文章编号:1004-0609(2009)03-0583-06

三相界面反应机制在SOM法制备金属钽中的应用

陈朝轶1, 2,鲁雄刚1,李重和1,钟庆东1

(1. 上海大学 上海市现代冶金与材料制备重点实验室,上海 200072;

2. 贵州大学 材料科学与冶金工程学院,贵阳 550003)

摘 要:利用固体透氧膜(SOM)法电解还原Ta2O5制备金属钽,通过三相界面反应机制讨论了阴极微结构对电解过程及产物形貌的影响。结果表明:阴极片的颗粒尺寸与孔隙率是影响有效三相界线的重要因素;孔隙率大和粒度小均有利于电解还原的进行,孔隙率小会导致阴极产物形成致密的金属钽外层,阻碍阴极进一步脱氧;成型压力4 MPa时1 150 ℃烧结2 h制备的阴极片具有合适的孔隙率和粒度,电化学活性良好,电解产物形貌均匀,氧含量低。

关键词:金属钽;五氧化二钽;三相界线;熔盐电解;SOM法

中图分类号:TG 146.4 文献标识码:A

Application of three-phase interline reaction mechanism on preparation of Ta metal using SOM process

CHEN Chao-yi1, 2, LU Xiong-gang1, LI Chong-he1, ZHONG Qing-dong1

(1. Shanghai Key Laboratory of Modern Metallurgy and Materials Processing,

Shanghai University, Shanghai 200072, China;

2. School of Materials Science and Metallurgical Engineering, Guizhou University, Guiyang 550003, China)

Abstract: Tantalum metal was prepared by solid oxygen-ion conducting membrane (SOM) technology from Ta2O5 directly in molten CaCl2. Through the reaction mechanism of metal-oxide-electrolyte three-phase interline, the influence of pellets microstructure on the electrolysis process and products morphology were discussed. The results show that the particle size and porosity of cathode pellets are significant factors for three-phase interline during electrolysis process. Big porosity and small particle size of cathode pellets can enhance the rate of deoxidization. Contrarily, small porosity results in the formation of compact out-layer of tantalum metal. While the Ta2O5 pellet pressed by 4 MPa and sintered at 1 150 ℃ for 2 h has appropriate porosity and particle size, which has better electrochemical activation, the morphology of the products is uniform, and the oxygen content of the products is low.

Key words: tantalum metal; Ta2O5; three-phase interline; molten electrolysis; SOM process

熔盐电解固态金属氧化物直接制备金属及合金是近年国际研究的热点领域之一,将金属氧化物制成阴极并在低于金属熔点温度和熔盐分解电压下进行电 解[1?4],并已证明微孔阴极内部的氧向外迁移为控制环节[4?5]。GORDO等[6]运用“三相界面”脱氧机制解释了盐电解法的反应过程,但研究认为,一旦形成稳定的中间产物,势必影响三相界面扩展,降低电流效率[7?9]。

固体透氧膜(SOM)法在熔盐电解法的基础上,采用只传导氧离子的膜管将阳极和熔盐隔离开,在膜管稳定条件下,两极间施加较高电压,熔盐也不会分解。用这种方法实验室制备了金属铬和钽[9?10],结果均显示出较高的电流效率和反应速度,相对于已有的熔盐电解法,具有明显的优势。本文作者通过分析Ta2O5阴极孔隙率和粒度与三相界线的关系,考查阴极微结构对电解的影响,验证三相界面反应机制的合理性,优化阴极的制备工艺,为SOM法提取金属钽提供理论依据。

1 三相界面反应机制

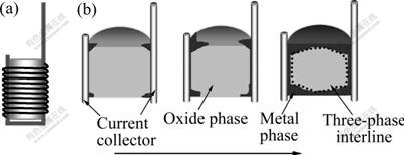

三相界面即阴极/熔盐/金属之间的界面,阴极的脱氧过程为三相界面在微孔阴极表面和纵深不断扩展的过程[1, 8]。图1(a)所示为外缠绕方式制备阴极的示意图。电解初期,反应发生在电极表面,与电极引线和熔盐接触的部分率先脱氧(见图1(b)),生成导电能力较强的Ta2O5?x[11],电荷迅速向周围传递,三相界面向阴极表面和内部同时扩展。当表面金属化后,反应发生在阴极内部,三相界面为Ta2O5/熔盐/金属钽,反应若要继续进行,阴极片必须具备一定的孔隙率,使得微孔毛管力能够克服熔盐的张力,向内部顺畅渗透。当三相界面扩展至试样心部时,阴极反应结束。

图1 三相界面脱氧机制示意图

Fig.1 Schematic illustration of 3PI (three-phase interline) propagation mechanism for cylindrical oxide pellet: (a) Schematic diagram of cathode form attached to molybdenum wire; (b) 3PI propagating from outsides wire along surface

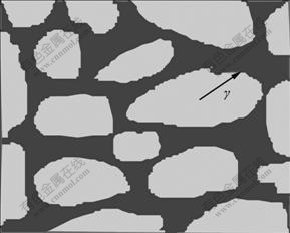

假设图2所示为理想的微孔阴极截面,黑色部分为渗入的熔盐,孔隙率为δ,截面积为A,γ为颗粒的特征半径,则截面上的颗粒数的计算式如下[12]: ,颗粒的总周长

,颗粒的总周长 近似于理想三相界线的特征长度

近似于理想三相界线的特征长度 ,即:

,即:

图2 微孔阴极截面示意图

Fig.2 Section schematic plot of porous cathode pellet

理想界线的特征长度取决于孔隙率δ和颗粒特征半径γ,当孔隙率一定时,粒度小具有更大的反应界面。

固体阴极与多孔气体电极的制作方式相同,而熔盐的渗入方向与气体电极的供气方向相反,故二者的边界条件相反,若阴极试样厚度为2L,根据多孔介质数学模型[12],沿厚度方向电解进行到x处(0≤x≤L)的三相界线分布为余弦波形态:

式中: Θa为特定条件下理想三相界线的总长度;n为形状因子(n≥2)。当渗入熔盐达到一定饱和度时构成有效三相界线,其长度可反映电解速度[4]。因此,可通过实验验证孔隙率和颗粒度对三相界线及电解的影响,最终确定适合于SOM法的阴极制备条件。

2 实验

SOM法制备金属的原理参见文献[10, 19]。利用24 T粉末压样机,将Ta2O5粉在不同成型压力下压制成直径为10 mm的圆片,1 150 ℃下烧结2 h后制成阴极;阳极为固体透氧膜管内碳饱和的铜液,钼丝作为电极引线;CaCl2为熔盐电解质,石墨坩埚为反应容器,以工业氩气为保护气体。实验条件均为分解电压3.5 V、1 150 ℃下电解2 h。将透氧膜管置于坩埚内熔盐中并缓慢升温,当熔盐温度达到1 150 ℃时,将悬挂在电极引线上的Ta2O5阴极片插入CaCl2熔盐中,施加3.5 V电压电解并记录电流。电解结束后,冷至室温取出产物,在振荡条件下用蒸馏水洗涤、干燥后称量[9],利用JSM?6700F 型扫描电子显微镜对电解阴极产物断面进行SEM和EDX分析,用日本理学D/max22500 PC型X射线衍射仪分析电解产物的相结构。

3 结果与讨论

3.1 成型压力对孔隙率及形貌的影响

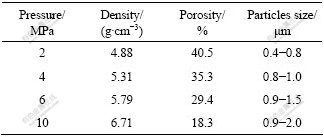

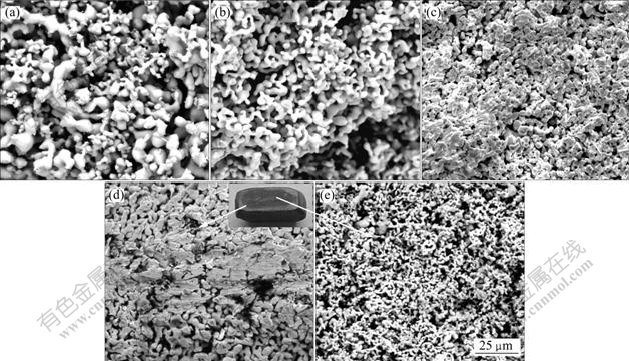

阴极片的制备压力对烧结片的孔隙率有较大影 响[13],孔隙率可表示为[14]δ=(ρ1-ρ2)/ρ1、。其中ρ1为Ta2O5粉的体密度(8.2 g/cm2),ρ2为烧结片的密度。不同成型压力的阴极烧结后孔隙率和粒度的测试结果如表1所列。由表1可知,阴极片烧结后的密度随成型压力的增加而增加,而孔隙率随成型压力的增加明显降低。对应的阴极片SEM形貌如图3所示。

表1 不同成型压力制备的Ta2O5阴极片在1 150 ℃烧结2 h后的孔隙率和颗粒尺寸

Table 1 Porosity and particles size of Ta2O5 pellets pressed under different pressures after sintering at 1 150 ℃ for 2 h

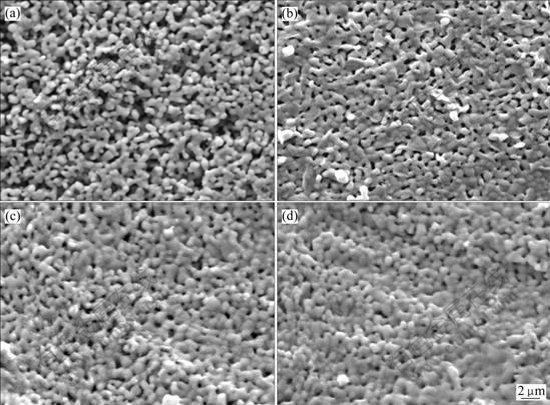

图3 不同成型压力制备的Ta2O5阴极片在1 150 ℃烧结2 h后的SEM形貌

Fig.3 SEM images of Ta2O5 pellets pressed under different pressures after sintering at 1 150 ℃ for 2 h: (a) 2 MPa; (b) 4 MPa; (c) 6 MPa; (d) 10 MPa

成型压力增加,颗粒间的接触逐渐紧密,孔隙数量和孔径尺寸都明显降低,这与表1所列的结果一致。由于成型压力增大,Ta2O5粉体间的气体被充分挤出,颗粒之间的机械结合强度增加,成型压力10 MPa时的试样在局部区域已经没有明显的晶界,烧结时晶粒熔合在一起。

3.2 阴极微结构对电解的影响

图4所示为不同成型压力的阴极片在1 150 ℃下电解2 h产物断面的SEM形貌。随着成型压力的增加,产物中钽颗粒变细小,结构致密。产物颗粒大一方面由于烧结片孔隙大,被还原的金属微粒受到“充足”渗入熔盐的浮力和自身张力作用,自发聚集;另一方面Ta2O5的还原是一个放热反应[15],还原速度快会引起阴极片中局部区域温度过高,高温区金属钽微粒发生烧结、再结晶现象,微粒易于熔合。而成型压力大时产物颗粒细小,此时试样反应速度慢,在有限的电解时间内金属产物发生烧结的时间短,还未及熔合所致。

图4 不同成型压力时制备的阴极片电解产物断面SEM形貌

Fig.4 Cross sectional SEM images of electrolysis cathode products from Ta2O5 pellets prepared under different pressures: (a) 2 MPa; (b) 4 MPa; (c) 6 MPa; (d) Outside of 10 MPa; (e) Inside of 10 MPa

成型压力为2 MPa的阴极产物疏松易脆,颗粒间结合强度较弱,易粉化,不利于收集,其SEM形貌如图4(a)所示;成型压力为4 MPa的阴极产物形貌均匀(见图4(b)),稍微用力便可使其粉碎,是合适的制片工艺;6 MPa时,阴极产物结构致密(见图4(c)),硬度较高,难以粉碎;当压力增大到10 MPa时,产物硬度更高,分为致密的金属钽外层和较为疏松的小内层(见图4(d)和(e)),内层部分氧含量较高,致密的金属外层会阻碍熔盐的渗入和氧离子的迁移,从而降低脱氧速度,使得电解后期电流小,脱氧不彻底。利用氧化称重法[11]测得产物氧含量见表2所示。

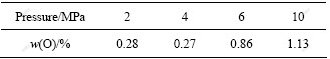

表2 不同成型压力下Ta2O5阴极片电解产物的氧质量分数

Table 2 Oxygen contents in products from Ta2O5 pellets pressed under different pressures

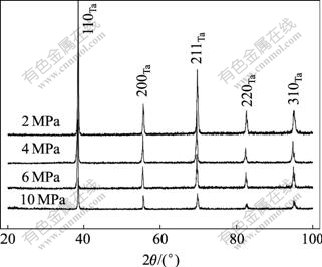

图5所示为电解阴极产物的XRD谱。由图5可知,除成型压力为10 MPa的阴极产物衍射峰强度较弱以外,所有阴极产物都只有金属钽的衍射峰,没有其它杂质衍射峰,SOM法制备金属钽可以获得较好的效果。能谱分析也只有钽和微量的氧,没有显示钙及其它杂质元素。WU等[16]研究认为,电解还原Ta2O5时首先生成Ca0.5Ta2O5和CaTa2O5。

图5 不同成型压力时制备的阴极片电解产物的XRD谱

Fig.5 XRD patterns for electrolysis products of Ta2O5 pellets prepared under different pressures

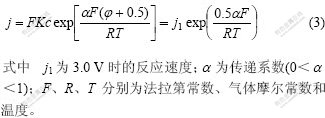

SOM法使用只传导氧离子的透氧膜将阳极与熔盐隔离开,与FFC法相比,SOM法可施加较高的电解电压,故具有更大的过电位,提高反应速度。文献[17]提到,在电极材料、熔盐组成、温度等因素不变的条件下,可通过改变电极电位来提高电化学反应速度,当电压从3.0 V升到3.5 V时,根据式(3)

设 =0.5,于是得到j=7.7j1,由此可见,当电解电压从3.0 V升到3.5 V时,反应速度增加了7.7倍。本实验没发现钽钙氧化物生成,是由于在高的过电位下,中间产物的寿命极短。

=0.5,于是得到j=7.7j1,由此可见,当电解电压从3.0 V升到3.5 V时,反应速度增加了7.7倍。本实验没发现钽钙氧化物生成,是由于在高的过电位下,中间产物的寿命极短。

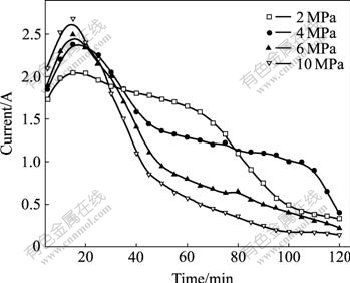

图6所示为阴极电解电流—时间曲线。电解初期,回路电流随着成型压力的增大而增大。这是由于电解反应发生在试样表面,阴极颗粒间接触紧密,更有利于电子传递,表现出较快的脱氧反应。当电流出现极值后,成型压力越大的试样,电流下降的趋势也越快,分析原因,认为孔隙率小,熔盐难以向试样内部渗透,内部熔盐饱和度降低,反应界面较少,反应速度减慢。

图6 不同成型压力下阴极片的电解电流—时间曲线图

Fig.6 Current—time plots during electrolysis of Ta2O5 pellets prepared at different pressures

成型压力为2 MPa的试样孔隙率大而颗粒较小,有利于脱氧反应的进行,长时间内保持较高的电流平台,由于颗粒间的连接疏松,电解后期试样外层已有部分金属粉化到熔盐中,影响电子传递,电流变小;成型压力为4 MPa的试样孔隙率和颗粒度均适中,颗粒间接触良好,出现较高的电流平台,电流下降缓慢,电解后期的反应速度也较快,脱氧效果较好;成型压力为6 MPa和10 MPa的试样电流下降的趋势较快,没有出现电流平台,脱氧速度较慢,电解产物氧含量较高。实验表明了反应速度与阴极片的孔隙率和颗粒尺寸密切相关。对照图1可知,反应按照阴极/熔盐/导体“三向界面” 脱氧机制进行的。

PAL等[18]认为,SOM法制备金属的限制环节为透氧膜管。本实验在改进膜管的制备后,测得1 000~ 1 200 ℃时其电导率为0.18~0.30 S/cm,控速环节取决于阴极的脱氧速度。

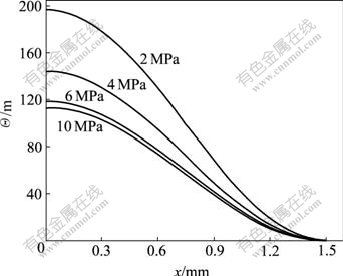

实验中阴极的微孔分布并非理想形态,孔隙的毛管力须达到一定值才能克服熔盐的张力,渗透到阴极内部。若试样截面积A=1 cm2,根据表1所示孔隙率和颗粒平均半径,由式(1)可计算出三相界线的特征总长度Θa的值。试样厚度2L=3 mm,由式(2)可拟合出三相界线Θ沿阴极表面到心部的分布,结果如图7所示(n=2)。由图7可见,Θ值随成型压力增大而减小,Θ值越小,反应速度越慢,与图6所示极值后的电流曲线一致。随着反应的进行,反应界面减少,当反应到达试样心部时,有效三相界线值为零。而此时仍然有电流,一是存在环境电流,二是氧化物颗粒表层形成金属包裹层后,内部的氧通过扩散达到界面,依然会形成电流。实验与理论计算表明,孔隙率大和颗粒度小均有利于电解反应。根据文献报道和大量实践,在产物具备一定强度的前提下,空隙率和颗粒尺寸的合理范围为30%~40%和0.6~1.0 μm。

图7 微孔阴极中Θ沿表面到心部的分布

Fig.7 Distributions of Θ from surface to center in porous electrodes

并非阴极片孔隙率越大或粒度越小就越好。成型压力为4 MPa的阴极片在电解过程中,由于强度适中,结构稳定且具有良好的电化学反应性能,因而其电解产物形貌均匀,氧含量低,易于收集;而成型压力为2 MPa的阴极片在电解过程中易于脱落,不能形成稳定的三相界面。因此,成型压力为4 MPa是制备阴极片的较好的工艺选择。

3 结论

1) 阴极脱氧按照阴极/熔盐/导体三向界面反应机制进行。根据多孔气体电极的数学模型可推出,阴极三相界面从表面到心部呈余弦波形态分布。

2) 成型压力对阴极孔隙率及粒度产生直接影响,进而影响三相界面的分布;压力增大,烧结片孔隙率明显降低,颗粒尺寸略有增;孔隙率小会导致电解产物形成致密的金属钽外层。

3) 阴极微结构是影响反应速度的重要因素;成型压力为4 MPa、在1 150 ℃烧结2 h的阴极片具有良好的电化学活性,电解产物强度适中,易收集,形貌均匀且氧含量低,是合适的制片工艺。

REFERENCES

[1] CHEN G Z,FRAY D J,FARTHING T W. Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride[J]. Nature,2000, 407(21): 361?364.

[2] WANG De-hua, CHEN Zheng. Innovation in molten electrochemistry[J]. Electrochemistry, 2005, 11(2): 119?125.

[3] CHEN G Z, FRAY D J, FARTHING T W. Catholic deoxygenation of the alpha case on titanium and alloys in molten calcium chloride[J]. Metallurgical and Materials Transactions B, 200l, 32: 1041?1052.

[4] CHEN G Z,GORDO,FRAY D J. Direct electrolytic preparation of chromium powder[J].Metallurgical and Materials Transactions B,2004, 35(2): 223?233.

[5] 刘美凤, 郭占成, 卢维昌. TiO2直接电解还原过程的研究[J]. 中国有色金属学报, 2004, 14(10): 1752?1758.

LIU Mei-feng, GUO Zhan-cheng, LU Wei-chang. Process of direct electrochemical reduction of TiO2[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1752?1758.

[6] GORDO E, CHEN G Z, FRAY D J. Toward optimization of electrolytic reduction of solid chromium oxide to chromium powder in molten chloride salts[J]. Electrochimica Acta, 2004, 49(13): 2195?2208.

[7] ALEXANDER D T L, SCHWANDT C, FRAY D J. Microstructural kinetics of phase transformations during electrochemical reduction of titanium dioxide in molten calcium chloride[J]. Acta Materialia, 2006, 54(11): 2933?2944.

[8] SCHWANDT C, FRAY D J. Determination of the kinetic pathway in the electrochemical reduction of titanium dioxide in molten calcium chloride[J]. Electrochimica Acta, 2005, 51: 66?76.

[9] 陈朝轶, 鲁雄刚. 固体透氧膜法与熔盐电解法制备金属铬的对比[J]. 金属学报, 2008, 44: 163?168.

CHEN Chao-yi, LU Xiong-gang. Comparison of FFC and SOM processes for preparation of chromium metal[J]. Acta Metallurgica Sinica, 2008, 44: 163?168.

[10] 程红伟, 鲁雄刚, 李 谦. 固体透氧膜法制备金属钽[J]. 金属学报, 2006, 42(5): 500?504.

CHENG Hong-wei, LU Xiong-gang, LI Qian. Preparation of metal tantalum by solid oxygen-ion membrane[J]. Acta Metallurgica Sinica, 2006, 42(5): 500?504.

[11] 邓丽琴, 许 茜, 李 兵. 电脱氧法由Nb2O5直接制备金属铌[J]. 中国有色金属学报, 2005, 15(4): 541?545.

DENG LI-qin, XU Qian, LI Bing. Preparation of niobium by direct electrochemical reduction of solid Nb2O5[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 541?545.

[12] 徐献芝, 朱 梅, 杨基明. 考虑多孔电极内气液分布的数学模型[J]. 中国工程科学, 2005, 7(8): 36?40.

XU Xian-zhi, ZHU Mei, YANG Ji-ming. Mathematical model of gas and liquid distribution in the porous electrode[J]. Engineering Science, 2005, 7(8): 36?40.

[13] 胡小锋, 许 茜. CaCl2-NaCl熔盐电脱氧法制备金属钽[J]. 金属学报, 2006, 42(3): 285?292.

HU Xiao-feng, XU Qian. Preparation of tantalum by electro-deoxidation in a CaCl2-NaCl melt[J]. Acta Metallurgica Sinica, 2006, 42(3): 285?292.

[14] BABA M, SUZUKI R O. Dielectric properties of tantalum powder with broccoli-like morphology[J]. Journal of Alloys and Compounds, 2005, 392(1/2): 225?230.

[15] BABA M, ONO Y, SUZUKI R O. Tantalum and niobium powder preparation from their oxides by calciothermic reduction in the molten CaCl2[J]. Journal of Physics and Chemistry of Solids, 2005, 66(2/4): 466?470.

[16] WU T, JIN X B, XIAO W, HU X H, WANG D H, CHEN G Z. Thin pellets: Fast electrochemical preparation of capacitor tantalum powders[J]. Chem Mater, 2007, 19: 153?160.

[17] LI Di. Electrochemistry principle[M]. Beijing: Beihang University Press, 2003: 297?298.

[18] PAL U B, WOLLY D E, KENNEY G B. Emerging SOM technology for the green synthesis of metals from oxides[J]. JOM, 2001, 53(10): 32?35.

基金项目:国家重点基础研究发展计划资助项目(2007CB613606);国家高技术研究发展计划资助项目(2006AA06Z124);国家自然科学基金资助项目(50774052);教育部长江学者和创新团队发展计划资助项目(IRT0739);教育部新世纪优秀人才计划资助项目(NCET-06-0434)

收稿日期:2008-09-02;修订日期:2008-11-27

通讯作者:鲁雄刚,教授,博士;电话/传真:021-56335768;E-mail: luxg@shu.edu.cn

(编辑 龙怀中)