文章编号:1004-0609(2011)08-1916-05

制备工艺对N型Bi2Te2.4Se0.6合金热电性能的影响

尹振忠,朱铁军,沈俊杰,杨胜辉,赵新兵

(浙江大学 材料科学与工程系 硅材料国家重点实验室,杭州 310027)

摘 要:采用缓慢冷却和液氮淬火两种真空熔炼工艺得到Bi2Te2.4Se0.6合金铸锭,再将铸锭研磨后热压烧结制备N型多晶样品。采用XRD、FESEM、激光热导仪及电学性能测试仪对样品的物相组成、断面形貌和热电性能进行分析和研究。结果表明:制备的多晶样品为单相;振动研磨得到的粉末热压后保留大量的微米级(1~5 μm)颗粒。结合取向因子的计算结果可以推断,样品中无明显的晶粒择优取向;采用液氮淬火制备的样品由于晶粒细化的影响,其热导率显著降低,热电性能得到改善。在300~500 K温度范围内,液氮淬火试样BTSRS-OM-HP具有最大的功率因子和最低的晶格热导率;室温至500 K范围内,样品的晶格热导率保持在0.42~0.51 W/(m?K)之间,在468 K时,获得最大ZT值0.87。

关键词:Bi2Te2.4Se0.6;液氮淬火;热电性能;热电材料

中图分类号:TB34 文献标志码:A

Effect of preparation methods on thermoelectric properties of N-type Bi2Te2.4Se0.6 bulk alloys

YIN Zhen-zhong, ZHU Tie-jun, SHEN Jun-jie, YANG Sheng-hui, ZHAO Xin-bing

(State Key Laboratory of Silicon Materials, Department of Materials Science and Engineering,

Zhejiang University, Hangzhou 310027, China)

Abstract: The Bi2Te2.4Se0.6 polycrystalline samples were prepared by smashing Bi2Te2.4Se0.6 alloys combined with a subsequent hot pressing sintering technique. The thermoelectric properties were measured at 300-500 K. XRD analysis shows that the single phase Bi2Te3 is obtained. The FESEM results show that the fracture morphologies of samples show that the particle size of hot pressed samples remains micrometer scale ranging from 1 to 5 μm. The crystal growth with disordered crystal orientation according to the values of orientation factor F. The measurements of thermoelectric properties show that an improvement in thermoelectric figure of merit is obtained caused by a remarkable decrease in thermal conductivity due to strong phonon scattering induced by a fine microstructure of the sample BTSRS-OM-HP prepared by rapid solidification combined with hot pressing process, whose lattice thermal conductivity ranges within 0.42~0.51 W/(m?K) from room temperature to 500 K, and the maximum dimensionless merit figure ZT value of 0.87 is obtained at 468 K.

Key words: Bi2Te2.4Se0.6; liquid nitrogen quenching; thermoelectric properties; thermoelectric materials

当今世界能源日益短缺,人类的生产与生活中产生的废热如果能利用热电发电装置转换为电能,将大大提高能源利用效率[1]。热电器件由于质量轻、尺寸小、无噪声、无污染而受到越来越多的关注[2]。表征热电材料的性能指数为无量纲优值 ,其中

,其中 、

、 、

、 、T分别为Seebeck系数、电导率、热导率和绝对温度,较好的热电材料要有较高的

、T分别为Seebeck系数、电导率、热导率和绝对温度,较好的热电材料要有较高的 和

和 以及较低的

以及较低的 [3-4]。在各种热电材料中,Bi2Te3基热电材料在室温具有最好的热电性能,一直以来都是热电领域的研究热点[5]。

[3-4]。在各种热电材料中,Bi2Te3基热电材料在室温具有最好的热电性能,一直以来都是热电领域的研究热点[5]。

商业化生产中应用的Bi2Te3基材料多为单晶或取向多晶材料[6]。Bi2Te3晶体结构为 斜方晶系的六面体层状结构,沿c轴方向来看,层与层之间 呈—Te(1)—Bi—Te(2)—Bi—Te(1)—的原子排布方式,Te(1)—Te(1)之间以较弱的范德华力相结合,所以,单晶和取向多晶材料易解离,不利于机械加工和商业化大规模应用。多晶Bi2Te3基材料具有较好的机械性能,如果能获得理想的热电性能就能广泛地应用于热电制冷和发电器件制备并能可观地延长器件使用寿命[7]。

斜方晶系的六面体层状结构,沿c轴方向来看,层与层之间 呈—Te(1)—Bi—Te(2)—Bi—Te(1)—的原子排布方式,Te(1)—Te(1)之间以较弱的范德华力相结合,所以,单晶和取向多晶材料易解离,不利于机械加工和商业化大规模应用。多晶Bi2Te3基材料具有较好的机械性能,如果能获得理想的热电性能就能广泛地应用于热电制冷和发电器件制备并能可观地延长器件使用寿命[7]。

大量研究表明,通过化学溶剂热、甩带以及液氮淬火等方法制备低维或纳米复合热电材料,所引入的纳米结构对声子散射作用强于对载流子的散射作用,在调节电性能的同时降低了热导率,可以显著提高多晶热电材料的热电性能。CAO等[3]采用水热合成和热压烧结的方法制备Bi2Te3/Sb2Te3块体纳米复合热电材料,其所含有的厚度为5~50 nm的层状结构不但增强对中长波声子的散射使热导率降低,而且由于量子限域效应获得较高的功率因子,Bi2Te3和Sb2Te3按摩尔比l:1复合的材料在温度为450 K时获得最高ZT值1.47[3]。TANG等[8]通过甩带和放电等离子体烧结的工艺制备具有层状纳米结构的P型Bi2Te3多晶材料,当温度为300 K时,ZT值达1.35。POUDEL等[7]将高能球磨得到的纳米粉末热压烧结制备了P型纳米晶BiSbTe合金,在100℃获得了最大ZT值1.4。ZHU 等[9]和ZHANG等[10]采用液氮淬火和退火的方法获得GeTe基非晶/纳米晶原位复合体系,在其非晶基体上弥散分布着尺寸为4~8 nm的纳米晶,电导率较非晶基体提高了3~4个数量级。YANG等[11]利用液氮快 淬的方法制备含有10 nm左右的纳米畴的(GeTe)x(AgSbTe2)100-x合金,ZT值大于1.50。

目前,关于P型Bi2Te3多晶材料的研究已经获得了较大的进展,而文献报道的N型Bi2Te3多晶材料的ZT值多在1.0以下,如何提高N型Bi2Te3多晶材料的热电性能成为了一个重要课题。本文作者分别采用液氮淬火和缓慢慢冷却结合热压烧结的方法制备N型Bi2Te2.4Se0.6合金,并对材料的成分、微观结构和热电性能进行了研究。

1 实验

将Bi(99.999%)、Te(99.999%)、Se(99.999%)按照Bi2Te2.4Se0.6化学计量比称料混合,在1 073 K真空熔炼10 h,每隔1 h左右将石英玻璃管中的熔体搅动一次,然后分别放入液氮中淬火和在箱式炉中缓慢冷却。将淬火和缓冷得到的2种铸锭分别放入Retsch MM200振动研磨机中在25 Hz频率下研磨10 min,另取部分缓冷铸锭在研钵中手工研磨,将得到的3种粉末分别在673 K温度下真空热压30 min,得到直径为12.7 mm、厚度为1~2 mm的圆片状试样,3个试样分别命名为BTSRS-OM-HP、BTS-OM-HP和BTS-HP。

采用RigakuD/MAX-2550PC型X射线衍射仪(Cu Kα射线,波长为0.154 06 nm)对试样进行物相分析。采用Hitachi S-4800场发射扫描电子显微镜(FESEM)观察试样断面微观形貌。室温Hall系数RH采用四探针法在Quantum DesignPPMS-9T上测量,载流子浓度由n = -1/(eRH)计算得到。采用德国耐驰公司Netzsch LFA-457激光热导仪测量样品的热导率[12]。用自制的由计算机控制的半导体电学性能测试仪器测量电学性能,测试的温度范围为300~500 K[13]。

2 结果与讨论

图1所示为热压得到的3个块状试样的XRD谱。通过与Bi2Te3的PDF#15—0863卡片比较可以看出,单相多晶试样的晶体结构为 斜方晶系,3个热压样品特征峰的强度与标准卡片相比差别不大。Bi2Te3的晶粒沿垂直于c轴的(00l)晶面的取向程度可以用取向因子F来表征,采用Lotgering方法计算[14]:

斜方晶系,3个热压样品特征峰的强度与标准卡片相比差别不大。Bi2Te3的晶粒沿垂直于c轴的(00l)晶面的取向程度可以用取向因子F来表征,采用Lotgering方法计算[14]:

(1)

(1)

(2)

(2)

(3)

(3)

式中:I(hkl)和I0(hkl)分别为晶粒存在择优取向和无序排布时XRD谱中衍射峰的相对强度。试样BTS-HP、BTS-OM-HP和BTSRS-OM-HP的取向因子F分别为0.21、0.07和0.13,说明热压得到的多晶试样无明显的织构取向。

图1 热压试样BTS-HP、BTS-OM-HP和BTSRS-OM-HP的XRD谱

Fig.1 XRD patterns of hot pressed BTS-HP, BTS-OM-HP and BTSRS-OM-HP samples

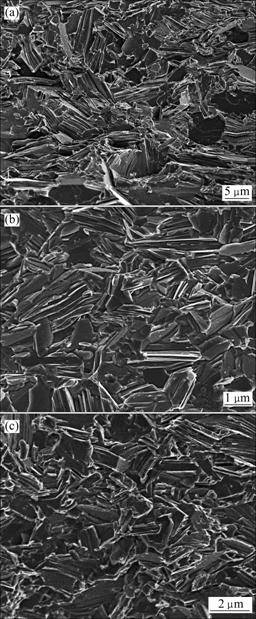

图2所示为试样BTS-HP、BTS-OM-HP和BTSRS- OM-HP断面的FESEM像。由图2可以看出,颗粒无序排列,材料无明显的晶粒择优取向。从图2(a)中可以看到,试样BTS-HP的颗粒尺寸大于10 μm。从图2(b)和(c)中可以看到,将铸锭振动研磨结合热压得到的试样含有大量微米级(1~5 μm)的颗粒,其中试样BTSRS-OM-HP颗粒尺寸比试样BTS-OM-HP的小,因为液氮快淬法制备的铸锭冷却速度快,原子扩散和晶体生长受到限制,使晶粒得到了细化[11]。

图2 试样BTS-HP(a)、BTS-OM-HP(b)和BTSRS-OM-HP(c)的断面FESEM像

Fig.2 Fracture FESEM images of BTS-HP(a), BTS-OM- HP(b) and BTSRS-OM-HP(c) samples

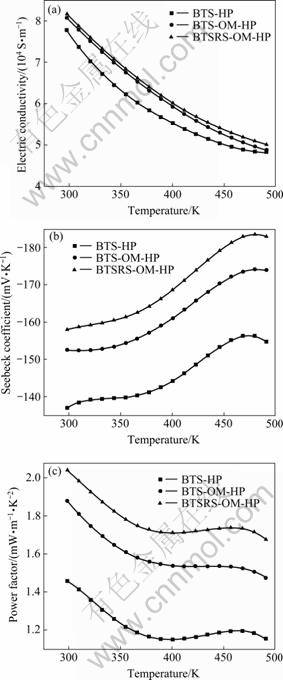

图3所示为3个试样的电学性能随温度变化的曲线。从图3(a)可以看出,3个样品都表现出了金属导电特性,它们的电导率没有显著的差别。室温霍尔测试结果表明:试样BTS-HP、BTS-OM-HP和BTSRS-OM-HP的室温载流子浓度分别为9.2×1019、8.2×1019和7.4×1019 cm-3 。从图3(b)可以看出,3个样品都具有负的Seebeck系数,表明它们具有N型导电特性;Seebeck系数的绝对值随温度的变化关系为先增加后减小;试样BTS-HP、BTS-OM-HP和BTSRS-OM-HP的Seebeck系数依次变大,因为微观结构对载流子的散射作用依次增强使3个试样的载流子浓度依次减小、散射因子γ依次增大[15]。表征热电材料的电学性能的参数为功率因子 。从图3(c)可以看出,试样 BTS-HP、BTS-OM-HP和BTSRS-OM-HP的功率因子也依次增大,在375~450 K温度范围内,每个试样的功率因子变化都不大。

。从图3(c)可以看出,试样 BTS-HP、BTS-OM-HP和BTSRS-OM-HP的功率因子也依次增大,在375~450 K温度范围内,每个试样的功率因子变化都不大。

图3 样品的电导率、Seebeck系数和功率因子随温度的 变化

Fig.3 Temperature dependences of electric conductivity(a), Seebeck coefficient(b) and power factor(c) of samples

热导率由载流子热导率( )和晶格热导率(

)和晶格热导率( )组成,即

)组成,即 ,

, 可由Wiedemann-Franz公式

可由Wiedemann-Franz公式 进行估算(式中:L是Lorenz常数,L=2.0×10-8 V2?K-2;

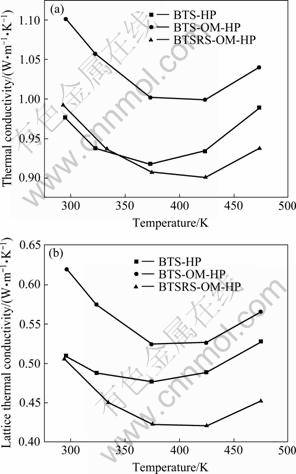

进行估算(式中:L是Lorenz常数,L=2.0×10-8 V2?K-2; 为电导率;T为绝对温度)[16]。图4所示为样品的热导率和晶格热导率随温度的变化。从图4(a)可以看到,热导率随温度的变化是先下降后上升,因为Bi2Te2.4Se0.6合金是窄禁带半导体材料,温度升高后双极扩散增强使热导率变大;在300~350 K温度范围内,3个试样中,BTS-HP的热导率最小;温度大于375 K后,试样BTSRS-OM-HP的热导率最小,并在425 K达到热导率的最低值0.9 W/(m?K)。为了进一步研究热导率变化规律,计算了3个试样的晶格热导率。从图4(b)可以看出,在300~500 K温度范围内,3个试样的晶格热导率均小于0.62 W/(m?K);样品BTS-HP、BTS-OM-HP和BTSRS- OM-HP的晶格热导率依次减小。试样BTSRS-OM-HP的晶粒得到了细化,晶界散射增强,声子受到的散射作用比其他两个样品要强烈,晶格热导率最小,在测试温度范围内,热导率始终保持在0.42~0.51 W/(m?K)之间[17]。在375~425 K温度范围内,每个试样的热导率和晶格热导率变化都不大。

为电导率;T为绝对温度)[16]。图4所示为样品的热导率和晶格热导率随温度的变化。从图4(a)可以看到,热导率随温度的变化是先下降后上升,因为Bi2Te2.4Se0.6合金是窄禁带半导体材料,温度升高后双极扩散增强使热导率变大;在300~350 K温度范围内,3个试样中,BTS-HP的热导率最小;温度大于375 K后,试样BTSRS-OM-HP的热导率最小,并在425 K达到热导率的最低值0.9 W/(m?K)。为了进一步研究热导率变化规律,计算了3个试样的晶格热导率。从图4(b)可以看出,在300~500 K温度范围内,3个试样的晶格热导率均小于0.62 W/(m?K);样品BTS-HP、BTS-OM-HP和BTSRS- OM-HP的晶格热导率依次减小。试样BTSRS-OM-HP的晶粒得到了细化,晶界散射增强,声子受到的散射作用比其他两个样品要强烈,晶格热导率最小,在测试温度范围内,热导率始终保持在0.42~0.51 W/(m?K)之间[17]。在375~425 K温度范围内,每个试样的热导率和晶格热导率变化都不大。

图5所示为试样的ZT值随温度的变化。从图5可以看出,试样BTS-HP、BTS-OM-HP和BTSRS- OM-HP在468 K分别取得最大ZT值,分别为0.57、0.69和0.87。熔炼后的铸锭经振动研磨再热压得到的两个样品BTS-OM-HP、BTSRS-OM-HP的ZT值均高于BTS-HP的,其中BTSRS-OM-HP由于有最大的功率因子,热导率较低,ZT值最高,最大ZT值较试样BTS-OM-HP和BTS-HP的最大ZT值分别提高了26%和53%。

图4 样品的热导率和晶格热导率随温度的变化

Fig.4 Temperature dependences of thermal conductivity (a) and lattice thermal conductivity (b) of samples

图5 样品的ZT值随温度的变化

Fig.5 Temperature dependences of ZT value for samples

3 结论

1) 用振动研磨得到的细化粉末热压制备的样品BTS-OM-HP和BTSRS-OM-HP由于含有大量的微米级的微观结构,热电性能要优于颗粒级别较大的样品BTS-HP,其中BTSRS-OM-HP的熔融铸锭经液氮快淬后晶粒得到细化,晶格热导率最低,具有最佳的热电性能,最大ZT值为0.87。

2) 液氮快淬是提高Bi2Te3基多晶材料热电性能的一种简便有效的方法。

REFERENCES

[1] JEFFREY S G, TOBERER E S. Complex thermoelectric materials[J]. Nature Materials, 2008, 7: 105-114.

[2] DISALVO F J. Thermoelectric cooling and power generation[J]. Science, 1999, 285: 703-706.

[3] CAO Yi-qi, ZHAO Xin-bing, ZHU Tie-jun, TU Jiang-ping. Syntheses and thermoelectric properties of Bi2Te3/Sb2Te3 bulk nanocomposites with laminated nanostructure[J]. Applied Physics Letters, 2008, 92(143106): 1-3.

[4] NI Hua-liang, ZHAO Xin-bing, ZHU Tie-jun, JI Xiao-hua, TU Jiang-ping. Synthesis and thermoelectric properties of Bi2Te3 based nanocomposites[J]. Journal of Alloys and Compounds, 2005, 397: 317-321.

[5] TRITT T M. Thermoelectric materials-holey and unholey semiconductors[J]. Science, 1999, 283: 804-805.

[6] LARSON P, MAHANTI S D, KANATZIDIS M G. Electronic structure and transport of Bi2Te3 and BaBiTe3[J]. Physical Review B, 2000, 61: 8162-8171.

[7] POUDEL B, HAO Qing, MA Yi, LAN Yu-cheng, MINNICH A, YU Bo, YAN Xiao, WANG De-zhi, MUTO A, VASHAEE D, CHEN Xiao-yuan, LIU Jun-ming, DRESSELHAUS M S, CHEN Gang, REN Zhi-feng. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys[J]. Science, 2008, 320: 634-638.

[8] TANG Xin-feng, XIE Wen-jie, HAN Li, ZHAO Wen-yu, ZHANG Qing-jie. Preparation and thermoelectric transport properties of high-performance p-type Bi2Te3 with layered nanostructure[J]. Applied Physics Letters, 2007, 90(012102): 1-3.

[9] ZHU Tie-jun, YAN Feng, ZHAO Xin-bing, ZHANG Sheng-nan, CHEN Yi, YANG Sheng-hui. Preparation and thermoelectric properties of bulk in situ nanocomposites with amorphous/ nanocrystal hybrid structure[J]. Journal of Physics D: Applied Physics, 2007, 40: 6094-6097.

[10] ZHANG Sheng-nan, HE Jian, ZHU Tie-jun, ZHAO Xin-bing , TRITT T M. Thermal conductivity and specific heat of bulk amorphous chalcogenides Ge20Te80-xSex (x=0, 1, 2, 8)[J]. Journal of Non-Crystalline Solids, 2009, 335: 79-83.

[11] YANG Sheng-hui, ZHU Tie-jun, SUN Ting, HE Jian, ZHANG Sheng-nan, ZHAO Xin-bing. Nanostructures in high- performance (GeTe)x(AgSbTe2)100-x thermoelectric materials[J]. Nanotechnology, 2008, 19(245707): 1-3.

[12] YU Cui, ZHU Tie-jun, SHI Rui-zhi, ZHANG Yun, ZHAO Xin-bing, HE Jian. High-performance half-Heusler thermoelectric materials Hf1-xZrxNiSn1-ySby prepared by levitation melting and spark plasma sintering[J]. Acta Materialia, 2009, 57: 2757-2764.

[13] ZHAO Xin-bing, JI Xiao-hua, ZHANG Yan-hua, ZHU Tie-jun, TU Jiang-ping, ZHANG Xiao-bing. Bismuth telluride nanotubes and the effects on the thermoelectric properties of nanotube- containing nanocomposites[J]. Applied Physics Letters, 2005, 86(062111): 1-3.

[14] BEN-YEHUDA O, SHUKER R, GELBSTEIN Y, DASHEVSKY Z, DARIEL M P. Highly textured Bi2Te3-based materials for thermoelectric energy conversion[J]. Journal of Applied Physics, 2007, 101(113707): 1-6.

[15] 王善禹, 谢文杰, 唐新峰. 制备工艺对n型Bi2Te3基材料热电性能和抗压强度的影响[J]. 无机材料学报, 2010, 25(6): 609-614.

WANG Shan-yu, XIE Wen-jie, TANG Xin-feng. Effect of preparation techniques on the thermoelectric properties and pressive strengths of n-type Bi2Te3 based materials[J]. J Inorg Mater, 2010, 25(6): 609-614.

[16] MI Jian-li, ZHAO Xin-bing, ZHU Tie-jun, TU Jiang-ping. Improved thermoelectric figure of merit in n-type CoSb3 based nanocomposites[J]. Applied Physics Letters, 2007, 91(172116): 1-3.

[17] 蔚 翠, 朱铁军, 肖 凯, 金 吉, 沈俊杰, 杨胜辉, 赵新兵. 快速凝固法制备ZrNiSn基Half-Heusler热电材料的微结构[J]. 无机材料学报, 2010, 25(6): 569-572.

YU Cui, ZHU Tie-jun, XIAO Kai, JIN Ji, SHEN Jun-jie, YANG Sheng-hui, ZHAO Xin-bing. Microstructure of ZrNiSn based Half-Heusler thermoelectric materials prepared by melt- spinning[J]. J Inorg Mater, 2010, 25(6): 569-572.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50731006,50971115);浙江省科技厅面上项目(2009C34007)

收稿日期:2010-07-30;修订日期:2010-10-21

通信作者:朱铁军,副教授,博士;电话:0571-87952181;E-mail: zhutj@zju.edu.cn