Creep and tensile properties of press molding joined GMT-sheets

Jin-Woo KIM1, Dong-Gi LEE2

1. Center for NDE, Iowa State University, Ames, IA 50011, USA;

2. Department of Mechatronics Engineering, Chosun University, Gwang-ju, 501-759, Korea

Received 21 April 2010; accepted 10 September 2010

Abstract: GMT-sheet is used in automobile bumper with high rigidity and strength, and its joining strength is influenced by lap length, one of the joined molding conditions. Fracture strength was calculated by dividing fracture load with cross-sectional area. Total five repeated measurements were made to obtain the average value. Tensile test was conducted at room temperature for 10 specimens. In addition, the effect of compression ratio on creep and tensile performance during lap joined molding was discussed. With increasing lap length, the lap joining efficiency of GMT-sheet was increased. However, higher compression ratio reduced the joining efficiency. Creep test on GMT-sheet showed abrupt fracture without tertiary creep. This can be explained by the weak thermal resistance of the resin. If GMT-sheet was exposed to high temperature for a long time, it was easily failed by external force.

Key words: GMT-sheet; randomly oriented composite; unidirectional oriented composite; compression ratio; lap joint

1 Introduction

Fiber reinforced plastics (FRP) can be classified as thermosetting and thermoplastic composites by the characteristics of resin. Most purposes of plastic composite are focused on the development of high rigidity and thermal resistant material. Therefore, research and development have been focused on thermosetting composite rather than thermoplastics[1-2].

However, FRP is superior composite material, but the environmental and recycling issues have been surfaced recently. That is, conventional plastic composites are based on thermosetting resin, but the issues of waste disposal, recycling, etc are raised. To overcome these challenges, glass mat reinforced thermoplastic sheet (GMT-sheet) made of impregnation of polypropylene into glass mat, which has superior performance, high functionality, and exceptional molding characteristics, has come into spotlight. Benefits of GMT-sheet are relatively low cost due to widely used material of polypropylene and glass mat, and high rigidity and toughness[3-4].

In addition, GMT-sheet has many advantages such as molding characteristics, strength, hardness, and chemical stability. Due to the thermoplastic resin, it is the most promising composite material. As described before, the applicability on automobile component in GMT-sheet is expanding. To expand its recycling application, GMT-sheet could be lap molding joined. Because joined GMT-sheet is usually applied on the external environment, its creep characteristic, which evaluates the maintenance of properties in the environment, should be understood. Research on creep has been focused on composite material. The tensile creep of a long-fiber glass mat thermoplastic (GMT) composite was researched by viscoelastic viscoplastic constitutive modeling. The temperature effects on creep behavior of continuous fiber GMT composites were studied. The shear creep of epoxy at the concrete FRP interfaces was studied. But the creep characteristics of GMT-sheet have been rarely studied[5-8].

In this study, to recycle GMT-sheet, which is applied to automobile bumper due to high rigidity and strength, the joining strength is anticipated through changing lap length, one of joined molding conditions. In addition, effect of compression ratio on creep and tensile performance during lap joined molding is discussed.

2 Compression ratio and lap joining efficiency

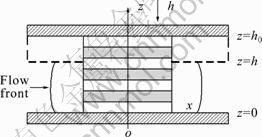

During high temperature and compression lap joined molding, specimen is arranged, and fixed in width direction, as shown in Fig.1. If specimen is pressed from initial thickness h0 to h, the compression ratio, Rcr, can be defined as[9]

(1)

(1)

where h is the thickness of molded joint GMT-sheet, and h0 is the thickness of GMT-sheet.

Fig.1 Schematic for slab-shaped part compression molding

Equation for average stress on cross-section of specimen is shown as Eq.(2), and five experiments were carried out to calculate the average value[10].

(2)

(2)

where σt is the maximum stress (MPa); Pt is the maximum load (N); b is the width of specimen (mm); and t is the thickness of specimen (mm).

The efficiency of lap joining (η) can be calculated by Eq.(3), and it is tested 5 times to calculate the average value.

η=(RGMT-MJ-RS)/(RGMT-RS) (3)

where RS is the strength of sheet, RGMT is the strength of GMT, and RGMT-MJ is the strength of the molded joint GMT.

3 Experimental

3.1 Property and molding condition for GMT-sheet composite

The material for this experiment was commercially available product from AZDEL (USA), and the initial thickness h0 was 3.8 mm. This GMT-sheet was cut into rectangular shape in dimensions of 32 mm (width) × 100 mm (length) × 3.8 mm (thickness) with diamond cutter.

To obtain optimal molding temperature for GMT-sheet, the thermal property of material was measured with STA 1500H. From the result, polypropylene in GMT-sheet exhibits mass change at 272.40 °C. Therefore, the molding temperature was set to 200 °C for hot compression molding. During molding process, GMT-sheet was heated with electric oven at 200 °C for 40 min, and then charged into mold. The dimensions of mold was 32 mm × 300 mm. A hydraulic hot press with 25 t capacity (Carver, 2518) was used. In the mold, a thermocouple was attached, and a rod/plate heater was used.

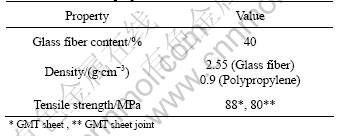

To estimate the lap joining efficiency of GMT-sheet molding, the mechanical properties of GMT-sheet molding before and after high temperature compressions are compared in Table 1. The tensile strength of the molded joint was decreased by about 10% compared with the GMT sheet strength. Because fibers were broken, the fiber orientation was wrenched. The blank and mold temperatures were set to 200 °C, the compression ratio was 0, and the pressing speed was 10 mm/min.

Table 1 Mechanical properties of GMT-sheet

3.2 Joined molding and tensile test of GMT-sheet

Thermoplastic polymer becomes soft with increaseing temperature, and can be joined at lower temperature through fusion welding. Fusion welding is especially beneficial to joining of GMT-sheet, which cannot be joined with adhesives. Therefore, the thickness of GMT-sheet was 3.8 mm, the lap length was constant as 9 mm, and the compression ratios were 0, 0.15, 0.29 and 0.42, respectively. The temperatures of blank and mold were maintained at 200 °C, and the lap joined welding was conducted by charging into mold with the same cavity. Mold was adjusted to longitudinal flow by limiting width direction.

During lap joined molding of GMT-sheet, the mechanical properties are degraded at high temperature and high pressure. Therefore, the estimation of lap joining efficiency is important. First of all, material was lap joined at the same condition to joined molding, and each tensile strength was measured. Lap joined molded GMT-sheet was cut into rectangular shape as 20 mm × 140 mm according to ASTM D2990 with diamond cutter. Fracture strength was calculated by dividing fracture load with cross-sectional area (width thickness). Total five repeated measurements were made to obtain the average value.

Tensile test was conducted with UTM (5 t, Houndfield) at room temperature for 10 specimens each. The cross head speed was 1.26 mm/min.

3.3 Creep test on GMT-sheet

Initial deformation is instantaneous deformation, which is the summation of elastic and time-independent plastic deformation. Primary creep is called as transient creep, which exhibits relatively high speed of deformation, but reduced strain rate. Secondary creep is steady state creep, which maintains constant deformation through balance between hardening and recovery. Tertiary creep is accelerated creep, which can be found in high stress and load condition. This area displays increased strain rate until fracture and reduction of effective cross-section due to internal void or shrinkage. In this experiment, testing equipment for creep consisted of furnace and temperature controller.

Test temperature for creep was selected as 50 °C with environment consideration of automobile bumper. Stress was chosen between 30%-60% of tensile strength from UTM. Displacement was measured with the Pan recorder from the signal of LVDT. Specimen was lap molding joined, and joined area will be fractured as notch. By reflecting fixation area by creep tester, specimen was cut into rectangular shape with diamond cutter. Test temperature was maintained constantly, and the load was applied after temperature reached steady state (secondary creep). Compression ratio and stress were changed until specimen was fractured.

4 Results and discussion

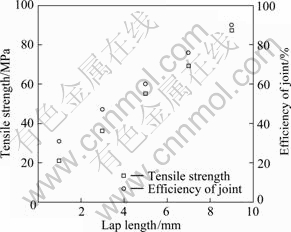

Figure 2 shows the effect of lap length on tensile strength of joint. To make the same thickness with commercial GMT-sheet, specimen was prepared with compression ratio (Rcr) of 0, and overlapped. The width direction was limited, and the flow to longitudinal was permitted. Randomly oriented composite with 40% of fiber content was lap joined at high temperature and compression. The tensile strength of lap joint with the change in lap length is shown in Fig.2. The larger lap length indicates enhanced tensile strength.

Fig.2 Effect of lap length on tensile strength and efficiency of joint

In addition, the lap joining efficiency with the change of lap length was calculated. The tensile strength values of lap joined molding and molding without lapping were compared to calculate lap joining efficiency. In addition, the difference in strength with lap length is shown in Fig.2. Lap joining efficiency is increased with increasing lap length.

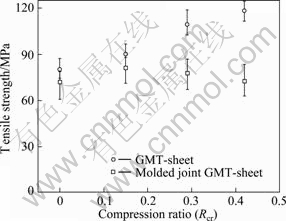

Figure 3 compares the tensile strength of additional joined molding specimens using the same lap length (9 mm), and press molded with different compression ratios and no-overlapping in GMT-sheet. In Fig.3, the molded specimens without joints exhibit fiber re-orientation by increased compression ratio due to the difference in flow rate between resin and reinforcement.

Fig.3 Tensile strength of GMT-sheet and molded joint GMT-sheet with compression ratio (Rcr)

Specimen with higher fiber content shows higher tensile strength. Specimens with joints show initial increase in strength due to fiber reorientation and increased fiber content at lower compression ratios, but experience fiber breakage in the joint interface at higher compression ratios and lose strength accordingly.

Meanwhile, for the lap joined molding, the low compression ratio shows higher tensile strength. This can be elucidated by the low lap joining efficiency from high flow in polypropylene at higher compression ratio as well as broken fibers. When comparing the tensile strength values of GMT-sheet and molded joint GMT-sheet, less than 0.1 of compression ratio shows the best efficiency.

However, if the compression ratio is set to be 0, the tensile strength is deteriorated by void effect from semi-fusion state of polypropylene.

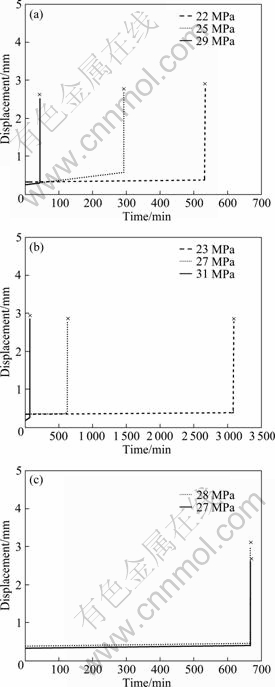

Figure 4 shows the creep test results of GMT-sheet at 30%, 35%, and 40% of fracture strength under constant temperature (50 °C). As shown in Fig.3, the joined molding specimen can endure longer time at lower compression ratio. Higher stress shows faster fracture. As expected from Fig.3, strain rate with load change is quite stable when the compression ratio is less than 0.1.

Fig.4 Creep curves of GMT-sheet with different compression ratios: (a) Rcr=0.29; (b) Rcr=0.15; (c) Rcr=0.06

The GMT-sheet does not exhibit typical creep curve, and fractures right away skipping tertiary creep. During creep deformation, the secondary creep fracture can be explained by the load concentration on reinforcing fiber. In addition, premature fracture without tertiary creep is from weak to heat resin. Thermoplastic resin is fractured right away when load capacity of reinforcing fiber is exceeded.

Figure 5 shows the change in creep state with compression ratios of 0.15 and 0.29 with changing temperature. Press molding joined GMT-sheet is very sensitive to temperature change from creep test. In addition, higher compression ratio induces high flow of resin, and increases fiber content. Therefore, there is much difference in fracture time with compression ratio.

Fig.5 Comparison of creep performance with temperature and at different compression ratios and tensile stress of 23 MPa

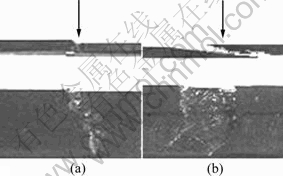

Figure 6(a) shows the front and side view of fracture in GMT-sheet after tensile test. During high temperature compression, cross-flow of fiber occurs between nearby layers. According to fiber bridging effect, fractured surface is sharp due to crack expansion when crack is propagated at room temperature.

Fig.6 Rupture shape of GMT-sheet: (a) Tensile rupture specimen; (b) Creep rupture specimen

Figure 6(b) shows the view of fracture in GMT-sheet after creep test. Due to the effect of temperature, fiber bridging effect does not occur, and long and inclined fracture surface is formed due to layered crack propagation.

Therefore, lap joined molding of GMT-sheet is not suitable for the application with longer exposure to high temperature. Therefore, appropriate joining method should be further studied.

5 Conclusions

With increasing the lap length, the lap joining efficiency of GMT-sheet is increased. However, higher compression ratio reduces the joining efficiency. Creep test on GMT-sheet shows abrupt fracture without tertiary creep. This can be explained by the weak thermal resistance of resin. If GMT-sheet is exposed to high temperature for a long time, it is easily failed by external force. When the compression ratio in lap joined molding increases, resin flows faster than reinforcement. Due to the reduced amount of polypropylene, the fracture speed is increased even faster. The fracture surface of lap joined molded GMT-sheet lap at room temperature shows fiber bridging effect. In creep test, the fracture surface shows slip of lap joining without fiber bridging effect due to thermal sensitivity of resin.

References

[1] MALLICK P K, NEWMAN S. Composite materials technology [M]. New York, USA: Hanser Publisher, 1990.

[2] SRIVASTAVA V K, KAWADA H. Fatigue behaviour of alumina-fibre-reinforced epoxy resin composite pipes under tensile and compressive loading conditions [J]. Comp Sci and Technol, 2001, 61: 2393-2403.

[3] EBERHARDT C, CLARKE A, VINCENT M, GIROUD T, FLOURET S. Fibre-orientation measurements in short-glass-fibre composites II: A quantitative error estimate of the 2D image analysis technique [J]. Comp Sci and Technol, 2001, 61: 1961-1974.

[4] KIM H, CHOI Y S, LEE C H, HAN K Y, LEE D G. Mechanical properties of GMT-sheet on press joined molding [J]. The Korea Comm for Oc Resources and Eng, 2000: 305-314.

[5] CHOI K, K MESHGIN P, TAHA M M. Shear creep of epoxy at the concrete-FRP interfaces [J]. Comp Part B: Eng, 2007, 38(5-6): 772-780.

[6] ZHAO R, ZHOU X, DAI G. Effect of the microstructure of GMT on its mechanical properties [J]. Polymer Comp, 2002, 23(6): 1026-1035.

[7] PRASAD D, PEAL L, XINRAN X. Temperature effects on creep behavior of continuous fiber GMT composites [J]. Comp Part A: Applied Sci and Manuf, 2009, 48(8): 1071-1081.

[8] PRASAD D, PEARL L, XINRAN X, PETER H F. Tensile creep of a long-fibre glass mat thermoplastic (GMT) composite. II. Viscoelastic-viscoplastic constitutive modeling [J]. Polymer Comp, 2008, 30(9): 1024-1211.

[9] YAGUCHI H, HOJO H, LEE D G, KIM E G. Measurement of planar orientationof fibers for reinforced thermoplastics using image processing [J]. Int Polymer Proc, 1995(3): 262-269.

[10] DENTON D L, MUNSON MCGEE S H. High modulus fiber composites in ground transportation and high volume application [S]. ASTM STP 873, 1985.

(Edited by YUAN Sai-qian)

Corresponding author: Dong-Gi LEE; Tel: +82-62-230-7015; E-mail: dglee@chosun.ac.kr