 不同工艺样品的EBSD极图和反极图

Fig. 2 EBSD PF and IPF of samples under different processes

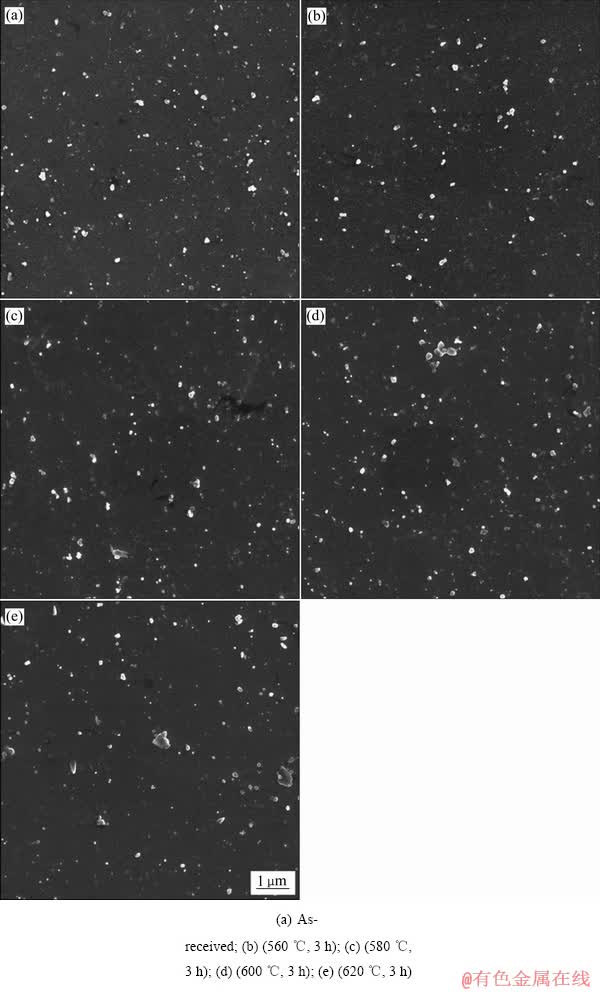

2.2 第二相

合金元素Nb在α-Zr中的固溶度较低,因此退火后的锆合金在室温下存在着第二相[10]。图3所示为Zr-Nb-O-Cu合金原材与不同退火工艺下的第二相分布情况与形貌特征,可以看出第二相分布均匀,在晶内和晶界上弥散分布,呈细小的圆形或较大的椭圆形。图3(b)、(c)、(e)中第二相出现尺寸相对较大的颗粒,图3(d)中有第二相聚集区。表明随着退火温度升高,部分第二相颗粒有所长大,且局部会有沉淀相聚集成簇。用图像分析软件统计分析所得到各个工艺条件下的第二相颗粒尺寸大部分集中在30~150 nm,少部分大于200 nm。不同工艺下的第二相平均尺寸均在70~80 nm之间。

图3 Zr-Nb-O-Cu合金第二相的分布与形貌特征

Fig. 3 Distribution and morphologies of SPPs of Zr-Nb-O-Cu alloy

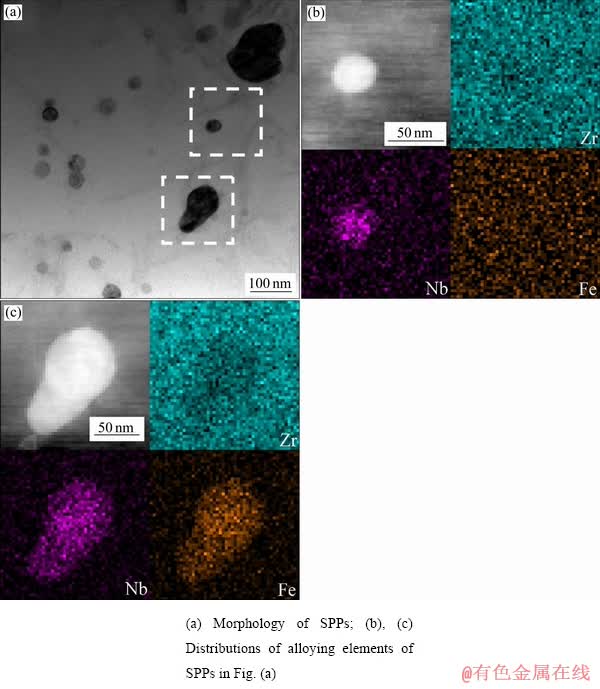

图4(a)与(b)所示为第二相TEM像。第二相在晶粒内部与晶界上均存在。对图4(a)中的较小的第二相P1与较大的第二相P2进行EDS能谱分析如图4(c)和(d)所示。结果显示P1含Zr、Nb两种元素,而P2相对于P1额外含有Fe元素。Fe是合金加工过程中引入的杂质元素并且在α-Zr中的固溶度很小,会参与第二相的析出。ALLAN等[10]的研究表明,锆合金的生产过程中完全去除Fe非常困难,因此在Zr-Nb合金中存在着Zr-Nb-Fe粒子,在低Sn含量的ZIRLOTM合金中,Fe集中在α-Zr基体与β-Nb相的界面。对于另一种合金元素Cu,张欣等[15]的研究表明,当Zr-1.0Nb合金中Cu含量小于0.2%(质量分数)时,大部分Cu固溶在α-Zr中,合金中析出的第二相主要是尺寸细小的β-Nb。刘二伟等[16]的研究则表明,Zr-Nb-Cu合金存在两种第二相,一种为尺寸较小的β-Nb,在晶粒内部弥散分布;另一种为尺寸较大的含有Fe与Nb的Zr2Cu相在晶界分布。本文EDS能谱分析未发现Cu元素形成的第二相。为了进一步观察合金中第二相的元素分布情况,对Zr-Nb-O-Cu合金第二相进行了能谱面扫描分析如图5所示。可以得出Nb元素在小尺寸与较大尺寸的第二相中均集中分布,Fe参与形成了较大尺寸的第二相。

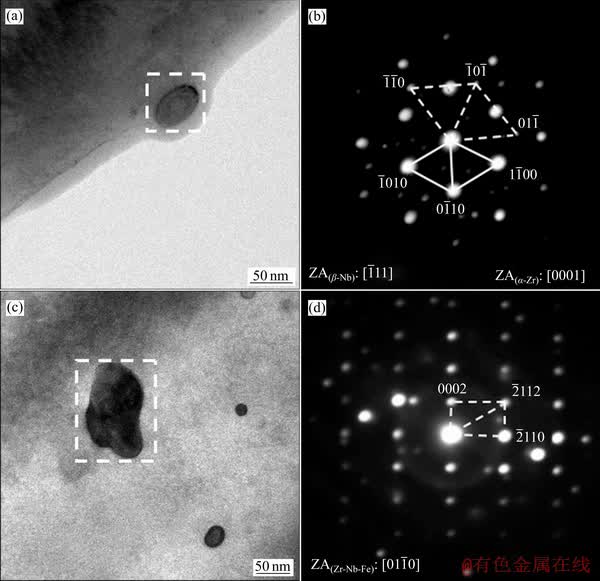

图6(a)所示为β-Nb第二相的形貌特征,图6(b)所示为图6(a)中第二相的选区电子衍射(SAED)。β-Nb相呈BCC结构,其衍射晶带轴为 [9, 17]。因第二相颗粒在α-Zr基体内部且尺寸较小,SAED中会观察到的密排六方结构的α-Zr基体的衍射斑点,α-Zr的衍射晶带轴为[0001]。与YANG等[18]运用SAED对β-Nb的的研究所得结果相似;图6(c) 中较大的颗粒为Zr-Nb-Fe粒子,其衍射斑点及对应的晶面信息如图6(d)所示,衍射晶带轴为

[9, 17]。因第二相颗粒在α-Zr基体内部且尺寸较小,SAED中会观察到的密排六方结构的α-Zr基体的衍射斑点,α-Zr的衍射晶带轴为[0001]。与YANG等[18]运用SAED对β-Nb的的研究所得结果相似;图6(c) 中较大的颗粒为Zr-Nb-Fe粒子,其衍射斑点及对应的晶面信息如图6(d)所示,衍射晶带轴为 ,其是一种HCP晶体结构的第二相[17]。相关研究[19]也运用SAED观察到了到了Zr-1.0Nb合金中的Zr-Nb-Fe粒子。故在本文所使用的Zr-Nb-O-Cu合金中存在两种类型的第二相,尺寸较小的主要为β-Nb相,含有Fe元素的第二相则认为是由加工过程中引入的杂质Fe元素而产生的Zr-Nb-Fe第二相。

,其是一种HCP晶体结构的第二相[17]。相关研究[19]也运用SAED观察到了到了Zr-1.0Nb合金中的Zr-Nb-Fe粒子。故在本文所使用的Zr-Nb-O-Cu合金中存在两种类型的第二相,尺寸较小的主要为β-Nb相,含有Fe元素的第二相则认为是由加工过程中引入的杂质Fe元素而产生的Zr-Nb-Fe第二相。

图4 Zr-Nb-O-Cu合金中第二相的TEM像与EDS谱

Fig. 4 TEM images and EDS spectra of particles of Zr-Nb-O-Cu alloy

图5 Zr-Nb-O-Cu合金第二相形貌及EDS元素面分布

Fig. 5 Morphologies of second phase particles(SPPs) in Zr-Nb-O-Cu alloy and EDS distribution of elements

图6 β-Nb与Zr-Nb-Fe相的TEM像与选区电子衍射

Fig. 6 TEM images((a), (c)) and selected area electron diffraction(SAED)((b), (d)) of β-Nb((a), (b)) and Zr-Nb-Fe phase((c), (d))

图7所示为原材料与不同退火工艺样品的XRD谱。从图7可以看出,除α-Zr的衍射峰强度较高外,其他角度出现了较弱的衍射峰,第二相的衍射峰并未出现。其中3个最强的峰从左至右边,分别对应2θ为34.84°附近的α-Zr的(002)晶面族、36.51°附近的(101)晶面族以及63.54°附近的(103)晶面族。该研究结果与其他诸多研究结果[20-21]可以较好地匹配,均在35°附近出现强峰,且60°以后的衍射峰几乎都与α-Zr相对应。此外与原材相比较,经过3h退火处理之后,在35°附近的α-Zr的衍射峰增强。虽然620 ℃高于合金的包析温度610 ℃,但并未发现β-Zr存在,室温下没有发现新的生成相。

图7 不同工艺条件下样品的XRD谱

Fig. 7 XRD patterns of samples under different processes

2.3 力学性能

对于薄板和薄带,除抗拉强度(σb)、屈服强度(σs)外,材料的应变硬化指数(n)、塑性应变比(r)是影响冲压成型性能的关键力学性能参数。图8为原材料与不同退火工艺下样品沿3个方向的应力应变曲线。经3 h退火后,材料在RD、TD方向的σs与σb相对于原材料均有所下降,除经600 ℃退火处理3 h外在45°方向也有相同的规律。从图8中还可以得出在同样的工艺下,σs在TD方向为最大值、σb在RD方向为最大值。原材料σs在TD方向为最大值458.2 MPa、σb在RD方向为最大值521.7 MPa。n值与r值在3个方向上存在着明显的差异,各个工艺条件下计算得到的结果如表1。在不同温度经过3 h退火后材料在RD方向的n值最大、45°的n值次之、TD方向的n值最小,r值则与n值在3个方向上存在着相反的趋势。原材料与经580 ℃退火3 h样品的n值均为最大值0.15,其余工艺均导致n值与原材料的相比有所下降。部分第二相与晶粒尺寸的增大、织构的变化等综合因素是造成力学性能变化的原因。相关的研究中也表明晶界和第二相等会影响锆合金的力学性能[6]。

图8 不同工艺条件下的应力-应变曲线

Fig. 8 Engineering stress-strain curves of samples under different processes from three directions

表1 不同工艺条件下的三向力学性能

Table 1 Mechanical properties of samples under different processing conditions from three directions

图9 RD方向拉伸时样品的断口形貌

Fig. 9 Fractured surface morphologies of sample during tensile-test in RD

图9所示为原材料和不同工艺的退火试样的拉伸断口形貌。这里仅对RD方向上的拉伸断口形貌进行分析,可以发现韧性断裂在各组试样中均占据主导地位。拉伸裂纹的扩展方式为韧性模式[20]。断口形貌也表明试样均具备较好的塑性,不同之处在于图9(a)原材试样的中间区域出现了少量脆性断裂区,断口形貌呈光亮的结晶状。考虑到经580 ℃退火处理3 h后材料的n值相对于其他退火工艺的更大,并具有非常可观的伸长率,且其韧窝的分布更加均匀具备更好的塑性,可能与其细小晶粒尺寸所占百分比较少、基面织构强度更低有关。此外,温度高于580 ℃退火试样的断面相对更不均匀,表明随着退火温度的升高,材料中微观组织与结构的转变会导致其力学性能产生差异。

3 结论

1) 新型Zr-Nb-O-Cu锆合金经过560~620 ℃不同温度退火,平均晶粒尺寸在2.3~2.8 μm之间,经580 ℃退火3 h时,晶粒为等轴状,平均尺寸为2.5 μm;{0001} 和{0001}

和{0001} 两种织构在580 ℃退火3 h前后均存在,织构类型的转变不明显,经580 ℃退火3 h时样品中基面织构强度降低。

两种织构在580 ℃退火3 h前后均存在,织构类型的转变不明显,经580 ℃退火3 h时样品中基面织构强度降低。

2) 第二相呈细小的圆形或较大的椭圆形,颗粒尺寸集中在30~150 nm,在晶内和晶界上弥散分布,为BCC结构的β-Nb相与HCP结构的Zr-Nb-Fe相。

3) 退火后样品在RD、TD方向的σs与σb相对于原材料均有所下降。n值与r值在3个方向有明显的差异。n值在RD方向最大、在45°方向次之、在TD方向最小;r值在3个方向与n值存在着相反的变化规律。原材料与580 ℃退火3 h后在RD方向的n值均为最大值0.15。晶粒、第二相以及织构等因素的综合作用使得力学性能发生变化。

REFERENCES

[1] LIANGJ L, ZHANGM, OUYANGY F, YUAN G H, ZHU J M, SHEN J Y, R.DAYMOND M. Contribution on the phase equilibria in Zr-Nb-Fe system[J]. Journal of Nuclear Materials, 2015, 466: 627-633.

[2] ZHAO W J, LIU Y Z, JIANG H M, PENG Q. Effect of heat treatment and Nb and H contents on the phase transformation of N18 and N36 zirconium alloys[J]. Journal of Alloys and Compounds, 2008, 462: 103-108.

[3] STEINBRüCK M, BOTTCHER M. Air oxidation of Zircaloy-4, M5 and ZIRLOTM cladding alloys at high temperatures[J]. Journal of Nuclear Materials, 2011, 414: 276-285.

and ZIRLOTM cladding alloys at high temperatures[J]. Journal of Nuclear Materials, 2011, 414: 276-285.

[4] MARTIN R, XAVIER F, DOMINIQUE P, JEAN M C. Microstructural characterization of creep anisotropy at 673 K in the M5 alloy[J]. Acta Materials, 2012, 60: 4319-4327.

alloy[J]. Acta Materials, 2012, 60: 4319-4327.

[5] JUNG Y, LEE M H, KIM H G, PARK J Y, JEONG Y H. Behavior of a recrystallization in HANA-4 and HANA-6 zirconium-based alloys[J]. Journal of Alloys and Compounds, 2009, 479: 423-426.

[6] YANG H L, KANO S, MATSUKAWA Y, LI Y F, SHEN J J, ZHAO Z S, LI F, SATOH Y. Study on recrystallization and correlated mechanical properties in Mo-modified Zr-Nb alloys[J]. Materials Science and Engineering A, 2016, 661: 9-18.

[7] JEONG Y H, LEEKO, KIM H G. Correlation between microstructure and corrosion behavior of Zr-Nb binary alloy[J]. Journal of Nuclear Materials, 2002, 302: 9-19.

[8] TIAN H, WANG X T, GONG W J, ZHOU J, ZHANG H L. Recrystallization behavior of cold-rolled Zr-1Nb alloy[J]. Journal of Nuclear Materials, 2015, 456: 321-328.

[9] 栾佰峰, 肖东平, 贺方方. 纯锆轧制过程中的组织与织构演变规律[J]. 电子显微学报, 2012, 31(6): 476-480.

LUAN Bai-feng, XIAO Dong-ping, HE Fang-fang. Evolution of microstructure and texture of pure zirconium during rolling process[J]. Journal of Chinese Electron Microscopy Society, 2012, 31(6): 476-480.

[10] ALLAN H, MALCOLM G, MICHAEL P. The characterisation of second phases in the Zr-Nb and Zr-Nb-Sn-Fe alloys: A critical review[J]. Journal of Nuclear Materials, 2018, 505: 227-239.

[11] CHANG K, FENG Wei-ming, CHEN L Q. Effect of second-phase particle morphology on grain growth kinetics[J]. Acta Materialia, 2009, 57: 5229-5236.

[12] 陈建伟, 栾佰峰, 柴林江, 余泓冰, 刘 庆. Zr-Sn-Nb新型锆合金板材加工过程中不均匀组织与织构演变[J]. 金属学报, 2012, 48(4): 393-400.

CHEN Jian-wei, LUAN Bai-feng, CHAI Lin-jiang, YU Hong-bing, LIU Qing. Heterogenous microstructure and texture evolution during fabrication of Zr-Sn-Nb Zirconium alloy sheets[J]. Acta Metallurgica Sinica, 2012, 48(4): 393-400.

[13] SAXENA K K, SURESH K S, KULKARNI R V, KRISHNA K V M, PANCHOLI V. Hot deformation behavior of Zr-1Nb alloy in two-phase region-microstructure and mechanical properties[J]. Journal of Alloys and Compounds, 2018, 741: 281-292.

[14] 刘二伟, 张喜燕, 陈建伟, 栾佰峰, 刘 庆, 李中奎, 周 军. Zr-Nb、Zr-Sn-Nb合金轧制板材织构分析[J]. 稀有金属材料与工程, 2012, 41(2): 226-229.

LIU Er-wei, ZHANG Xi-yan, CHEN Jian-wei, LUAN Bai-feng, LIU Qing, LI Zhong-kui, ZHOU Jun. Study on the texture of Zr-Nb and Zr-Sn-Nb alloys[J]. Rare Metal Materials and Engineering, 2012, 41(2): 226-229.

[15] 张 欣, 姚美意, 彭剑超, 周邦新. Zr-1Nb-xCu合金在400 ℃过热蒸汽中的耐腐蚀性能[J]. 稀有金属材料与工程, 2017, 46(12): 3910-3915.

ZHANG Xin, YAO Mei-yi, PENG Jian-chao, ZHOU Bang-xin. Corrosion resistance of Zr-1Nb-xCu alloys in super-heated steam at 400 ℃[J]. Rare Metal Materials and Engineering, 2017, 46(12): 3910-3915.

[16] 刘二伟, 张喜燕, 陈建伟, 李中奎, 周 军, 石明华. Zr-Nb-Cu合金第二相分析[J]. 稀有金属材料与工程, 2012, 41(11): 2010-2012.

LIU Er-wei, ZHANG Xi-yan, CHEN Jian-wei, LI Zhong-kui, ZHOU Jun, SHI Ming-hua. Second phases in the Zr-Nb-Cu alloy[J]. Rare Metal Materials and Engineering, 2012, 41(11): 2010-2012.

[17] 邱日盛, 栾佰峰, 柴林江, 周 宇, 陈建伟. 锆合金第二相研究述评(Ⅱ): Zr-Sn-Nb-Fe系合金[J]. 中国有色金属学报, 2012, 22(6): 1605-1615.

QIU Ri-sheng, LUAN Bai-feng, CHAI Lin-jiang, ZHOU Yu, CHEN Jian-wei. Review of second phase particles on zirconium alloys (Ⅱ): Zr-Sn-Nb-Fe alloys[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1605-1615.

[18] YANG H L, MATSUKAWA Y, KANO S, DUAN Z G, MURAKAMI K, ABE H. Investigation on microstructural evolution and hardening mechanism in dilute Zr-Nb binary alloys[J]. Journal of Nuclear Materials, 2016, 481: 117-124.

[19] LIU Yan-zhang, KIM H G, PARK J Y, JEONG Y H. Evaluation of microstructure and texture development in Zr-1.0Nb sheet during cold-colling[J]. Rare Metal Materials and Engineering, 2013, 42(4): 0667-0672.

[20] ZHANG M, LI Y N, ZHANG F C, WANG X B, CHEN L Y, YANG Z N. Effect of annealing treatment on the microstructure and mechanical properties of a duplex Zr-2.5Nb alloy[J]. Materials Science and Engineering A, 2017, 706: 236-241.

[21] FENG Z H, XIA C Q, JIANG X J, LIU S G, ZHANG X, ZHANG X Y, MA M Z, LIU R P. Investigating the structure-property correlation of a novel Zirconium alloy by annealing treatment[J]. Materials Science and Engineering A, 2016, 677: 393-399.

Influence of annealing on microstructure and properties of a novel zirconium alloy

ZHANG Fu-quan1, 2, HUANG Yang-zheng1, 2, ZHOU Dian-wu2, LIU Jin-shui1, WANG Lian3

(1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

3. State Nuclear Bao Ti Zirconium Industry Company, Baoji 721013, China)

Abstract: Scanning electron microscopy(SEM), electron backscatter diffractometry(EBSD), X-ray diffractometry(XRD), transmission electron microscopy(TEM) and universal testing machine were used to research the effects of vacuum annealing on the microstructure and mechanical properties of a novel Zr-Nb-O-Cu alloy. The results show that the grain is equiaxed possessing an average size of 2.5 μm and the strength of basal texture is reduced by being annealed at 580 ℃ for 3 h, {0001} and {0001}

and {0001} texture exist stably. The second phase particles (SPPs) are body-centered cubic (BCC) β-Nb phase and hexagonal close packed (HCP) Zr-Nb-Fe phase, it disperses inside the grain and along the grain boundary and its size is concentrated in 30-150 nm. Comparing to original material, the yield strength(σs) and tensile strength(σb) after annealing are decreased in rolling direction (RD) and transverse direction (TD), the fractured surfaces are ductile. There are significant differences in strain hardening index (n) and plastic strain ratio (r) in three directions. The factors including the size of grains and the SPPs, the transform of texture, have considerable effect on the mechanical properties.

texture exist stably. The second phase particles (SPPs) are body-centered cubic (BCC) β-Nb phase and hexagonal close packed (HCP) Zr-Nb-Fe phase, it disperses inside the grain and along the grain boundary and its size is concentrated in 30-150 nm. Comparing to original material, the yield strength(σs) and tensile strength(σb) after annealing are decreased in rolling direction (RD) and transverse direction (TD), the fractured surfaces are ductile. There are significant differences in strain hardening index (n) and plastic strain ratio (r) in three directions. The factors including the size of grains and the SPPs, the transform of texture, have considerable effect on the mechanical properties.

Key words: novel zirconium alloy; texture; second phase; mechanical property; annealing

Foundation item: Project(2017ZX06002005) supported by the National Science and Technology Major Project, China

Received date: 2019-01-22; Accepted date: 2019-05-05

Corresponding author: ZHANG Fu-quan; Tel: +86-731-88821497; E-mail: zhangfq@hnu.edu.cn

(编辑 龙怀中)

基金项目:国家科技重大专项资助项目(2017ZX06002005)

收稿日期:2019-01-22;修订日期:2019-05-05

通信作者:张福全,教授,博士;电话:0731-88821497;E-mail:zhangfq@hnu.edu.cn