直径为160 mm AZ40镁合金棒材的混晶组织和力学性能各向异性

来源期刊:中国有色金属学报(英文版)2015年第12期

论文作者:石国梁 张奎 李兴刚 李永军 马鸣龙 袁家伟 卢春芳

文章页码:3944 - 3952

关键词:AZ40镁合金;混晶组织;力学性能;各向异性;微观偏析;织构

Key words:AZ40 magnesium alloy; mixed grain structure; mechanical properties; anisotropy; micro-segregation; texture

摘 要:采用“多向锻造(MDF)+挤压+在线冷却”技术制备的AZ40(直径为160 mm)镁合金棒材具有混晶组织和力学性能各向异性,通过光学显微镜(OM)、扫描电镜(SEM)、X射线衍射织构测量和室温拉伸试验对上述特征进行表征和分析。结果表明:混晶组织来源于半连续铸锭中Al的微观偏析。均匀化处理((380 °C, 8 h)+(410 °C, 12 h))不能完全消除这种微观偏析。在后续MDF和挤压过程中,Al含量为3%~4%(质量分数)的枝晶心部转变成细晶区,而Al含量约为6%的枝晶边缘转变成粗晶区。表层、R/2和心部的XRD宏观织构都呈现典型的纤维织构特征,且表层的[0001]//RaD取向强度(11.245)约为R/2处(6.026)和心部(6.979)的两倍。挤压态AZ40镁合金棒材沿挤压方向和半径方向具有优异的伸长率(A)和中等抗拉强度(Rm):A为19%~25%,Rm为256~264 MPa;然而,屈服强度(Rp0.2)呈现出各向异性和内外不均匀性,即RaD为103 MPa,ED-C(心部)为137 MPa,ED-O(边部)为161 MPa,这主要是织构造成的。(155 °C, 7 h) + (170 °C, 24 h)时效处理对AZ40镁合金棒材的强度和伸长率几乎没有影响。

Abstract: The mixed grain structure and mechanical property anisotropy of AZ40 magnesium alloy bar with a diameter of 160 mm manufactured by “multi-direction forging (MDF) + extrusion + online cooling” technique were investigated by optical microscopy (OM), scanning electron microscopy (SEM), X-ray diffraction macro-texture measurement and room temperature (RT) tensile test. The results show that mixed grain structure is caused by the micro-segregation of Al in semi-continuous casting ingot. Homogenization of (380 °C, 8 h) + (410 °C, 12 h) cannot totally eliminate such micro-segregation. During MDF and extrusion, the dendrite interiors with 3%-4% Al (mass fraction) transform to fine grain zones, yet the dendrite edges with about 6% Al transform to coarse grain zones. XRD macro-textures of the outer, R/2 and center show typical fiber texture characteristics and the intensity of [0001]//RaD orientation in the outer (11.245) is about twice as big as those in the R/2 (6.026) and center (6.979). The as-extruded AZ40 magnesium alloy bar has high elongation (A) and moderate ultimate tensile strength (Rm) in both extrusion direction (ED) and radius direction (RaD), i.e., A of 19%-25% and Rm of 256-264 MPa; however, yield strength (Rp0.2) shows anisotropy and heterogeneity, i.e., 103 MPa in RaD, 137 MPa in ED-C (the center) and 161 MPa in ED-O (the outer), which are mainly caused by the texture. (155 °C, 7 h) + (170 °C, 24 h) aging has no influence on strength and elongation of AZ40 magnesium bar.

Trans. Nonferrous Met. Soc. China 25(2015) 3944-3952

Guo-liang SHI, Kui ZHANG, Xing-gang LI, Yong-jun LI, Ming-long MA, Jia-wei YUAN, Chun-fang LU

State Key Laboratory for Fabrication and Processing of Nonferrous Metals, General Research Institute for Nonferrous Metals, Beijing 100088, China

Received 5 March 2015; accepted 31 October 2015

Abstract: The mixed grain structure and mechanical property anisotropy of AZ40 magnesium alloy bar with a diameter of 160 mm manufactured by “multi-direction forging (MDF) + extrusion + online cooling” technique were investigated by optical microscopy (OM), scanning electron microscopy (SEM), X-ray diffraction macro-texture measurement and room temperature (RT) tensile test. The results show that mixed grain structure is caused by the micro-segregation of Al in semi-continuous casting ingot. Homogenization of (380 °C, 8 h) + (410 °C, 12 h) cannot totally eliminate such micro-segregation. During MDF and extrusion, the dendrite interiors with 3%-4% Al (mass fraction) transform to fine grain zones, yet the dendrite edges with about 6% Al transform to coarse grain zones. XRD macro-textures of the outer, R/2 and center show typical fiber texture characteristics and the intensity of [0001]//RaD orientation in the outer (11.245) is about twice as big as those in the R/2 (6.026) and center (6.979). The as-extruded AZ40 magnesium alloy bar has high elongation (A) and moderate ultimate tensile strength (Rm) in both extrusion direction (ED) and radius direction (RaD), i.e., A of 19%-25% and Rm of 256-264 MPa; however, yield strength (Rp0.2) shows anisotropy and heterogeneity, i.e., 103 MPa in RaD, 137 MPa in ED-C (the center) and 161 MPa in ED-O (the outer), which are mainly caused by the texture. (155 °C, 7 h) + (170 °C, 24 h) aging has no influence on strength and elongation of AZ40 magnesium bar.

Key words: AZ40 magnesium alloy; mixed grain structure; mechanical properties; anisotropy; micro-segregation; texture

1 Introduction

AZ40 alloy is a typical wrought magnesium alloy, which can get moderate strength and high ductility after hot deformation. WANG et al [1] investigated the influence of hot rolling on AZ40 extruded plate and found that the extruded plate possessed mixed grain structure (grain sizes range from 10 to 60 μm) and mechanical property anisotropy (longitudinal direction (ED): Rp0.2=100 MPa and A=20%; transverse direction (TD): Rp0.2=230 MPa and A=13%), but after five or more rolling passes the mixed grain structure was eliminated (about 10 μm) and Rp0.2 and A in both ED and TD are 175 MPa and 20%, respectively.

Mixed grain structure is a usual phenomenon in wrought magnesium alloy products, and its main reason is uneven or incomplete dynamic recrystallization (DRX) [2-4]. During hot deformation of magnesium alloys, DRX is the most important grain refinement mechanism [5-9]. Dislocation pile-up is a prerequisite for DRX, so grain (twin) boundaries and particle interfaces are preferred DRX sites. There are many DRX mechanisms in magnesium alloys, such as discontinuous DRX (DDRX), continuous DRX (CDRX), twinning- induced DRX (TDRX), particle-stimulated DRX and rotation DRX (RDRX). DDRX is the dominant mechanism in most hot deformations, which involves four steps: 1) dislocation pile-up causes local stress concentration at grain (twin) boundaries; 2) grain boundaries become serrated; 3) DDRX nuclei form on serrated boundaries by bulging; and 4) DDRX nuclei grow by the migration of high-angle boundaries [10,11]. In contrast, CDRX is generally considered as a recovery process and its activation needs high stacking fault energy (SFE) to enable dislocations of smaller core width to constitute low-angle boundaries of sub-grains at the polygonization stage [12]. The volume fraction and average size of DRX grains are closely related to Zener-Hollomon (Z) parameter and plastic strain (such as extrusion ratio and rolling reduction). Parameter Z is defined as  , where

, where  is the strain rate, T is the temperature, Q is the activation energy and R is the mole gas constant [2,13,14]. THIRUMU- RUGAN and KUMARAN [15] studied the influence of temperature on DRX mechanism during extrusion of AZ91 at 300 and 350 °C with a extrusion ratio of 4, and the results show that the DRX grains of about 59 μm only concentrate on grain boundaries and particle interfaces at 300 °C, but DRX grains of about 120 μm have covered the whole matrix at 350 °C. FATEMI- VARZANEH et al [11] investigated the effect of temperature (250-450 °C) and strain rate (0.0005-0.1 s-1) on the DRX during hot compression of AZ31 alloy and found that the volume fraction and size of DDRX grains increase as parameter Z decreases and the volume fraction of DDRX grains increases in a S-shape manner as strain rises. TANG et al [10] investigated the influence of extrusion parameters (extrusion ratio: 6.25 and 25; temperature: 370, 400 and 430 °C; ram speed: 0.8-7 m/min) on grain size of AZ31 alloy. They found that DRX grains of 5-15 μm look like “necklaces” along grain boundaries in all conditions, and extrusion ratio is the most important parameter for grain refinement, that is, higher extrusion ratio leads to higher volume fraction of DRX grains and lower average grain size.

is the strain rate, T is the temperature, Q is the activation energy and R is the mole gas constant [2,13,14]. THIRUMU- RUGAN and KUMARAN [15] studied the influence of temperature on DRX mechanism during extrusion of AZ91 at 300 and 350 °C with a extrusion ratio of 4, and the results show that the DRX grains of about 59 μm only concentrate on grain boundaries and particle interfaces at 300 °C, but DRX grains of about 120 μm have covered the whole matrix at 350 °C. FATEMI- VARZANEH et al [11] investigated the effect of temperature (250-450 °C) and strain rate (0.0005-0.1 s-1) on the DRX during hot compression of AZ31 alloy and found that the volume fraction and size of DDRX grains increase as parameter Z decreases and the volume fraction of DDRX grains increases in a S-shape manner as strain rises. TANG et al [10] investigated the influence of extrusion parameters (extrusion ratio: 6.25 and 25; temperature: 370, 400 and 430 °C; ram speed: 0.8-7 m/min) on grain size of AZ31 alloy. They found that DRX grains of 5-15 μm look like “necklaces” along grain boundaries in all conditions, and extrusion ratio is the most important parameter for grain refinement, that is, higher extrusion ratio leads to higher volume fraction of DRX grains and lower average grain size.

Mechanical property anisotropy is caused by texture which origins from grain rotation during plastic deformation [16]. For single crystal, under compressive stress, slip planes tend to be perpendicular to compressive direction. During hot extrusion, grains in deformation zone bear three-dimensional compressive stress, i.e., the axial compressive stress, radial compressive stress and circumferential compressive stress. Since radial compressive stress is the largest one [17], basal planes which are the dominant slip planes in magnesium alloy are inclined to be normal to radial direction, resulting in typical extrusion fiber texture [10,16,18,19].

Although the mixed grain structure of wrought magnesium alloys has been observed by many researchers [1, 20], its origin has rarely been studied. Moreover, before wrought magnesium alloys are used as structure materials which sustain complex loads, its mechanical property anisotropy must be carefully analyzed. In this work, the origin of mixed grain structure and mechanical property anisotropy of AZ40 magnesium alloy bar with a diameter of 160 mm were investigated.

2 Experimental

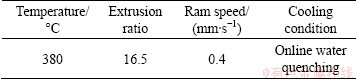

A d482 mm × 1500 mm AZ40 semi-continuous casting ingot was used, and its chemical composition is listed in Table 1. After two-step homogenization of (380 °C, 8 h) + (410 °C, 12 h), a d160 mm bar was produced by “multi-direction (MDF) + extrusion + online water quenching” technique. MDF consisted of three passes of “upsetting + stretching” at above 350 °C, and then the forged billet was immediately extruded. The extrusion parameters are listed in Table 2. In order to avoid grain growth, online water quenching was applied as soon as the bar went out the mold. Finally, (155 °C, 7 h) + (170 °C, 24 h) two-step aging was employed.

Table 1 Chemical composition of semi-continuous casting AZ40 ingot (mass fraction, %)

Table 2 Extrusion parameters of AZ40 forged billet in direct extrusion

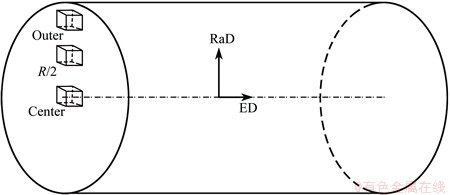

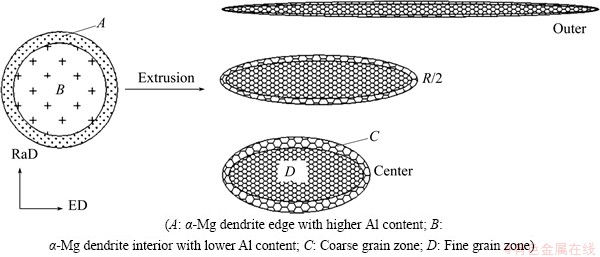

OM and SEM were used for microstructure observation, and element content was measured by energy dispersive spectrometer (EDS) equipped on SEM. The macro-texture was characterized by XRD pole figures with a detection area of 8 mm × 8 mm. Samples for microstructure observation and XRD macro-texture were cut from the center, R/2 and outer of the bar, as shown in Fig. 1, and microstructure samples were also cut from the center and outer of the ingot. After grinding and polishing, ingot samples were etched by nitric acid and alcohol solution (4 mL nitric acid and 96 mL alcohol), and bar samples were etched by a solution of 1 mL nitric acid, 1 mL acetic acid, 1 g oxalic acid and 150 mL water. The average grain size was measured by the linear intercept method. RT tensile test was conducted at a speed of 2 mm/min. Six kinds of tensile samples with a gauge of d5 mm × 25 mm were tested, i.e., RaD-E (E: as-extruded), RaD-A (A: as-aged), ED-O-E (O: outer), ED-C-E (C: center), ED-O-A and ED-C-A, and three samples were measured for each kind.

Fig. 1 Sampling positions and coordinate system of extruded bar

3 Results

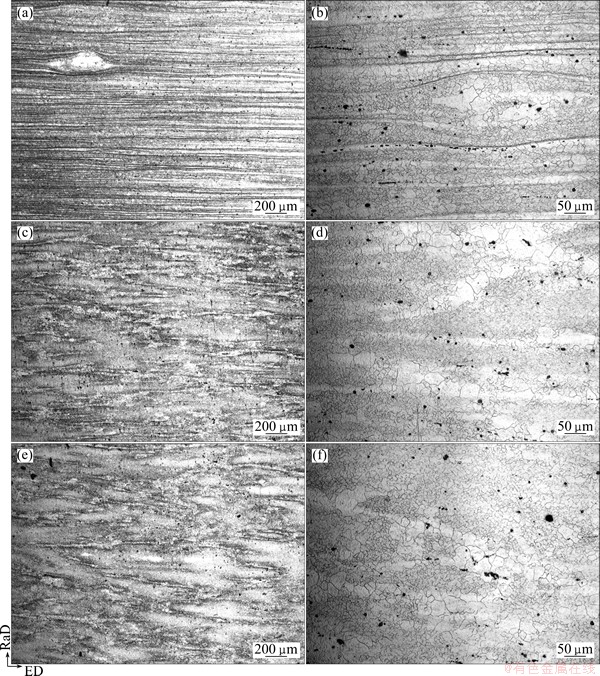

3.1 Microstructures in outer, R/2 and center

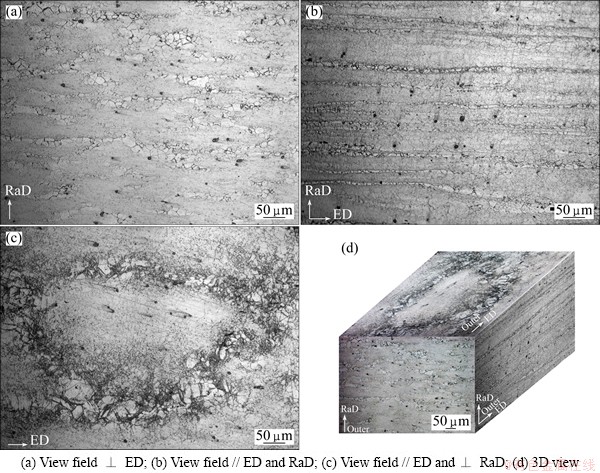

Figure 2 shows the OM images of extrude bar in the outer, R/2 and center, from which the following features can be seen: 1) mixed grain structure exists in all three positions; 2) coarse and fine grain zones in the outer are narrow straight lines, but in R/2 and center, coarse grain zones become necklace-shaped which surround fine grain zones, indicating that the deformation degree gradually reduces from the outer to the center; 3) on the etched surfaces, coarse grain zones are concave zones, but fine grain zones are convex zones, indicating that coarse grain zones have higher corrosion rate than fine grain zones, in other words, coarse and fine grain zones have different chemical components.

Figure 3 shows the 3D morphologies of the mixed grain structure in the outer. In Fig. 3(a) (the view filed⊥ ED), necklace-shaped coarse grain zones surround fine grain zones; in Fig. 3(b) (the view field//ED and RaD), both coarse and fine grain zones are straight lines; and in Fig. 3(c) (the view field//ED and ⊥ RaD), necklace-like coarse grain zones also surround fine grain zones.

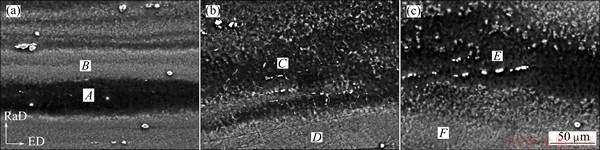

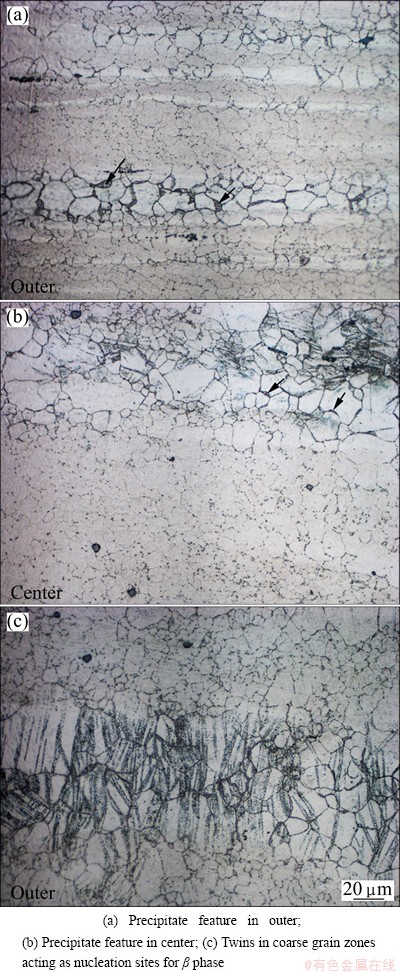

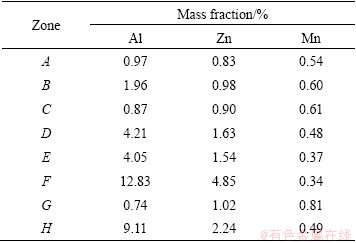

Figure 4 shows SEM images of the mixed grain structure in the outer, R/2 and center. It can be seen that the coarse grain zones A, C and E have faster corrosion rate than fine grain zones B, D and F. The EDS results in coarse and fine grain zones are listed in Table 3, indicating that coarse grain zones have higher Al content which is about twice as high as that of fine grain zones.

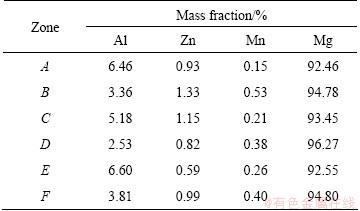

3.2 Microstructure after aging

After (155 °C, 7 h) + (170 °C, 24 h) aging treatment, precipitation reactions in coarse grain zones are more sufficient than those in fine grain zones. In coarse grain zones, all grain boundaries are wholly occupied by discontinuously precipitated β-Mg17Al12, and in some places such cellular precipitates expand inward, as marked by arrows in Figs. 5(a) and (b). However, in fine grain zones, only sparse β-Mg17Al12 particles nucleate at grain boundaries, particularly at triple grain boundary junctions. Moreover, twins in coarse grain zones can act as nucleation sites for β particles, as shown in Fig. 5(c).

Fig. 2 OM images of outer (a, b), R/2 (c, d) and center (e, f) with view field parallel to both ED and RaD

Fig. 3 Morphologies of mixed grain structure in outer

Fig. 4 SEM images of mixed grain structure in outer (a), R/2 (b) and center (c) (view field // ED and RaD)

Table 3 EDS results of coarse and fine grain zones in Fig. 4

3.3 Mechanical properties

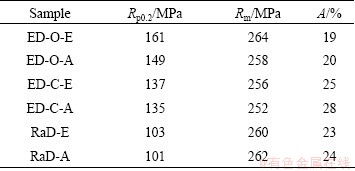

Table 4 lists the RT tensile properties of six kinds of samples and Fig. 6 compares their typical strain-stress curves, from which it can be known that: 1) the AZ40 bar has excellent elongation (19%≤A≤28%) and moderate ultimate tensile strength (252 MPa≤Rm≤264 MPa), but yield strength (Rp0.2) shows anisotropy and heterogeneity, that is, Rp0.2 of ED is higher than that of RaD, and Rp0.2 of ED-O is higher than that of ED-C; 2) (155 °C, 7 h) + (170 °C, 24 h) aging treatment has no strengthening effect and does not reduce elongation; 3) ED and RaD have totally different curve shapes, indicating different plastic deformation mechanisms.

Fig. 5 OM images of samples after (155 °C, 7 h) + (170 °C, 24 h) aging treatment

Table 4 RT tensile properties of six kinds of samples

4 Discussion

4.1 Microstructure heterogeneity

The AZ40 bar with a diameter of 160 mm shows remarkable microstructure heterogeneity. Firstly, mixed grain structure exists in the whole cross section; secondly, the morphology of mixed grain structure changes from the outer to the center. Such microstructure heterogeneity is mainly caused by micro-segregation of Al and different deformation degrees.

Fig. 6 Strain-stress curves of six kinds of tensile samples

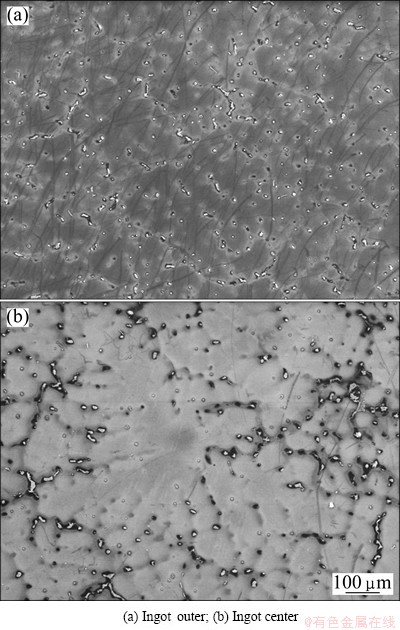

The micro-segregation of Al is inherited from ingot with a diameter of 482 mm. Figure 7 shows its center and outer microstructures, from which it can be seen that the outer has refined α-Mg dendrites and dispersed eutectic compounds as compared with the center. Such microstructure difference is caused by enormous difference in solidification rate. During semi-continuous casting, the outer has faster solidification rate and higher undercooling degree than the center, resulting in moreα-Mg nucleus in the outer.

Fig. 7 SEM images of semi-continuous casting ingots

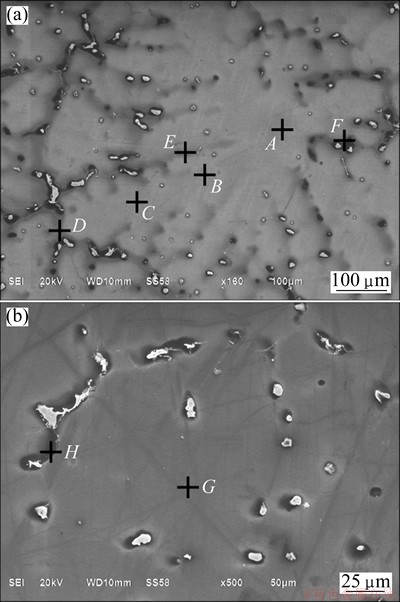

Figure 8 and Table 5 show the element distribution of an α-Mg dendrite in the center and outer of the ingot, from which it can be found that: dendrite interiors (marked by A, B, C and G) have lower Al content of 0.74%-1.96% (mass fraction), much lower than its additive amount of 4%, but, by contrast, dendrite edges (marked by D, E, F and H) have higher Al content of 4.05%-12.83%. These results indicate that the semi-continuous casting ingot has severe micro-segregation of Al, which is mainly caused by the wide solid-liquid-coexistence-zone of Mg-Al system.

Based on Tables 3 and 5, it can be seen that the homogenization of (380 °C, 8 h) + (410 °C, 12 h) cannot totally eliminate the micro-segregation of Al. Such micro-segregation of Al is the main reason for the mixed grain structure. During hot extrusion, Al-rich zones have higher deformation resistance than Al-poor zones because of solid solution strengthening effect of Al, so Al-poor zones have higher stain rate ( ) than Al-rich zones. Since extrusion temperature remains consistent, Al-poor zones have larger parameter Z than Al-rich zones. The relationship between the average diameter of DRX grains dDRX and Z is dDRX=kZ-n [2,10,11], where k and n are constants, thus Al-poor zones will have smaller dDRX than Al-rich zones.

) than Al-rich zones. Since extrusion temperature remains consistent, Al-poor zones have larger parameter Z than Al-rich zones. The relationship between the average diameter of DRX grains dDRX and Z is dDRX=kZ-n [2,10,11], where k and n are constants, thus Al-poor zones will have smaller dDRX than Al-rich zones.

On the other hand, during the direct extrusion, the outer of the billet bears additional shear stress which is derived from the friction between the outer material and the mold, so the outer of the bar has higher deformation degree than the center.

Fig. 8 SEM images of α-Mg dendrite in center (a) and outer (b) of ingot with detecting points for EDS analysis

Table 5 EDS results of α-Mg dendrites in different zones of ingot in Fig. 8

Figure 9 shows the formation of microstructure heterogeneity. It can be deduced that such mixed grain structure can be weakened by thorough refinement of dendrites or by further homogenization.

4.2 Mechanical property anisotropy and heterogeneity

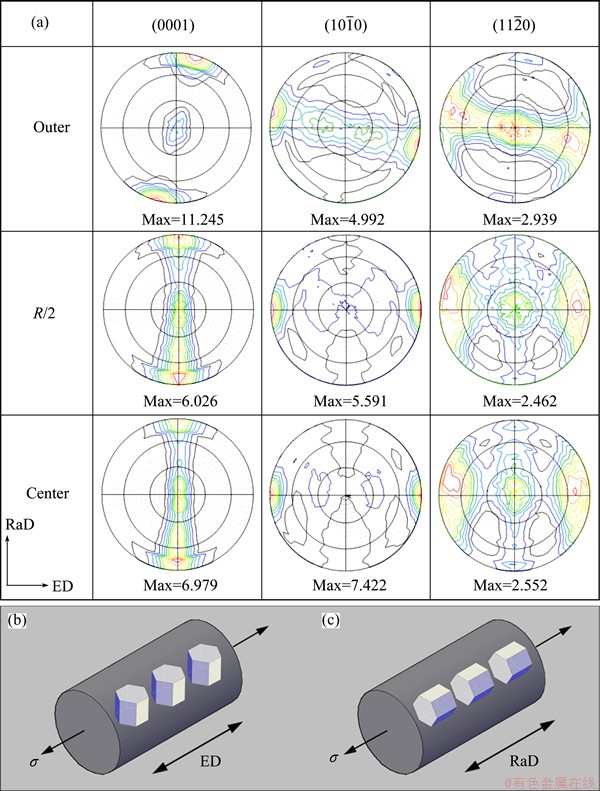

Table 4 and Fig. 6 show that the AZ40 bar with a diameter of 160 mm has mechanical property anisotropy and heterogeneity, which can be attributed to the intense texture. XRD macro-textures of the outer, R/2 and center in Fig. 10(a) show typical fiber texture characteristics, i.e., {0001}//ED and  //ED [10,16,18,19]. During the RT deformation of magnesium alloy, (0001)

//ED [10,16,18,19]. During the RT deformation of magnesium alloy, (0001) basal slip and

basal slip and  c-axis tensile twinning are the major plastic deformation mechanisms since they have much lower critical resolved shear stress (CRSS) than prismatic slip, pyramidal slip and

c-axis tensile twinning are the major plastic deformation mechanisms since they have much lower critical resolved shear stress (CRSS) than prismatic slip, pyramidal slip and  c-axis contraction twinning [12]. When ED samples are stretched, basal planes of most grains are parallel to tensile stress direction, as shown in Fig. 10(b), so both basal slip and c-axis tensile twinning are extremely hard to be activated, which is the reason why ED samples have much higher Rp0.2. On the other hand, when RaD samples are stretched, axes of most grains are parallel to tensile stress direction, as shown in Fig. 10(c), which is adverse to basal slip but favors c-axis tensile twinning, resulting in lower Rp0.2. Consequently, deformation texture is the key reason for mechanical property anisotropy.

c-axis contraction twinning [12]. When ED samples are stretched, basal planes of most grains are parallel to tensile stress direction, as shown in Fig. 10(b), so both basal slip and c-axis tensile twinning are extremely hard to be activated, which is the reason why ED samples have much higher Rp0.2. On the other hand, when RaD samples are stretched, axes of most grains are parallel to tensile stress direction, as shown in Fig. 10(c), which is adverse to basal slip but favors c-axis tensile twinning, resulting in lower Rp0.2. Consequently, deformation texture is the key reason for mechanical property anisotropy.

Fig. 9 Schematic diagram demonstrating formation of microstructure heterogeneity

Fig. 10 XRD macro-textures of outer, R/2 and center of extruded bar (a), relation between orientation of unit cell and tensile stress σ of ED (b) and RaD (c) samples

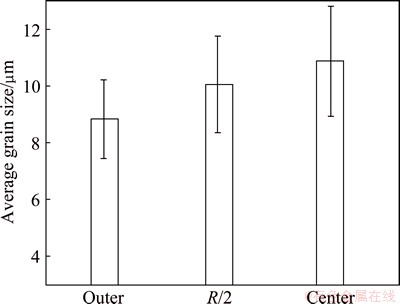

Table 4 demonstrates that ED-O samples have higher strength but lower elongation compared with ED-C samples. It can be seen from three (0001) pole figures in Fig. 10(a) that the orientation of [0001]//RaD has the maximum normalized intensity and the outer has the highest intensity of 11.245, which is about twice as large as those of the R/2 (6.026) and center (6.979). Consequently, it can be deduced that there are much more grains in the outer which has {0001}//ED orientation than in the center, and then during stretching along ED it is more difficult for basal slip and c-axis tensile twinning to be activated in the outer, resulting in higher strength but lower elongation of ED-O sample. Moreover, Fig. 11 shows that the average grain size rises from 8.8 to 10.9 μm from the outer to the center, indicating that the outer has higher deformation degree than the center. Based on the Hall-Petch equation, the yield strength of ED-O is higher than that of ED-C.

Fig. 11 Average grain sizes of different positions on cross section of extruded bar

After (155 °C, 7 h) + (170 °C, 24 h) aging treatment, precipitation reaction in Al-poor zones (fine grain zones) is especially weak and only fine and sparse β particles are precipitated at grain boundaries. In Al-rich zones (coarse grain zones), the precipitation reaction is also slow, that is, only at several places discontinuous β precipitates slightly grow into interiors. Consequently, the aging treatment has no strengthening effect. Since β particles only cover limited grain boundaries, stress concentration is hard to happen, and thus aging treatment does not decrease the elongation.

5 Conclusions

1) The AZ40 magnesium alloy bar with a diameter of 160 mm manufactured by “MDF + extrusion + online cooling” technique is of the mixed grain structure. Fine grain zones contain 3%-4%Al (mass fraction), but coarse grain zones contain about 6% Al. Such uneven Al distribution is inherited from the Al micro-segregation of the ingot. Dendrite interiors have 0.74%-1.96% Al (mass fraction), but dendrite edges possess 4.05%-12.83% Al (mass fraction). Homogenization cannot completely eliminate such micro-segregation. During MDF and extrusion, Al-rich and Al-poor zones undergo totally different DRX processes. Moreover, the outer of the bar suffers larger deformation degree than the center, so the outer and the center have different average grain sizes, morphologies of mixed grain structure and texture intensity.

2) The as-extruded AZ40 magnesium alloy bar has high elongation and moderate ultimate tensile strength, i.e., elongation of 19%-25% and ultimate tensile strength of 256-264 MPa; however, yield stress shows obvious anisotropy and heterogeneity, i.e., 103 MPa in RaD, 137 MPa in ED-C and 161 MPa in ED-O, which are mainly caused by the texture. (155 °C, 7 h) + (170 °C, 24 h) aging treatment has no influence on strength and elongation of the extruded bar.

3) XRD macro-textures of the outer, R/2 and center of the extruded bar show typical fiber texture characteristics, i.e., {0001}//ED and  //ED. In (0001) pole figures of all three places, [0001]//RaD orientation has the maximum normalized intensity, and the intensity of the outer (11.245) is about twice as large as those of the R/2 (6.026) and center (6.979), which is the main reason why ED-O samples have higher strength but lower elongation than ED-C samples.

//ED. In (0001) pole figures of all three places, [0001]//RaD orientation has the maximum normalized intensity, and the intensity of the outer (11.245) is about twice as large as those of the R/2 (6.026) and center (6.979), which is the main reason why ED-O samples have higher strength but lower elongation than ED-C samples.

References

[1] WANG Hai-lu, WANG Guo-jun, HU Lian-xi, WANG Qiang, WANG Er-de. Effect of hot rolling on grain refining and mechanical properties of AZ40 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S2): s229-s234.

[2] BEER A, BARNETT M. Microstructure evolution in hot worked and annealed magnesium alloy AZ31 [J]. Materials Science and Engineering A, 2008, 485(1-2): 318-324.

[3] SHAHZAD M, WAQAS H, RAFI-UD-DIN, QURESHI A H, WAGNER L. The roles of Zn distribution and eutectic particles on microstructure development during extrusion and anisotropic mechanical properties in a Mg–Zn–Zr alloy [J]. Materials Science and Engineering A, 2015, 620: 50-57.

[4] SHAHZAD M, QURESHI A, WAQAS H, RAFI-UD-DIN. Influence of pre- and post-extrusion heat treatments on microstructure and anisotropy of mechanical properties in a Mg-Al-Zn alloy [J]. Materials and Design, 2013, 51: 870-875.

[5] GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Effect of multiple forging on microstructure and mechanical properties of magnesium alloy AZ80 [J]. Acta Metallurgica Sinica, 2006, 42(7): 739-744. (in Chinese)

[6] LIU Chu-ming, LIU Zi-juan, ZHU Xiu-rong, ZHOU Hai-tao. Research and development progress of dynamic recrystallization in pure magnesium and its alloy [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 1-12. (in Chinese)

[7] XU Yan, HU Lian-xi, SUN Yu. Dynamic recrystallization kinetics of as-cast AZ91D alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1683-1689.

[8] DING H L, WANG T Y, YANG L, KAMADO S. FEM modeling of dynamical recrystallization during multi-pass hot rolling of AM50 alloy and experimental verification [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2678-2685.

[9] LI Jing-yuan, XIE Jian-xin, JIN Jun-bing, WANG Zhi-xiang. Microstructural evolution of AZ91 magnesium alloy during extrusion and heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1028-1034.

[10] TANG Wei-qin, HUANG Shi-yao, ZHANG Shao-rui, LI Da-yong, PENG Ying-hong. Influence of extrusion parameters on grain size and texture distributions of AZ31 alloy [J]. Journal of Materials Processing Technology, 2011, 211(7): 1203-1209.

[11] FATEMI-VARZANEH S, ZAREI-HANZAKI A, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2007, 456 (1-2): 52-57.

[12] PEKGULERYUZ M, KAINER K, KAYA A. Fundamentals of magnesium alloy metallurgy [M]. Cambridge: Woodhead Publishing, 2013: 42-73.

[13] LI Hui-zhong, WEI Xiao-yan, OUYANG Jie, JIANG Jun, LI Yi. Hot deformation behavior of extruded AZ80 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3180-3185.

[14]  Wen-quan, QUAN Guo-zheng, YU Chun-tang, ZHAO Lei, ZHOU Jie. Effect of strain, strain rate and temperature on workability of AZ80 wrought magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S3): s650-s655.

Wen-quan, QUAN Guo-zheng, YU Chun-tang, ZHAO Lei, ZHOU Jie. Effect of strain, strain rate and temperature on workability of AZ80 wrought magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S3): s650-s655.

[15] THIRUMURUGAN M, KUMARAN S. Extrusion and precipitation hardening behavior of AZ91 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1595-1601.

[16] CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11. (in Chinese)

[17] XIAO Li-long, XIAO Han-xi. Aluminium alloy tubes, bars and profiles produced by casting and extrusion [M]. Beijing: Metallurgical Industry Press, 2013: 86-92. (in Chinese)

[18] SADEGHI A, PEKGULERYUZ M. Recrystallization and texture evolution of Mg-3%Al-1%Zn-(0.4-0.8)%Sr alloys during extrusion [J]. Materials Science and Engineering A, 2011, 528(3): 1678-1685.

[19] SHAHZAD M, WAGNER L. Influence of extrusion parameters on microstructure and texture developments, and their effects on mechanical properties of the magnesium alloy AZ80 [J]. Materials Science and Engineering A, 2009, 506(1-2): 141-147.

[20] ZARANDI F, SEALE G, VERMA R, ESSADIQI E, YUE S. Effect of Al and Mn additions on rolling and deformation behavior of AZ series magnesium alloys [J]. Materials Science and Engineering A, 2008, 496(1-2): 159-168.

石国梁,张 奎,李兴刚,李永军,马鸣龙,袁家伟,卢春芳

北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088

摘 要:采用“多向锻造(MDF)+挤压+在线冷却”技术制备的AZ40(直径为160 mm)镁合金棒材具有混晶组织和力学性能各向异性,通过光学显微镜(OM)、扫描电镜(SEM)、X射线衍射织构测量和室温拉伸试验对上述特征进行表征和分析。结果表明:混晶组织来源于半连续铸锭中Al的微观偏析。均匀化处理((380 °C, 8 h)+(410 °C, 12 h))不能完全消除这种微观偏析。在后续MDF和挤压过程中,Al含量为3%~4%(质量分数)的枝晶心部转变成细晶区,而Al含量约为6%的枝晶边缘转变成粗晶区。表层、R/2和心部的XRD宏观织构都呈现典型的纤维织构特征,且表层的[0001]//RaD取向强度(11.245)约为R/2处(6.026)和心部(6.979)的两倍。挤压态AZ40镁合金棒材沿挤压方向和半径方向具有优异的伸长率(A)和中等抗拉强度(Rm):A为19%~25%,Rm为256~264 MPa;然而,屈服强度(Rp0.2)呈现出各向异性和内外不均匀性,即RaD为103 MPa,ED-C(心部)为137 MPa,ED-O(边部)为161 MPa,这主要是织构造成的。(155 °C, 7 h) + (170 °C, 24 h)时效处理对AZ40镁合金棒材的强度和伸长率几乎没有影响。

关键词:AZ40镁合金;混晶组织;力学性能;各向异性;微观偏析;织构

(Edited by Wei-ping CHEN)

Foundation item: Project (2013CB632202) supported by the National Basic Research Program of China

Corresponding author: Guo-liang SHI; Tel: +86-10-82241163; E-mail: shigl@grinm.com

DOI: 10.1016/S1003-6326(15)64042-0