Ti-6Al-4V合金高温拉伸变形Norton-Hoff与Arrhenius本构理论的模型化与比较

来源期刊:中国有色金属学报(英文版)2012年第z2期

论文作者:张 超 李小强 李东升 金朝海 肖军杰

文章页码:457 - 464

关键词:Ti-6Al-4V合金;高温拉伸行为;本构模型;模型化;Arrhenius模型;应变补偿;Norton-Hoff改进 模型

Key words:Ti-6Al-4V alloy; hot tensile behaviour; constitutive model; modelization; Arrhenius model; compensation of strain; modified Norton-Hoff model

摘 要:为研究Ti-6Al-4V合金在热成形过程中的力学性能,在923~1023 K温度和0.0005~0.05 s-1应变速率范围内,进行片状试样的恒温高温拉伸试验,采集应力-应变试验数据并建立材料的本构模型。将Arrhenius和Norton-Hoff本构模型用于表征合金的高温拉伸行为。拟合结果显示,考虑材料常数应变补偿的Arrhenius模型和改进的Norton-Hoff模型均可以准确地预测Ti-6Al-4V合金多数条件下的流变应力,由拟合结果比较可知改进的Norton-Hoff模型比Arrhenius模型更精确。

Abstract: In order to study the workability of Ti-6Al-4V alloy in the hot forming process for sheets and profiles, the stress-strain experimental data from isothermal hot tensile tests of flat specimens, in the temperature range of 923-1023 K and strain rate range of 0.0005-0.05 s-1 were used to develop the constitutive equation. Arrhenius and Norton-Hoff constitutive models were proposed to characterize the tensile behavior. The fitting results suggest that both Arrhenius constitutive equation (material constants consider the compensation of strain) and modified Norton-Hoff one can predict flow stress of Ti-6Al-4V alloy under most experimental conditions. Further, the modified Norton-Hoff model is more accurate and precise than Arrhenius model.

Trans. Nonferrous Met. Soc. China 22(2012) s457-s464

ZHANG Chao1, 2, LI Xiao-qiang3, LI Dong-sheng3, JIN Chao-hai3, XIAO Jun-jie3

1. School of Large Aircraft, Beihang University, Beijing 100191, China;

2. School of Materials Science and Engineering, Beihang University, Beijing 100191, China;

3. School of Mechanical Engineering and Automation, Beihang University, Beijing 100191, China

Received 28 August 2012; accepted 25 October 2012

Abstract: In order to study the workability of Ti-6Al-4V alloy in the hot forming process for sheets and profiles, the stress—strain experimental data from isothermal hot tensile tests of flat specimens, in the temperature range of 923-1023 K and strain rate range of 0.0005-0.05 s-1 were used to develop the constitutive equation. Arrhenius and Norton-Hoff constitutive models were proposed to characterize the tensile behavior. The fitting results suggest that both Arrhenius constitutive equation (material constants consider the compensation of strain) and modified Norton-Hoff one can predict flow stress of Ti-6Al-4V alloy under most experimental conditions. Further, the modified Norton-Hoff model is more accurate and precise than Arrhenius model.

Key words: Ti-6Al-4V alloy; hot tensile behaviour; constitutive model; modelization; Arrhenius model; compensation of strain; modified Norton-Hoff model

1 Introduction

As a kind of α+β type titanium alloy, Ti-6Al-4V is attractive to material designers because of its high specific strength and stiffness, reasonable ductility and ability to withstand high temperatures and resistance to corrosion. Because of these properties this alloy is utilized in industrial and aeronautical applications [1-3]. However, Ti-6Al-4V alloy is difficult to fabricate by conventional machining processes owing to several inherent properties at room temperature. Hot forming is extensively used for manufacturing products of the alloy [4-6].

The constitutive model is important for simulating the hot forming processes because of its effective role in describing the flow behavior of the materials [7]. The reliability of simulation results is seriously influenced by the prediction accuracy of the constitutive equation [8,9] and the research about constitutive equation predicting elevated temperature flow behavior of Ti-6Al-4V alloy was carried out [10].

Arrhenius constitutive model is most widely used to describe the compression behavior of Ti-6Al-4V alloy and excellent results are obtained. MOHAMMAD et al [11] used Arrhenius model to predict the hot compression flow curves of Ti-6Al-4V alloy in α+β phase region at 750–950 °C and constant strain rates of 0.001, 0.005 and 0.01 s-1. CAI et al [12] used Arrhenius equation to describe isothermal hot compression test results in the temperature range of 800-1050 °C and strain rate of 0.0005-1 s-1.

VANDERHASTEN et al [13] explored the tensile behaviour of Ti-6Al-4V alloy in the strain rate range of 0.0005-0.05 s-1 and temperature range of 298-1323 K and the Norton-Hoff constitutive model was chosen to fit all experimental results. The fitting results were excellent and satisfactory except for the temperature range of 923-1023 K and strain rate range of 0.0005-0.05 s-1 [14].

The objective of this study is to establish the relationship between the flow stress, strain, strain rate and temperature to predict high temperature tensile behaviour in hot forming process of Ti-6Al-4V alloy. Toward this end, isothermal hot tensile tests of flat specimens were conducted in temperature range of 923-1023 K and strain rate range of 0.0005-0.05 s-1. The data of stress—strain experiments were then employed to derive both Arrhenius and modified Norton-Hoff constitutive equations.

To make the developed constitutive model more accuracy and reliable, the compensation of the strain for material constants of Arrhenius model was taken into account and the Norton-Hoff model was reasonably modified and improved. Finally, the validity of the developed constitutive models was examined over the entire experimental ranges by the comparison of the experimental and predicted results. Meanwhile, the comparison on fitting accuracy and applicability between Arrhenius and Norton–Hoff models was researched.

2 Experimental

2.1 Test material

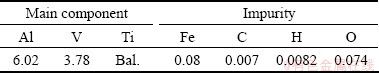

The chemical composition of Ti-6Al-4V alloy is listed in Table 1. The as-received alloy was annealed after hot and cold rolling into sheet of 1.5 mm thickness. The specimen was fabricated at rolling direction, keeping consistent with the longitude direction. Flat samples with a gauge length of 35 mm and width of 12.5 mm were cut by laser cutting.

Table 1 Chemical composition of as-received Ti-6Al-4V alloy (mass fraction, %)

2.2 Testing equipment and procedure

The tensile tests were performed on Zwick/Roell Z100 electric universal test machine equipped with a furnace with three independent heating zones. This furnace had a constant temperature zone of 30 cm and offered the possibility to control the atmosphere temperature with ±3 K precision. Then, the isothermal tensile tests were carried out in the strain rate range of 0.0005–0.05 s–1 and temperature range of 923–1023 K. Prior to the hot uniaxial tensile test, the specimens were heated to the deformation temperature for 5 min to ensure a homogenous temperature distribution through the specimens. The tensile machine was programmed to operate at a constant strain rate. The experimental setup utilized an extensometer to measure the amount of specimen deformation in length via two long cylindrical contacts. The sample deformation was determined from the mobile extensometer displacement due to the friction between two cylindrical contacts. After each test, the engineering curves obtained from the uniaxial tensile tests were converted into true stress—true strain curves. The oxidation was avoided by the introduction of a nitrogen gas flow, which prevented the formation of oxygen enriched alloy layer (alpha case) on the specimen surface [15-17].

2.3 Results of tensile test

The Ti-6Al-4V alloy shows excellent plasticity at high temperature [13]. The elongation of tensile specimens can exceed 100% and the necking does not occur when the experimental temperature is higher than 923 K [13]. In this work, the elongation ranged from 0 to 25% because of the measuring range of the extensometer. Considering the excellent testing equipment and procedure, it can be concluded that the deformation of the specimens is homogeneous under experimental conditions and the true stress—strain data are accurate.

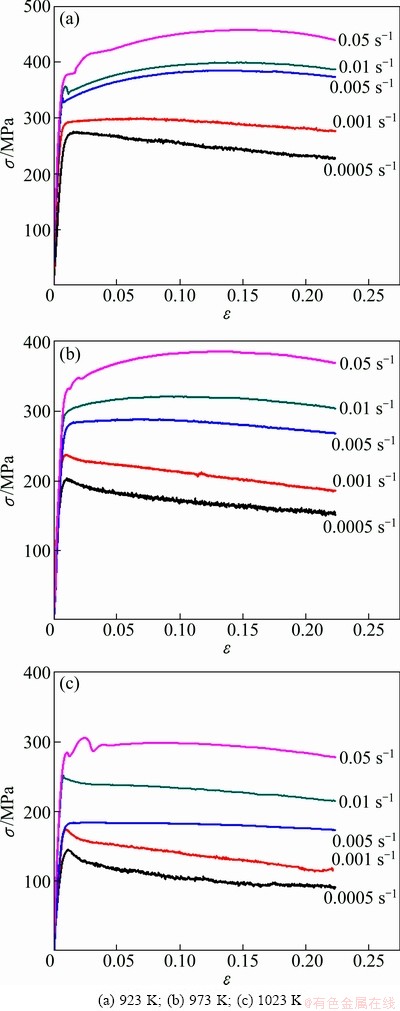

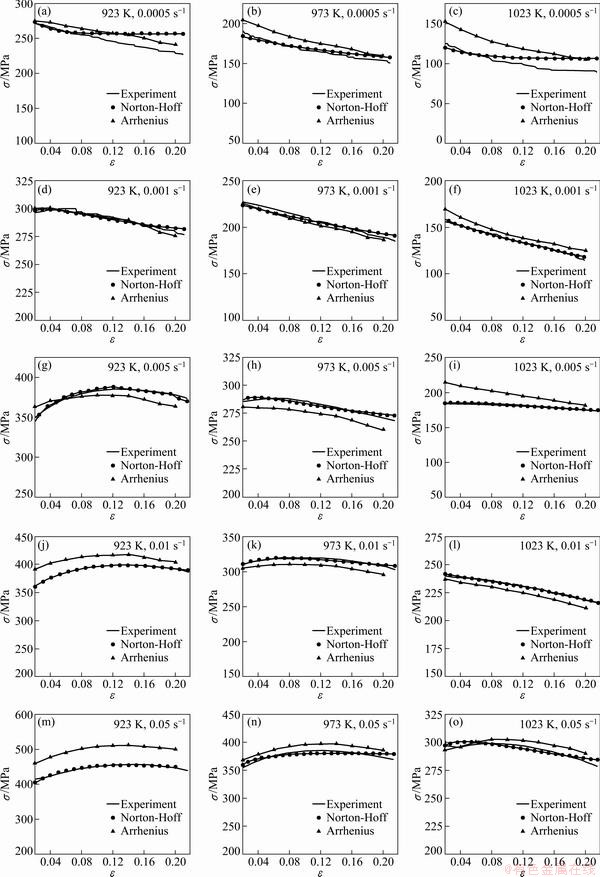

The true stress—strain curves resulting from the uniaxial tensile tests at temperatures of 923, 973 and 1023 K and strain rates of 0.0005, 0.001, 0.005, 0.01 and 0.05 s-1 are presented in Fig. 1. It is found that the Ti-6Al-4V alloy shows the features in hot environment, such as non-proportional, temperature coupling and strain rate relating. All the curves present softening under the condition of strain rate less than 0.005 s-1 and the work hardening is almost vanished at 1023 K and all strain rates. The work hardening becomes obvious under the condition of strains rate above 0.01 s-1 and temperature below 973 K.

Fig. 1 True stress—true strain curves of Ti-6Al-4V alloy under different experimental conditions

There are no sharp peaks in all curves, which suggests that the dynamic recrystallization does not happen and the softening results from the dynamic recovery. The flow stress and work hardening increase with strain rate increasing and temperature decreasing. On the contrary, the dynamic recovery and softening become more significant with temperature increasing and strain rate decreasing. The influence of the strain rate on the tensile strength is significant.

3 Modelization of Arrhenius model

The Arrhenius equation is widely employed to describe the relationship among the strain rate, flow stress and temperature, especially at elevated temperatures. And the effects of temperature and strain rate on the material deformation behavior can be expressed by Zener-Holloman parameter in an exponent-type equation [18-20]:

(1)

(1)

for ασ<0.8 (2)

for ασ<0.8 (2)

for ασ>1.2 (3)

for ασ>1.2 (3)

for all σ (4)

for all σ (4)

where R is the universal gas constant (R=8.3145 J/(mol·K)); T is the absolute temperature (K); Q is the activation energy of hot deformation (J/mol); σ is the flow stress (MPa);  is the strain rate (s-1); A1, A2, A3, α(α=β/n1), n1, n2 and β are the temperature-independent material constants determined by experiment and vary with the change of the strain values [21,22], respectively.

is the strain rate (s-1); A1, A2, A3, α(α=β/n1), n1, n2 and β are the temperature-independent material constants determined by experiment and vary with the change of the strain values [21,22], respectively.

3.1 Determination of model constants

The true stress and true strain data from the tensile tests under various processing conditions were used to evaluate the materials constants of the constitutive equations. The true plastic strain of 0.1 was taken as an example to introduce the solution procedures of the material constants.

Taking nature logarithm of both sides of Eq. (2) and Eq. (3), the following equations can be obtained:

(5)

(5)

(6)

(6)

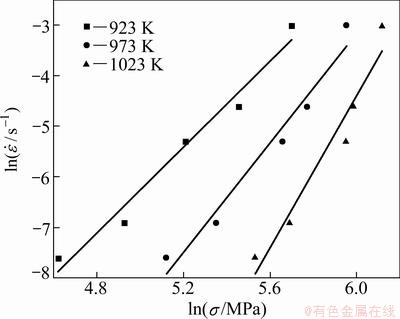

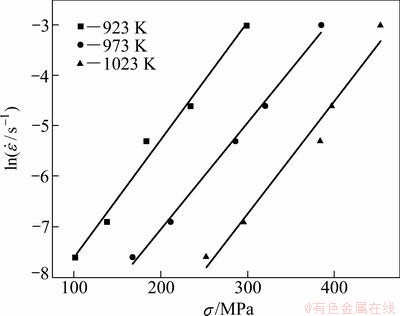

The values of n1 and β can be obtained from the slope of the lines in the  —ln σ and

—ln σ and  —σ plots, respectively (Fig. 2 and Fig. 3). It is apparent that the lines are almost parallel, and the slopes of the lines consequently vary in a very small range. The slight variation in the slope of the lines can be attributed to scattering in the experimental data points. The mean value of the slopes is taken as the value of n1 and β, which are 5.73385 and 0.022343 MPa-1. Therefore, the value of α (α=β/n1) is calculated to be 0.0039 MPa-1.

—σ plots, respectively (Fig. 2 and Fig. 3). It is apparent that the lines are almost parallel, and the slopes of the lines consequently vary in a very small range. The slight variation in the slope of the lines can be attributed to scattering in the experimental data points. The mean value of the slopes is taken as the value of n1 and β, which are 5.73385 and 0.022343 MPa-1. Therefore, the value of α (α=β/n1) is calculated to be 0.0039 MPa-1.

Fig. 2 Relationship between ln and ln σ

and ln σ

Fig. 3 Linear relationship between ln and σ

and σ

Taking natural logarithm of both sides of Eq. (4), the following equations can be obtained:

(7)

(7)

(8)

(8)

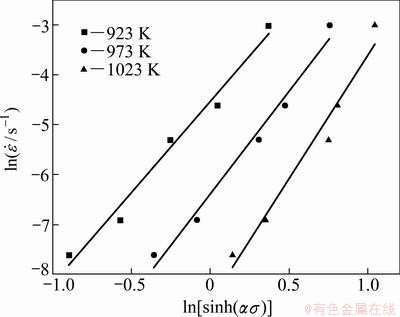

The value of n2 can be obtained from the slope of the lines in the ln —ln[sinh(ασ)] plot. Put α=0.0039 to Eq. (7) and plot the relationship between ln

—ln[sinh(ασ)] plot. Put α=0.0039 to Eq. (7) and plot the relationship between ln and ln[sinh(ασ)] (Fig. 4). It is apparent that the slopes of the lines consequently vary in a very small range. The mean value of the slopes is taken as the value of n2 that is 4.237923.

and ln[sinh(ασ)] (Fig. 4). It is apparent that the slopes of the lines consequently vary in a very small range. The mean value of the slopes is taken as the value of n2 that is 4.237923.

Fig. 4 Relationship between ln and ln[sinh(ασ)]

and ln[sinh(ασ)]

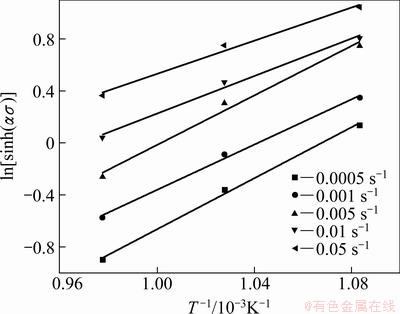

It can be seen from Eq. (8) and the relationship between ln[sinh(ασ)] and 1/T (Fig. 5) that the average value of the slope is 8.317264. So, at true plastic strain of 0.1, the value of Q is found to be 293.05 kJ/mol. The value of ln A3 at a particular strain can be obtained by plotting the relationship between ln and ln[sinh(ασ)], as shown in Fig. 4. The interception value of the ln

and ln[sinh(ασ)], as shown in Fig. 4. The interception value of the ln —ln[sinh(ασ)] curve equals lnA3—Q/(RT), the mean value of ln A3 at strain of 0.1 is found to be 29.80782.

—ln[sinh(ασ)] curve equals lnA3—Q/(RT), the mean value of ln A3 at strain of 0.1 is found to be 29.80782.

Fig. 5 Relationship between ln[sinh(ασ)] and 1/T

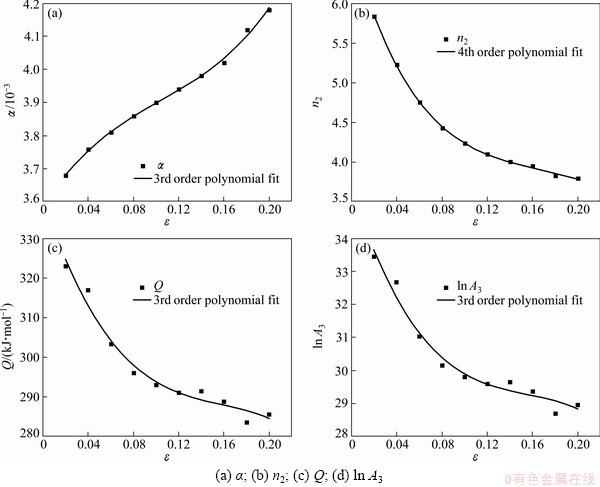

Fig. 6 Variation of α, n2, Q and ln A3 with true plastic strain

3.2 Compensation of strain

It is usually assumed that the influence of strain on the flow stress at evaluated temperature is insignificant and thereby would not be considered in Eq. (1) [21,22]. However, the effect of strain on the material constants is significant in the entire strain range (Fig. 6). Therefore, the compensation of strain for the material constants should be taken into account in order to derive the constitutive equations to predict the flow stress more accurately.

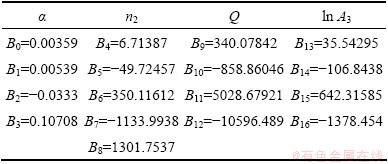

The influence of strain in the constitutive equation is incorporated by assuming that the material constants (α, n2, Q and ln A3) are polynomial function of strains [23,24]. In this work, the values of material constants (α, n2, Q and ln A3) of the constitutive equations were evaluated at different true plastic strains within the range of 0.02-0.2 and the interval of 0.02. The order of the polynomial varied from 1 to 9. As shown in Eq. (9), a third order polynomial was found to represent the influence of strain on material constants (α, Q and ln A3) with a good correlation and generalization (Fig. 6). A fourth order polynomial was found to represent the influence of strain on material constants (n2). The coefficients of the polynomial are given in Table 2.

(9)

(9)

Table 2 Coefficients of polynomial for α, n, Q and ln A3

Once the materials constants are evaluated, the flow stress at a particular strain can be predicted. The constitutive equation that relates flow stress and Zener-Holloman parameter can be written in the following form:

(10)

(10)

4 Modelization of Norton-Hoff model

The Norton-Hoff law is a viscoplastic law with 4 constants and is written in one dimension as presented in Eq. (11), where p1, p2, p3 and p4 are 4 material dependent constants. This law was developed by Norton and generalized to three dimensions by Hoff [25].

(11)

(11)

p1 has an effect in the large strain domain so that softening can be fitted; p2 has an effect on the level of the curve; p3 is used to model viscosity and is the exponent of the strain rate, regulating the distance among curves at different strain rates; and p4 is used to fit hardening.

4.1 Modification of Norton-Hoff model

It clearly appears that the part of exp(-p1ε) in Norton-Hoff equation represents the softening behavior and increasing the value of p1 is possible to model the softening. However, the influence of strain on the softening under specific experiment condition is also significant, which is easy to be found form the σ—ε curves (Fig. 1).

It can be seen from σ—ε curves that the flow stress is hardening when ε is less than ε* and the softening occurs until ε becomes larger than ε*. ε* is defined as true plastic strain matched along with the tensile strength and ε* is determined by experiment and can be calculated through Eq.(12):

ε*=εb-ε0.2 (12)

where εb is true strain matched along with tensile strength and ε0.2 is true strain matched along with yield stress. εb and ε0.2 can be obtained from the true stress—true strain curves.

In order to make the Norton-Hoff model more accurate and reasonable, it is necessary to modify the Norton-Hoff equation. Considering the fact that the softening effect varies with the change of strain, the modified Norton-Hoff law can be expressed in following equation:

(13)

(13)

where σ0.2 is the yield stress and determined by the experiment. σ0.2 is assumed to be equal to the flow stress at which the stress—strain curve is no more linear.

Comparing Eq. (13) with Eq. (11), it can be found that the modified Norton-Hoff model can modify the material constants of p1 and avoid the deviation coming from different σ0.2 values of specific experiment conditions. The material constants of the modified one are more reasonable and reliable.

4.2 Determination of model constants

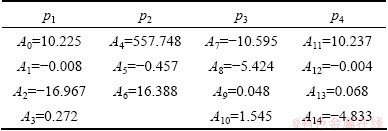

The constants of the Norton-Hoff law were determined in σ—ε data by fitting Eq. (13) to the experimental curves. The evolution of constants p1 to p4 as a function of strain rate and temperature was studied separately and some expressions relating these evolutions were determined. The influences of the strain rate and temperature were combined in one expression and these expressions were introduced in the main expression of the Norton-Hoff law, giving a new equation with a new series of constants only related to the material.

Fig. 7 Comparison of experimental σ—ε curves and fitting curves for tensile tests

Using the method described above and a fitting procedure on the results of tensile test carried out in temperature range of 923-1023 K and strain rate of 0.0005-0.05 s-1, the constitutive equation was established (Eq. 14), where A1, …, A14 are material constants. The values of different A constants were determined and the results are listed in Table 3.

(14)

(14)

Table 3 Values of material constants for Norton-Hoff model law

5 Verification and comparison

The Arrhenius constitutive equation (considering the compensation of strain) and modified Norton-Hoff constitutive equation were verified by comparing the experimental data and predicted one (Fig. 7). It can be observed that the Arrhenius predicted data are satisfactory under all conditions except for two processing conditions (1023 K, 0.0005 s-1; 923 K, 0.05 s-1), which reflects excellent prediction capabilities of the developed constitutive equation. Meanwhile, the modified Norton-Hoff predicted data are relatively precise under all conditions except for the condition of 1023 K and 0.0005 s-1. Additionally, it is obvious that under processing condition of 1023 K and 0.0005 s-1, both Norton-Hoff and Arrhenius constitutive equation cannot fit well to the experimental curve.

From Fig. 7, it is easy to draw the following conclusions. Firstly, both the Norton-Hoff model and Arrhenius one are satisfactory for fitting the experimental data under most conditions. Secondly, the modified Norton-Hoff model prediction is more accurate and precise than the Arrhenius one and the best curve fitted is Norton-Hoff.

It can be found from the modelization process that the determination of Arrhenius model constants is much more complex and difficult than that of the Norton-Hoff. Firstly, the determination of the Arrhenius material coefficient needs more steps of curve fitting than that of Norton-Hoff and each curve fitting process has to bring deviation to the final results. Secondly, the Arrhenius determination steps make the average values for α, β, n2, Q and A3 under the condition of different strain rates, which ignores the influence of the strain rate on material constants and leads to more errors compared with the Norton-Hoff one.

6 Conclusions

1) The flow stress and work hardening increase with strain rate increasing and temperature decreasing. Dynamic recovery and softening become more significant with strain rate decreasing and temperature increasing. Dynamic recrystallization does not happen and the influence of the strain rate on the tensile strength is significant.

2) For the Arrhenius constitutive model, strain shows significant influence on the material constants and polynomials equation is found to be suitable to represent the influence. The Arrhenius model considering the compensation of strain can well predict the flow stress under all experimental conditions except for the conditions of 923 K, 0.05 s-1 and 1023 K, 0.0005 s-1.

3) The fitting result of modified Norton-Hoff model is rather satisfactory under all experimental conditions except for the condition of 1023 K and 0.0005 s-1. The predicted flow stress value can track the experimental data excellently under most experimental conditions.

4) The prediction result of the modified Norton-Hoff model is more accurate and precise than that of Arrhenius one. The determination of the Arrhenius material coefficient needs lots of linear fit steps and has to make average value for material constants at different strain rates, which will bring deviations to fitting results.

References

[1] HU Mei-juan, LIU Jin-he. Effects of zonal heat treatment on residual stresses and mechanical properties of electron beam welded TC4 alloy plates [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 324-329.

[2] LI Min, YU Hai-ping, LI Chun-feng. Microstructure and mechanical properties of Ti6Al4V powder compacts prepared by magnetic pulse compaction [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 553-558.

[3] VANDERHASTEN M, RABET L, VERLINDEN B. Deformation mechanisms of Ti-6Al-4V during tensile behavior at low strain rate [J]. J Mater Eng Perform, 2007, 16: 208-212.

[4] ABBASI S M, MOMENI A. Effect of hot working and post-deformation heat treatment on microstructure and tensile properties of Ti-6Al-4V alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1728-1734.

[5] BAUFELD B, van der BIEST O. Mechanical properties of Ti-6Al-4V specimens produced by shaped metal deposition [J]. Sci Technol Adv Mater, 2009, 10: 1-10.

[6] BAUFELD B, van der BIEST O, GAULT R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: microstructure and mechanical properties [J]. Mater Des, 2010, 31: 106-111.

[7] SAMANTARAY D, MANDAL S, BHADURI A K. Constitutive analysis to predict high temperature flow stress in modified 9Cr-1Mo (P91) steel [J]. Mater Des, 2010, 31: 981-984.

[8] DENG Tai-qing, YE Lei, SUN Hong-fei, HU Lian-xi, YUAN Shi-jian. Development of flow stress model for hot deformation of Ti-47%Al alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: s308-s314.

[9] WANG Zhe-jun, QIANG Hong-fu, WANG Xue-ren, WANG Guang. Constitutive model for a new kind of metastable β titanium alloy during hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 634-641.

[10] REN Guo-guan, YOUNG Tae-je, ZHAN Yong-zhao, CHONG Soo-lee. Effect of microstructure on deformation behaviour of Ti-6Al-4V alloy during compressing process [J]. Materials and Design, 2012, 36: 796-803.

[11] MOHAMMAD A S, HAMID O, BEHZAD F. Prediction of hot compression flow curves of Ti-6Al-4V alloy in α+β phase region [J]. Materials and Design, 2011, 32: 4689-4695.

[12] CAI Jun, LI Fu-guo, LIU Tai-ying, CHEN Bo, HE Min. Constitutive equations for elevated temperature flow stress of Ti-6Al-4V alloy considering the effect of strain [J]. Materials and Design, 2011, 32: 1144-1151.

[13] VANDERHASTEN M,RABET L,VERLINDEN B. Ti-6Al-4V: Deformation map and modelisation of tensile behaviour [J]. Materials and Design, 2008, 29: 1090–1098.

[14] VANDERHASTEN M. Ti-6Al-4V: Deformation map and modelisation of tensile behavior [D]. Brussels: Royal Military Academy, 2007: 18-19.

[15] PATANKAR S N, YEO T K, TAN M J. Alpha casing and superplastic behavior of Ti-6Al-4V [J]. Journal of Materials Processing Technology, 2001, 112: 24-28.

[16] YUE L, WANG Z, LI L. Material morphological characteristics in laser ablation of alpha case from titanium alloy [J]. Applied Surface Science, 2012, 258: 8065-8071.

[17] SUNG S Y, KIM Y J. Alpha-case formation mechanism on titanium investment castings [J]. Materials Science and Engineering A, 2005, 405: 173-177.

[18] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation [J]. Acta Metall, 1966, 14: 1136-1138.

[19] ZENER C, HOLLOMON JH. Effect of strain rate upon plastic flow of steel [J]. Journal of Applied Physics, 1994, 15: 22-32.

[20] SAMANTARAY D, MANDAL S, BHADURI A K, SIVAPRASAD P V. An overview on constitutive modelling to predict elevated temperature flow behaviour of fast reactor structural materials [J]. Transactions of the Indian Institute of Metals, 2010, 63(6): 823-831.

[21] RAO K P, HAWBOLT E B. Development of constitutive relationships using compression testing of medium carbon steel [J]. Transactions of the ASME Journal of Engineering Materials and Technology, 1992, 114: 116-123.

[22] PU Z J, WU K H, SHI J, ZOU D. Development of constitutive relationships for the hot deformation of boron microalloying TiAl-Cr-V alloys [J]. Materials Science and Engineering A, 1995, 192-193: 780-787.

[23] LIN Y C, CHEN M S, ZHONG J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel [J]. Comput Mater Sci, 2008, 42: 470-477.

[24] MANDAL S, RAKESH V, SIVAPRASAD P V, VENUGOPAL S, KASIVISWANATHAN K V. Constitutive equations to predict high temperature flow stress in a Ti–modified austenitic stainless steel [J]. Materials Science and Engineering A, 2009, 500: 114-121.

[25] HOFF N J. Approximate analysis of structure in the presence of moderately large creep deformation [J]. Quarterly of Applied Mathematics, 1954, 12: 49-55.

张 超1, 2,李小强3,李东升3,金朝海3,肖军杰3

1. 北京航空航天大学 大飞机班,北京 100191;

2. 北京航空航天大学 材料科学与工程学院,北京 100191;

3. 北京航空航天大学 机械工程及自动化学院,北京 100191

摘 要:为研究Ti-6Al-4V合金在热成形过程中的力学性能,在923~1023 K温度和0.0005~0.05 s-1应变速率范围内,进行片状试样的恒温高温拉伸试验,采集应力—应变试验数据并建立材料的本构模型。将Arrhenius和Norton-Hoff本构模型用于表征合金的高温拉伸行为。拟合结果显示,考虑材料常数应变补偿的Arrhenius模型和改进的Norton-Hoff模型均可以准确地预测Ti-6Al-4V合金多数条件下的流变应力,由拟合结果比较可知改进的Norton-Hoff模型比Arrhenius模型更精确。

关键词:Ti-6Al-4V合金;高温拉伸行为;本构模型;模型化;Arrhenius模型;应变补偿;Norton-Hoff改进模型

(Edited by CHEN Wei-ping)

Foundation item: Project (51175022) supported by the National Natural Science Foundation of China; Project (2010ZE51050) supported by the Aviation Science Foundation of China; Project (51318040315) supported by the National Defence Pre-research Program of China

Corresponding author: LI Xiao-qiang; Tel: +86-13810937753; E-mail: littlestrongcn@163.com

DOI: 10.1016/S1003-6326(12)61746-4