Trans. Nonferrous Met. Soc. China 22(2012) 1674-1679

Microstructural examination and mechanical properties of replicated aluminium composite foams

Ekkapak WICHIANRAT1, Yuttanant BOONYONGMANEERAT2, Seksak ASAVAVISITHCHAI1

1. Department of Metallurgical Engineering, Faculty of Engineering, Chulalongkorn University,Bangkok 10330, Thailand;

2. Metallurgy and Materials Science Research Institute (MMRI), Chulalongkorn University,Bangkok 10330, Thailand

Received 17 October 2011; accepted 29 April 2012

Abstract: Open-cell aluminium foams can be produced with the structural replication of dimensional accuracy from polymeric foam patterns through a pressure infiltration casting process. The strength of open-cell foam is much less than that of the closed-cell counterpart, and thereby subjects to mainly functional applications. An improvement in mechanical properties of the foams can be implemented with the addition of ceramic particles. In the present study, the composite foams were produced using AC3A alloy added with varying contents of SiC particles. The resultant foams have ceramic particles embedded in the alloy matrix and on the strut surface. Higher volume fraction of ceramic particles resulted in an increase in the compressive strength, energy absorption and microhardness of the foams. The improvement of these properties is due to the modification of the microstructure of the foams and the increased strength in the node and struts at which the ceramic particles reside.

Key words: aluminium; metallic foam; pressure infiltration; investment casting

1 Introduction

Metallic foams are a relatively new class of materials that offer the possibility of reducing the density of materials while maintaining a high level of mechanical integrity [1]. Owing to a combination of their appealing properties, including high surface area and high specific strength, they have received much interest both in research and in industrial contexts, and have recently found use in many advanced structural and functional applications. Metallic foams are generally classified into two types: open-cell and closed-cell foams. The open-cell foams refer to those with interpenetrating pores, while the closed-cell ones contain pores that are not interconnected. Typically, the closed-cell foams exhibit relatively high compressive strength, and therefore, they are used in applications that require high strength and high energy absorption, such as automotive bumper and body armor applications [2-4]. On the other hand, the open-cell foams can be utilized in a wide variety of applications that benefit from the presence of interpenetrating pores and high internal surface areas of foam materials [5-7]. Good examples of such applications include heat exchangers, bone-replacement implants, interconnects, catalyst supports, and sound insulators.

Among all types of metallic foams, aluminium (Al) foams with open-cell structures have attracted much attention [8-11]. This is partly due to the commercial need for ultra-light, interpenetrating-pore structures combined with the feasibility of low-temperature processing provided by the materials. However, with relatively low intrinsic strength and modulus of aluminium, coupled with interconnected-pore structures, the use of open-cell Al foams in many cases is only limited to low-stress applications, unlike its closed-cell counterparts. Furthermore, Al and other metals in general are known to exhibit relatively large thermal expansion. When metallic foams are used in conjunction with ceramic materials at an elevated temperature, such as in the interconnect applications, the relatively high thermal expansions of the metals would be problematic, causing thermal stress which may lead to failures of the components.

One of the possible approaches to improve and tailor physical and thermal properties of Al foams is to reinforce the base cell wall materials with ceramic particles, resulting in porous Al foams whose struts exhibit metal matrix composite structures. Silicon carbide (SiC) is a ceramic material with high hardness and high wear resistance which stands as a good candidate for reinforcement for Al. Studies have shown that when SiC particles are introduced to monolithic Al, mechanical properties, such as tensile strength, yield strength, and specific stiffness, are significantly improved over those of pure Al or Al alloys [12,13].

There present some studies of closed-cell Al-SiC foams, to our knowledge, but a study on the fabrication process of open-cell Al-alloy metal matrix foams, including Al-SiC foams, has not been carried out. The objective of this work is therefore to develop Al foam composites containing SiC particles, by the replication pressure infiltration casting process, and to study the influence of particle addition on structure and mechanical properties of the foams.

2 Experimental

Open-cell Al foam samples were fabricated using commercial reticulated open-cell polyurethane (PU) foam as preform. PU foams (obtained from Sydney Heath & Son, UK) with pore sizes of 2.12 mm were invested with plaster of Paris and pyrolyzed in a resistant furnace at 500 ℃ in air for 10 h to completely eradicate the polymer foams and strengthen the plaster mold. AC3A alloy (obtained from Daiki Auminium Industry, Thailand) was melted in an alumina crucible at 700 ℃ for 1 h and SiC particles (obtained from MTEC) were added at amounts of 1%-5% (mass fraction), and rigorously stirred by hand for 5 min before cooling in air. The mixture was remelted and infiltrated into the plaster mold placed in an old moon BU 450 vacuum system machine at 1000 ℃ with a pressure of 100 kPa from 99.99% purity Ar gas. After infiltration, the molds were disintegrated by repetitively quenching in water for 10 min and further cleaned by water jet. Finally, the samples were cleaned in ultrasonic bath filled with acetone. The samples were sectioned into a cubic shape of 20 mm, using precisely cutting machine to eliminate surface defects associated with processing and handling and to ensure flat and parallel surfaces for testing. Net sample densities were determined by measuring dry mass and dimensions. Characterization of SiC particle size was carried out using Mastersizers particle size laser analyzer. Chemical compounds of AC3A alloy were determined using X-ray fluorescence (XRF). Characterization of the foam samples was conducted using optical and scanning electron microscopy (SEM). Compressive testing was performed on the samples using an Instron 5567 universal mechanical testing machine at a crosshead speed of 0.5 mm/min. The microhardness of the foam samples was measured using a HM-100 Mitutoyo microhardness tester. Each datum reported is an average of five measurements.

3 Results and discussion

3.1 Materials

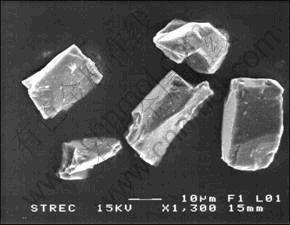

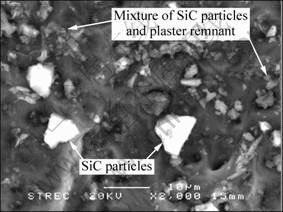

The morphology of SiC particles is presented in Fig. 1. The shape of ceramic particles is irregular and no agglomeration of the particles is observed. The ceramic particles have a mean diameter of 5.38 μm and D10, D50 and D90 of 0.06, 0.1 and 19.78 mm, respectively. The analysis of particle size distribution suggests that most ceramic particles are not larger than 20 mm and more than 50% of the particles are smaller than the mean value. The chemical composition of AC3A alloy is shown in Table 1. It can be seen that the major alloying element of this alloy is Si, which has the composition close to the eutectic point in the Al-Si binary phase diagram.

Fig. 1 Morphology of SiC particles

Table 1 Chemical composition of AC3A sample (mass fraction, %)

3.2 Foam structure

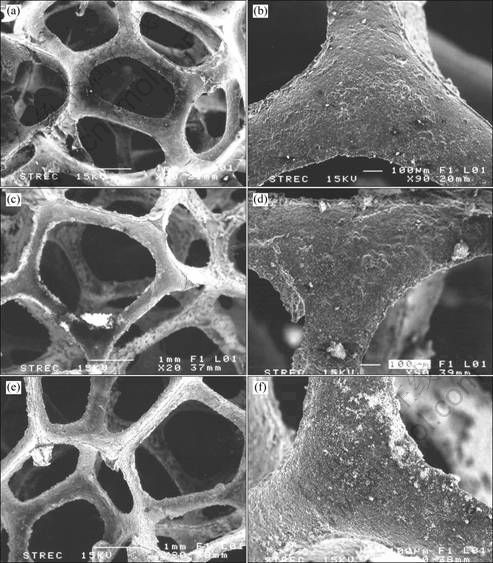

Figure 2 presents the structures of pure AC3A and composite foams containing 1% and 5% SiC particles. In all cases, the composite foams well replicate the cellular structure, strut and pore architectures of the PU foams. The struts are rather linear with concave-triangular cross section. There are some visible defects in the foam structure such as partial infiltration region and broken struts. The uncompleted investment casting coupled with retained plaster resulted in an increase in the surface roughness of struts. Using pressurised water jet to remove the remaining plaster from the foam structure could also lead to the rupture of struts. However, no major defects, such as strut buckling, twisting or rotation, were detected.

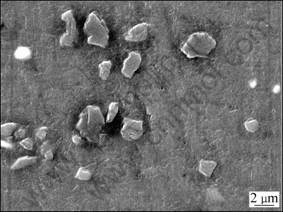

For pure AC3A foam, no ceramic particle was present on the surface of strut. The foam with l% SiC has a small amount of ceramic particles on its strut surface. More amount of ceramic particles were found on the strut surface of the foam with 5% SiC, as shown in Fig. 3. Higher ceramic particle addition resulted in more particle attachment to the strut surface. Using an image analyzer, the area fractions of the ceramic particles are determined to be 1.2%, 2.0%, 2.8%, 3.6% and 4.8% for the particle loading of 1%, 2%, 3%, 4% and 5%, respectively. It is also observed that the distribution of SiC particles on the strut surface is not homogenous. The ceramic particles are partly immersed into the strut, exposing sharp edges in air, and mainly distribute along the edge of concave strut surface. Furthermore, large ceramic particles are isolated while small particles tend to form a cluster. Agglomeration of fine ceramic particles is to reduce the surface energy of the system. There are also some ruptured plaster remnants attached to the surface. In the present work, it is difficult to remove completely the fractured plasters, particularly at a very small size, from the strut surface.

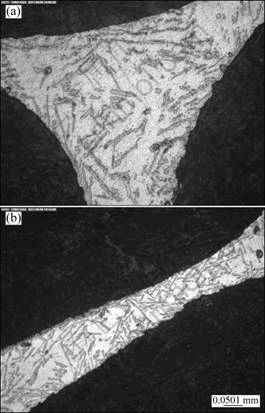

Figure 4 shows the cross-sectional cellular node and strut structure of AC3A composite foam with 2% particle contents. SEM micrographs of foam structure at a node and strut are presented in Fig. 5. The microstructure shows a coarse dendritic structure with an acicular type of eutectic Si. No major defect is observed. The distribution of particles is rather uniform. A small amount of particle agglomeration in the matrix is observed.

Fig. 2 SEM micrographs showing structures of pure AC3A and composite foams containing 1% and 5% SiC particles: (a), (b) Pure AC3A; (c), (d) AC3A+1%SiC; (e), (f) AC3A+5%SiC

Fig. 3 SEM micrograph showing attachment of SiC particles on strut surface of Al foams with 5% SiC particles

Fig. 4 Optical micrographs showing cross-sectional structure of AC3A composite foam containing 2% SiC particles at node (a) and strut (b)

Embedding of SiC particles in Al alloy matrix is observed in the composite foam, as shown in Fig. 6. No clear segregation of SiC particles is observed, suggesting a relatively good wettability of the ceramic particles by the melt. An improvement of wettability is thought to be the effect of dissolved Si from Al-Si alloy which can decrease the wetting angle between the SiC particles and the melt. The dissolution of Si also can hinder the formation of intermetallic layer of Al4C3 as a result of the chemical reaction between SiC and the melt [14].

3.3 Mechanical properties

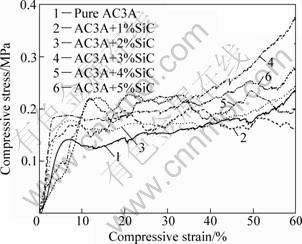

Figure 7 presents the compressive strength of AC3A and composite foams with different ceramic particle contents. The compressive plots, in all cases, show a plastic semi-plateau region, which is similar to other open-cell Al foams [4,6,11]. Plots with irregular profiles indicate that the foams are brittle. Of equivalent density to the pure AC3A foam, all composite foams have higher yield strength and larger energy absorption, for a given strain. Generally, the strength and energy absorbability of the foams increase with increasing particle contents. The improvement of these properties is due to the modification of the microstructure of the foams and the increased strength in the node and struts at which the SiC particles reside.

Fig. 5 SEM micrographs showing cross-sectional structure of AC3A composite foam containing 2% SiC particles at node (a) and strut (b)

Fig. 6 SEM micrographs showing SiC particles embedded in matrix of composite foam

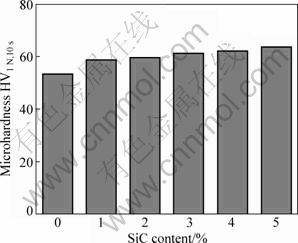

Figure 8 shows the microhardness of composite foams with various SiC particle contents. It is clear that the microhardness values increase as the ceramic particle content increases. This is due to the increase in the volume fraction of hard SiC particles in the matrix. The increase in foam microhardness results in an increase in brittleness of the foams, which is present in the oscillating configuration of compressive stress—strain plots in Fig. 7. The oscillation tends to be wider when the foams have higher volume fraction of ceramic particles.

Fig. 7 Compressive behavior of composite foams added with SiC particles at various contents

Fig. 8 Microhardness values of composite foams added with SiC particles at various contents

Different from closed-cell metallic foams at which the addition of ceramic particles is mainly used for an improvement in foam expansion and stability [15,16], due to lower drainage and cell coalescence influenced by increasing bulk viscosity and decreasing surface tension, the objective of ceramic particle addition in open-cell foams in this fabrication method is solely for an improvement in mechanical properties of the foams. In fact, an increase in the viscosity of molten alloy, due to the dispersion of ceramic particles in the melt, hinders the melt flow through constricted passages in mold cavity during infiltration casting process. With a higher volume fraction of ceramic particles in the molten alloy, the melt flow is even more difficult. This can result in unfilled mold cavity. It is, therefore, necessary to increase either the infiltration pressure, to drive the melt into the mold, or the casting temperature, to reduce the viscosity, in order to fill up the mold cavity.

The present work demonstrated that production of open-cell composite foams with ceramic particles through pressure infiltration casting technique is successfully achieved and could lead to developments of other types of composite foams used in various structural and functional applications that require high material performance.

4 Conclusions

1) Open-cell Al alloy composite foams with 1%-5% SiC particles have been successfully produced using pressure infiltration casting method with polyurethane preform.

2) The resultant composite foams well-replicate the cellular structure, strut and pore architectures of the PU foams and have ceramic particles embedded in the alloy matrix and on the strut surface.

3) The small ceramic particles tend to form clusters in the matrix, along the strut surface.

4) Higher ceramic particle addition leads to higher volume fraction of the particles both in the matrix and on the strut surface, and results in the increased improvement of the compressive strength, energy absorption and microhardness of the foams.

5) The improvement of these properties is due to the modification of the microstructure of the foams and the increasing strength in the node and struts at which the ceramic particles reside.

Acknowledgements

The authors are gratefully acknowledged for a research grant ‘The 90th Anniversary of Chulalongkorn University Fund (Ratchadaphiseksomphot Endowment Fund)’ for the present research work.

References

[1] BANHART J. Manufacture, characterisation and application of cellular metals and metal foams [J]. Progress in Materials Science, 2001, 46(6): 559-632.

[2] BANHART J. Aluminium foams for lighter vehicles [J]. International Journal of Vehicle Design, 2005, 37(2-3): 114-125.

[3] MUKAI T, MIYOSHI T, NAKANO S, SOMEKAWA H, HIGASHI K. Compressive response of a closed-cell aluminum foam at high strain rate [J]. Scripta Materialia, 2006, 54: 533-537.

[4] ANDREWS E, SANDERS W, GIBSON L J. Compressive and tensile behaviour of aluminum foams [J]. Materials Science and Engineering A, 1999, 270(2): 113-124.

[5] BROTHERS A H, SCHEUNEMANN R, DEFOUW J D, DUNAND D C. Processing and structure of open-celled amorphous metal foams [J]. Scripta Materialia, 2005, 52(4): 335-339.

[6] POLLIEN A, CONDE Y, PAMBAGUIAN L, MORTENSEN A. Graded open-cell aluminium foam core sandwich beams [J]. Materials Science and Engineering A, 2005, 404(1-2): 9-18.

[7] DESPOIS J F, MORTENSEN A. Permeability of open-pore microcellular materials [J]. Acta Materialia, 2005, 53(5): 1381-1388.

[8] QUADRINI F, GUGLIELMOTTI A, SQUEO E A, TAGLIAFERRI V. Laser forming of open-cell aluminium foams [J]. Journal of Materials Processing Technology, 2010, 210(11): 1517-1522.

[9] JAMSHIDI-ALASHTI R, ROUDINI G. Producing replicated open-cell aluminum foams by a novel method of melt squeezing procedure [J]. Materials Letters, 2012, 76: 233-236.

[10] BOOMSMA K, POULIKAKOS D, ZWICK F. Metal foams as compact high performance heat exchangers [J]. Mechanics of Materials, 2003, 35(12): 1161-1176.

[11] MARCHI S C, MORTENSEN A. Deformation of open-cell aluminum foam [J]. Acta Materialia, 2001, 49(19): 3959-3969.

[12] LLOYD D J. Particle reinforced aluminium and magnesium matrix composites [J]. International Materials Reviews, 1994, 39(1): 1-23.

[13] RAY S. Synthesis of cast metal matrix particulate composites [J]. Journal of Materials Science, 1993, 28(20): 5397-5413.

[14] GERGELY V, DEGISCHER H P, CLYNE T W. Recycling of MMCs and production of metallic foams [J]. Comprehensive Composite Materials, 2000, 3: 797-820.

[15] KENNEDY A R, ASAVAVISITHCHAI S. Effects of TiB2 particle addition on the expansion, structure and mechanical properties of PM Al foams [J]. Scripta Materialia, 2004, 50(1): 115-119.

[16] ESMAEELZADEH S, SIMCHI A, LEHMHUS D. Effect of ceramic particle addition on the foaming behavior, cell structure and mechanical properties of P/M AlSi7 foam [J]. Materials Science and Engineering A, 2006, 424(1-2): 290-299.

浸渍法制备泡沫铝的显微组织和力学性能

Ekkapak WICHIANRAT1, Yuttanant BOONYONGMANEERAT2, Seksak ASAVAVISITHCHAI1

1. Department of Metallurgical Engineering, Faculty of Engineering, Chulalongkorn University,Bangkok 10330, Thailand;

2. Metallurgy and Materials Science Research Institute (MMRI), Chulalongkorn University,Bangkok 10330m Thailand

摘 要:利用聚合物泡沫采用压力浸渗铸造工艺制备开孔泡沫铝。所制备的泡沫铝能够很好地复制聚合物泡沫的几何尺寸。开孔泡沫铝的强度比闭孔泡沫铝的低很多,从而得到更多的应用。添加陶瓷颗粒可以改善泡沫铝的力学性能。本研究中,向AC3A铝合金中添加SiC颗粒得到复合材料泡沫。在复合材料泡沫中,SiC颗粒嵌入在合金基体中及孔筋表面。高体积分数的陶瓷颗粒使合金泡沫铝的压缩强度、能量吸收、显微硬度增大。这些性能的改善归结为于泡沫铝的结构改变以及SiC颗粒存在于结点和孔筋处而引起的强度增加。

关键词:铝;泡沫金属;压力渗透;熔模铸造

(Edited by YANG Hua)

Corresponding author: Seksak ASAVAVISITHCHAI; Tel: +66-2-218 6938; Fax: +66-2-218 6942; E-mail: fmtsas@eng.chula.ac.th

DOI: 10.1016/S1003-6326(11)61372-1