Ti-36Nb-2Ta-3Zr-0.35O合金在热加工与冷加工过程中的组织演变

来源期刊:中国有色金属学报(英文版)2016年第5期

论文作者:张卫东 刘咏 吴 宏 刘 彬 陈紫瑾 汤慧萍

文章页码:1310 - 1316

关键词:橡胶金属;热锻;冷旋锻;显微组织;无位错;应力诱导马氏体相变

Key words:gum metal; hot forge; cold swage; microstructure; dislocation-free; stress-induced martensitic transformation

摘 要:采用元素粉末法通过冷等静压、真空烧结、热锻、冷锻等方法制备了Ti-36Nb-2Ta-3Zr-0.35O(质量分数,%)(TNTZO)合金。运用透射电子显微镜、扫描电子显微镜、金相显微镜以及万能试验机对加工前后合金材料进行显微组织分析和力学性能检测,探究热加工与冷加工对合金组织与性能的影响。结果表明:TNTZO合金具有良好的可加工性,通过热锻与冷旋锻可以得到良好的细晶组织;85%冷旋锻的合金样品呈现典型大理石状显微组织,并且在其冷加工过程中伴随有应力诱导α"马氏体相变。此外,热加工与冷加工后合金的强度及塑形都有显著提高。

Abstract: The Ti-36Nb-2Ta-3Zr-0.35O (mass fraction, %) (TNTZO) alloy was produced by cold isostatic pressing and sintering from elemental powders, followed by hot and cold deformation. The effects of deformation process on microstructures and mechanical properties were investigated using the SEM, TEM, OM and the universal material testing machine. Results show that the alloy can be easily hot forged and cold swaged due to the fine-grained microstructure. Only after cold swaging by 85%, the alloy shows the typical “marble-like” structure. And the cold deformation is accompanied by stress-induced α" phase transformations. Moreover, both the strength and the ductility of the alloy are significantly improved by hot and cold working.

Trans. Nonferrous Met. Soc. China 26(2016) 1310-1316

Wei-dong ZHANG1, Yong LIU1, Hong WU1, Bin LIU1, Zi-jin CHEN1, Hui-ping TANG2

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. State Key Laboratory of Porous Metal Materials,

Northwestern Institute of Nonferrous Metals Research, Xi’an 710012, China

Received 9 November 2015; accepted 12 April 2016

Abstract: The Ti-36Nb-2Ta-3Zr-0.35O (mass fraction, %) (TNTZO) alloy was produced by cold isostatic pressing and sintering from elemental powders, followed by hot and cold deformation. The effects of deformation process on microstructures and mechanical properties were investigated using the SEM, TEM, OM and the universal material testing machine. Results show that the alloy can be easily hot forged and cold swaged due to the fine-grained microstructure. Only after cold swaging by 85%, the alloy shows the typical “marble-like” structure. And the cold deformation is accompanied by stress-induced α" phase transformations. Moreover, both the strength and the ductility of the alloy are significantly improved by hot and cold working.

Key words: gum metal; hot forge; cold swage; microstructure; dislocation-free; stress-induced martensitic transformation

1 Introduction

β-Type titanium alloys are one of the most attractive implant materials due to their light mass, high corrosion resistance, biocompatibility and mechanical properties. However, the elastic modulus of Ti alloys is much higher than that of human bone (~30 GPa), giving rise to the so-called “stress shielding effect”. Thus, Mo, Nb, Ta, Zr and Sn alloying elements have been selected to develop titanium alloys with a low elastic modulus and high strength for implant applications [1-5].

In 2003, SAITO et al [6] firstly developed a multifunctional Ti-23Nb-0.7Ta-2Zr-1.0O alloy (mole fraction, %), called “gum metal”. Gum metal possesses many attractive properties, such as high strength, low modulus, and superplasticity at room temperature. It is important that the unique properties are obtained after substantial cold working. The gum metal was prepared through sintering, hot deformation, solution treatment and cold deformation [6], but other routes have been attempted to obtain similar alloys. GUO et al [7] gave a summary of some of the key studies carried out since the discovery of the alloys. Some studies attempted the variations of different hot and cold deformations, for example, cold rolling [8-10] and cold forging [11]. TALLING et al [8] also attempted to produce the alloys by casting. BESSE et al [12] used the cold crucible semi-levitation melting (CCLM) technique to produce the alloy, but did not obtain the same properties as gum metal.

Although many studies have been conducted on the processing and properties of gum metal, many issues remain unresolved, for example, the relationship between the process and the microstructures. The aim of the present work was to investigate the evolutions of microstructures during the hot and cold deformation of the Ti-36Nb-2Ta-3Zr-0.35O alloy and the corresponding tensile properties.

2 Experimental

Pure titanium powder and other elemental powders according to the nominal composition of Ti-36Nb-2Ta- 3Zr-0.35O (mass fraction, %) were blended in an attrition mixer for 0.5 h. Oxygen was calculated

according to its original contents in Ti and other powders, so no external oxides were added. The blended powders were compacted by cold isostatic pressing (CIP) at a pressure of 200 MPa, and sintered at 1573 K for 16 h in a vacuum of 1×10-4 Pa (45 mm in diameter, the sample was named as EP1). The sintered billet was hot forged at temperatures ranging in 1073-1423 K into a bar of 17 mm in diameter (the sample was named as EP2). The surface oxide was mechanically removed prior to the solution treatment at 1273 K for 1 h in argon. The samples were then quenched into iced water (the sample was named as EP3). Cold swaging was conducted at room temperature, and finally several bars in diameters of 10 mm (area reduction 56%), 8 mm (72%) and 6 mm (85%, EP4) were prepared.

The chemical compositions of all the alloy were assessed by JXA-8530 F electron probe micro-analyzer (EPMA) in many different areas of the sintered alloy. Dog-bone-shaped specimens with a gauge length of 8 mm were machined and mechanically polished. The mechanical properties of the alloy were measured by using a universal material testing machine (Instron 3369). The tensile axis of the material was parallel to the longitudinal direction of the bar. The densities of the specimens were determined by Archimedes’ method. The samples for the microstructural observation were ground, polished, and etched in a solution composed of 8% HF and 15% HNO3 (volume fraction) in H2O. Microstructures of the alloys were observed using scanning electron microscopy (SEM), optical microscopy (OM) and transmission electron microscopy (TEM).

3 Results

3.1 Microstructural evolution

The measured chemical composition of the alloy (EP1) is listed in Table 1. Apparently, the oxygen concentration is in the range of 0.7%-3.0% proposed by SAITO et al [6].

Table 1 Composition of sintered alloy, as determined by EPMA

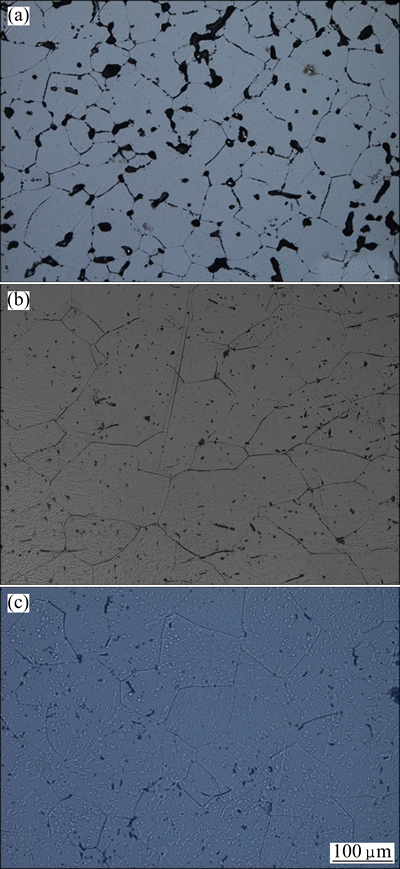

The sintering process was required for generating the desirable composition and density. Figure 1 shows the porosity of the alloy at each processing stage. It indicates that through sintering alone, a full density can not be obtained in the alloy. A porosity of approximately 9% still exists, and pores up to 5 μm in size can be found. The hot forging process effectively eliminates the residual porosity. However, there are still small amount of residual pores in the alloy after hot forging (Fig. 1(b)). After hot forging and subsequent annealing, almost full density alloy was obtained, as shown in Fig. 1(c). The measurement of density also confirms the elimination of pores. The as-sintered alloy has a density of 5.2 g/cm3 while the as-forged alloy has a density of 5.63 g/cm3.

Fig. 1 SEM images of Ti-36Nb-2Ta-3Zr-0.35O alloy showing residual porosity after sintering (a), hot forging (b), and annealing at 1273 K (c)

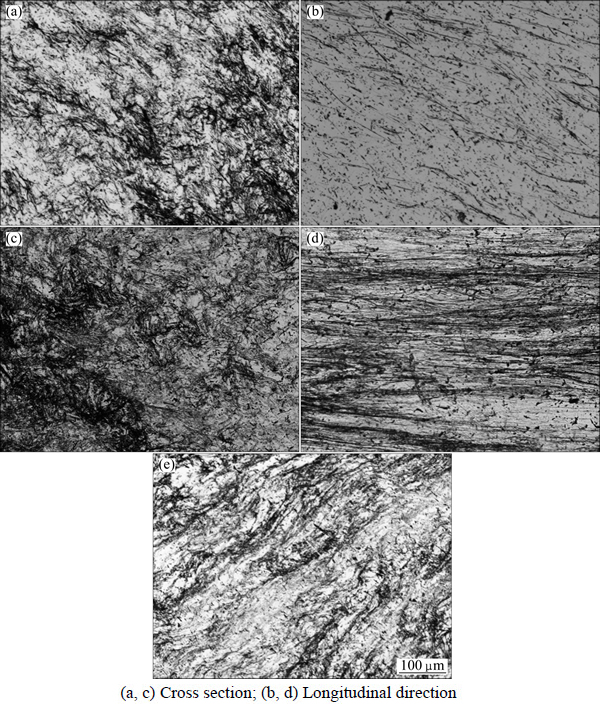

Figure 2 shows the microstructures of the alloys under different conditions. The as-sintered alloy has an equixed microstructure. The grain size is about 50 μm, but a large number of pores locate at the grain boundaries. Since the temperature of the hot forging is high, the grain size is obviously increased to be 80-100 μm. Annealing at 1273 K does not change the grain size much, but the distortion of the grains after the hot forging is adjusted.

Fig. 2 Optical micrographs of Ti-36Nb-2Ta-3Zr-0.35O alloy after sintering (a), hot forging (b), and annealing at 1273 K (c)

Optical micrographs of Ti-36Nb-2Ta-3Zr-0.35O alloy (Fig. 3) show that the microstructure changes dramatically during the cold working. The microstructure in Fig. 2(c) (before cold working) is composed of equiaxed grains of 50 to 100 μm in size. Deformation bands are observed after cold working by 56% (Fig. 3(a)). Subsequently, as the cold deformation increases, the deformation bands are gradually distorted as seen in Fig. 3(e), and after cold working by 85%, the microstructure finally changes into a characteristic ‘‘marble-like’’ structure, as shown in Fig. 3(c). Along the longitudinal direction of the bar, when the area deduction increases to 56%, the grain size is about 30 μm in width and several hundreds microns in length (Figs. 3(a) and (b)). The application of cold working by 85% highly elongated the grains, with fiber-like shear bands along the longitudinal direction.

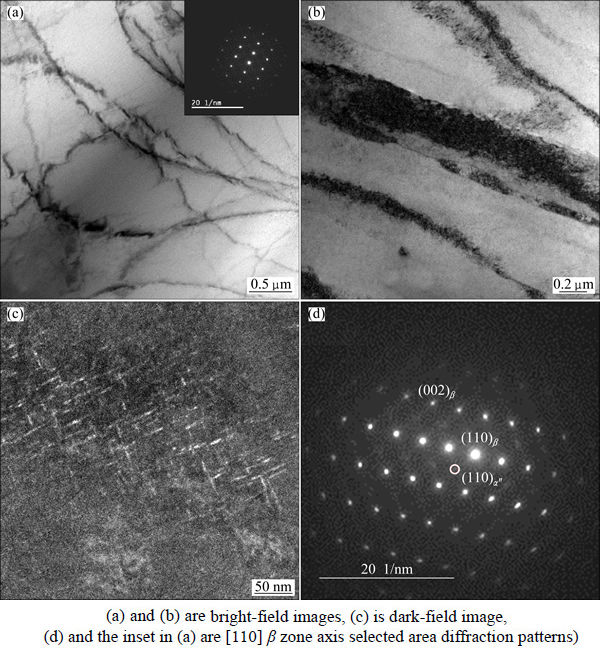

Figure 4 shows the detailed microstructures of TNTZO alloy after heat treatment and cold swaging. The SAED pattern in Fig. 4(a) indicates that the alloy after the heat treatment is dominated by β-phase. In micro shear bands in Fig. 4(b), many nanometer-sized α" phase can be found (Fig. 4(c)), which is proved by the SAED pattern in Fig. 4(d). In general, there are very few dislocations observed in the alloys of the two conditions.

3.2 Mechanical properties

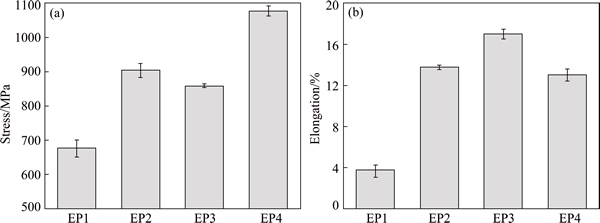

The mechanical properties of the alloys under different conditions are shown in Fig. 5. The alloy after sintering shows a low tensile strength and elongation, which are 677 MPa and 3.75%, respectively. The process of hot forging and the solution treatment have great effects on both the tensile strength and the elongation. The tensile strength of the alloy after hot forging reaches 910 MPa. After heat treatment, the elongation of the alloy has an obvious increment from 13.6% to 17%, but the tensile strength decreases to 860 MPa. The alloy after cold swaging by 85% has the best mechanical properties. The tensile strength reaches 1077 MPa, and the elongation is 13%.

4 Discussion

4.1 Microstructural evolution during hot and cold deformation

The β transus temperature of the TNTZO alloy can be estimated by the following empirical equation: T(K)= 1158-8.5[Nb]-1[Ta]-2[Zr]+200[O] [13], where the elements in square brackets denote their mass fractions in the alloy. The β transus temperature of the alloy is about 908 K, and the recrystallization temperature was reported to be 1073 K [14]. Therefore, the hot forging of TNTZO alloy occurred in the β-phase field. The solution treatment was carried out at a temperature of 1273 K, which is in the recrystallization region. The SAED pattern for the recrystallized alloy does not show an obvious existence of α" phase and ω phase. The results are different from what was reported by GUO et al [7]. The reason may be a certain amount of oxygen and the quick cooling rate in the present study, which fully suppress the formation of secondary phases. The hot forging and subsequent heat treatment effectively eliminate the pores in the as-sintered TNTZO alloy, and generate a fully dense β-phase alloy with a fine-grained microstructure, which improved the cold working performance.

Fig. 3 Optical micrographs of Ti-36Nb-2Ta-3Zr-0.35O alloy after cold swaging 56% (a, b), 85% (c, d) and 72% (e) area reductions: (a, c) Cross section; (b, d) Longitudinal direction

During the cold swaging, the initial equaixed microstructure becomes highly distorted and broken up into highly fragmented, elongated grains. With the cold deformation increasing, the deformation bands gradually form, and the grains are severely elongated along the longitudinal direction. After cold working by 85%, the microstructure finally changes into a ‘‘marble-like’’ in the cross section and “fiber-like” structures along the longitudinal direction. FURUTA et al [15] has determined that the deformation band does not related to {112}<111> or {332}<113> twinning. The “fiber-like” features have also been found by KURAMOTO et al [16], and are believed to be “giant fault”, which stores a large amount of elastic stain energy.

The stress-induced α" martensite transformation in the swaged alloy is consistent with other studies on gum metal [11] and β-Ti alloys [17]. TALLING et al [8] reported that the martensitic transformation in the gum metal is reversible. In this work, the size of α" phase is several nanometers in width and tens of nanometers in length, which is much smaller than that reported in other studies [8,11]. Moreover, other researchers found that, ω phase and dislocation can be observed in the deformed alloy [7,11,18,19]. In this work, such features do not exist. The methods of cold deformation may influence the existence of second phases. However, the underlying mechanism is still to be explored.

4.2 Relationship between structure and mechanical properties

The effect of hot and cold deformations on the tensile strength and ductility of gum metal is found to be significant. The insufficient densification and the effect of Kirkendall during the sintering induce a high porosity, therefore, the as-sintered alloy has a low strength and elongation. Since the hot forging process effectively eliminates the residual porosity, both the strength and the elongation of the alloy are significantly increased. The fact that the alloy after the heat treatment has a lower strength but is more ductile than the cold-worked specimens suggests that heat treatment allows recovery of dislocations and the relaxation of the residual stress in EP3.

Fig. 4 TEM images of Ti-36Nb-2Ta-3Zr-0.35O alloy after heat treatment (a) and after 85% cold swaging (b, c, d) ((a) and (b) are bright-field images, (c) is dark-field image, (d) and the inset in (a) are [110] β zone axis selected area diffraction patterns)

Fig. 5 Tensile strength (a) and elongation (b) of tensile-deformed Ti-36Nb-2Ta-3Zr-0.35O alloy after CIP/sintering (EP1), hot forging (EP2), annealing at 1273K (EP3), and 85% cold swaging (EP4)

For the alloy after the cold swaging by 85%, a high strengthening effect is observed by comparison with the alloy after the heat treatment. In conventional alloys, the activity of dislocations produces the work hardening. However, in this study, very few dislocations are observed in the alloy after cold swaging. The giant shear step [6,16] or “nanodisturbance” [20] mechanisms are proposed to explain the deformation behavior of gum alloys. The increase of the strength may be more largely due to the refinement of the “giant fault”, and partially due to the precipitation of nanostructured α" phase (shown in Fig. 4(c)).

5 Conclusions

1) Hot deformation and heat treatment effectively eliminate the pores in the as-sintered TNTZO alloy, and generate a fully dense β-phase alloy with a fine-grained microstructure.

2) During the cold deformation, deformation bands are detected and gradually distorted with the deformation increasing. After cold swaging by 85%, the alloy shows the typical “marble-like” structure.

3) The cold deformation is accompanied by numerous giant faults and a small amount of stress-induced α" phase transformations.

4) After hot and cold working, the alloy shows excellent mechanical properties, i.e., both high strength and high ductility.

References

[1] SONG Y, XU D S, YANG R, LI D, WU W T, GUO Z X. Theoretical study of effects of alloying elements on the strength and modulus of β-type bio-titanium alloys [J]. Materials Science and Engineering A, 1999, 260: 269-274.

[2] ELIAS L M, SCHNEIDER S G, SCHNEIDER S, SILVA H M, MALVISI F. Microstructural and mechanical characterization of biomedical Ti-Nb-Zr-(Ta) alloys [J]. Materials Science and Engineering A, 2006, 432: 108-112.

[3] GORDIN D M, GLORIANT T, NEMTOI G H, CHELARIU R, AELENEI N, GUILLOU A, ANSEL D. Synthesis, structure and electrochemical behavior of a beta Ti-12Mo-5Ta alloy as new biomaterial [J]. Materials Letters, 2005, 59: 2936-2941.

[4] ZHANG Ling-bo, WANG Ke-zheng, XU Li-juan, XIAO Shu-long, CHEN Yu-yong. Effect of Nb addition on microstructure, mechanical properties and castability of β-type Ti-Mo alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2214-2220.

[5] XU Li-juan, XIAO Shu-long, TIAN Jing, CHEN Yu-yong. Microstructure, mechanical properties and dry wear resistance of β-type Ti-15Mo-xNb alloys for biomedical applications [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 692-698.

[6] SAITO T, FURUTA T, HWANG J H, KURAMOTO S, NISHINO K, SUZUKI N. Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism [J]. Science, 2003, 300: 464-467.

[7] GUO W, QUADIR M Z, MORICCA S, EDDOWS T, FERRY M. Microstructural evolution and final properties of a cold-swaged multifunctional Ti-Nb-Ta-Zr-O alloy produced by a powder metallurgy route [J]. Materials Science and Engineering A, 2013, 575: 206-216.

[8] TALLING R J, JACKSON M, DASHWOOD R J, DYE D. On the mechanism of superelasticity in Gum metal [J]. Acta Materialia, 2009, 57: 1188-1198.

[9] TALLING R J, DASHWOOD R J, JACKSON M, DYE D. Compositional variability in gum metal [J]. Scripta Materialia, 2009, 60: 1000-1003.

[10] PREMKUMAR M, HIMABINDU V S, BANUMATHY S, BHATTACHARIEE A, SINGH AK. Effect of mode of deformation by rolling on texture evolution and yield locus anisotropy in a multifunctional β titanium alloy [J]. Materials Science and Engineering A, 2012, 552: 15-25. ?

[11] YANG Y, WU S Q, LI G P, LI Y L, LU Y F, YANG K, GE P. Evolution of deformation mechanisms of Ti-22.4Nb-0.73Ta-2Zr- 1.34O alloy during straining [J]. Acta Materialia, 2010, 58: 2778-2787.?

[12] BESSE M, CASTANCY P, GLORIANT T. Mechanism of deformation in gum metal TNTZ-O and TNTZ titanium alloys: A comparative study on the oxygen influence [J]. Acta Materialia, 2011, 59: 5982-5988.

[13] LI S J, HAO Y L, YANG R, CUI Y Y, NIINOMI M. Effect of Nb on microstructural characteristics of Ti-Nb-Ta-Zr alloy for biomedical applications [J]. Materials Transactions, 2002, 43: 2964-2969.

[14] GUO W Y, XING H, SUN J, LI X L, WU J S, CHEN R. Evolution of microstructure and texture during recrystallization of the cold-swaged Ti-Nb-Ta-Zr-O alloy [J]. Metallurgical and Materials Transactions A, 2008, 39A: 672-678.

[15] FURUTA T, KURAMOTO S, HWANG J H, NISHINO K, SAITO T. Elastic deformation behavior of multi-functional Ti-Nb-Ta-Zr-O alloys [J]. Materials Transactions, 2005, 46: 3001-3007.

[16] KURAMOTO S, FURUTA T, HWANG J H, NISHINO K, SAITO T. Plastic deformation in a multifunctional Ti-Nb-Ta-Zr-O alloy [J]. Metallurgical and Materials Transactions A, 2006, 37: 657-662.

[17] KIM H Y, SASAKI T, OKUTSU K, KIM J I, IMAMURA T, HOSODA H, MIYAZAKI S. Texture and shape memory behavior of Ti-22Nb-6Ta alloy [J]. Acta Materialia, 2006, 54: 423-433.

[18] PLANCHEER E, TASAN C C, SANDLOEBES S, RAABE D. On the dislocation involvement in Ti-Nb gum metal plasticity [J]. Scripta Materialia, 2013, 68: 805-808.

[19] LAI M J, TASAN C C, RAABE D. Deformation mechanism of ω-enriched Ti-Nb-based gum metal: Dislocation channeling and deformation induced ω–β transformation [J]. Acta Materialia, 2015, 100: 290-300.

[20] GUTKIN M Y, ISHIZAKI T, KURAMOTO S, OVIDKO I A. Nanodisturbances in deformed gum metal [J]. Acta Materialia, 2006, 54: 2489-2499.

张卫东1,刘 咏1,吴 宏1,刘 彬1,陈紫瑾1,汤慧萍2

1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 西北有色金属研究院,金属多孔材料国家重点实验室,西安 710012

摘 要:采用元素粉末法通过冷等静压、真空烧结、热锻、冷锻等方法制备了Ti-36Nb-2Ta-3Zr-0.35O(质量分数,%)(TNTZO)合金。运用透射电子显微镜、扫描电子显微镜、金相显微镜以及万能试验机对加工前后合金材料进行显微组织分析和力学性能检测,探究热加工与冷加工对合金组织与性能的影响。结果表明:TNTZO合金具有良好的可加工性,通过热锻与冷旋锻可以得到良好的细晶组织;85%冷旋锻的合金样品呈现典型大理石状显微组织,并且在其冷加工过程中伴随有应力诱导α"马氏体相变。此外,热加工与冷加工后合金的强度及塑形都有显著提高。

关键词:橡胶金属;热锻;冷旋锻;显微组织;无位错;应力诱导马氏体相变

(Edited by Yun-bin HE)

Foundation item: Project (2014CB644002) supported by the National Key Fundamental Research and Development Project of China; Project (51301203) supported by the National Natural Science Foundation of China; Project (2015CX004) supported by the Innovation-driven Plan in Central South University, China; Project supported by the Outstanding Graduate Project of Advanced Non-ferrous Metal Structural Materials and Manufacturing Collaborative Innovation Center, China

Corresponding author: Yong LIU; Tel: +86-731-88836939; E-mail: yonliu@csu.edu.cn

DOI: 10.1016/S1003-6326(16)64251-6