不同铸造工艺制备A356-CNT纳米复合材料的摩擦学行为

来源期刊:中国有色金属学报(英文版)2019年第10期

论文作者:Benyamin ABBASIPOUR Behzad NIROUMAND Sayed Mahmoud MONIR VAGHEFI Mohammad ABEDI

文章页码:1993 - 2004

关键词:A356 铝合金;纳米复合材料;复合铸造; 碳纳米管(CNT);磨损机制;耐磨性能

Key words:A356 aluminum alloys; nanocomposite; compocasting; carbon nanotube (CNT); wear mechanism, wear properties

摘 要:研究液态成形和半固态成形法制备的A356铝合金整体铸件和A356-CNT纳米复合铸造件的摩擦学行为。采用熔体搅拌、流变铸造、搅拌铸造、复合铸造等不同工艺制备样品。研究碳纳米管(CNTs)的加入、铸造工艺和施加载荷对磨损性能和磨损机理的影响。结果表明,添加碳纳米管显著降低了纳米复合材料的磨损量、磨损率和摩擦因数。铸造工艺由液态成形变为半固态成形,和初相含量的增加是提高合金尤其是纳米复合合金样品耐磨性能的两个主要因素。此外,研究还发现液态成形和半固态成形两种方法制备的整体铸件其主要磨损机理分别是粘着磨损和剥层磨损。然而,无论制备工艺如何,磨粒磨损是纳米复合材料的主要磨损机理。

Abstract: Tribological behaviors of monolithic A356 aluminum alloy castings and A356-CNT nanocomposite castings, fabricated by fully liquid and semisolid routes were examined. Samples were prepared by melt agitation, rheocasting, stir casting, and compocasting techniques. Effects of addition of carbon nanotubes (CNTs), casting process and the applied load on wear properties and mechanisms were investigated. It was found that wear loss, wear rate and friction coefficient of nanocomposite samples remarkably declined by the addition of CNTs. Moreover, changing the casting process from fully liquid to semisolid routes, plus increasing fractions of the primary phase were the two factors that improved the wear properties of the investigated samples, especially nanocomposite ones. In addition, it was revealed that adhesion and delamination were the dominant wear mechanism of the monolithic samples produced by fully liquid and semisolid routes, respectively. However, regardless of fabrication techniques, the abrasion was the main wear mechanism of nanocomposite samples.

Trans. Nonferrous Met. Soc. China 29(2019) 1993-2004

Benyamin ABBASIPOUR1, Behzad NIROUMAND1, Sayed Mahmoud MONIR VAGHEFI1, Mohammad ABEDI2

1. Department of Materials Engineering, Isfahan University of Technology, Isfahan 84156-83111, Iran;

2. National University of Science and Technology “MISiS”, Moscow 119049, Russia

Received 3 December 2018; accepted 14 August 2019

Abstract: Tribological behaviors of monolithic A356 aluminum alloy castings and A356-CNT nanocomposite castings, fabricated by fully liquid and semisolid routes were examined. Samples were prepared by melt agitation, rheocasting, stir casting, and compocasting techniques. Effects of addition of carbon nanotubes (CNTs), casting process and the applied load on wear properties and mechanisms were investigated. It was found that wear loss, wear rate and friction coefficient of nanocomposite samples remarkably declined by the addition of CNTs. Moreover, changing the casting process from fully liquid to semisolid routes, plus increasing fractions of the primary phase were the two factors that improved the wear properties of the investigated samples, especially nanocomposite ones. In addition, it was revealed that adhesion and delamination were the dominant wear mechanism of the monolithic samples produced by fully liquid and semisolid routes, respectively. However, regardless of fabrication techniques, the abrasion was the main wear mechanism of nanocomposite samples.

Key words: A356 aluminum alloys; nanocomposite; compocasting; carbon nanotube (CNT); wear mechanism, wear properties

1 Introduction

Metal matrix composites (MMCs) have drawn the attention of both researchers and manufacturers (i.e. automotive and aerospace) worldwide in recent years owing to their unique combination of physical and mechanical properties. These advanced materials exhibit higher specific strength, hardness, stiffness, and wear resistance when compared to conventional metals and alloys [1].

Classical definitions indicate that MMCs consist of at least two chemically and physically distinct phases that are suitably distributed to provide properties which are obtainable with none of the individual phases [2]. A wide range of metals such as Mg, Cu, Ni alloys, metallic glasses, and high entropy alloys (HEAs) have been used as metal matrix material [3-9]. Nonetheless, aluminum alloys have been the most widely used matrices due to such remarkable properties as low density, suitable strength, good toughness, and excellent corrosion resistance [2].

The experiences of the last few decades have proven that the liquid state (casting) processes are the most economically viable methods for the production of MMCs [10]. They are relatively simple, cost-effective and potentially scalable to the industrial level. However, they suffer from some inherent problems such as agglomeration and poor distribution of reinforcements in the matrix [11]. Compocasting is an improvement in the liquid state methods to overcome some of these shortcomings. In this process, reinforcements are added to the matrix at a temperature corresponding to the solid-liquid state of the matrix alloy, following by intensely stirring in the semisolid slurry. In some researches, the addition of reinforcement is made at the fully liquid state and then the temperature of the slurry is brought down to the solid-liquid state [12,13].

A new concept which further enhances the properties of MMCs is reinforcing with nanoparticles or tubes. Since the discovery of CNT, many potential applications have been proposed and investigated. CNT is regarded as a suitable reinforcement material for MMCs because of its low density, excellent mechanical properties, good electrical and thermal conductivity and distinctive physicochemical properties originating from its unique structure of cylindrical graphene sheets [14]. Regarding these unique properties, incorporation of CNT into the aluminum matrix has been reported in a large number of papers [15,16]. It has been demonstrated that incorporation of CNT into an aluminum matrix would result in enhancement of tensile strength, stiffness, hardness and elastic modulus along with a concomitant decrease in the coefficient of thermal expansion compared to those of pure aluminum [17-19]. Despite extensive studies conducted on methods of production and mechanical properties of Al-CNT composites, there is a lack of understanding of the tribological behavior of this composite system. AL-QUTUB et al [20] examined friction and wear behavior of Al6061 monolithic alloy and 1 wt.% CNTs reinforced Al6061 composite prepared through ball milling and spark plasma sintering. They found that, under mild wear conditions, the composite shows a lower wear rate and friction coefficient compared to the monolithic alloy. For severe wear conditions, however, the composite displays a higher wear rate and friction coefficient. They claimed that this behavior is associated with crack nucleation caused by the presence of pores in the composite, as well as CNTs agglomeration and weak CNT/Al6061 particle bonding in the sintered samples. BASTWROS et al [15] reported that Al-CNT composites produced by cold compaction and hot extrusion methods show superior wear behavior compared to a pure aluminum with the same process history, as well as this fact that increasing the CNT content in the composite significantly increases the wear resistance, provided that CNTs are well dispersed. It is concluded that the fractured CNTs create a carbon film that covers the surface and acts as a solid lubricant enhancing significantly the wear characteristics. ABDULLAHI et al [16] also examined the wear behavior of pure aluminum and Al-CNT nanocomposites synthesized by the powder metallurgy route. They demonstrated that the wear rate decreases with increasing the CNT content from 0 to 1.5 wt.%. Then it increases slightly from 1.5 to 2 wt.% CNT, and increases rapidly at higher CNT contents. It is suggested that this trend is a result of the hardness decrease of the nanocomposite samples having more than 1.5 wt.% CNT.

To the best of authors’ knowledge, no research has been published on tribological behavior of Al-CNT nanocomposites fabricated by compocasting method. The aim of this work is therefore to investigate the tribological properties of compocast A356-CNT nanocomposites and to draw a comparison between the tribological behaviors of these semisolid composites and those produced by the fully liquid casting method.

2 Experimental

2.1 Materials

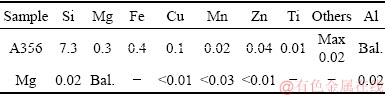

A356 aluminum alloy and commercially pure magnesium ingots were used as the matrix alloy and the wetting agent, respectively. Chemical analyses of these materials measured by spark emission spectroscopy (SES) are provided in Table 1.

Table 1 Chemical analyses of used A356 aluminum alloy and pure magnesium ingots (wt.%)

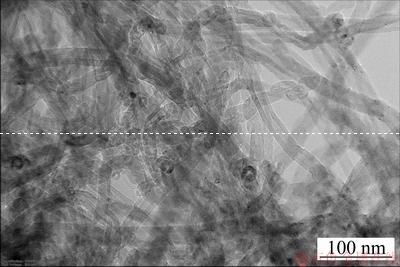

Furthermore, Al-Ni-P-CNT composite powders produced by the electroless plating process were used for the addition of the reinforcement to the melt. The procedure for electroless co-deposition of Ni-P coating and CNTs on aluminum powder has been reported elsewhere [21]. The list of materials used in this process includes: (1) Commercially pure aluminum powder with an average particle size of 50 μm manufactured by Khorasan Powder Metallurgy (Iran); (2) A commercial electroless plating solution (Slotonip 70A series) produced by Schloetter Company (Germany), and (3) Multiwall carbon nanotubes (MWCNTs) with 95% purity and outer diameters in the range of 10-30 nm produced by Research Institute of Petroleum Industry (Iran). A transmission electron microscopy (TEM) micrograph of the as-received MWCNTs is shown in Fig. 1.

Fig. 1 TEM micrograph of as-received MWCNTs

2.2 Fabrication of A356-CNT nanocomposites

A356-CNT nanocomposite samples were produced by a special compocasting method, as previously described in details in Ref. [22]. In each experiment, a given amount of the alloy was heated up and melted in a top-loading electric furnace to 700 °C. Then, 1 wt.% pure magnesium ingot was added to the melt. Subsequently, a ceramic-coated stirrer rotating at 500 r/min was introduced in the melt. At the same time, a given amount of Al-Ni-P-CNT composite powder, corresponding to 2 vol.% of CNTs, was injected on the surface of the melted alloy by argon flow, as a carrier gas. Once the injection completed, while the slurry was being concurrently stirred, the temperature was decreased to a predetermined temperature, subsequently, the slurry was cast into a steel die placed below the furnace. The used casting temperatures were 700 °C (fully liquid, hence stir casting) as well as 610 and 601 °C (semisolid, hence compocasting), corresponding to solid fractions of 15% and 30% according to Scheil equation, respectively. Analogous castings, but without reinforcement addition, were also produced for comparison.

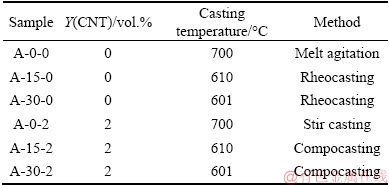

Table 2 shows the experimental conditions in different experiments. The designation A-X-Y was employed for identification of the samples, where “A” represents the A356 aluminum alloy, “X” indicates the solid fraction of the matrix alloy at the time of casting, and “Y” denotes the volume fraction of CNTs injected into the melt. “Melt agitation” and “rheocasting” methods were applied for casting monolithic samples at the fully liquid and the semisolid conditions, respectively. “Stir casting” and “compocasting” methods were implemented for casting composite samples at the fully liquid and the semisolid conditions, respectively.

Table 2 Experimental conditions in different experiments (Stirring speed: 500 r/min, reinforcement injection temperature: 700 °C)

2.3 Microstructural characterization

Microstructural characteristics including CNTs distribution, secondary dendrite arm spacing (SDAS) for the melt agitated stir cast samples and primary particle size of α(Al) grains for the rheocast and compocast samples were studied using optical (OM) and scanning electron (SEM) microscopy. Further details are shown elsewhere [22]. Moreover, energy dispersive X-ray analysis was employed for analyzing the wear debris after the test.

2.4 Density measurement

The experimental density of the composites was obtained by the Archimedes method, while the theoretical density was calculated using the mixture rule. The porosities of the produced composites were evaluated from the difference between the expected and the observed densities of each sample. The porosity of the composites was estimated using the following relation:

(1)

(1)

where P is the porosity, ρmc is the measured density of the composites, ρm is the theoretical density of the matrix alloy, ρCNT is the theoretical density of the reinforcement and VCNT is the volume fraction of CNT.

2.5 Wear test

Disc-shaped samples with 50 mm-diameter and 5 mm-thickness were cut from the cast specimens for the wear tests. The dry wear and the sliding friction behaviors were studied using a pin-on-disk tribometer. The pin (counterpart) was made from bearing steel with a diameter of 5 mm and an average hardness of HBN 695.

Wear tests were carried out at a sliding distance of 500 m, a constant sliding velocity of 0.11 m/s and three different applied loads of 1, 2 and 3 N. The room temperature and humidity were (23±2) °C and (56±5)%, respectively. The mass variations of discs were measured after the sliding distances of 10, 20, 30, 40, 60, 80, 100, 150, 200, 250, 300, 400 and 500 m by a precision balance with 0.0001 g resolution. Moreover, the wear surfaces and the wear debris of the selected samples, as well as their counterpart surfaces, were investigated by a Philips XL30 scanning electron microscope (SEM) to determine the governing wear mechanisms.

3 Results and discussion

3.1 Microstructure

Microstructural studies show the dendritic microstructures for the samples cast from the full liquid state, and non-dendritic microstructures for those cast within the semi-solid temperature range. In addition, it is observed that CNTs uniformly distributed in the Al matrix. It is worth noting that the average SDAS decreased by the addition of CNTs for samples which cast from the full liquid state (i.e. A-0-0 and A-0-2). Furthermore, the average cell size declined in the present of CNTs for samples cast from the semi-solid state (i.e. A-15-2 and A-30-2), which indicates that nanocomposite samples have smaller α(Al) particles than their corresponding monolithic samples. More detailed review can be seen in Ref. [22].

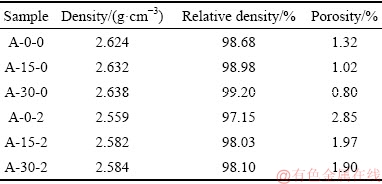

3.2 Density

The measured densities are listed in Table 3 for the various methods. As can be seen, the density of the monolithic sample grows by increasing the solid fraction phase. It is claimed that porosity can form by gas entrapment during stirring, air bubbles entering the slurry either independently or as air envelops around the reinforcement particles, water vapor on the surface of the particles, hydrogen evolution and solidification shrinkage [23]. In addition, the turbulent flow of the liquid alloy into the mold can result in the entrapment of air and mold gases into the melt, which in turn may translate into micro and macro porosity (voids or oxides) [24]. The reduction of turbulent flow during rheocasting results in decreasing the porosity formation that originates from entrained air [25]. Moreover, the nanocomposite samples have higher porosity than the unreinforced counterpart. This is due to the presence of interstitial voids in clusters and discontinuity caused during stirring such as gas entrapment and solidification shrinkage [24,25]. It should be noted that the compocast samples have less porosity than the stir cast one. Since in compocast samples, a considerable portion of solidification has taken place before pouring the slurry and the temperature of the slurry is lower than that in stir casting, the porosity arising from the solidification shrinkage and hydrogen evolution is smaller [12]. Also, less air entrapment is expected during pouring and mold filling due to the relatively high viscosity of composite slurries [26].

Table 3 Measured densities of different samples

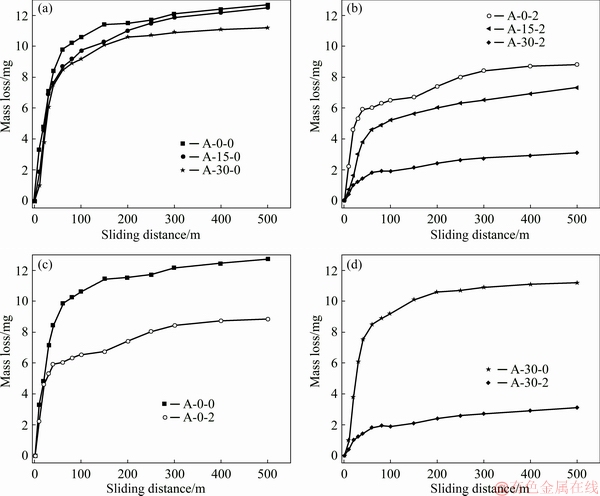

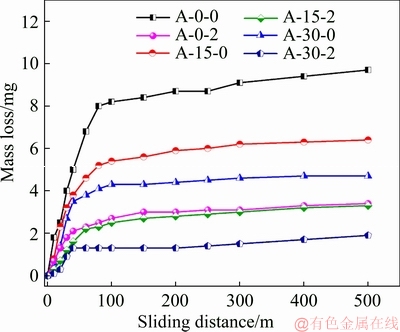

3.3 Effect of CNT on wear properties

Figures 2 and 3 show the variations of mass loss and wear rate versus the sliding distance under an applied load of 3 N for all samples, respectively. Figure 2 shows that the slopes of the wear loss curves for all the samples are sharp at the beginning of sliding distances but smooth out at higher distances. The reason for this behavior is that with the continuation of the sliding process, the temperature between metal-metal surfaces increases, and causes oxidation of the exposed metal. Then, the oxide debris is compacted and comminuted between the sliding surfaces to develop the wear- protective oxide layer [27].

Fig. 2 Mass loss versus sliding distance under load of 3 N for monolithic samples (a), nanocomposite samples (b), samples produced without solid fraction (c) and samples produced with solid fraction of 30% (d)

Fig. 3 Wear rate versus sliding distance under load of 3 N for monolithic samples (a), nanocomposite samples (b), samples produced without solid fraction (c) and samples produced with solid fraction of 30% (d)

In Fig. 2 (a), it can be seen that the mass loss of monolithic specimens is almost identical in the first 40 m, but after that, they exhibit different wear behaviors that root in the amount of their initial solid fraction. At the end of the test, sample A-30-0 that has the highest initial solid fraction possesses the lowest mass loss after a sliding distance of 500 m. Although all monolithic samples exhibit approximately identical wear rates (Fig. 3(a)). The reason for this behavior, in spite of the difference in the mass loss, is rooted in the difference in sample density. On the other hand, the wear properties of nanocomposite samples are more sensitive to the casting method (Figs. 2(b) and 3(b)). To be more precisely, the compocast samples (i.e. A-15-2 and A-30-2) demonstrate better wear properties than the stir cast one. Furthermore, the wear properties of the compocast samples with a higher solid fraction (A-30-2) improve in comparison with sample A-15-2.

It is also clear from Figs. 2(c, d) and 3(c, d) that the wear properties of nanocomposite samples are considerably better than the monolithic ones. For example, Fig. 3(d) demonstrates that at the end of the sliding distance (500 m), the wear rate of rheocast sample A-30-0 is 8.49×10-3 mm3/m, whereas that of the corresponding compocast sample A-30-2 is 2.4×10-3 mm3/m. Improvement in the wear properties of nanocomposite samples can be attributed to the enhancement of the hardness and resistance to plastic deformation of the samples in the presence of CNTs as well as the self-lubrication effects of CNTs [15,28].

Archard’s equation (Eq. (2)) determines the relationship of wear volume (V), hardness (H) and sliding distance (L).

(2)

(2)

where k is a dimensionless constant known as the wear coefficient and P is the load. According to this equation, the wear volume is diminished by increasing the hardness.

The hardness of the samples has been reported previously [22], where it is shown that hardness is significantly increased by the addition of CNTs, and the compocast A-30-2 sample has the highest hardness among the investigated samples. This is attributed to the decrease in the grain size of the matrix as well as the potential increase in the dislocation density at the interface of CNTs and the matrix due to the CTE (coefficients of thermal expansion) mismatch between them which would hinder the movement of the dislocations. It is also shown that the hardnesses of semisolid cast samples are higher than those of the corresponding fully liquid cast samples. This is associated with the less gas and shrinkage defects formed in the samples, as well as more uniform reinforcement dispersion in the matrix in the semisolid cast [29]. These results are consistent with the improvements observed in the wear properties as presented in Figs. 2 and 3, where the lowest mass loss and wear rate belong to the nanocomposite sample which was cast at the highest solid fraction, i.e. compocast A-30-2 sample.

Another reason that can be taken into account to describe the improvement of wear properties in nanocomposite samples is the self-lubrication effect of CNTs [30]. By formation of a CNT film on the surface, friction and wear are reduced, which is often correlated to the ability of CNTs to roll, thus, separate the rubbing surfaces. In fact, CNTs smear on the surface and create a tribolayer, which reduces the direct contact between the base body and the counterpart and results in smoother sliding.

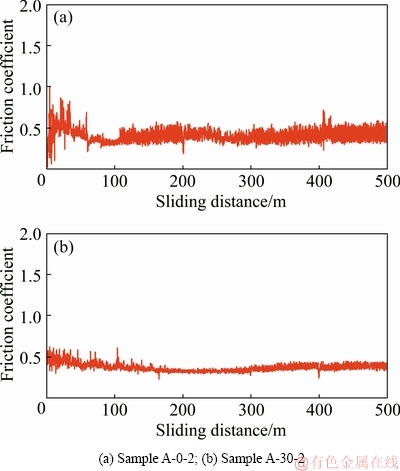

The friction coefficient of all the samples is also determined. As examples, the friction coefficients versus sliding distance of samples A-30-0 and A-30-2 at an applied load of 3 N are shown in Fig. 4.

Fig. 4 Friction coefficient versus sliding distance under load of 3 N

As shown in Fig. 4, in all cases, the friction coefficient tends to increase first, then it decreases and stabilizes. This seems to be due to the separation of impurities sticking on the sample surface as well as oxidation of the exposed metal, as mentioned previously [27,31]. It is obvious from Fig. 4(a) that the friction coefficient in the steady-state region fluctuates between 0.38 and 0.65 for the rheocast sample A-30-0, and 0.28 to 0.4 for the compocast sample A-30-2. This indicates that the mean friction coefficient is decreased in the presence of CNTs. This can be also related to the greater hardness of nanocomposite samples, as well as the self-lubricating property of CNTs. It is believed that on the harder surfaces of nanocomposite samples, the counterpart is not able to penetrate as much as it does on the softer surfaces of monolithic samples. As a result, the force required for plastic deformation decreases and the frictional force and friction coefficient are declined.

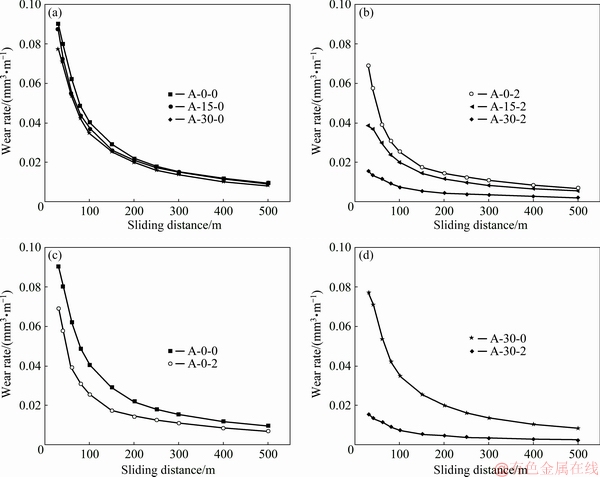

3.4 Effect of casting process on wear properties

Comparison of the mean friction coefficients of various samples produced in this study (Fig. 5) indicated that the semisolid cast samples have smaller friction coefficients than their corresponding fully liquid cast samples. Graph of friction coefficient versus sliding distance for two of the nanocomposite samples, i.e. stir cast sample A-0-2, and compocast sample A-30-2 are depicted in Fig. 6. As it is evident, the steady-state friction coefficient for these examples fluctuates in the range of 0.35-0.55 for the stir cast sample and in the range of 0.2-0.3 for the compocast sample.

Fig. 5 Mean steady-state friction coefficient of monolithic and nanocomposite samples

Figures 2, 3, 5 and 6 demonstrate that tribological properties of both monolithic and nanocomposite samples are improved by using the semisolid route and by increasing the solid fraction of the primary phase before casting, i.e. casting at lower temperatures within the semisolid region.

Higher hardness of semisolid cast samples (both rheocast and compocast) than their corresponding fully liquid cast samples is believed to be due to smaller grain size and lower gas and shrinkage defects formed in the semisolid cast samples [22]. Furthermore, as discussed in the Section 3.2, the samples fabricated by semisolid technique possess the higher densities which result in the improvement of mechanical properties.

Fig. 6 Friction coefficient versus sliding distance under load of 1 N

Furthermore, it has been evidently shown that compocasting improves the distribution and increases the incorporation of the reinforcements in the slurry [12,13,32-34]. In fact, during stirring within the semisolid temperature range of the matrix alloy, the primary solid particles formed are constantly colliding and rubbing against each other. This will result in the deagglomeration of the reinforcements and their better distribution in the slurry. The higher viscosity of the semisolid slurry and existence of solid particles in the slurry, reduce the chance of reinforcement segregation during casting and subsequent solidification in the mold. These benefits are supplementary to those mentioned for rheocasting. That may be the reason why the effects of the casting process are more pronounced in the composite samples.

It is interesting to see that not only the compocast sample in Fig. 6 has a smaller average friction coefficient than the stir cast sample, but its oscillation range is smaller than that of the stir cast sample. The latter is thought to be mainly due to better incorporation and distribution of CNTs in the matrix [35].

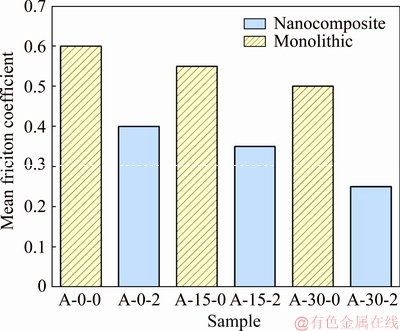

3.5 Effect of applied load on wear properties

Curves of mass loss versus sliding distance under the load of 3 N for all the samples are shown in Fig. 2. Furthermore, Fig. 7 depicts a similar graph under the load of 1 N. It can be concluded that the wear resistance of samples improves by both CNT addition to the matrix and semisolid processing (rheocasting/ compocasting). In addition, the sample A-30-2, reinforced by 2 vol.% CNT and cast at a solid fraction of 30%, experiences the lowest wear loss. The reasons for such behavior are explained in the previous sections.

Fig. 7 Curves of mass loss versus sliding distance under load of 1 N

Furthermore, it is interesting to note that under the load of 1 N (Fig. 7), the mass loss curves of nanocomposite samples are situated relatively close to each other, whereas, in the case of the monolithic samples, they are more widely spaced. However, under 3 N, the opposite is true (Figs. 2(a) and (b)). Apparently, this is due to the fact that the produced samples response differently to the wear process under various loads. It can be hypothesized that under 1 N, the wear intensity is low and the presence of CNTs in the structure can drastically drop the wear loss. Therefore, the microstructural characteristics have a lower influence on the wear rate of nanocomposite samples. However, in the absence of CNTs, the structural characteristics play a more remarkable role, and the less defective structure of rheocast samples produces a better wear resistance.

Under the load of 3 N, the wear condition is severer, hence the applied load could easily activate different wear mechanisms regardless of the sample’s structure. Under such conditions, the dispersion of CNTs in the matrix improves the wear resistance of the samples through the various mechanisms, discussed in Section 3.6. Higher incorporation and better distribution of CNTs in the matrix will further improve the wear properties of the compocast samples.

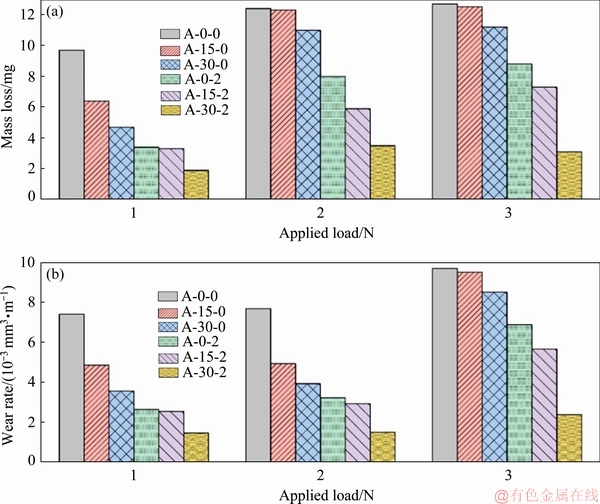

The effects of applied load on the mass loss and wear rate of monolithic and nanocomposite samples are plotted in Figs. 8(a) and (b), respectively. As it is evident, the mass loss and the wear rate of both monolithic and nanocomposite samples increase by the applied load raise. This behavior can be justified by changing the wear regime from mild to severe mode. The increase in the applied load leads to increase in penetration of the hard asperities of the counterpart surface to the softer disk surface (produced samples), increasing the microcracking tendency of the subsurface, and also increases in the deformation and fracture of asperities of the softer surface [36].

Fig. 8 Effect of applied load on mass loss (a) and wear rate (b) of samples (The presented data measured after sliding distance of 500 m)

In addition, Fig. 8 shows that the mass loss and the wear rate decrease by the addition of CNTs and processing in the semisolid condition.

3.6 Wear mechanism

Under the action of a normal force, the contact surfaces between a base body and a counterpart could bond to each other by inter-diffusion and interatomic (Van de Waal’s) forces at their asperities. Wear occurs when the interfaces in contact are made to slide resulting in separation of locally adhered regions. This separation may occur by one or more mechanisms [37].

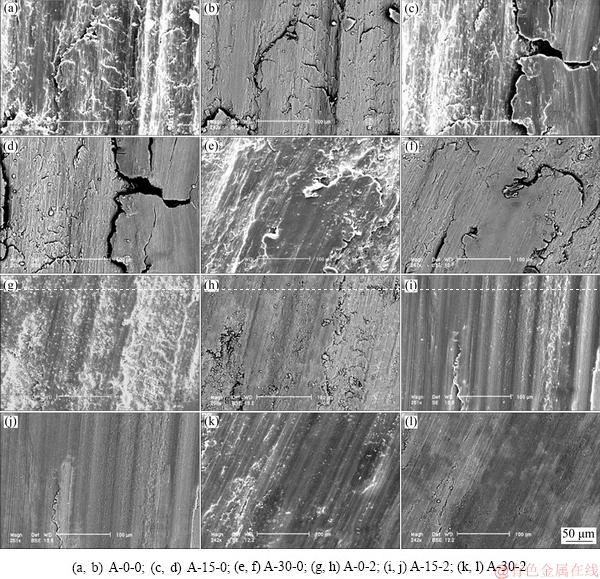

Figure 9 illustrates representative SEM images of the worn surface of all the samples. As represented in Fig. 9, several mechanisms are involved in the wearing of the samples. The backscattered electron (BSE) SEM images shown in Fig. 9 can be helpful for the identification of the wear mechanism. In these images, any color change indicates an alteration in the material and the chemical composition of the worn surface. The aforementioned color variations can be linked to oxide layers, oxide wear debris, and the presence of carbon arising from CNTs on the worn surface.

3.6.1 Wear mechanism of monolithic samples

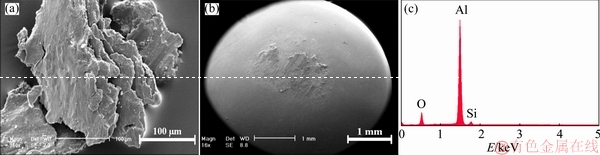

Figure 9(a) shows signs of metal flow and deep craters on the worn surface of the monolithic sample produced by the melt agitation technique (sample A-0-0). Evidence of metal flow and stretch of coarse particles on each other are clearly visible on the wear debris (Fig. 10(a)). Figure 10 (c) depicts the energy dispersive X-ray spectrometry (EDS) spectra for the coarse particles indicated in Fig. 10(a). The result indicates that there is no metal transfer from counterpart to the disk. Moreover, the oxygen pick confirms the presence of an oxide layer on the surface of the aluminum alloy disk. Metal transfer to the counterpart pin used in the wear test of this sample is shown in Fig. 10(b). Additionally, the steel pin used in the test gained 0.8 mg after a sliding distance of 500 m. These indications present an extreme plastic deformation and effective transfer of material from the basebody to the counterpart during the wear test. Such characteristics of the worn surface indicate the predominant wear mechanism of sample A-0-0 to be the adhesive one.

Figures 9(c) and (e) indicate that the dominant wear mechanism for rheocast samples A-15-0 and A-30-0 is delamination. According to the delamination mechanism, plastic deformation and crack nucleation and propagation at a subsurface of the basebody lead to the separation of wear particles.

Fig. 9 SEM images (SE and BSE modes) of wear surfaces of different samples under load of 3 N

Fig. 10 SEM image of wear debris of monolithic sample A-0-0 produced by melt agitation (a), surface of counterpart pin used in wear test of sample (b) and EDS analysis (c) of wear debris shown in Fig. 10(a)

Delamination is based on the theory of dislocation accumulation at the subsurface [38]. At the early stages of wear, dislocations close to the surface do not have a high density, because the atomic layers on the surface bond only from one side. Therefore, the surface dislocations are able to show themselves as plastic deformation. That is why the work hardening phenomenon does not dramatically occur below and on the surface of the samples at the beginning of the wear. By increasing the sliding distance, dislocations can accumulate at the subsurface. This will cause plastic deformation and consequently lead to void formation. The voids are stretched by the continuation of the wear process leading to the formation of cracks. Then, the cracks propagate and join together and eventually reach the surface of samples, which results in delamination. Cracks caused by delamination are clearly visible in Figs. 9(c) and (e).

3.6.2 Wear mechanism of nanocomposite samples

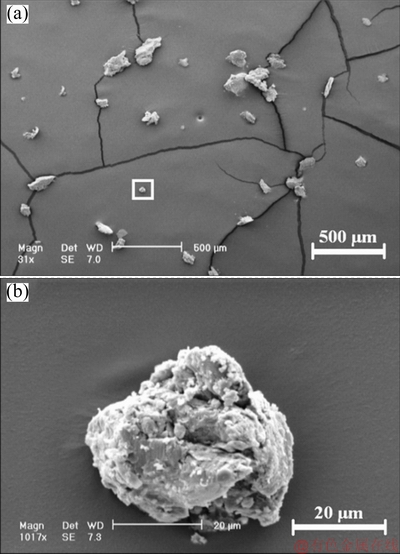

As depicted in Figs. 9(g), (i) and (k), the wear surfaces of the nanocomposite samples consist of many grooves which are signs of the abrasive wear mechanism. These figures also show that depth and width of the grooves are reduced by changing the casting process from stir casting (A-0-2) to compocasting (A-15-2 and A-30-2) and by increasing the solid fraction from 15% to 30% in the compocast samples. Figure 11 displays that morphology of the wear debris has changed from coarse delaminates, which prevailed in monolithic samples, to finer rather equiaxed particles. Therefore, it is clear that the predominant wear mechanism has changed from delamination to abrasion by the addition of CNTs in the matrix. ZHOU et al [39] reported the same mechanism for wear of Al-CNT nanocomposites fabricated by a pressureless infiltration process.

Fig. 11 SEM images of wear debris of compocast sample A-30-2

It has been suggested that surfaces with hardness less than half of that of the abrasive material, are typically prone to the abrasion mechanism [40]. In this study, the hardness of the counterpart surface used was HBN 695. The hardness of the basebodies [22], is equal or less than HBN 75 which is by far less than half of this value. Consequently, the occurrence of abrasive wear is very likely in these composites. Figures 9(a), (c) and (e) illustrate that the abrasive wear has also occurred in the monolithic samples. Nevertheless, it is not the predominant mechanism as discussed before.

Abrasive wear occurs when a hard and rough surface has a sliding motion against a soft and smoother one. Due to the usually small size of the contact points between the abrasive and the basebody surfaces, very high local pressures may occur at the contact points. During the relative movement of the surfaces, scratches, grooves, and waves are formed on the surface of the softer surface which are typical wear forms of the abrasive wear [41]. There are two general situations for abrasive wear, i.e. two-body and three-body abrasions. In the latter, the hard surface is the third body, which usually consists of small abrasive particles, is a hard surface caught between the two other surfaces. The third body is sufficiently harder and is able to abrade one or both mating surfaces [42]. It should be noted that the intensity of the abrasive wear depends on the basebody hardness.

It was noticed that surfaces of nanocomposite samples would oxidize during the wear tests. Similar findings are reported by DONG et al [43] and ZHOU et al [39] in the case of copper matrix and aluminum matrix composites reinforced by CNTs, respectively. It is shown that during the wear test, such oxide films fracture and turn to oxide debris between the two surfaces. This will result in a three-body abrasion of the sample surface. With gradual abrasion of the metal matrix, the near-surface CNTs are revealed and maybe also abraded to form a low-friction lubricant layer between the two surfaces that significantly reduces the abrasive wear [43,44]. DICKRELL et al [45] allege that MWCNTs which perpendicularly aligned to the contact plane consistently show a high friction coefficient (μ=0.795). However, when they are parallelly aligned to the contact plane, the friction coefficient would be very low (μ=0.090). Considering this, ARAI et al [46] believe that during the wear process, when the matrix around the CNTs is removed, plastic deformation gradually arranges the revealed CNTs, in which one of their ends is still locked into the matrix in the transverse direction. This causes that CNTs act as a solid lubricant resulting in a lower friction coefficient. It is also possible that some of the CNTs detach from the matrix and prevent direct contact of the counterpart and the basebody. These very small and tubular CNTs can easily move and slide in the tribolayer. As a result, the wear rate and friction coefficient drop drastically.

It should be noted that such conditions diminish the load transmission to the subsurface of the basebody and result in less subsurface plastic deformation and, consequently, a lower chance of activation of the delamination mechanism. This may be why no indication of delamination is detected on the worn surfaces of the composite samples in this work. It is postulated that in monolithic samples since no surface lubrication occurs, load transfer through the surface results in large subsurface plastic deformation and activation of delamination mechanism as discussed in the previous section.

4 Conclusions

(1) The addition of CNTs to the A356 matrix could substantially reduce the wear loss, wear rate and friction coefficient of nanocomposite samples.

(2) The wear properties of nanocomposite samples are more sensitive to the casting technique rather than monolithic ones, and improved by changing the casting process from fully liquid (melt agitation or stir casting) to semisolid routs (rheocasting or compocasting) and also by casting at higher fractions of the primary phase.

(3) The adhesion and delamination are the dominant wear mechanism of monolithic samples fabricated by fully liquid or semisolid routes.

(4) The abrasion mechanism is the main wear mechanism of nanocomposite samples, regardless of the casting methods.

(5) The difference in the wear mechanisms is discussed in terms of the effects of CNTs on the friction coefficient of the surfaces and the load transfer to subsurface areas of the nanocomposite samples.

Acknowledgments

The authors gratefully acknowledge the financial support of the Ministry of Science and Higher Education of the Russian Federation in the framework of Increase Competitiveness Program of NUST “MISiS” (No. К2-2019-007), implemented by a governmental decree dated 16th of March 2013, N 211.

References

[1] SEKHAR R, SINGH T P. Mechanisms in turning of metal matrix composites: A review [J]. Journal of Materials Research and Technology, 2015, 4: 197-207.

[2] CHAWLA N, CHAWLA K K. Metal matrix composites [M]. Boston: Springer, 2006.

[3] CHENG H, XIE Y C, TANG Q H, RAO C, DAI P Q. Microstructure and mechanical properties of FeCoCrNiMn high-entropy alloy produced by mechanical alloying and vacuum hot pressing sintering [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 1360-1367.

[4] WANG B P, WANG L, XUE Y F, WANG Y W, ZHANG H F, FU H M. Dynamic indentation response of porous SiC/Ti-based metallic glass composite [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 3154-3160.

[5] NIU T, CHEN W W, CHENG H W, WANG L. Grain growth and thermal stability of nanocrystalline Ni-TiO2 composites [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 2300-2309.

[6] YAO Y T, JIANG L, FU G F, CHEN L Q. Wear behavior and mechanism of B4C reinforced Mg-matrix composites fabricated by metal-assisted pressureless infiltration technique [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2543-2548.

[7] SUN Y H, WANG R C, PENG C Q, FENG Y, YANG M. Recent progress in Mg-Li matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1-14.

[8] LI J F, ZHANG L, XIAO J K, ZHOU K C. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3354-3362.

[9] CAI A H, XIONG X, LIU Y, AN W K, ZHOU G J, LUO Y, LI T L, LI X S. A Cu-based bulk amorphous alloy composite reinforced by carbon nanotube [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2191-2197.

[10] NATARAJAN N, KRISHNARAJ V, DAVIM J P. Metal matrix composites [M]. Cham: Springer International Publishing, 2015.

[11] EL-ESKANDARANY M S. Fabrication of nanocomposite materials [M]. 2nd ed. Oxford: William Andrew Publishing, 2015.

[12] AMIRKHANLOU S, NIROUMAND B. Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s788-s793.

[13] GHAHREMAINIAN M, NIROUMAND B. Compocasting of an Al-Si-SiCp composite using powder injection method [J]. Solid State Phenomena, 2008, 141-143: 175-180.

[14] ONO-OGASAWARA M. CNTs in composites: A case study [C]// DOLEZ P I. Nanoengineering. Amsterdam: Elsevier, 2015: 673-692.

[15] BASTWROS M M H, ESAWI A M K, WIFI A. Friction and wear behavior of Al-CNT composites [J]. Wear, 2013, 307: 164-173.

[16] ABDULLAHI U, MALEQUE M A, NIRMAL U. Wear mechanisms map of CNT-Al nano-composite [J]. Procedia Engineering, 2013, 68: 736-742.

[17] LI H P, FAN J W, KANG J L, ZHAO N Q, WANG X X, LI B E. In-situ homogeneous synthesis of carbon nanotubes on aluminum matrix and properties of their composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2331-2336.

[18] HAO X N, ZHANG H P, ZHENG R X, ZHANG Y T, AMEYAMA K, MA C L. Effect of mechanical alloying time and rotation speed on evolution of CNTs/Al-2024 composite powders [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2380-2386.

[19] HE W J, LI C H, LUAN B F, QIU R S, WANG K, LI Z Q, LIU Q. Deformation behaviors and processing maps of CNTs/Al alloy composite fabricated by flake powder metallurgy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3578-3584.

[20] AL-QUTUB A M, KHALIL A, SAHEB N, HAKEEM A S. Wear and friction behavior of Al6061 alloy reinforced with carbon nanotubes [J]. Wear, 2013, 297: 752-761.

[21] ABBASIPOUR B, MONIRVAGHEFI S M, NIROUMAND B. Electroless Ni-P-CNT composite coating on aluminum powder [J]. Metals and Materials International, 2012, 18: 1015-1021.

[22] ABBASIPOUR B, NIROUMAND B, MONIR VAGHEFI S M. Compocasting of A356-CNT composite [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1561-1566.

[23] ILEGBUSI O J, YANG J. Porosity nucleation in metal-matrix composites [J]. Metallurgical and Materials Transactions A, 2000, 31: 2069-2074.

[24] PODDAR P, MUKHERJEE S, SAHOO K L. The microstructure and mechanical properties of SiC reinforced magnesium based composites by rheocasting process [J]. Journal of Materials Engineering and Performance, 2008, 18: 849.

[25] DEVARAKONDA S K, SUMAN K N S, SASANKA T, RAVINDRA K, PODDAR P, SIVA B V. Microstructure, mechanical response and fractography of AZ91E/Al2O3 (p) nano composite fabricated by semi solid stir casting method [J]. Journal of Magnesium and Alloys, 2017, 5: 48-55.

[26] AMIRKHANLOU S, REZAEI M R, NIROUMAND B, TOROGHINEJAD M R. High-strength and highly-uniform composites produced by compocasting and cold rolling processes [J]. Materials & Design, 2011, 32: 2085-2090.

[27] GLASCOTT J, STOTT F H, WOOD G C. The effectiveness of oxides in reducing sliding wear of alloys [J]. Oxidation of Metals, 1985, 24: 99-114.

[28] DEUIS R L, SUBRAMANIAN C, YELLUP J M. Dry sliding wear of aluminium composites—A review [J]. Composites Science and Technology, 1997, 57: 415-435.

[29] KHOSRAVI H, BAKHSHI H, SALAHINEJAD E. Effects of compocasting process parameters on microstructural characteristics and tensile properties of A356-SiCp composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2482-2488.

[30] REINERT L, SUAREZ S, ROSENKRANZ A. Tribo-mechanisms of carbon nanotubes: Friction and wear behavior of CNT-reinforced nickel matrix composites and CNT-coated bulk nickel [J]. Lubricants, 2016, 4: 11.

[31] SUNDARKRISHNAA K L. Friction material composites: Materials perspective [M]. Berlin: Springer, 2012.

[32] AMIRKHANLOU S, NIROUMAND B. Development of Al356/SiCp cast composites by injection of SiCp containing composite powders [J]. Materials & Design, 2011, 32: 1895-1902.

[33] GHAHREMANIAN M, NIROUMAND B, PANJEPOUR M. Production of Al-Si-SiCp cast composites by injection of low-energy ball-milled Al-SiCp powder into the melt [J]. Metals and Materials International, 2012, 18: 149-156.

[34] SHAYAN M, NIROUMAND B. Synthesis of A356–MWCNT nanocomposites through a novel two stage casting process [J]. Materials Science and Engineering A, 2013, 582: 262-269.

[35] MICHAUD V J. Liquid-state processing [C]// SURESH S, MORTENSEN A, NEEDLEMAN A. Fundamentals of Metal-Matrix Composites. Boston: Butterworth-Heinemann, 1993: 3-22.

[36] MAZAHERY A, SHABANI M O. Nano-sized silicon carbide reinforced commercial casting aluminum alloy matrix: Experimental and novel modeling evaluation [J]. Powder Technology, 2012, 217: 558-565.

[37] LUDEMA K C. Friction, wear, lubrication: A textbook in tribology [M]. Boca Raton: CRC Press, 1996.

[38] JAHANMIR S, SUH N P, ABRAHAMSON E P. The delamination theory of wear and the wear of a composite surface [J]. Wear, 1975, 32: 33-49.

[39] ZHOU S M, ZHANG X B, DING Z P, MIN C Y, XU G L, ZHU W M. Fabrication and tribological properties of carbon nanotubes reinforced Al composites prepared by pressureless infiltration technique [J]. Composites Part A: Applied Science and Manufacturing, 2007, 38: 301-306.

[40] SALEHI M, ASHRAFIZADEH F. Surface metallurgy and tribology [M]. Isfahan: Iranian Society of Surface Science & Technology Publishing, 1995. (in Persian)

[41] ENGLERT M, SCHLARB A K. Tribological characterization of polymer nanocomposites[C]// MITTAL V. Characterization Techniques for Polymer Nanocomposites. Weinheim: Wiley, 2012: 143-166.

[42] BHUSHAN B. Principles and applications of tribology [M]. 2nd ed. Hoboken: Wiley, 2013.

[43] DONG S R, TU J P, ZHANG X B. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes [J]. Materials Science and Engineering A, 2001, 313: 83-87.

[44] KIM K T, CHA S I, HONG S H. Hardness and wear resistance of carbon nanotube reinforced Cu matrix nanocomposites [J]. Materials Science and Engineering A, 2007, 449-451: 46-50.

[45] DICKRELL P L, SINNOTT S B, HAHN D W, RARAVIKAR N R, SCHADLER L S, AJAYAN P M, SAWYER W G. Frictional anisotropy of oriented carbon nanotube surfaces [J]. Tribology Letters, 2005, 18: 59-62.

[46] ARAI S, FUJIMORI A, MURAI M, ENDO M. Excellent solid lubrication of electrodeposited nickel-multiwalled carbon nanotube composite films [J]. Materials Letters, 2008, 62: 3545-3548.

Benyamin ABBASIPOUR1, Behzad NIROUMAND1, Sayed Mahmoud MONIR VAGHEFI1, Mohammad ABEDI2

1. Department of Materials Engineering, Isfahan University of Technology, Isfahan 84156-83111, Iran;

2. National University of Science and Technology ‘‘MISiS’’, Moscow 119049, Russia

摘 要:研究液态成形和半固态成形法制备的A356铝合金整体铸件和A356-CNT纳米复合铸造件的摩擦学行为。采用熔体搅拌、流变铸造、搅拌铸造、复合铸造等不同工艺制备样品。研究碳纳米管(CNTs)的加入、铸造工艺和施加载荷对磨损性能和磨损机理的影响。结果表明,添加碳纳米管显著降低了纳米复合材料的磨损量、磨损率和摩擦因数。铸造工艺由液态成形变为半固态成形,和初相含量的增加是提高合金尤其是纳米复合合金样品耐磨性能的两个主要因素。此外,研究还发现液态成形和半固态成形两种方法制备的整体铸件其主要磨损机理分别是粘着磨损和剥层磨损。然而,无论制备工艺如何,磨粒磨损是纳米复合材料的主要磨损机理。

关键词:A356 铝合金;纳米复合材料;复合铸造; 碳纳米管(CNT);磨损机制;耐磨性能

(Edited by Xiang-qun LI)

Corresponding author: Mohammad ABEDI; Tel: +7-495-9550113; Fax: +7-495-9550113; E-mail: abedi@edu.misis.ru

DOI: 10.1016/S1003-6326(19)65107-1