J. Cent. South Univ. (2017) 24: 2773-2782

DOI: https://doi.org/10.1007/s11771-017-3691-6

Numerical optimization of gourd-shaped surface texture and experiment of tribological performance

CHEN Ping(陈平), LI Jun-ling(李俊玲), SHI Zhe(史哲), XIANG Xin(项欣)

School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China

Central South University Press and Springer-Verlag GmbH Germany,part of Springer Nature 2017

Central South University Press and Springer-Verlag GmbH Germany,part of Springer Nature 2017

Abstract: A numerical optimization approach based on the finite element (FE) simulation was used to design the optimum irregular gourd-shaped pattern parameters for generating the highest hydrodynamic pressure. Then the optimum parameters of the gourd-shaped surface texture were determined and the textures were processed on the stainless steel surface by the laser technology. The tribological performance of gourd-shaped surface texture was analyzed using the type of UMT2 tester, and compared with that of the regular circle surface texture and none-texture surface by considering the effect of sliding speeds and applied loads on the tribological performance. The results show that the compound factor n, the diameter ratio Dr and the texture depth Hd are more significant parameters and the optimum values are 0.618, 2.0 and 4 μm, respectively. In addition, irregular gourd-shaped surface texture with optimum parameters is the most effective in the friction reduction among the patterns investigated under different speeds and applied loads in this work. Moreover, better coordination and combination effect can be obtained by gourd-shaped surface texture. The main reason responsible for the results is the irregular symmetric nature of the gourd-shaped texture along the direction of lubricants flowing which can generate the higher fluid dynamic pressure.

Key words: gourd-shaped texture; irregular symmetric; tribological performance; numerical and experimental

1 Introduction

It is well known that surface texturing technology is an effective way to improve tribological properties of contacting surfaces, and it has been applied in various mechanical components, such as sliding bearing, cylinder, piston ring, hard disk, resulting from its benefits reducing the coefficient of friction and enhancing the lifetime of the contact components [1–5].

In recent years, the application of surface texture in the metal sheet forming and forming rolls has been propelled, such as the skin-pass mill roll to control the surface profile of the sheet steel and meet the requirements in automotive applications [6–8]. ELKOCA [7] investigated and found that the surface textured metal sheet could offer good pressing formability and image clarity, significantly improving the visual characteristics of the finished products. WAN et al [9] designed a new laser beam chopping and modulating device based on the beam expanding and focusing transformation characteristics. WU et al [10] presented an experimental study on the groove surface texture processed by laser on the surface of high-speed steel. GARCIA et al [11] measured the positive effects in the lubrication condition through the application of micro texture with different types and it was concluded that the laser texturing significantly reduced the friction and wear in die processing. CHEN et al [12] researched the combined influences of surface texturing and TiN coating of die under lubricated sliding condition, and the results showed that the tribological performance of texturing and TiN coating surface was improved resulting from several factors, such as high hardness and low elastic modulus of TiN coating, the generation of hydrodynamic pressure, function of micro-trap for wear debris. SHEN et al [13] investigated the mechanical and microstructure effects of laser texturing on steel sheets, and found that the laser textured sheets exhibited different behaviors in plastic instability and had obvious tendency to postpone strain localization as compared with the normal rolled sheets. However, to the knowledge of the authors, the researches about the optimization of surface texture on cold rolls, especially about the shape of irregular symmetrical dimples, have been so far not much reported.

Since surface textures can improve the load carrying capacities, act as reservoirs for lubricants and trap wear particles [3], the geometric parameter of surface pattern itself is an important factor to design surface textures. Significant amount of studies have been done to investigate the influence of different surface pattern shapes on the tribological performances. Micro-dimple and micro-groove surface texture have attracted great attention. JI et al [14] investigated the effect of elliptical dimples on hydrodynamic lubrication by multi-grid method, and indicated that geometrical parameters of elliptical dimples had an obvious effect on the hydrodynamic pressure. YUAN et al [15] compared the tribological behaviors of different orientations of micro-grooves both experimentally and numerically, and the results showed that the micro-groove perpendicular to the sliding direction exhibited the higher load-carrying capacity. Similar results were obtained by ZUMGAHR et al [16]. No matter the micro-dimple, micro-groove or elliptical surface texture, they are characterized a common feature, that is, they are in geometric symmetry on the lubricant flowing distribution. The texture surfaces with irregular shapes in the direction of lubricant flowing, however, show better tribological behavior. XING et al [17] compared the tribological performance of regular line grooves and irregular wavy grooves, and found that the irregular wavy grooves presented the lowest friction coefficient under non- lubricated and MoS2 lubricated conditions. SHEN et al [18] optimized the texture shape for parallel surfaces under unidirectional sliding, and the results showed that the optimum directional textures had chevron-shapes with flat fronts.

Not like the regular patterns, the direction of lubricant flowing has a significant influence on tribological performance of irregular patterns. Hence, the comparison on the influence of direction of lubricant flowing has been studied primly, and the results show that the gourd-shaped surface texture with positive direction presents best friction-reduction [19]. However, the influence of sliding speeds and applied loads on the irregular patterns is of little attention.

According to the above researches, the main of this work is to perform the tribological performance of gourd-shaped surface texture with positive direction. To this end, the parameters of gourd-shaped surface texture were designed by the orthogonal experiments and optimized by the finite element (FE) simulation. The average pressure (Pave) of optimum gourd-shaped and circle texture surface in different distribution forms was compared to evaluate the performance of friction reduction. The tribological experimental tests were carried out to investigate the effect of sliding speeds and applied loads and verify the results of the FE simulation result.

2 Finite element simulation and experimental tests

2.1 Establishment of finite element model

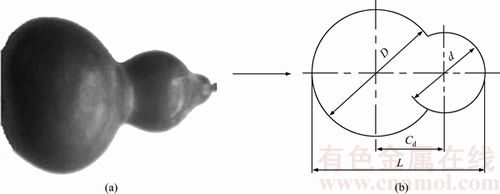

The gourd has two asymmetry ends (Fig. 1(a)), of which cross-sectional shape can be abstracted as the union of two circles with different diameters, as shown in Fig. 1(b). In the direction of lubricant flowing, the fluid hydrodynamic effect can be enhanced if we reduce the area of divergence and increase the area of convergence appropriately. Therefore, it is necessary to analyze the parameters of gourd-shaped texture, listed as follows.

n, defined as the compound factor, can be calculated according to Eq. (1).

(1)

(1)

where d and D represent the diameters of the small circle and the big one, respectively; Cd is the center distance of the two circles (shown in Fig. 1(b)).

Dr, defined as the diameter ratio, means the ratio of D to d, that is,

(2)

(2)

In addition, Hd, Sp and H0 represent the texture depth, texture area ratio and oil film thickness, respectively. Meanwhile, the parameters of gourd-shaped texture were set as follows: the compound factor n and the diameter of small circle d were varied from 0.418 to 0.818 and from 120 to 180 μm, respectively. The diameter ratio Dr and texture area ratio Sp were changed from 1.2 to 2.0 and from 5% to 35%, respectively. The texture depth Hd was varied from 2 to 10 μm, and the oil film thickness H0 was set as 4 μm [19, 20].

Fig. 1 Actual model of gourd (a) and geometric model of gourd-shaped texture (b)

In order to reduce calculation and save computational memory, a single texture was taken as the research object in this study. By using CAD, the geometry of a single texture was established, and imported into Gambit for meshing, then, the single texture with quality meshing was imported into computational fluid dynamics (CFD) software. The geometry model and the setting of the boundary conditions are identical to those in Ref. [19], and the result that gourd-shaped texture with positive direction (from the big end to the small one) has been proven to generate greater friction reduction. Therefore, in this work, the gourd-shaped texture with positive direction was investigated.

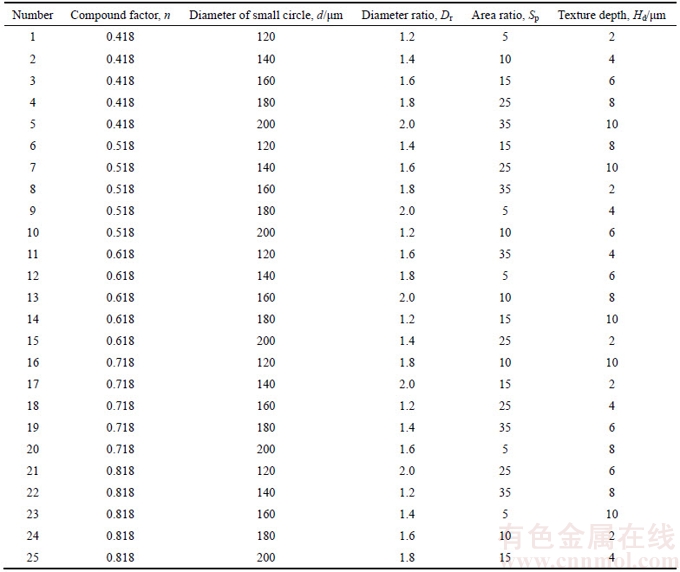

2.2 Design of orthogonal experiment

There are five parameters involved in the gourd-shaped surface texture and each parameter will have an influence on the tribological performance. However, the influence significance level is distinguishing and complicated. Therefore, the orthogonal experiment is used to analyze the influence significance level of gourd-shaped parameters in order to optimize parameters. Based on the standard orthogonal array of  the orthogonal array was designed as Table 1. The CFD software was used to simulate the fluid flowing of the texture unit, and the average pressure (Pave) of the upper surface was selected as the criteria to evaluate the effect of gourd-shaped parameters on the tribological performance.

the orthogonal array was designed as Table 1. The CFD software was used to simulate the fluid flowing of the texture unit, and the average pressure (Pave) of the upper surface was selected as the criteria to evaluate the effect of gourd-shaped parameters on the tribological performance.

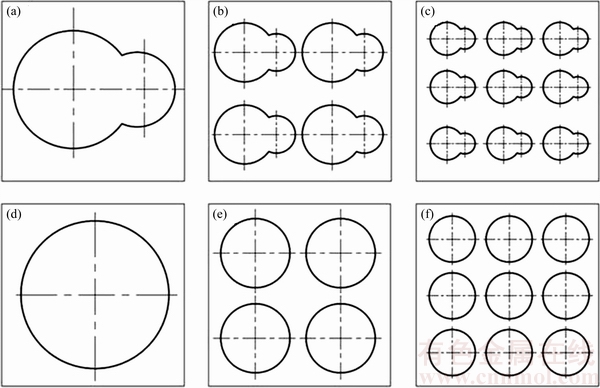

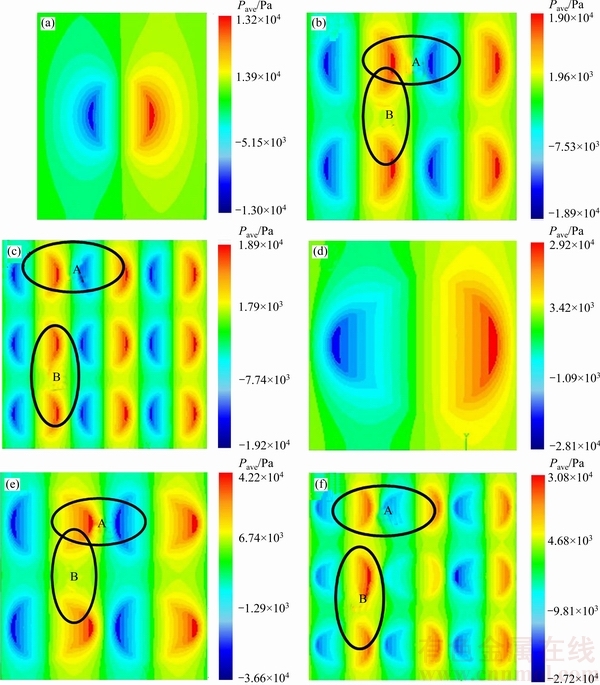

In order to compare the tribological performance of gourd-shaped and micro-circle surface texture, the pressure distribution of gourd-shaped with optimized parameters and micro-circle surface texture was analyzed through a single texture (Figs. 2(a) and (d)). For further understanding, the coupled effect due to coordination and combination effect generated by several surface texture (Fig. 2) was investigated by exploring the average pressure of texture surface in different forms of 2×2 and 3×3. Normally, the larger the average pressure, the more the friction reduction.

Table 1 Parameters and levels

2.3 Experimental tests

A series of friction tests were conducted on a pin- on-disc UMT2 tribological tester at room temperature. As shown in Ref. [20], the pins with 6 mm in diameter were fixed as the upper specimen, and the disc with 70 mm in diameter and 3 mm in thickness was fixed on the panel as lower specimen. The friction tests were carried out under normal loads from 2 to 14 N, corresponding to the contact pressure from 0.04 to 0.28 MPa. The rotational speeds of the crank varied from 50 to 400 r/min, corresponding to the sliding speed from 0.13 to 1.05 m/s, and the friction test lasted for 3 min at each speed or load. The repetition number of each test was three times. A commercial diesel engine oil CD 15W-40 was used as the lubricant and dropped in and inner of the friction track concentrating about 5×10–3 mL/cm2 before each trail without further replenishing during the test. At the beginning of each test, the specimens were ultrasonically cleaned for about 5 min in ethanol and acetone. In addition, in order to get a better surface-to-surface contact, sandpaper was used to replace the disc to running-in for about 10 min until it came to a uniform grinding crack.

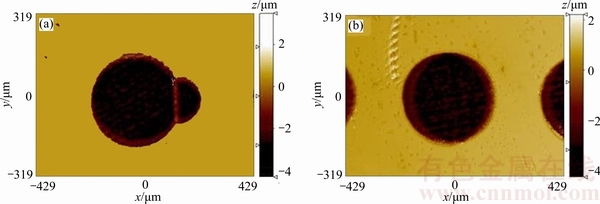

Before the tests, the pins and disc were smoothly polished to achieve a similar average roughness (Ra) of 0.02 μm and 0.045 μm, respectively. The tribological test was composed of three different surface textures of discs, that is, gourd-shaped texture, circular texture and none-texture. The femtosecond laser system was used to fabricate the textures. The power, the space of filling line and the processing time were needed to adjust and coordinate to get different texture depths and smooth bottom surfaces of the dimple. The 2D profiles of the laser textured dimple are presented in Fig. 3. It was obvious that the surface of the dimples were smooth after the laser textured. After measuring, the detailed parameters after laser textured were close to that in the numerical simulation part.

3 Results and discussion

3.1 FE simulation results

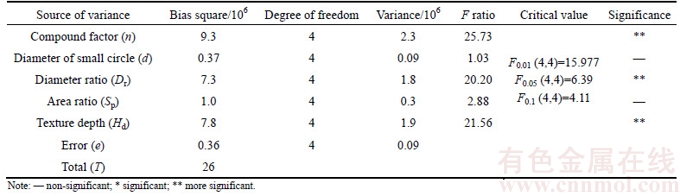

Table 2 lists the results of the orthogonal experiments. It can be clearly seen that the diameter of small circle d and the texture area ratio Sp play the non-significant role. Among the other three factors, the compound factor n and the diameter ratio Dr will affect the diameter of micro-dimple, and hence the three significant impact factors, that is, compound factor n, the diameter ratio Dr and the texture depth Hd, can be classified as the influence of depth to diameter ratio. Based on this, the diameter of small circle d and the area ratio Dr were set as 180 μm and 35%, respectively, and the others were set by using CFD numerical simulation analysis.

Fig. 2 Typical distribution forms 1×1 (a), 2×2 (b), 3×3 (c) of gourd-shaped texture and 1×1 (d), 2×2 (e), 3×3 (f) of circle texture

Fig. 3 Profile of gourd-shaped texture (a) and circle texture (b)

Table 2 Analysis of variance table

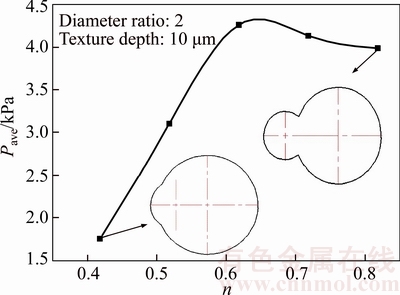

Figure 4 shows the average pressure curve of gourd- shaped texture upper surface under different compound factors. With the increase of the compound factor n, the average pressure increased first, and then reduced modestly. The better effect was achieved when the compound factor n varied from 0.618 to 0.718. As a result, the compound factor n was set as 0.618 in the next section.

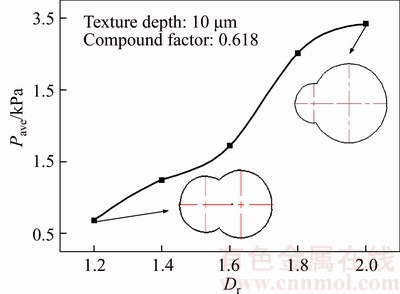

The relationship between the average pressure of gourd-shaped upper surface and the diameter ratio Dr is shown in Fig. 5. With the increase of the diameter ratio,the average pressure increased sharply then slowly. When the diameter ratio Dr was smaller, the symmetry of gourd-shape was relatively obvious, it was difficult to form strong fluid dynamic effect, but the advantage was to take shape of small pools for lubricant as well as to provide continuous and homogeneous lubrication. When the diameter ratio Dr was getting larger, the change of gourd-shaped surface texture cross-section was bigger to form strong hydrodynamic pressure and to increase the load carrying capacity, but the uniformity of lubrication would degrade at the same time. Therefore, the balance effect was achieved at the optimal value of 2.0 [21].

Fig. 4 Relationship between average pressure and compound factor

Fig. 5 Relationship between average pressure and diameter ratio

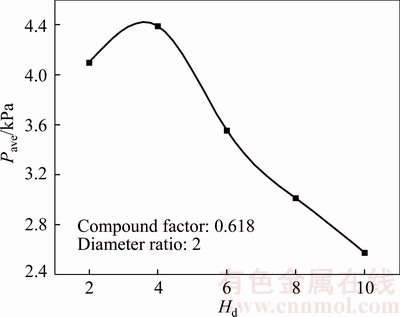

The curve shown in Fig. 6 represents the relationship between the average pressure of gourd-shaped upper surface and the texture depth Hd. With the increase of texture depth, the average pressure decreased after the initial increased, and the maximum average pressure was obtained at the depth of 4 μm. Two main reasons may account for the phenomena, i.e. supplying lubrication to improve the contact condition and forming dynamic pressure effect to increase the load carrying capacity. When the texture depth was small, it was easier for the lubricant to squeeze to improve the lubrication condition, but the effect of dynamic pressure may be weaker. When the texture depth was large, the situation was reversed. In this work, the optimized depth to diameter ratio was about 0.008, which was very close to the optimal value put forward in Refs. [22, 23].

Fig. 6 Relationship between average pressure and texture depth

As for the friction reduction, the coupled effect of surface textures is of great significant, especially for the irregular symmetrical surface textures. Therefore, in this work, the pressure distribution is shown in Fig. 7. On one hand, it can be seen that the average pressure of the single gourd-shaped texture was 2214 Pa (Fig. 7(a)). It is almost three times larger than that of the micro-circle texture which was 803 Pa (Fig. 7(d)). The symmetric feature of the micro-circle resulted in the increasing of positive and negative pressure offset. But the gourd-shaped texture was of irregular symmetric characteristics, the cross-section was changing all the time and the gradient was different, and then the offset of the positive and negative pressure will be less than those of the micro-circular texture [24]. On the other hand, the combination effect of the textures was influenced by the texture shape. It can be seen in Figs. 7(a)–(c), the maximum and minimum of the pressure on the circular texture surface increased, and the increase rates were 30.1%, 0.62% and 30.9%, 0.62%, respectively. As for Figs. 7(d)–(f) of gourd-shaped texture surface, the increase rates were 30.6%, –26.9% and 23%, –25.5%, respectively. It was assumed that due to the influence of negative pressure area generated by adjacent texture, the maximum pressure reduced, but the area of effective pressure increased, so as to realize the pressure area of positive and negative coordinate with each other (part A). As can be seen from the data analysis, the coordination upon the gourd-shaped texture was stronger than that of the micro-circular texture. And the pressure distribution diagrams showed that the longitudinal connection upon the gourd-shaped texture was closer than that of the micro-circle texture, and the combination was more apparent (part B). Both the irregular symmetry on the direction of lubricant flowing and the better combination and coordination resulted in greater effective hydrodynamic pressure, which was consistent of the results reported by SHEN et al [18] and the theory reported by SEGU et al [25].

Based on the above analysis, the gourd-shaped texture surface exhibited better average pressure than that of the circular texture, and the conclusion that the friction reduction of gourd-shaped surface texture is greater than that of circle surface texture can be deduced.

3.2 Experimental test results

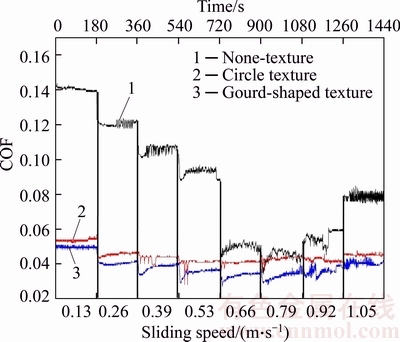

Figure 8 shows the curves of coefficient of friction (COF) with sliding speed during the testing under the applied load of 14 N. The significant differences of COFs with the testing specimen can be seen from Fig. 8. For the none-texture specimen, the COF trend showed a clear transition from 0.14 at the lowest speed to lower values as the speed increased, which was consistent with the Stribeck curve. However, the COF of the texture specimens remained low, even at the lowest speed. At higher sliding speeds, the differences of COF between the test specimens became insignificant, which may be due to the thickness of lubrication film increasing with sliding speed, and the effect of surface texture was expected to be minimal. However, when the sliding speed increases to 1.1 m/s, the COF increased instead of maintained lower for none-texture specimens. Compared with the results in Ref. [20], a similar trend was observed with the curve of frictional coefficient under the applied load of 2 N, but with a higher magnitude of COF was achieved. This difference is, perhaps, due to the fact that the applied load was heavier, resulting in thin lubrication film and high frictional coefficient under the present conditions.

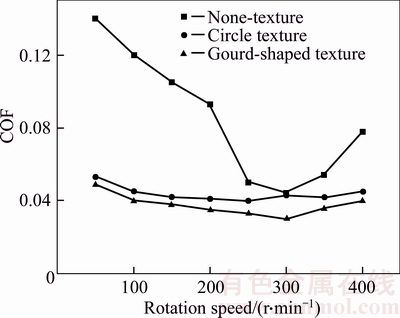

In order to evaluate the representative frictional properties of the entire stroke, the average frictional coefficient was used to show the relationship between the rotation speed and frictional coefficient, as shown in Fig. 9. It can be obviously seen that the COF of the none- texture specimen was, at the beginning of the test, 0.14 more or less, then decreased to 0.05 as the sliding speed increased, which indicates that the lubrication regime translated from boundary or mixed lubrication to hydrodynamic lubrication. However, the COF of texture specimens maintained lower than 0.06, even much lower for the gourd-shaped texture specimen. This might indicate that the texture specimens were kept in the hydrodynamic lubrication regime. The trend was similar to KOVALCHENKO’s results [26], who investigated the effect of the surface texture on transition in lubrication regime. In the test with the texture specimens, the frictional coefficient for the gourd-shaped texture specimen was lower than that for the circle texture specimen under all applied loads. Note that the operated condition between textured specimens was similar to each other, thus, the difference was due to the shape of dimples, which will be discussed later.

Fig. 7 Pressure contours of distribution forms 1×1 (a), 2×2 (b), 3×3 (c) of circle texture and 1×1 (d), 2×2 (e), 3×3 (f) of gourd-shaped texture

Fig. 8 Curves of COF with sliding speed under applied load of 14 N

Fig. 9 Curves of average COF with rotation speed under applied load of 14 N

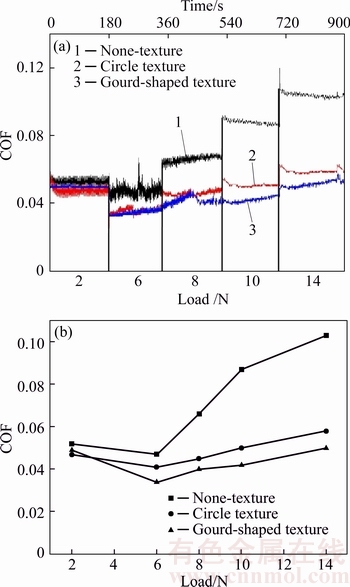

The influence of applied loads on the frictional coefficient was investigated at the rotation speed of 200 r/min, as shown in Fig. 10. It can be seen that the texture specimens exhibited lower frictional coefficient than the none-texture specimen, and the frictional coefficient of gourd-shaped texture specimen was the lowest. For example, when the applied load was 6 N, compared with the none-texture and micro-circle texture specimen, the average COF of gourd-shaped texture specimen was reduced by 26.1% and 17.1%, respectively. Moreover, all of the frictional coefficients decreased when the applied load reached 6 N, but increased thereafter with the applied load up to 8 N. It might be due to the fact that when the applied load was in a small range, it was difficult to form stable and thick lubrication film, when the applied load became larger, it was uneasy for the lubricant to be stored in the micro-dimple because of the contact area being squeezed or deformed.

Fig. 10 Relationship between COF and time (a) and relationship between average COF and load (b) at rotation speed of 200 r/min

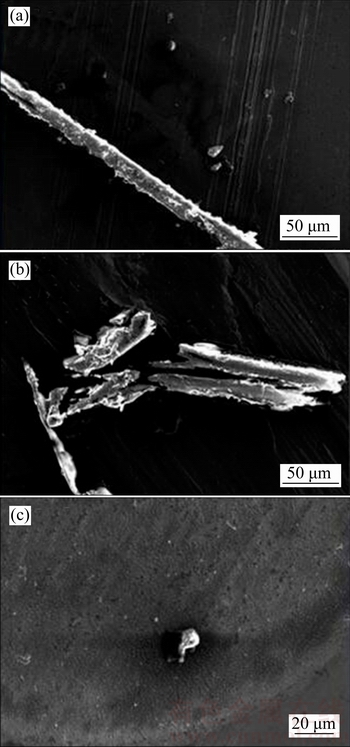

Checking and comparing the worn surface of specimens after friction tests were effective methods to explore the friction reducing mechanism of surface texture. It has been proved in many researches [12, 20, 27, 28]. Normally, the wear tracks on none-texture surface are more evident as compared with texture surface, meanwhile, the wear debris and lubricants were trapped into the texture to avoid the high instability of the friction coefficient. It is well known that wear debris induce the model of “three-body friction” easily and gradually terminate effective lubrication. On the contrary, the wear debris on the texture surface were observed in the dimple, and the dimples acted like reservoirs for lubricant and abrasives, in order to remain low frictional coefficient [29]. In addition to these proven mechanisms, another interesting phenomenon was found in this test, that is, the wear debris found on the worn surfaces was different in the shape and size as shown in Fig. 11. The debris on the none-texture surface was shaped in bar-liked or/and bulk-liked (Figs. 11(a) and (b)), but on the texture surface, they were shaped in particle-liked (Fig. 11(c)). Moreover, the debris size on none-texture surface was much bigger than that on the textured surface, and it may be another reason responsible for the results. However, what is the relationship between the shape, size of wear debris and the friction behavior is still needed to explore.

4 Conclusions

This work presents a study on the tribological performance of the irregular symmetric gourd-shaped surface texture. FE simulations were carried out to optimize the parameters of gourd-shaped surface texture, and the coupled effect between gourd-shaped and circle surface texture was compared. Experimental tests considering the effect of sliding speeds and applied loads were conducted. The following conclusion can be drawn:

1) The compound factor n, the diameter ratio Dr and the texture depth Hd are more significant parameters within gourd-shaped texture. The parameters optimized by FE simulation show that when the compound factor n, the diameter ratio Dr and the texture depth Hd are 0.618, 2.0 and 4 μm, respectively, the average pressure of texture surface can be greatly improved.

Fig. 11 SEM image of wear debris in bar-liked shape (a), bulk-liked shape (b) and particle-liked shape (c)

2) The experimental tests are consistent with FE simulation and FE simulation is capable to predict the tribological performance of surface texture. Among the surface textures investigated, gourd-shaped texture achieved greater average pressure and the lower coefficient of friction than that of the micro-circular texture and none-texture.

3) Based on results of FE simulation and friction test, it can be deduced that the irregular symmetric characteristics of the texture is the dominant reason. The irregular symmetry can generate greater effect of coordination and combination that help to produce stronger fluid dynamic pressure effect, thus, significantly improve the lubrication condition and reduce frictional coefficient. Moreover, the new findings about the shape and size of wear debris on the worn surfaces have important practical implications.

Acknowledgement

The authors would like to express special thanks to Tian-min SHAO (State Key Laboratory of Tribology, Tsinghua University) for scientific guidance and English writing assistance.

References

[1] Wang Xiao-lei, Adachi K, Otsuka K, KATO K. Optimization of the surface texture for silicon carbide sliding in water [J]. Applied Surface Science, 2006, 253: 1282–1286.

[2] QIU Ming-feng, DELIC A, RAEYMAEKERS B. The effect of texture shape on the load-carrying capacity of gas-lubricated parallel slider bearings [J]. Tribology Letters, 2012, 48(3): 315–327.

[3] SHAO Tian-min, GENG Zhe. Research progress in patterned thin solid techniques and their tribological performance [J]. China Surface Engineering, 2015, 28(2): 1–26. (in Chinese)

[4] RAPOPORT L, MOSHKOVICH A, PERFILYEV V, GEDANKEN A, KOLTYPIN Y, SOMINSKI E, HALPERIN G, ETSION I. Wear life and adhesion of solid lubricant films on laser-textured steel surfaces [J]. Wear, 2009, 267: 1203–1207.

[5] LIN Qi-yin, WEI Zheng-ying, WANG Ning, CHEN Wei. Effect of large-area texture/slip surface on journal bearing considering cavitation [J]. Industrial Lubrication and Tribology, 2015, 67(3): 216–226.

[6] DE MELLO J D B, GONCALVES J L Jr, COSTA H L. Influence of surface texturing and hard chromium coating on the wear of steels used in cold rolling mill rolls [J]. Wear, 2013, 302: 1295–1309.

[7] ELKOCA O. A study on the characteristics of electrical discharge textured skin pass mill work roll [J]. Surface & Coatings Technology, 2008, 202(12): 2765–2774.

[8] UTSCH M, VINKE P. EDT: Roll texturing technology as a base of modern surfaces in automotive cold mill flat products [J]. Iron & Steel Technology, 2005, 2(9): 50–55.

[9] WAN Da-ping, LIU Hong-bin, WANG Yu-ming, HU De-jin, GUI Zhen-xing. CO2 laser beam modulating for surface texturing machining [J]. Optics & Laser Technology, 2008, 40(2): 309–314.

[10] WU Wei, CHEN Gui-ming, ZHAO Na, FAN Bo-xuan. Experimental study on the groove surface texture processed by laser on the surface of high-speed steel [J]. Infrared and Laser Engineering, 2016, 45(2): 206008.

[11] García G T G, Garza M T V, Garza A Q, Zuazua D V, Cortés D M, Tellez A M, Zamarrón R B. Development of a methodology for improving the tribological properties in die processing using laser surface texturing [J]. Tribologia, 2014, 3: 47–58.

[12] CHEN Ping, XIANG Xin, SHAO Tian-min, LA Ying-qian, LI Jun-ling. Effect of triangular texture on the tribological performance of die steel with TiN coatings under lubricated sliding condition [J]. Applied Surface Science, 2016, 389: 361–368.

[13] SHEN Huan, CHEN Guang-nan, LI Guo-chen. The plastic instability behaviour of laser-textured steel sheet [J]. Materials Science and Engineering A, 1996, 219(1): 156–161.

[14] JI Jing-hu, WANG Hao, FU Yong-hong. Effect of elliptical dimples on hydrodynamic lubrication [J]. Key Engineering Materials, 2015, 645–646: 474–479.

[15] YUAN Si-huan, HUANG Wei, WANG Xiao-lei. Orientation effects of micro-grooves on sliding surfaces [J]. Tribology International, 2011, 44(9): 1047–1054.

[16] ZUMGAHR K H, WAHL R, WAUTHIER K. Experimental study of the effect of microtexturing on oil lubricated ceramic/steel friction pairs [J]. Wear, 2009, 267(5): 1241–1251.

[17] XING You-qiang, DENG Jian-xin, WU Ze, CHENG Hong-wei. Effect of regular surface textures generated by laser on tribological behavior of Si3 N4/TiC ceramic [J]. Applied Surface Science, 2013, 265: 823–832.

[18] SHEN Cong, KHONSARI M M. Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding [J]. Tribology International, 2015, 82: 1–11.

[19] LI Jun-ling, CHEN Ping, SHAO Tian-min, XIANG Xin. The effect of gourd-shaped surface texture on tribological performance of stainless steel [J]. Tribology, 2016, 36(2): 207–214. (in Chinese)

[20] CHEN Ping, LI Jun-ling, SHAO Tian-min, XIANG Xin, LIU Guang-lei. Optimal analysis of geometric parameters of surface texture with surface tension considered [J]. Journal of Mechanical Engineering, 2016, 52(19): 123–131. (in Chinese)

[21] WANG Xiao-lei, HAN Wen-fei, KATO K. Surface texture optimal design for silicon carbide under water lubrication [J]. Chinese Journal of Mechanical Engineering, 2008, 19(2): 457–460. (in Chinese)

[22] WANG Xiao-lei, KATO K, ADACHI K, AIZAWA K. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water [J]. Tribology International, 2003, 36(3): 189–197.

[23] ETSION I, KLIGERMAN Y, HALPERIN G. Analytical and experimental investigation of laser-textured mechanical seal faces [J]. Tribology Transactions, 1999, 42(3): 511–516.

[24] RUAN Hong-yan, LV Jian-jun, SI Hui, LIU Hui-xia, WANG Xiao. Hydrodynamic lubrication performance on multi-textured surface structured by multi-arcs and triangle textures [J]. Journal of Jiangsu University, 2010, 31(3): 254–258. (in Chinese)

[25] SEGU D Z, CHOI S G, CHOI J H, KIM S S. The effect of multi-scale laser textured surface on lubrication regime [J]. Applied Surface Science, 2013, 270: 58–63.

[26] KOVALCHENKO A, AJAYI O, ERDEMIR A, FENSKE G, ETISON I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact [J]. Tribology International, 2005, 38(3): 219–225.

[27] MENEZES P L, KISHORE, KAILAS S V. Influence of surface texture and roughness parameters on friction and transfer layer formation during sliding of aluminium pin on steel plate [J]. Wear, 2009, 267(9, 10): 1534–1549.

[28] HUANG Wei, JIANG Liang, ZHOU Chuan-xi, WANG Xiao-lei. The lubricant retaining effect of micro-dimples on the sliding surface of PDMS [J]. Tribology International, 2012, 52(3): 87–93.

[29] XIONG Dang-sheng, QIN Yong-kun, LI Jian-liang, WAN Yi, TYAGI R. Tribological properties of PTFE/laser surface textured stainless steel under starved oil lubrication [J]. Tribology International, 2015, 82: 305–310.

(Edited by YANG Hua)

Cite this article as: CHEN Ping, LI Jun-ling, SHI Zhe, XIANG Xin. Numerical optimization of gourd-shaped surface texture and experiment of tribological performance [J]. Journal of Central South University, 2017, 24(12): 2773–2782. DOI:https://doi.org/10.1007/s11771-017-3691-6.

Foundation item: Project(51305023) supported by the National Natural Science Foundation of China; Project(FRF-GF-17-B20) supported by the Fundamental Research Funds for the Central Universities of China

Received date: 2016-09-26; Accepted date: 2017-03-15

Corresponding author: CHEN Ping, PhD, Associate Professor; Tel: +86–10–62332357; Fax: +86–10–62329145; E-mail: chenp@ustb.edu.cn