Influence of microstructure and texture on formability of AZ31B magnesium alloy sheets

来源期刊:中国有色金属学报(英文版)2011年第4期

论文作者:张华 黄光胜 宋波 张雷 孔德强

文章页码:844 - 850

关键词:镁合金板材;单向多道次弯曲;显微组织;织构;成形性能

Key words:magnesium alloy sheet; repeated unidirectional bending; microstructure; texture; formability

摘 要:通过单向多道次弯曲(RUB)工艺及随后的退火处理来改变镁合金的显微组织和织构,研究显微组织和织构对其成形性能的影响。RUB工艺和不同温度下的退火处理对显微组织有两方面的影响:粗化晶粒和削弱织构。经RUB处理并在300 °C退火的板材表现出最好的成形性能。这主要归因于(0002)基面织构强度的削弱,而织构的削弱导致了较低的屈服强度、较大的断裂伸长率、较小的Lankford值(r值)和较大的加工硬化指数(n值)。与原始板材相比,经RUB处理并在400 °C退火而产生的具有粗大晶粒的板材具有较低的拉伸性能,但却表现出较高的成形性能。这主要是由于粗大晶粒增强了变形孪晶,而变形孪晶可以协调厚向应变。

Abstract: The effect of the repeated unidirectional bending (RUB) process and annealing on the formability of magnesium alloy sheets was investigated. The RUB process and annealing treatments produce two effects on microstructure: grain coarsening and weakening of the texture. The sheet that underwent RUB and was annealed at 300 °C exhibits the best formability owing to the reduction of the (0002) basal texture intensity, which results in low yield strength, large fracture elongation, small Lankford value (r-value) and large strain hardening exponent (n-value). Compared with the as-received sheet, the coarse-grain sheet produced by RUB and annealing at 400 °C exhibits lower tensile properties but higher formability. The phenomenon is because the deformation twin enhanced by grain coarsening can accommodate the strain of thickness.

Zhang Hua1, 2, Huang Guang-sheng1, 2, Song Bo1, 2, Zhang Lei1, 2, KONG De-qiang1

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400045, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China

Received 13 September 2010; accepted 22 December 2010

Abstract: The effect of the repeated unidirectional bending (RUB) process and annealing on the formability of magnesium alloy sheets was investigated. The RUB process and annealing treatments produce two effects on microstructure: grain coarsening and weakening of the texture. The sheet that underwent RUB and was annealed at 300 °C exhibits the best formability owing to the reduction of the (0002) basal texture intensity, which results in low yield strength, large fracture elongation, small Lankford value (r-value) and large strain hardening exponent (n-value). Compared with the as-received sheet, the coarse-grain sheet produced by RUB and annealing at 400 °C exhibits lower tensile properties but higher formability. The phenomenon is because the deformation twin enhanced by grain coarsening can accommodate the strain of thickness.

Key words: magnesium alloy sheet; repeated unidirectional bending; microstructure; texture; formability

1 Introduction

As the lightest metal structural material, magnesium alloys have many advantages, such as high specific strength, high specific stiffness, and high electromagnetic shielding. The use of Mg alloys is expanding, especially in automobile industry and consumer electronics industry[1-2]. However, because the magnesium alloy is in hexagonal structure and the critical resolved shear stresses (CRSS) for a basal slip are far below that for non-basal slips[3], it is difficult to deform at room temperature. Furthermore, normal rolled magnesium alloy has a strong (0002) basal plane texture, which leads to a greater anisotropy and affects the enhancement of its press formability[4-5]. MUKAI et al[6] and CHINO et al[7] showed that the ductility and the press formability of magnesium alloys are strongly affected by the texture and they can be improved effectively by controlling the (0002) basal texture. IWANAGA et al[8] revealed that the press formability of AZ31B magnesium alloy is strongly affected by texture variation, and the Erichsen value and LDR can reach 7.4 mm and 1.4 respectively at room temperature by lowering (0002) texture. Therefore, changing or weakening the (0002) base texture of magnesium alloy sheet is an effective way to improve the formability. In addition, CHINO et al[9] showed that the specimens with a larger grain size exhibit higher stretch formability. The enhanced basal slip due to lattice rotation by the twins (such as ![]() twin) plays a critical role in deformation under biaxial tensile stress. Twin formation is enhanced by grain coarsening. Thus, not only the texture but also the grain size affects the stretch formability.

twin) plays a critical role in deformation under biaxial tensile stress. Twin formation is enhanced by grain coarsening. Thus, not only the texture but also the grain size affects the stretch formability.

Previous studies[10-12] revealed that the repeated unidirectional bending (RUB) process could improve the formability of magnesium alloy sheets by weakening the basal texture of sheets. In this work, the AZ31B magnesium alloy sheets after RUB are annealed at different temperatures and sheets with different microstructures and textures are obtained. Tensile and Erichsen tests at room temperature are conducted to investigate the effects of microstructure and texture on formability.

2 Experimental

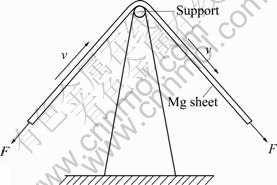

The as-received AZ31B magnesium alloy (Mg- 3%Al-1%Zn, mass fraction) sheets with a thickness of 0.6 mm were cut into 1 000 mm × 2 00 mm (length× width) pieces, and used in the experiments. Figure 1 shows an abridged general view of the RUB process, where the magnesium alloy sheet was bent on a cylindrical support under a constant force F and a constant speed v. The bend direction was parallel to RD direction of the sheet. The radius of the cylindrical support was 1 mm and the bending angle was 90°. In the experiments, six-pass bending was used. The sheets that underwent RUB process were annealed at 200, 300 and 400 °C for 60 min, respectively.

Fig.1 Schematic illustration of apparatus for RUB

Tensile specimens with 50 mm in gauge length, 10 mm in gauge width and 0.6 mm in gauge thickness were machined along planes coinciding with the angles of 0° (RD) and 45° and 90° (TD) to the rolling direction by wire-cutting. The uniaxial tensile tests were carried out on a CMT6305-300KN electronic universal testing machine with a strain rate of 1×10-3 s-1 at room temperature to investigate the mechanical properties, such as yield strength, ultimate tensile strength and fracture elongation. The strain-hardening exponent (n-value) was determined from the uniform plastic deformation region of the tensile stress—strain curve. Also, additional tensile tests were conducted at room temperature to investigate the Lankford value (r-value). Thickness strain and width strain were measured for the r-value using specimens deformed to a true tensile-direction strain of 12%.

The circular blank with a diameter of 90 mm was machined from the AZ31B magnesium alloy sheets for the Erichsen test. The Erichsen tests were carried out using a hemispherical punch with a diameter of 20 mm to investigate the press formability of AZ31B magnesium alloy sheets at room temperature. The punch speed was set to 10 mm/min and the blank-holder force was set to 10 kN. A graphite grease as a lubricant was pasted on only central part of the specimens. And the Erichsen value (IE), which was the punch stroke at fracture initiation, was measured.

The microstructure was observed by using a metallographic microscope and the (0002) pole figure of AZ31B magnesium alloy sheets was investigated by XRD.

3 Results and discussion

3.1 Microstructures and texture evolution

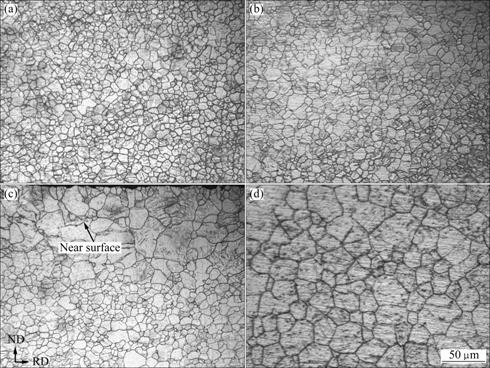

The microstructures of AZ31B magnesium alloy along the RD–ND plane are shown in Fig.2, It can be seen that fine equiaxial grains with an average size of 7.5 μm distributed in specimen A (Fig.2(a)). However, a few twins appeared in specimen B and the average grain size was 7.2 μm. Those twins were induced during RUB, which cannot be eliminated completely during annealing. This is because the recovery temperature 200 °C cannot cause fully recrystallization. Those twins disappeared owing to static recrystallization and those grains near the surface of sheet grew obviously in specimen C (Fig.2(c)). This is because those magnesium alloy sheets used in the experiments have a given thickness. There is a gradient of strain during bending of the sheet. The amount of deformation experienced in the region near the surface is higher than that in the center, which makes it possible to produce the gradient microstructure in the coarse-grained surface layer and the fine-grained layer in the middle of the sheet[13]. The average grain size was 8.0 μm in specimen C. The coarse grains evenly distributed in the entire region of specimen D and the grain size increased to 18.4 μm (Fig.2(d)).

The (0002) pole figures of the magnesium alloy sheets in different states are shown in Fig.3. The as-received magnesium alloy sheet has a strong (0002) basal texture (Fig.3(a)) and the (0002) planes are intensively distributed parallelly to the RD–TD plane, which was typical (0002) plane texture for a rolled specimen[8, 14]. For the magnesium alloy sheet that underwent RUB and was annealed at 200 °C, the c-axis of the grains had slight spread distribution in the RD and the basal texture tended to incline from the ND towards the RD. After the magnesium alloy sheet underwent RUB and was annealed at 300 and 400 °C, the texture components became more disperse, and the basal texture was weakened because c-axis became inclined from the ND towards the RD.

3.2 Tensile properties and stretch formability

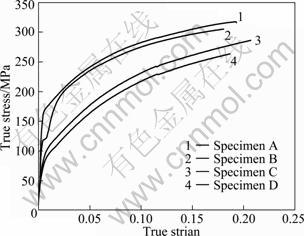

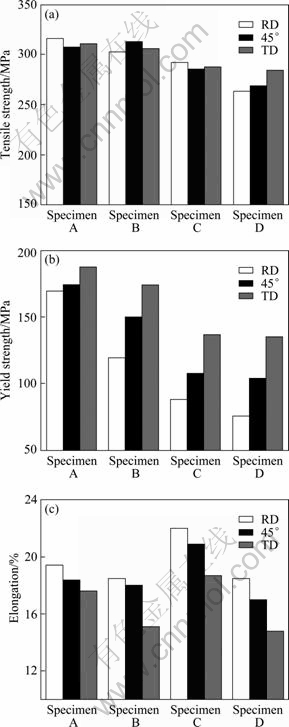

The true stress—strain curves of the sheets in different states in the tensile directions of RD are shown in Fig.4. The tensile strength, yield strength and the fracture elongation are shown in Fig.5. The tensile strength of specimen B was nearly the same as that of specimen A regardless of the tensile directions. While the tensile strength of specimens C and D was slightly lower than that of specimen A, especially for specimen D in the RD and 45° directions. However, compared with specimen A, the yield strength decreased significantly with increasing annealing temperature for specimens B, C and D in three directions, especially in the RD direction, as shown in Fig.5(b). It was pointed out that the contribution of grain refinement to the strength is significant in magnesium alloys with HCP structure[15]. Previous studies[16-17] showed that the strength and grain size of magnesium alloy are consistent with Hall-Petch relationship. Grain refinement will increase the number of obstacles to dislocation motion and reduce the length of groups of dislocations within the grain, resulting in increased yield strength. On the other hand, magnesium alloys can be strengthened by introducing the strong basal texture parallel to the tensile direction[18-19]. It is expected that the inclination of the basal plane in the material would decrease the contribution of strengthening by texture change. These results indicate that the annealing temperature after RUB has a little effect on the tensile strength but a strong effect on the yield strength.

Fig.2 Optical micrographs of AZ31B magnesium alloy: (a) As-received specimen A; (b) RUB specimen B after annealing at 200 °C for 1 h; (c) RUB specimen C after annealing at 300 °C for 1 h; (d) RUB specimen D after annealing at 400 °C for 1 h

Fig.3 {0002} pole figures of specimen A (a), specimen B (b), specimen C (c) and specimen D (d)

Fig.4 True stress–true strain curves of AZ31B sheets in different states in tensile directions of RD

The fracture elongations of specimen B were lower in all tensile orientations than those of specimen A, as shown in Fig.5(c). Some studies[20-21] found that twin induced can cause work hardening during RUB. The deformation twinning is harmful for the forming of sheets[22-23]. This is because work-hardening and twins induced during RUB are not eliminated completely during annealing. However, the fracture elongation of specimen C was improved in all tensile orientations owing to the elimination of work hardening and twins. Because the c-axis is mainly inclined towards the RD, the yield strength was the lowest and the fracture elongation showed the largest increase in the RD tensile orientation [10]. Additionally, the fracture elongations of specimen D were lower in all tensile orientations than those of specimen C though the difference of the (0002) plane texture intensity between specimens C and D is small. The phenomenon is because of the coarse grains[9]. The result indicates that the effects of tilted texture on the fracture elongation are negligible in AZ31B magnesium alloy with coarse grains. As a result, the ductility enhancement is probably associated with the slight change in the basal texture[24] and/or reduction in grain size[15].

Fig.5 Ultimate tensile strength (a), yield strength (b) and fracture elongation (c) of AZ31B sheets in different states in tensile directions of RD, TD and 45°

The r-values of the specimens are shown in Fig.6(a). The r-value decreased significantly with increasing annealing temperature after RUB in all tensile directions especially in the RD direction. While the r-values of specimens C and D were almost the same. It is interesting to note that the specimens with lower texture intensity had lower r-value for specimens A, B and C with nearly the same grain size. HUANG et al[25] showed that a weak basal texture favored basal slip during deformation compared with a strongly basal textured sheet. For the sheet with well-tilted c-axis, the basal áa? slip with the lowest CRSS greatly contributes to the thickness strain, which leads to a decrease in the r-value. CHINO et al[26] showed that a rolled AZ31B magnesium alloy sheet with low (0002) plane texture intensity exhibited low average r-value, which corresponds to the enhancement of thickness-direction strain. So, the decrease in the r-value indicates that it is easy to reduce or increase the thickness of sheet during the plastic deformation.

Fig.6 r-value (a) and n-value (b) of AZ31B sheets in different states in tensile directions of RD, 45° and TD

The n-values of the specimens are shown in Fig.6(b). The n-value increased significantly with increasing annealing temperature after RUB in all tensile directions. The n-value increased most significantly for specimens B and C. The inclination of the c-axis may increase the n-value due to the restricted dynamic recovery and the activated ![]() extension twinning[27-28]. SOMEKAWA et al[29] showed that AZ31B Mg alloy processed by ECAE had high n-value, and the increase in n-value was due to the modified distribution of basal texture. The n-value is one of the important factors which control metal sheet’s resistance to plastic instability. CHINO et al[30] reported that the reduction of plastic instability should be also responsible for lower texture intensity of the AZ31B magnesium alloy sheets. The high n-value leads to a low sensitivity to strain localization in the form of necking and is responsible for the increase in the uniform elongation, which is known to be equivalent to the n-value at the point of the maximum load[27].

extension twinning[27-28]. SOMEKAWA et al[29] showed that AZ31B Mg alloy processed by ECAE had high n-value, and the increase in n-value was due to the modified distribution of basal texture. The n-value is one of the important factors which control metal sheet’s resistance to plastic instability. CHINO et al[30] reported that the reduction of plastic instability should be also responsible for lower texture intensity of the AZ31B magnesium alloy sheets. The high n-value leads to a low sensitivity to strain localization in the form of necking and is responsible for the increase in the uniform elongation, which is known to be equivalent to the n-value at the point of the maximum load[27].

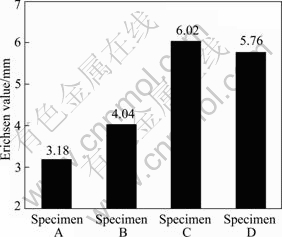

Figure 7 shows the Erichsen values (IE) of the specimens. The Erichsen values were 3.18, 4.04, 6.02 and 5.76 mm for specimens A, B, C and D, respectively. The Erichsen value of as-received sheet (specimen A) was only 3.18 mm due to the strong (0002) textural component, which is harmful to the formability. Although the (0002) basal texture was weakened significantly for the sheet that underwent RUB followed by annealing at 200 °C, the value was only 4.04 mm. This can be attributed to work-hardening and twining, which were not eliminated completely. However, the Erichsen value was remarkably enhanced to 6.02 mm for the sheet that underwent RUB followed by annealing at 300 °C. While the Erichsen value reached 5.76 for the sheet that underwent RUB and was annealed at 400 °C though it had the lower fracture elongation and coarse grains. It should be noted that the stretch formability is more sensitive to the r-value and the n-value than the tensile elongation. The width strain can contribute to the total strain for uniaxial tensile extension, while the thickness strain is most necessary under a biaxial tension stress state of stretch forming, and a smaller r-value and a larger n-value may enhance the deformation capability of sheet thinning[27]. The above analysis shows that a lower texture intensity induces a smaller r-value and a larger n-value. It is concluded that the superior stretch formability of AZ31B magnesium alloy sheet can be mainly attributed to the reduction of the (0002) basal texture intensity, which results in the small r-value and the large n-value. The formability of AZ31B magnesium alloy sheet with coarse-grained surface layer and fine-grained layer is better.

Fig.7 Erichsen values of AZ31B sheets in different states

Additionally, specimen D with coarse grains showed excellent stretch formability compared with specimen A with fine equiaxial grains. The microstructural observations show that there are more twins in the sheet that underwent RUB and was annealed at 400 °C than in the as-received sheet, as shown in Fig.8. CHINO et al[9] reported that not only the texture but also the grain size affects the stretch formability. Twin formation during deformation was enhanced by grain coarsening. While the lattice rotation by the twins (such as ![]() twin) played a critical role in deformation under the biaxial tensile stress, inducing strain in the thickness direction. This resulted in the improvement of stretch formability. The present results well agree with the results in the previous researches.

twin) played a critical role in deformation under the biaxial tensile stress, inducing strain in the thickness direction. This resulted in the improvement of stretch formability. The present results well agree with the results in the previous researches.

Fig.8 Microstructures of AZ31B magnesium alloy sheets stretch-formed to failure: (a) As-received; (b) RUB + 400 °C annealing

4 Conclusions

1) The RUB and annealing produce two effects on microstructure: grain coarsening and weakening of the texture.

2) The formability of sheet with coarse-grained surface layer and fine-grained middle layer is better. The superior stretch formability of AZ31B magnesium alloy sheet can be mainly attributed to the reduction of the (0002) basal texture intensity, which results in low yield strength, large fracture elongation, small r-value and large n-value.

3) AZ31B magnesium alloy sheet with coarse grains shows excellent stretch formability because the deformation twin enhanced by grain coarsening can accommodate the strain of thickness.

References

[1] Aghion E, BronFIN B. Magnesium alloys development towards the 21st century [J]. Materials Science Forum, 2000, 350-351: 19-30.

[2] MORDIKE B L, EBERT T. Magnesium: Properties- Applications-Potential [J]. Materials Science and Engineering A, 2001, 302: 37-45.

[3] Reed-hill R E, Robertson W D. The crystallographic characteristics of fracture in magnesium single crystals [J]. Acta Metallurgica, 1957, 5: 728-737.

[4] Perez-Prado M T, Del Valle J A, Contreras J M. Microstructural evolution during large strain hot rolling of an AM60 Mg alloy [J]. Scripta Materialia, 2004, 50: 661-665.

[5] Kaneko J, Sugamata M, Numa M, Takada H. Effect of texture on the mechanical properties and formability of magnesium wrought materials [J]. Journal of the Japan Institute of Metals, 2000, 64(2): 141-147.

[6] Mukai T, Yamanoi M, Watanabe H, Higashi K. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure [J]. Scripta Materialia, 2001, 45(1): 89-94.

[7] Chino Y, Lee J S, Sassa K, Kamiya A, MABUCHI M. Press formability of a rolled AZ31 Mg alloy sheet with controlled texture [J]. Materials Letters, 2006, 60: 173-176.

[8] Iwanaga K, Tashiro H, Okamoto H, Shimizu K. Improvement of formability from room temperature to warm temperature in AZ31 magnesium alloy [J]. Journal of Materials Processing Technology, 2004, 155-156: 1313-1316.

[9] Chino Y, Kimura K, Mabuchib M. Deformation characteristics at room temperature under biaxial tensile stress in textured AZ31 Mg alloy sheets [J]. Acta Materialia, 2009, 57: 1476-1485.

[10] Song Bo, Huang Guang-sheng, Li Hong-cheng, Zhang Lei, Huang Guang-jie, Pan Fu-sheng. Texture evolution and mechanical properties of AZ31B magnesium alloy sheets processed by repeated unidirectional bending [J]. Journal of Alloys and Compounds, 2010, 489: 475-481.

[11] Huang Guang-sheng, Xu Wei, Huang Guang-jie, Li Hong-cheng, Song Bo. Textural evolution of AZ31B magnesium alloy sheets undergoing repeated unidirectional bending at room temperature [J]. Journal of Materials Sciences and Technology, 2009, 25(3): 365-369.

[12] Huang Guang-sheng, Li Hong-cheng, Song Bo, Zhang Lei. Tensile properties and microstructure of AZ31B magnesium alloy sheet processed by repeated unidirectional bending [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 28-33.

[13] Takayama Y, Szpunar J A, Jeong H T. Cube texture development in an Al-Mg-Mn alloy sheet worked by continuous cyclic bending [J]. Materials Transactions, 2001, 42(10): 2050-2058.

[14] Koike J, Ohyama R. Geometrical criterion for the activation of prismatic slip in AZ61 Mg alloy sheets deformed at room temperature [J]. Acta Materialia, 2005, 53: 1963-1972.

[15] Kubota K, Mabuchi M, Higashi K. Review Processing and mechanical properties of fine-grained magnesium alloys [J]. Journal of Materials Science, 1999, 34(10): 2255-2262.

[16] Mann G, Griffiths J R, Cáceres C H. Hall-Petch parameters in tension and compression in cast Mg-2Zn alloys [J]. Journal of Alloys and Compounds, 2004, 378: 188-191.

[17] Bohlen J, Dobroň P, Swiostek J, Letzig D, Chmelík F, Luká? P, Kainer K U. On the influence of the grain size and solute content on the AE response of magnesium alloys tested in tension and compression [J]. Materials Science and Engineering A, 2007, 462: 302-306.

[18] Kaneko J, Sugamata M, Numa M, Nishikawa Y, Takada H. Effect of texture on the mechanical properties and formability of magnesium wrought materials [J]. Journal of the Japan Institute of Metals, 2000, 64(2): 141-147.

[19] Mabuchi M, Chino Y, Iwasaki H, Aizawa T, Higashi K. The grain size and texture dependence of tensile properties in extruded Mg-9Al-1Zn [J]. Materials Transaction, 2001, 42(7): 1182-1189.

[20] Barnett M R, Kehavarz Z, Beer A G, Atwell D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn [J]. Acta Materialia, 2004, 52: 5093-5103.

[21] Salem A A, Kalidindi S R, Doherty D R. Strain hardening of titanium: role of deformation twinning [J]. Acta Materialia, 2003, 51: 4225-4237.

[22] Yin S M, Yang F, Yang X M, Wu S D, Li S X, Li G Y. The role of twinning-detwinning on fatigue fracture morphology of Mg-3% Al-1% Zn alloy [J]. Materials Science and Engineering A, 2008, 494: 397-400.

[23] Christian J W, Mahajan S. Deformation twinning [J]. Progress in Materials Science, 1995, 39: 131-150.

[24] Watanabe H, Mukai T, Ishikawa K. Differential speed rolling of an AZ31 magnesium alloy and the resulting mechanical properties [J]. Journal of Materials Science, 2004, 39: 1477-1480.

[25] Huang X S, Suzuki K, Saito N. Textures and stretch formability of Mg-6Al-1Zn magnesium alloy sheets rolled at high temperatures up to 793 K [J]. Scripta Materialia, 2009, 60: 651-654

[26] Chino Y, Sassa K, Kamiya A, Mabuchi M. Enhanced formability at elevated temperature of a cross-rolled magnesium alloy sheet [J]. Materials Science and Engineering A, 2006, 441: 349-356.

[27] Huang X S, Suzuki K, Watazu A, Shigematsu I, Saito N. Mechanical properties of Mg-Al-Zn alloy with a tilted basal texture obtained by differential speed rolling [J]. Materials Science and Engineering A, 2008, 488: 214-220.

[28] Del Valle J A, Carreno F, Ruano O A. In?uence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling [J]. Acta Materialia, 2006, 54: 4247-4259.

[29] Somekawa H, Mukai T. Fracture toughness in Mg-Al-Zn alloy processed by equal-channel-angular extrusion [J]. Scripta Materialia, 2006, 54: 633-638.

[30] Chino Y, Iwasaki H, Mabuchi M. Stretch formability of AZ31 Mg alloy sheets at different testing temperatures [J]. Materials Science and Engineering A, 2007, 466: 90-95.

张 华1 ,2, 黄光胜1, 2, 宋 波1, 2, 张 雷1, 2, 孔德强1

1. 重庆大学 材料科学与工程学院,重庆 400045;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044

摘 要:通过单向多道次弯曲(RUB)工艺及随后的退火处理来改变镁合金的显微组织和织构,研究显微组织和织构对其成形性能的影响。RUB工艺和不同温度下的退火处理对显微组织有两方面的影响:粗化晶粒和削弱织构。经RUB处理并在300 °C退火的板材表现出最好的成形性能。这主要归因于(0002)基面织构强度的削弱,而织构的削弱导致了较低的屈服强度、较大的断裂伸长率、较小的Lankford值(r值)和较大的加工硬化指数(n值)。与原始板材相比,经RUB处理并在400 °C退火而产生的具有粗大晶粒的板材具有较低的拉伸性能,但却表现出较高的成形性能。这主要是由于粗大晶粒增强了变形孪晶,而变形孪晶可以协调厚向应变。

关键词:镁合金板材;单向多道次弯曲;显微组织;织构;成形性能

(Edited by YUAN Sai-qian)

Foundation item: Project (CSTC2010AA4035) supported by Scientific and Technological Project of Chongqing Science and Technology Commission, China; Project (50504019) supported by the National Natural Science Foundation of China; Project (CDJZR11130008) supported by the Fundamental Research Funds for the Central Universities, China; Project (CDJXS10130001) supported by the Chongqing University Postgraduates’ Science and Innovation Fund, China

Corresponding author: HUANG Guang-sheng; Tel: +86-23-65112239; E-mail: gshuang@cqu.edu.cn

DOI: 10.1016/S1003-6326(11)60791-7