DOI:10.19476/j.ysxb.1004.0609.2017.04.006

基于m值高效法的TA15合金超塑性变形

孙前江,王高潮

(南昌航空大学 航空制造工程学院 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:对TA15合金在拉伸试验机上进行应变速率敏感因子( 值)高效超塑性变形试验,研究合金的超塑性性能和显微组织。结果表明:在780~950℃变形时,TA15合金呈现出良好的超塑性能;900 ℃变形时,该合金的超塑性能最好,

值)高效超塑性变形试验,研究合金的超塑性性能和显微组织。结果表明:在780~950℃变形时,TA15合金呈现出良好的超塑性能;900 ℃变形时,该合金的超塑性能最好, 值达到0.62,最大伸长率为1287%;随着变形温度的升高,合金的超塑性能降低,950 ℃时伸长率仅为567%。显微组织分析表明:TA15合金在超塑性变形过程中,晶粒始终保持等轴状;由于变形温度升高,晶粒合并长大,950 ℃时发生

值达到0.62,最大伸长率为1287%;随着变形温度的升高,合金的超塑性能降低,950 ℃时伸长率仅为567%。显微组织分析表明:TA15合金在超塑性变形过程中,晶粒始终保持等轴状;由于变形温度升高,晶粒合并长大,950 ℃时发生 →

→ 相转变,初生

相转变,初生 相体积分数大幅度降低。与最大

相体积分数大幅度降低。与最大 值法相比较,

值法相比较, 值高效超塑性变形不仅使TA15合金获得了良好超塑性能,变形效率也显著提高。

值高效超塑性变形不仅使TA15合金获得了良好超塑性能,变形效率也显著提高。

关键词: TA15合金;超塑性; 值;显微组织

值;显微组织

文章编号:1004-0609(2017)-04-0716-08 中图分类号:TG146.2 文献标志码:A

TA15合金属一种高Al当量的近 型钛合金,既具有

型钛合金,既具有 型钛合金良好的热强性和可焊性,又具有接近于

型钛合金良好的热强性和可焊性,又具有接近于 型钛合金的工艺塑性[1-2]。该合金在航空航天等领域得到了广泛的应用,主要用于制造500 ℃以下长时间工作的结构零件和焊接承力零部件等,例如发动机的各种叶片、机匣,飞机各种大的钣金件、梁、接头、壁板和隔框等[3-4]。

型钛合金的工艺塑性[1-2]。该合金在航空航天等领域得到了广泛的应用,主要用于制造500 ℃以下长时间工作的结构零件和焊接承力零部件等,例如发动机的各种叶片、机匣,飞机各种大的钣金件、梁、接头、壁板和隔框等[3-4]。

超塑性指材料在一定的内部条件和外部条件下,呈现出较低的流变抗力和较高的流变性能的现象,具有伸长率大、抗颈缩能力强等特点[5-6]。近年来,采用超塑性成形工艺对钛合金进行加工已成为热门的研究方向[7],国内外学者对钛合金超塑性技术进行了大量的研究,双相钛合金组织超塑性仍然是研究的热点。ASHIDA等[8]采用高压扭转法(High pressure torsion, HPT)制备了晶粒尺寸约为100 nm的Ti-6Al-7Nb合金;MOTYKA等[9]和BABU等[10]分别采用不同热机械处理工艺对Ti-6Al-4V合金进行了细晶处理,晶粒细化后,合金超塑性能均显著提高。ROY等[11]研究了添加硼元素Ti-6Al-4V合金的超塑性能,发现加入0.1%(质量分数)的硼元素后,伸长率提高了17%,他们认为这主要是由于动态球化形成了大量细晶等轴初生 相,由此增强了

相,由此增强了 的晶界滑移。此外,研究人员还对超塑性变形方法进行了研究,万菊林[12]采用两段速率法对非理想组织Ti-6Al-4V合金进行了超塑性变形,该方法使合金获得了较好的超塑性能,在技术手段上突破了对钛合金微观组织的苛刻要求。王高潮等[13-14]采用最大

的晶界滑移。此外,研究人员还对超塑性变形方法进行了研究,万菊林[12]采用两段速率法对非理想组织Ti-6Al-4V合金进行了超塑性变形,该方法使合金获得了较好的超塑性能,在技术手段上突破了对钛合金微观组织的苛刻要求。王高潮等[13-14]采用最大 值法分别对TC11和Ti-6Al-4V合金进行了超塑性拉伸,合金的超塑性能得到大幅度提高,然而最大

值法分别对TC11和Ti-6Al-4V合金进行了超塑性拉伸,合金的超塑性能得到大幅度提高,然而最大 值法的变形速率较低,变形时间较长。

值法的变形速率较低,变形时间较长。

由于TA15合金具有六方晶体结构,滑移系较少、塑性较差、变形抗力大、成形加工过程困难[14],采用超塑性技术是解决该合金高筋薄壁等复杂构件成形的有效途径,然而目前对近 型钛合金的超塑性变形研究相对较少。为此,本文作者采用

型钛合金的超塑性变形研究相对较少。为此,本文作者采用 值法研究TA15合金的高效超塑性变形,克服最大m值法变形效率低的问题,深入探究其超塑性变形机制和组织演变规律,为该合金复杂航空结构件的精确成形提供相关技术参考和理论依据。

值法研究TA15合金的高效超塑性变形,克服最大m值法变形效率低的问题,深入探究其超塑性变形机制和组织演变规律,为该合金复杂航空结构件的精确成形提供相关技术参考和理论依据。

1 实验

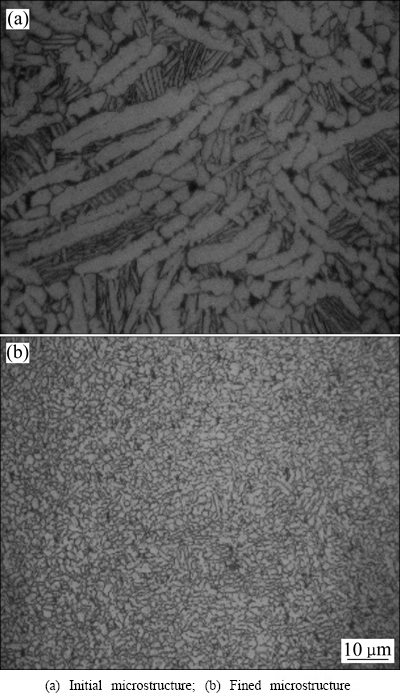

实验用TA15合金由北京航空材料研究院提供,其化学成分如表1所列,金相法测定其相变点为982 ℃。供货态合金的原始组织如图1(a)所示,显微组织非常不均匀, 基体上分布着大量的粗条状

基体上分布着大量的粗条状 相和细条状

相和细条状 相,初生等轴

相,初生等轴 相的含量非常少,平均晶粒尺寸约为25 μm,条状

相的含量非常少,平均晶粒尺寸约为25 μm,条状 相的最大长度达到约100 μm,属典型的非理想组织,不利于合金超塑性变形。为提高TA15合金的超塑性能,本文作者首先采用高低温复合形变热处理工艺对原始组织进行了细化处理,形变热处理后的显微组织如图1(b)所示。由图1中可以看出,与原始组织相比较,显微组织非常均匀,在复合形变热处理工艺过程中,大变形量的锻造和热处理工艺使粗条状

相的最大长度达到约100 μm,属典型的非理想组织,不利于合金超塑性变形。为提高TA15合金的超塑性能,本文作者首先采用高低温复合形变热处理工艺对原始组织进行了细化处理,形变热处理后的显微组织如图1(b)所示。由图1中可以看出,与原始组织相比较,显微组织非常均匀,在复合形变热处理工艺过程中,大变形量的锻造和热处理工艺使粗条状 相得到了充分的细化和等轴化,因此

相得到了充分的细化和等轴化,因此 基体上分布着大量细小的等轴

基体上分布着大量细小的等轴 相,其平均晶粒尺寸约为2 μm,等轴

相,其平均晶粒尺寸约为2 μm,等轴 相的含量约为95%(体积分数)。

相的含量约为95%(体积分数)。

表1 TA15合金化学成分

Table 1 Chemical composition of TA15 alloy (mass fraction, %)

图1 TA15合金形变热处理前后的显微组织

Fig. 1 Microstructures of TA15 alloy before and after thermo- mechanical treatment

超塑性拉伸试样加工成圆棒状,试样标距为15 mm,直径为5 mm。超塑性拉伸试验在Sans CMT4104型高温电子拉伸实验机上进行,设备横梁移动速度在0.001~500 mm/min之间连续可调,试样采用电阻炉加热,最高加热温度为1200 ℃,工作区温差≤±3 ℃。为防止试样在高温加热及变形过程中发生氧化,试样标距部分涂覆玻璃防护润滑剂进行保护,试样断裂后立即水淬以保存试样变形后的显微组织,采用光学显微镜和透射电镜观察和分析断口附近和夹头部位的显微组织。

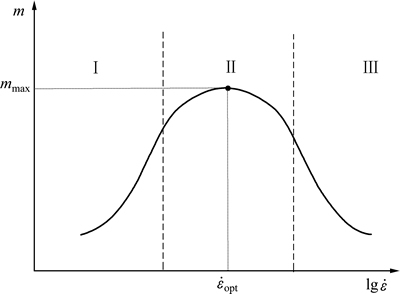

尝试采用m值法对TA15合金进行高效超塑性拉伸,其基本原理是在最大 值法的基础上,通过控制系统进一步对材料实验机进行调节,使得应变速率始终在图2中的Ⅱ区与Ⅲ区过渡区域内循环变化,同时为保证合金始终进行超塑性变形,在控制系统中设定最小

值法的基础上,通过控制系统进一步对材料实验机进行调节,使得应变速率始终在图2中的Ⅱ区与Ⅲ区过渡区域内循环变化,同时为保证合金始终进行超塑性变形,在控制系统中设定最小 值为0.3。为实现

值为0.3。为实现 值高效超塑性变形,利用Visual Basic语言对拉伸试验机的控制软件进行了二次开发。

值高效超塑性变形,利用Visual Basic语言对拉伸试验机的控制软件进行了二次开发。

图2 m值与 的关系[4]

的关系[4]

Fig. 2 Relationship between and

and  [4]

[4]

2 结果与分析

2.1 超塑性变形力学行为

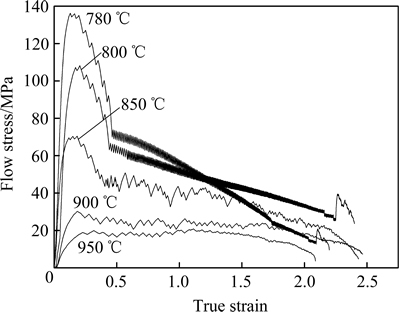

图3所示为TA15合金高效超塑性拉伸时的应力–应变曲线。由图3中可以看出,各变形温度下的应力–应变曲线均呈现明显的锯齿状波动,其主要原因是超塑性变形过程中控制系统为追求最大m值,应变速率始终在最佳应变速率附近不断的振荡变化,然而钛合金超塑性变形对应变速率非常敏感,因此导致流动应力也不断的振荡变化而形成了锯齿状曲线。

分析图3中的应力–应变曲线可知,变形温度对TA15合金的超塑性有着重要的影响,随变形温度逐渐升高,峰值应力降低,如780 ℃时的峰值应力达到136 MPa,而950 ℃时的峰值应力仅为20 MPa。变形温度升高,TA15合金的热激活作用增强,促进了晶界滑移及晶界扩散能力,晶体产生滑移的临界分切应力减小,减少了对位错运动的阻碍,使得变形容易。在780~850 ℃低温条件下,TA15合金在变形初期表现为典型的应变硬化效应,流动应力随应变增加而迅速增加;当应变增加到某一数值,应力达到峰值,然后快速进入软化阶段,应力–应变曲线为典型的应变软化型曲线[16]。相反,在900 ℃和950 ℃高温条件下,TA15长时间处于稳态变形阶段,具有典型的超塑性变形特征[17]。稳态变形阶段是变形过程中应变硬化和软化之间达到了动态平衡,稳态变形阶段的延长有利于合金伸长率的增加。另外,由图3中还可以看出,在780 ℃和800 ℃时,临近变形结束前,流动应力迅速增加,然后又迅速降低,直至试样断裂。这主要是由于TA15合金在低温条件下变形时,位错运动活跃,位错在晶界处呈缠结组态,不利于晶界滑移运动;其次,变形后期合金的晶粒粗化,致使位错运动受阻,晶界滑移困难,晶界处产生应力集中,此时应力松弛机制已无法缓解应力集中,导致试样缩颈快速发展直至试样断裂。

图3 TA15合金高效超塑性拉伸应力–应变曲线

Fig. 3 Flow stress–strain curves during high efficient superplastic deformation

2.2 变形温度对超塑性的影响

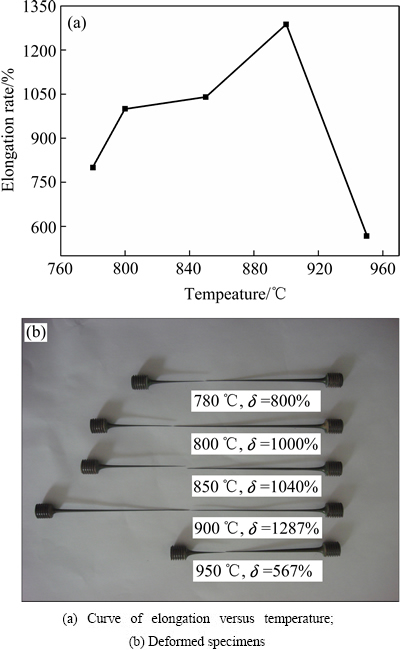

变形温度对TA15合金超塑性的影响如图4所示。分析图4(a)中的伸长率变化曲线可知,在780~950 ℃温度范围内变形时,TA15合金均有较好的超塑性能,其在780 ℃时的伸长率仍然达到800%。随变形温度升高,伸长率逐渐增加,900 ℃时TA15合金的超塑性能最佳,伸长率达到1287%;当变形温度升高至950 ℃时,超塑性能降低,伸长率仅为567%。因此可以推断900 ℃是TA15合金的最佳超塑性变形温度。图4(b)所示为TA15合金超塑性变形后试样的宏观形貌。由图4(b)中试样可以看出,超塑性能好的试样变形比较均匀,900 ℃时试样断裂位置正好处在变形区域的中间位置,说明在该温度下试样一直处于比较均匀的变形状态,这与图3中900 ℃下应力–应变曲线具有较长时间的稳态变形阶段相吻合。当温度升高至950 ℃时,试样变形主要集中于左端部分,右端部分变形较小,变形过程中缩颈未能很好地转移,局部应力集中,加速了试样的断裂,从而导致TA15合金在该温度下超塑性能大幅度降低。

图4 变形温度对TA15合金超塑性的影响

Fig. 4 Effect of deformation temperature on superplasticity of TA15 alloy

2.3 应变速率敏感性指数m值

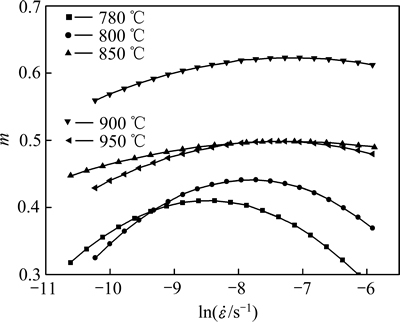

应变速率敏感性指数m值的大小反映了抑制局部出现缩颈的能力,m值越大,抑制缩颈的能力越强,出现高伸长率的可能性也就越大。TA15合金高效超塑性变形后,变形工艺参数对应变速率敏感性指数m值的影响如图5所示。由图5中可以看出,m值与 的关系曲线基本呈典型的覆罩型,类似于图2中的理想曲线,尤其在低温变形条件下。分析图5中的曲线可知,在各变形温度条件下,m值均大于0.3,这也表明TA15合金在780~950 ℃范围内具有良好的超塑性能。随变形温度升高,m值逐渐增大,在900 ℃时最大m值达到0.62,因此获得了1287%的最大伸长率。当变形温度升高至950 ℃时,m值下降,TA15合金在各变形温度下获得的最大

的关系曲线基本呈典型的覆罩型,类似于图2中的理想曲线,尤其在低温变形条件下。分析图5中的曲线可知,在各变形温度条件下,m值均大于0.3,这也表明TA15合金在780~950 ℃范围内具有良好的超塑性能。随变形温度升高,m值逐渐增大,在900 ℃时最大m值达到0.62,因此获得了1287%的最大伸长率。当变形温度升高至950 ℃时,m值下降,TA15合金在各变形温度下获得的最大 值如表2所示。

值如表2所示。

图5 变形工艺参数对m值的影响

Fig. 5 Effect of deformation processing parameters on m value

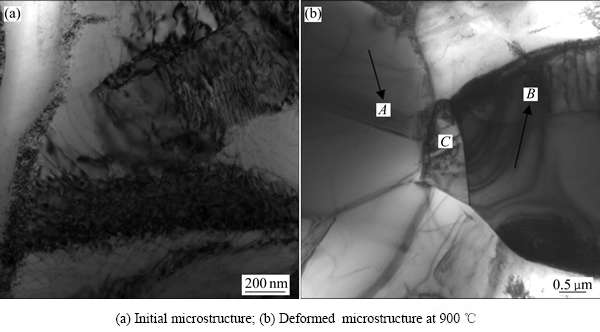

表2 不同变形温度下的最大m值

Table 2 Maximum m value at different deformation temperature

2.4 显微组织演变

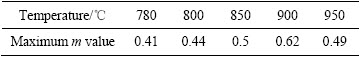

图6所示为TA15合金试样超塑性变形后夹头部位和断口附近的显微组织。由图6可以看出,超塑性变形后,试样夹头和断口附近的显微组织均不同程度粗化,随变形温度不断升高,晶粒粗化越来越严重。夹头部位和断口附近的显微组织粗化程度显著不同,夹头部位由于未变形,晶粒粗化是长时间保温发生静态再结晶所致,晶粒粗化程度相对较小;而断口附近晶粒粗化是变形和热效应的共同作用所致,因此晶粒粗化更严重。此外,由图6中还可以看出,在780~850 ℃温度范围内变形时,试样断口附近的显微组织虽然发生了粗化,但在 基体上仍可以看到很多细小的

基体上仍可以看到很多细小的 晶粒,如图6(b)、(d)和(f)所示。这说明TA15合金在相对较低变形温度下变形时,加工硬化效应显著,合金畸变能快速增加,促进了变形晶粒的动态再结晶,因此不断有新的细小

晶粒,如图6(b)、(d)和(f)所示。这说明TA15合金在相对较低变形温度下变形时,加工硬化效应显著,合金畸变能快速增加,促进了变形晶粒的动态再结晶,因此不断有新的细小 相在

相在 基体上形核析出。当变形温度升高至900 ℃时,夹头和断口附近显微组织中的等轴

基体上形核析出。当变形温度升高至900 ℃时,夹头和断口附近显微组织中的等轴 相开始互相合并长大而形成粗片状

相开始互相合并长大而形成粗片状 相,如图6(g)和(h)所示。这主要是由于温度的升高促使

相,如图6(g)和(h)所示。这主要是由于温度的升高促使 相的相界扩散能力增强,有机会吞并附近细小的

相的相界扩散能力增强,有机会吞并附近细小的 相,导致初生

相,导致初生 相发生聚集再结晶而合并长大。当变形温度继续升高至950 ℃,TA15合金发生了显著的

相发生聚集再结晶而合并长大。当变形温度继续升高至950 ℃,TA15合金发生了显著的 →

→ 相转变,如图6(i)和(j)所示。与其他温度条件下的显微组织相比,无论是夹头部位还是断口附近,初生等轴

相转变,如图6(i)和(j)所示。与其他温度条件下的显微组织相比,无论是夹头部位还是断口附近,初生等轴 相含量急剧减少,而

相含量急剧减少,而 相含量大幅度增加,显微组织中

相含量大幅度增加,显微组织中 晶界清晰完整,并且

晶界清晰完整,并且 晶粒由于变形和热效应共同作用也发生聚集合并长大,晶界

晶粒由于变形和热效应共同作用也发生聚集合并长大,晶界 相也发生了不同程度的粗化。

相也发生了不同程度的粗化。 相和

相和 相比例的严重失调和粗化导致晶界滑移运动困难,从而导致TA15合金在该温度下超塑性能降低,尽管最大m值达到了0.49。

相比例的严重失调和粗化导致晶界滑移运动困难,从而导致TA15合金在该温度下超塑性能降低,尽管最大m值达到了0.49。

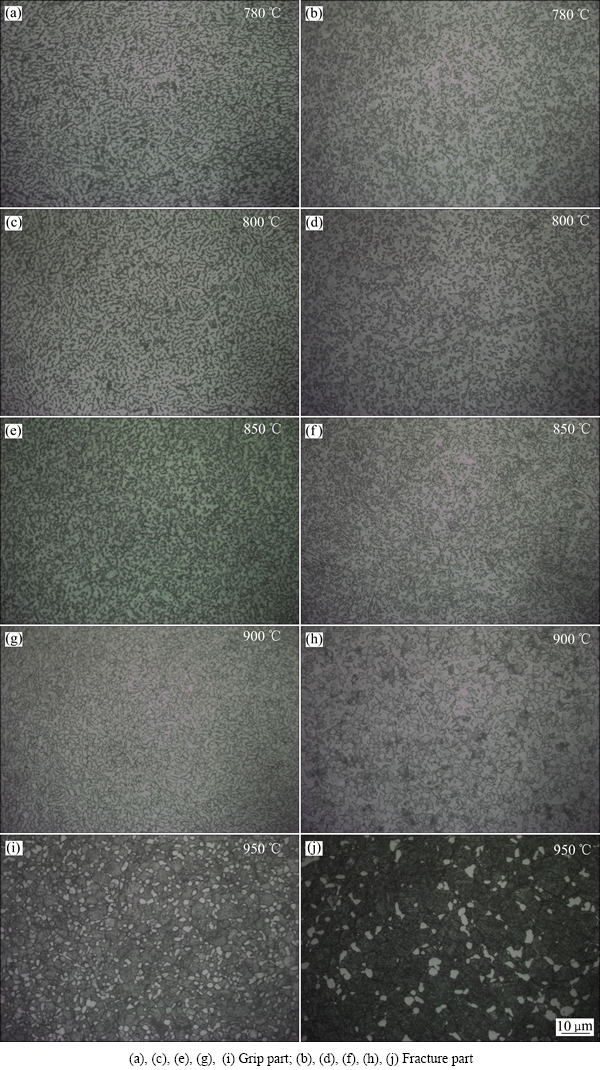

图7所示为TA15合金的TEM像,其中图7(a)所示为试样原始组织,图7(b)所示为900 ℃超塑性变形后的微观组织。由图7(a)可知,TA15合金经复合形变热处理后, 晶粒内部和晶界处存在高密度的位错、位错网和位错缠结。900 ℃超塑性变形后,位错密度大幅度降低,如图7(b)所示。这说明超塑性变形过程中TA15 合金的大量晶内位错在晶界附近被吸收,即在晶界附近存在强烈的晶内位错回复机制,张俊红[16]在研究TiAl 基合金的超塑性变形时也发现了类似的现象。由图7(b)还可以看出,变形后合金的晶粒仍然保持了较好的等轴状,晶界圆弧化趋势非常显 著,具有典型的超塑性变形特征,这是晶界滑移、转动和扩散共同作用所致[18]。此外,变形后位错分布如图中箭头所指的位置A和B处所示,晶粒内部的位错排列成位错墙而形成了亚晶界;

晶粒内部和晶界处存在高密度的位错、位错网和位错缠结。900 ℃超塑性变形后,位错密度大幅度降低,如图7(b)所示。这说明超塑性变形过程中TA15 合金的大量晶内位错在晶界附近被吸收,即在晶界附近存在强烈的晶内位错回复机制,张俊红[16]在研究TiAl 基合金的超塑性变形时也发现了类似的现象。由图7(b)还可以看出,变形后合金的晶粒仍然保持了较好的等轴状,晶界圆弧化趋势非常显 著,具有典型的超塑性变形特征,这是晶界滑移、转动和扩散共同作用所致[18]。此外,变形后位错分布如图中箭头所指的位置A和B处所示,晶粒内部的位错排列成位错墙而形成了亚晶界; 晶界附近的位错从晶界一侧处发出,即晶界为位错源。这说明晶界滑移是由位错的滑移和攀移进行协调,由此可以推断这种位错是由晶界滑移受阻所诱发的非固有晶界位错[19-21]。因此,非固有晶界位错运动协调的晶界滑移是TA15合金超塑性变形的主要机制。同时,在三叉晶界处可以观察到较小尺寸的动态再结晶晶粒,如图7(b)中C处所示。这说明在超塑性变形过程中,TA15合金发生了显著的动态再结晶。

晶界附近的位错从晶界一侧处发出,即晶界为位错源。这说明晶界滑移是由位错的滑移和攀移进行协调,由此可以推断这种位错是由晶界滑移受阻所诱发的非固有晶界位错[19-21]。因此,非固有晶界位错运动协调的晶界滑移是TA15合金超塑性变形的主要机制。同时,在三叉晶界处可以观察到较小尺寸的动态再结晶晶粒,如图7(b)中C处所示。这说明在超塑性变形过程中,TA15合金发生了显著的动态再结晶。

2.5 变形效率

为对最大m值法和m值高效超塑性变形进行比较,引入超塑性变形效率 ,

, 表示单位变形时间内获得的超塑性伸长率,其数学表达式如下:

表示单位变形时间内获得的超塑性伸长率,其数学表达式如下:

(1)

(1)

式中: 为试验超塑性伸长率,%;

为试验超塑性伸长率,%; 为变形时间,min。

为变形时间,min。

图6 TA15合金在780、800、850、900和950 ℃下超塑性变形后夹头部位和断口显微组织

Fig. 6 Micrographs of TA15 alloy after superplastic deformation at temperatures of 780, 800, 850, 900 and 950 ℃

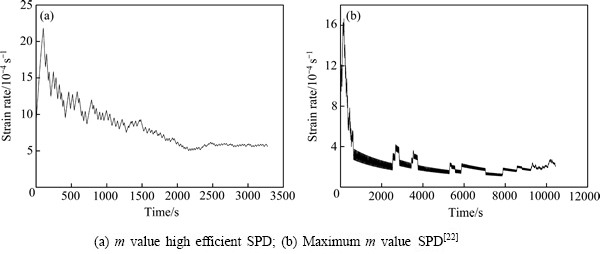

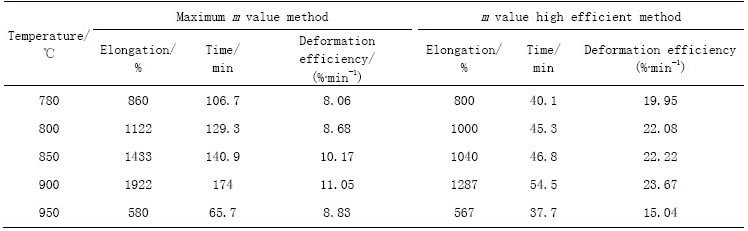

图8所示最大m值法和m值高效超塑性变形在900 ℃下应变速率随时间变化曲线,根据两种方法不同变形温度条件下获得的伸长率和变形时间,利用式(1)对超塑性变形效率 进行计算,结果如表3所列。分析表3中的数据可知,m值高效法超塑性变形效率高于最大m值法的变形效率,前者约为后者的2倍左右。此外,随变形温度升高,变形效率

进行计算,结果如表3所列。分析表3中的数据可知,m值高效法超塑性变形效率高于最大m值法的变形效率,前者约为后者的2倍左右。此外,随变形温度升高,变形效率 增加,当升高至950 ℃时,变形效率又开始降低。由此可见,采用m值高效法进行超塑性变形,TA15合金不仅获得了良好的超塑性能,并且变形效率大幅度提高。

增加,当升高至950 ℃时,变形效率又开始降低。由此可见,采用m值高效法进行超塑性变形,TA15合金不仅获得了良好的超塑性能,并且变形效率大幅度提高。

图7 高效超塑性变形前后TA15合金的TEM像

Fig. 7 TEM images of TA15 alloy before and after high efficient superplastic deformation

图8 900 ℃应变速率随时间变化曲线[22]

Fig. 8 Curves of strain rate versus time during deformation at 900 ℃

表3 最大m值法[22]和m值高效法超塑性变形效率

Table 3 Superplastic deformation efficiency of maximum m value[22] and m value high efficient methods

3 结论

1) 复合形变热处理工艺实现对TA15合金粗大原始组织有效地细化,细化后合金等轴 相的平均晶粒尺寸约为2 μm,为超塑性变形作好显微组织准备。

相的平均晶粒尺寸约为2 μm,为超塑性变形作好显微组织准备。

2) 在变形温度为780~950 ℃范围内,TA15合金均具有良好的超塑性能,m值与 的关系曲线呈典型的覆罩型。TA15合金最佳超塑性变形温度为900 ℃,该条件下的伸长率为1287%,最大m值达到0.62。

的关系曲线呈典型的覆罩型。TA15合金最佳超塑性变形温度为900 ℃,该条件下的伸长率为1287%,最大m值达到0.62。

3) TA15合金经过超塑性变形后,晶粒仍然保持了较好的等轴性,晶界圆弧化的趋势非常明显,非固有晶界位错运动协调的晶界滑移是TA15合金超塑性变形的主要机制。

4) 与最大m值法超塑性变形相比较,m值高效超塑性变形效率显著提高,后者约为前者2倍左右。

REFERENCES

[1] 黄 旭, 朱知寿, 王红红. 先进航空钛合金材料与应用[M]. 北京: 国防工业出版社, 2012: 27.

HUANG Xu, ZHU Zhi-shou, WANG Hong-hong. Advanced aeronautical titanium alloys and application[M]. Beijing: National Defense Industry Press, 2012: 27.

[2] 杨 雷, 王宝雨, 刘 钢, 赵慧俊. 基于内变量的TA15板材室温拉伸力学性能预测模型[J]. 中国有色金属学报, 2015, 25(3): 652-661.

YANG Lei, WANG Bao-yu, LIU Gang, ZHAO Hui-jun. Prediction model of tensile mechanical properties of TA15 sheet at room temperature based on internal variables[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 652-661.

[3] 姚彭彭, 李 萍, 薛克敏, 李成铭, 甘国强. β相区加热TA15钛合金热变形显微组织演化[J]. 中国有色金属学报, 2014, 24(10): 2482-2489.

YAO Peng-peng, LI Ping, XUE Ke-min, LI Cheng-ming, GAN Guo-qiang. Microstructure evolution of thermal deformation TA15 titanium alloy under β phase region heating institution[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2482-2489.

[4] WU Chuan, YANG He, LI Hong-wei. Simulated and experimental investigation on discontinuous dynamic recrystallization of a near-α TA15 titanium alloy during isothermal hot compression in β single-phase field[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 1819-1829.

[5] 陈浦泉. 组织超塑性[M]. 哈尔滨: 哈尔滨工业大学出版社, 1988: 1-4.

CHEN Pu-quan. Microstructural superplasticity[M]. Harbing: Harbing Institute of Technology Press, 1988: 1-4.

[6] 何景素, 王燕文. 金属的超塑性[M]. 北京: 科学出版社, 1993: 3-11.

HE Jing-su, WANG Yan-wen. Superplasticity of metals[M]. Beijing: Science Press, 1993: 3-11.

[7] 曾立英, 赵永庆, 李丹柯, 李 倩. 超塑性钛合金的研究进 展[J]. 金属热处理, 2005, 30(5): 28-33.

ZENG Li-ying, ZHAO Yong-qing, LI Dan-ke, LI Qian. Research progress on superplastic titanium alloys[J]. Heat Treatment of Metals, 2005, 30(5): 28-33.

[8] ASHIDA M, CHEN P, DOI H, TSUTSUMI Y, HANAWA T, HORITA Z. Superplasticity in the Ti-6Al-7Nb alloy processed by high-pressure torsion[J]. Materials Science and Engineering A, 2015, 640: 449-453.

[9] MOTYKA M, SIENIAWSKI J, ZIAJA W. Microstructural aspects of superplasticity in Ti-6Al-4V alloy[J]. Materials Science and Engineering A, 2014, 640: 57-63.

[10] BABU J, DUTTA A. Low temperature superplasticity through grain refinement in Ti-6Al-4V by a novel route of quench-roll-recrystallize[J]. Journal of Materials Research and Technology, 2015, 4(3): 348-352.

[11] ROY S, SUWAS S. Enhanced superplasticity for (α+β)-hot rolled Ti-6Al-4V-0.1B alloy by means of dynamic globularization[J]. Materials and Design, 2014, 58: 52-64.

[12] 万菊林. 非理想组织材料超塑性变形的研究[D]. 北京: 清华大学, 1995: 118-141.

WAN Ju-lin. Superplastic deformation of materials with non-ideal SPD microstructures[D]. Beijing: Tsinghua Universtiry, 1995: 118-141.

[13] WANG G C, FU M W. Maximum m superplasticity deformation for Ti-6A1-4V titanium alloy[J]. Journal of Materials Processing Technology, 2007, 192/193: 555-560.

[14] 王高潮, 曹春晓, 董洪波, 李臻熙, 杨 刚, 赵晓宾. TC11合金最大m值超塑变形机理[J]. 航空学报, 2009, 30(2): 357-361.

Wang Gao-chao, CAO Chun-xiao, DONG Hong-bo, LI Zhen-xi, YANG Gang, ZHAO Xiao-bin. Superplastic deformation mechanism of titanium alloy TC11 at maximum m value[J] Acta Aeronautica et Astronautica Sinica, 2009, 30(2): 357-361.

[15] 李成铭, 李 萍, 赵 蒙, 甘国强, 薛克敏. TA15 钛合金的热变形微观组织与织构[J]. 中国有色金属学报, 2014, 24(1): 91-96.

LI Cheng-ming, LI Ping, ZHAO Meng, GAN Guo-qiang, XUE Ke-min. Microstructures and textures of TA15 titanium alloy after hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 91-96.

[16] 张俊红. TiAl基合金的组织超塑性研究[D]. 长沙: 中南大学, 2003: 58-60.

ZHANG Jun-hong. Research on the superplasticity of TiAl-based alloy[D]. Changsha: Central South University, 2003: 58-60.

[17] SERGUEEVA A V, STOLYAROV V V, VALIEV R Z, MUKHERJEE A K. Superplastic behaviour of ultrafine-grained Ti-6A1-4V alloys[J]. Materials Science and Engineering A, 2002, 323: 318-325.

[18] DERBY B. The dependence of grain size on stress during dynamic recrystallization[J]. Acta Metallurgica et Materialia, 1991, 39(5): 955-962.

[19] ALABORT E, KONTIS P, BARBA D, DRAGNEVSKI K, REED R C. On the mechanisms of superplasticity in Ti-6Al-4V[J]. Acta Materialia, 2016, 105: 449-463.

[20] MCLEAN D. Grain boundary dislocations: Their effect on vacancies and sliding[J]. Philosophical Magazine, 1971, 23(182): 467-472.

[21] 周善佑, 刘 勤, 汪立勤. 晶界位错在超塑性变形中的作用[J]. 兵器材料科学与工程, 1988, 9: 1-7.

ZHOU Shan-you, LIU Qin, WANG Li-qin. The effect of grain boundary dislocation in superplastic deformation[J]. Ordnance Material Science and Engineering, 1988, 9: 1-7.

[22] 孙前江. 细晶TA15 合金的制备及超塑性变形行为研究[D]. 西安: 西北工业大学, 2013: 54-57.

SUN Qian-jiang. Fabrication and superplastic deformation behavior of the fine-grained TA15 alloy[D]. Xi’an: Northwestern Polytechnical University, 2013: 54–57.

High efficient superplastic deformation of TA15 alloy based on m value

SUN Qian-jiang, WANG Gao-chao

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology, School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The high efficient superplastic deformation experiments of TA15 alloy based on m value were performed on the tensile testing machine. The superplastic properties and microstructure were studied. The results indicate that TA15 alloy exhibits excellent superplasticity at temperatures of 780-950 ℃. The superplasticity is the best at 900 ℃. The m value is 0.62 and the maximum elongation is 1287%. With temperature increases, the superplasticity decreases and the elongation is only 567% at 950 ℃. The microstructure analysis shows that the equiaxed grains are kept during deformation. The grains merge and grow up due to increasing temperature. The volume fraction of primary  phase decreases greatly because

phase decreases greatly because  →

→ phase transformation occurs at 950 ℃. Compared with the method of maximum m value, not only the excellent superplasticity of TA15 alloy is obtained by the high efficient superplastic deformation, but also the deformation efficiency is enhanced obviously.

phase transformation occurs at 950 ℃. Compared with the method of maximum m value, not only the excellent superplasticity of TA15 alloy is obtained by the high efficient superplastic deformation, but also the deformation efficiency is enhanced obviously.

Key words: TA15 alloy; superplasticity; m value; microstructure

Foundation item: Project(51261020) supported by the National Natural Science Foundation of China; Project (20142BAB206021) supported by the Natural Science Foundation of Jiangxi Province, China; Project(GJJ150735) supported by the Program of Jiangxi Provincial Education Department, China; Project (gf201501006) supported by Fund of National Defense Key Discipline Laboratory of Light Alloy Processing Science and Technology, China

Received date: 2015-11-10; Accepted date: 2016-06-09

Corresponding author: SUN Qian-jiang; Tel: +86-791-83863032; E-mail: cruzesun@nchu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51261020);江西省自然科学基金资助项目(20142BAB206021);江西省教育厅科技项目(GJJ150735);轻合金加工科学与技术国防重点学科实验室基金资助项目(gf201501006)

收稿日期:2015-11-10;修订日期:2016-06-09

通信作者:孙前江,副教授,博士;电话:0791-83863032;E-mail: cruzesun@nchu.edu.cn