SIMA法制备AM60B镁合金球晶组织及触变成形

来源期刊:中国有色金属学报(英文版)2012年第z2期

论文作者:王丽萍 姜文勇 陈 添 冯义成 周洪宇 赵思聪 梁镇强 朱 言

文章页码:435 - 444

关键词:镁合金;组织;力学性能;触变成形;部分重熔;往复挤压;半固态

Key words:magnesium alloy; microstructure; mechanical properties; thixoforming; partial remelting; cyclic extrusion compression; semi-solid state

摘 要:通过应变诱导熔化激活法制备半固态AM60B镁合金,并研究其组织演变。分别采用往复挤压-镦粗(CEC法)和传统压缩预成形铸态AM60B镁合金,并在半固态区间部分重熔和触变成形。结果表明,CEC态镁合金的粗晶组织消失,出现细小晶粒组织,但是压缩态合金的粗晶和再结晶晶粒共存。在局部重熔过程中,CEC态合金获得理想的细晶组织,完全球化的晶粒被液相均匀包裹。在压缩态合金中,多边形晶粒在一定程度上球化,但是之前不规则的形状仍然明显存在。CEC加上二次重熔触变成形的AM60B镁合金,其力学性能优于压缩态加上二次重熔触变成形的镁合金的。

Abstract: The microstructure development in the semi-solid state of AM60B magnesium alloy prepared by strain induced melt activation (SIMA) was described. In the SIMA route, cyclic extrusion compression (CEC) and conventional compression were used to predeform as-cast AM60B, respectively. Partial remelting and thixoforming were also carried out within the semi-solid zone. The results showed that coarse-grained structure disappeared and a fine-grained structure resulted in the CEC formed alloy. However, coarse grains and recrystallized grains co-existed in the compression formed alloy. During partial remelting, the alloy treated by CEC exhibited ideal, fine microstructure, in which completely spheroidized grains contain little entrapped liquid. Polygonal grains were spheroidized to some extent but the previous irregular shape was still obvious in the compression formed alloy. The mechanical properties of the thixoformed AM60B produced by CEC plus partial remelting were better than those of the thixoformed alloy produced by compression plus partial remelting.

Trans. Nonferrous Met. Soc. China 22(2012) s435-s444

WANG Li-ping, JIANG Wen-yong, CHEN Tian, FENG Yi-cheng, ZHOU Hong-yu, ZHAO Si-cong, LIANG Zhen-qiang, ZHU Yan

College of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China

Received 28 August 2012; accepted 25 October 2012

Abstract: The microstructure development in the semi-solid state of AM60B magnesium alloy prepared by strain induced melt activation (SIMA) was described. In the SIMA route, cyclic extrusion compression (CEC) and conventional compression were used to predeform as-cast AM60B, respectively. Partial remelting and thixoforming were also carried out within the semi-solid zone. The results showed that coarse-grained structure disappeared and a fine-grained structure resulted in the CEC formed alloy. However, coarse grains and recrystallized grains co-existed in the compression formed alloy. During partial remelting, the alloy treated by CEC exhibited ideal, fine microstructure, in which completely spheroidized grains contain little entrapped liquid. Polygonal grains were spheroidized to some extent but the previous irregular shape was still obvious in the compression formed alloy. The mechanical properties of the thixoformed AM60B produced by CEC plus partial remelting were better than those of the thixoformed alloy produced by compression plus partial remelting.

Key words: magnesium alloy; microstructure; mechanical properties; thixoforming; partial remelting; cyclic extrusion compression; semi-solid state

1 Introduction

Magnesium alloys are being increasingly used in electronics, automobile and aerospace industries because of their low density, high specific strength and excellent machineability [1-6]. Although high pressure die casting (HPDC) is the dominant method in manufacturing components of magnesium alloys, semi-solid processing offers significant advantages over HPDC because of near-net shape processing, better mechanical properties, less energy consumption and longer die life [7]. Thixoforming belongs to semi-solid processing and describes the process where suitable material is heated into the semi-solid state and then is held into the die for processing [8,9]. Subsequently, the material in the semi-solid state is extruded to form components. For thixoforming to be possible, the microstructure of the starting material must be non-dendritic [10]. There are various routes to achieve this, including mechanical stirring, magnetohydrodynamic stirring, sprayforming, near-liquidus casting, cooling slope, semi-solid thermal transformation (SSTT), strain induced melt activation (SIMA) and recrystallization and partial remelting (RAP). These are summarized by ATKINSON [11]. The SIMA process involves severe hot working producing directional grain structure in the alloy. A critical level of strain must be introduced into the alloy either as an integral part of the hot working, or by cold working as a separate step subsequent to the hot working, prior to heating to above the solidus temperature[12,13]. In the RAP process, material which has been worked, such as by extrusion at temperatures below the recrystallization temperature, is then reheated into the semi-solid state [14]. The main similarity between the SIMA process and the RAP process is that a critical level of strain must be introduced into the material through deformation. Clearly, the difference between the SIMA and RAP processes is the deformation temperature, hot working opposed to warm working.

Several researchers [15-17] have reported the microstructural evolution of SIMA processed magnesium alloys. CHEN et al [15] have conducted on repetitive upsetting-extrusion as a SIMA process for AZ80 magnesium alloy semi-solid processing. The results showed that solid grain size decreased and the rate of liquation was improved with increasing number of RUE passes. Prolonging holding time resulted in grain coarsening and the improvement of degree of spheroidization. The variation of the solid grains with holding time obeyed the Lifshitz, Slyozov and Wagner law. LUO et al [16] have reported the effects of isothermal temperature and isothermal holding time on the semi-solid microstructures of AZ91D alloys prepared by the SIMA route. The results indicated that recrystallization first occurred in deformed areas and increasing isothermal temperature shortened the time of complete recrystallization in the semi-solid state. JI et al [17] reported the formation process of AZ31B semi-solid microstructures through the SIMA process. They found that increasing the heating temperature could accelerate the spheroidizing process, resulting in semi-solid microstructures containing small spheroidal particles; with a longer holding time, the solid content slightly changed and the solid particles became irregular in shape. Although many researchers [15-17] have reported semisolid processing of magnesium alloys, including AZ80, AZ91D, AZ31B, only limited work has been reported on semi-solid processing of AM60B magnesium alloy [18].

In the SIMA process, conventional compression was used to predeform as-cast magnesium alloy. However, due to the limited degree of deformation, the microstructure treated by compression was in-homogeneous, which exerted disadvantage influences on the formation of spheroidal grains and mechanical properties of final components [19-21]. To overcome this disadvantage mentioned above, the cyclic extrusion compression (CEC) process was firstly introduced by CHEN et al [15] into a SIMA process for semi-solid forming. Because magnesium alloys are subjected to severe plastic deformation (SPD), fine, spherical and homogeneous solid grains are obtained during partial remelting.

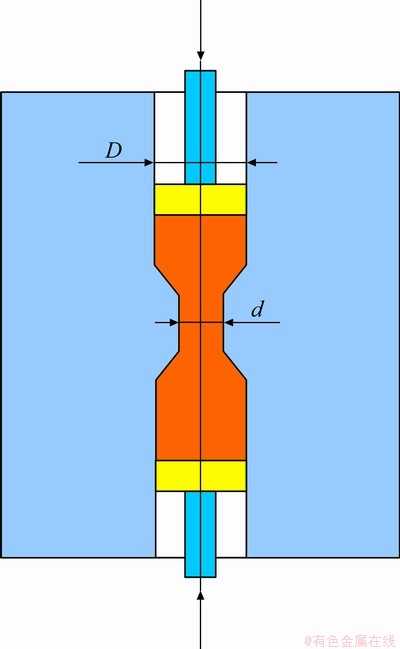

The CEC process is a promising technique to induce a great strain in bulk metals. The principle of the CEC process is represented schematically in Fig. 1. In the CEC process, a sample is contained within a chamber and then extruded repeatedly backwards and forwards. This process was invented to allow arbitrarily large strain deformation of a sample with preservation of the original sample shape after n passes. The accumulated equivalent strain is approximately given by

(1)

(1)

where D is the chamber diameter; d is the channel diameter; n is the number of deformation cycles. Since the billet in the CEC process is compressed from the both ends, a high hydrostatic pressure is imposed.

Fig. 1 Schematic of cyclic extrusion compression (CEC)

Based on the above analysis, the present paper aims to employ CEC and conventional compression to predeform as-cast AM60B magnesium alloy in the SIMA process. The microstructural evolution of AM60B magnesium alloy treated by CEC and compression during partial remelting is studied. Furthermore, this paper also presents recent new results on mechanical properties of AM60B magnesium alloy thixoformed from the starting material treated by CEC and conventional compression after partial remelting.

2 Experimental

The feedstock material used in the present study was an cast AM60B magnesium alloy with the measured composition (mass fraction, %) of 6.2Al, 0.31Mn and 0.12Zn. The as-cast AM60B magnesium alloy was machined into billets with a diameter of 80 mm and a length of 160 mm for CEC. Therefore, the true strain of the billet for a single CEC operation, which includes extrusion and compression, was 2.77 according to equation (1). Before CEC, as-cast AM60B billets were preheated at 380 °C for 60 min. A heating jacket was put around the die, and the extrusion temperature was controlled within ±5 °C of the set temperature. During CEC, the die was first set as 380 °C; the samples were then inserted into the die, staying in the die for about 3 min to allow the samples to reach 380 °C. Both the die and billets were lubricated with molybdenum disulphide (MoS2). As-cast billets were processed two passes and the true strain of the billet treated by two-pass CEC was 5.54. For comparison, some as-cast billets were subjected to deformation by compression at 380 °C with a compression ratio of 50%. The compression ratio was defined as the relative reduction of height of the sample, which was (H0-H)/H0, where H0 is the original height and H is height after compression. Therefore, the true strain of the billet treated by compression was 0.69.

The solidus and the liquidus temperatures for the AM60B magnesium alloy were obtained at 540 °C and 618 °C from a differential scanning calorimetry (DSC) experiment at 5 °C/min. Theoretical solid fractions were calculated according to the Scheil equation [22]:

(2)

(2)

where Tm is the melting temperature of pure metal, TL is the liquidus temperature of the alloy and k0 is the equilibrium distribution coefficient.

In this study, Tm, TL and k0 are taken as 650 °C, 618 °C and 0.34, respectively. Therefore, the expected solid fraction (fs) of AM60B magnesium alloy was 0.70 at 580 °C. The partial remelting experiments were carried out to gain some insight into the microstructural development. The microstructure evolution during partial remelting was done on CEC and compression formed samples with a diameter of 10 mm and a length of 15 mm. The samples were heated into the semi-solid state in a vertical infrared tube under a protective gas flow (argon atmosphere), isothermally held and quenched in water to 0 °C. A thermocouple placed in a hole of 1 mm in diameter and 5 mm in depth in the centre of the sample ensured accurate temperature measurement and feedback control. After the predetermined holding time, the sample was immersed into the quencher.

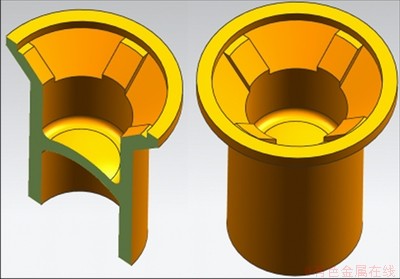

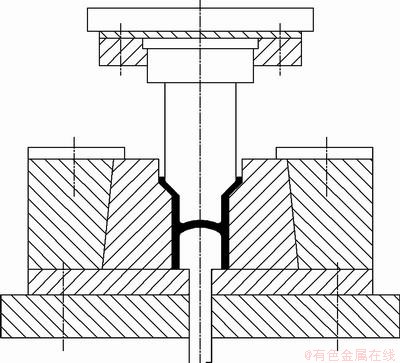

Before thixoforming, the CEC and compression formed billets were machined into some bars with a diameter of 60 mm and a length of 70 mm. The diagrammatic sketch of component is shown in Fig. 2. The die used in thixoforming is shown in Fig. 3. Thixoforming was carried out on an oil hydraulic press. The temperature of the slug was monitored by a K-type thermocouple embedded in the slug. After the required temperature was reached, the thermocouple was removed and the heated slug was held into the cartridge receiver die for thixoforming. The bar was heated in an argon gas environment to reduce oxidation. The preheating of bar was carried out at 580 °C for 10 min isothermal holding. The preheating temperature of die used for thixoforming was 350 °C. The speed rate of punch was about 15 mm/s to prevent the heating loss of billets in the semi-solid state.

Fig. 2 Diagrammatic sketch of component

Fig. 3 Diagrammatic sketch of die used in thixoforming

Preparation of metallographic sample consisted of grinding with SiC paper of different fineness and subsequently polishing with 3 μm and 1 μm-diamond paste and colloidal 0.05 μm-alumina. The microstructural characterization was carried out using imaging system software connected to an optical microscope. Samples for tensile testing were machined from the side wall of thixoformed components and were tested using an Instron 5569 material testing machine at a cross head speed of 1 mm/min. Mean size and shape factor (F) of solid grains were calculated in each case by Eqs. (3) and (4) [23-25],

(3)

(3)

(4)

(4)

where A and P are area and perimeter of grains respectively; N is the number of grains.

3 Results and discussion

3.1 Microstructure formed by CEC and compression

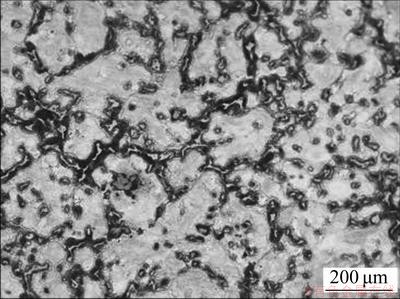

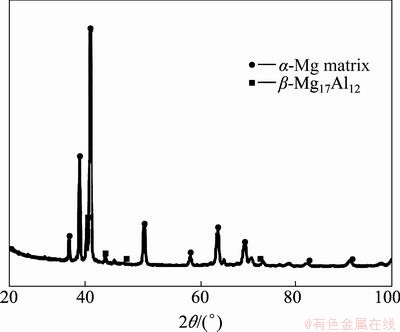

Figure 4 shows the microstructure of as-cast AM60 magnesium alloy. The microstructure of as-cast AM60 magnesium alloy consisted of α-Mg matrix and eutectic compounds. The eutectic compounds precipitated as discontinuous network at grain boundaries. Eutectic compounds precipitated as discontinuous network at grain boundaries. XRD analysis indicates that as-cast AM60B magnesium alloy consisted of α-Mg matrix and β-Mg17Al12 phase (Fig. 5).

Fig. 4 Microstructure of as-cast AM60 magnesium alloy

Fig. 5 XRD pattern of as-cast alloy

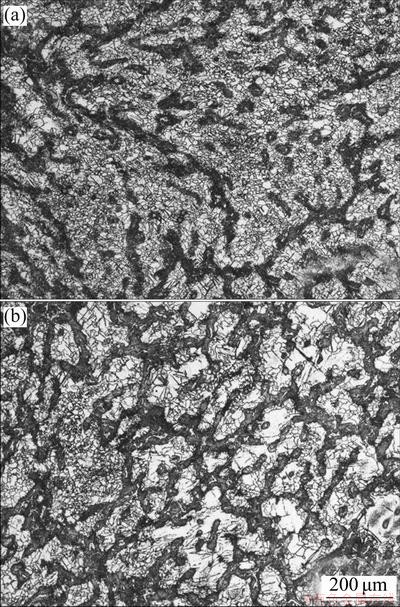

Figure 6 shows the microstructure of CEC and compression formed AM60B magnesium alloys. Compared Fig. 4 with Fig. 6(a), it is indicated that coarse-grained structure disappeared and a fine-grained structure resulted in the CEC formed alloy, which indicated that dynamic recrystallization had been completed. However, in the compression formed alloy, a large number of fine grains appeared at the initial grain boundaries, especially at triple junctions, which indicated the occurrence of dynamic recrystallization during hot compression. Furthermore, non-recrystallized regions of old grains remained and the mean grain size was about 50 μm. Therefore, the refinement of grains was initially not uniform, as there were coarse grains surrounded by fine ones. This was “bimodal” microstructure and was also observed by CHEN et al [26]. Note that after CEC or compression, eutectic compounds were deformed. Magnesium alloys contained high level of aluminum, e.g.>3% Al (mass fraction), and the grain boundaries were often obscured by the eutectic phase. The eutectic phase, Mg17Al12, was created by non-equilibrium solidification. Processing temperature was within the single-phase field α-Mg for the investigated AM60B magnesium alloys and the intermetallic Mg17Al12 got partially dissolved [27]. However, the time was too short to allow complete homogenization during processing, namely, segregation was only reduced but not eliminated [28]. On cooling from the processing temperature (380 °C), the intermetallic Mg17Al12 occurred only in the areas of high Al-content since diffusion of Al in Mg was rather slow. As shown in Fig. 6, after CEC or compression, intermetallic Mg17Al12 phase appeared in the microstructure of Mg alloy [29].

Fig. 6 Microstructures of CEC formed (a) and compression formed (b) alloy

3.2 Microstructure evolution of CEC and compression formed AM60B magnesium alloys during partial remelting

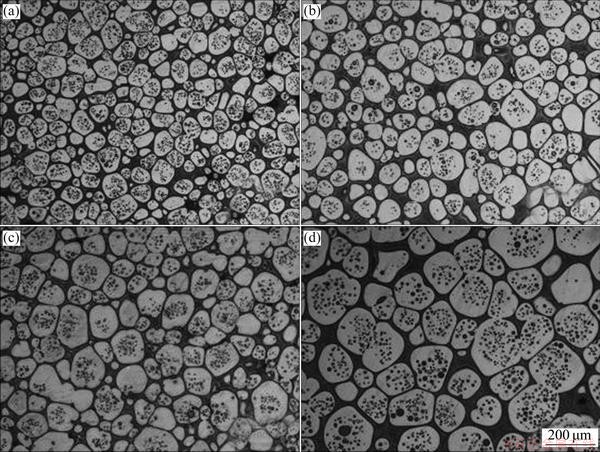

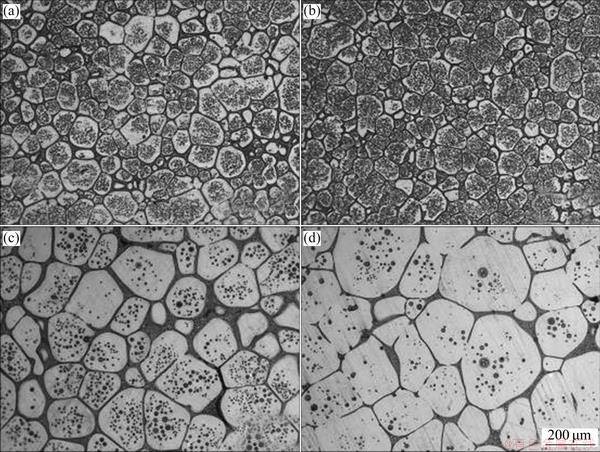

The semi-solid microstructures of the CEC formed AM60B alloys after partial remelting at 580 °C for different holding time: 10 min, 20 min, 40 min and 80 min, are shown in Fig. 7. With increasing temperature up to 580 °C and holding for 10 min, deformed microstructure was replaced by spheroidal grains surrounded by liquid phases (Fig. 7(a)). The process (CEC plus partial remelting) has been shown to produce ideal, fine semi-solid microstructure, in which completely spheroidal grains are essentially free of entrapped liquid. With increasing isothermal holding time, liquid fraction increased and grain boundaries were completely penetrated by liquid film (Fig. 7(b) and Fig. 7(c)). With further increasing holding time, the segregation of liquid was more obvious. At the same time, obvious grain coarsening occurred (Fig. 7(d)). Figure 8 shows microstructure of compression formed AM60B magnesium alloy partially remelted at 580 °C for different holding time: 10 min, 20 min, 40 min and 80 min. When heated to 10 min, intermetallic Mg17Al12 disappeared and changed into liquid among solid grains. The “bimodal” microstructure was also replaced by polygonal grains. Although most of grains were irregular in shape, some solid grains surrounded by liquid had undergone a significant degree of spheroidization (Fig. 8(a)). When the holding time was extended to 20 min, most of the edges of polygonal solid grains melted, which resulted in the spheroidization of polygonal solid grains and the increase in the amount of liquid phase. It can be concluded that the spheroidization of polygonal grains was the main event occurring at 40 min. As the holding time was prolonged, grains coarsened and the degree of spheroidization was further improved. Simultaneously, liquid fraction was slightly increased.

Fig. 7 Optical micrographs of as-cast AM60B magnesium alloys treated by CEC and then isothermally held at 580 °C for 10 min (a), 20 min (b), 40 min (c) and 80 min (d)

It is interesting to note that liquid droplets were present in the most of grain cross-sections in all samples, as shown in Fig. 7 and Fig. 8. The intragranular liquid droplets were present in a large number of the solid particles, appeared to coarsen with time, reducing the number and increasing average size. The formation of liquid droplets inside grains can be attributed to chemical segregation and grain coalescence [30-35]. During heating, the regions of higher Al and Mn contents lead to the solid state precipitation of Mg17Al12 intermetallic or, at higher temperatures, the formation of so-called “entrapped liquid” pools as a result of partial remelting [16,20]. Moreover, to reduce interface energy between solid phase and liquid phase, grains tend to aggregation in certain directions because of the relatively low energy grain boundaries along certain directions. It has been shown that a grain boundary was not penetrated by liquid when γgb<2γsl, where γ is surface energy and subscripts gb and sl stand for solid-solid and solid-liquid interface, respectively. Some grains, whose grain boundaries were not wetted, became interconnected by coalescence and formed agglomerates. Under this condition, it was inevitable that some liquid was entrapped into the new formed grains [8]. With increasing holding time, some contiguous intragranular liquid droplets gradually merged into some big intragranular liquid droplets by coalescence. To minimize the solid-liquid interface energy inside grains, liquid droplets diffused through solid grains and then merged into some irregular liquid pools. Furthermore, some liquid droplets or liquid pools inside grains also migrated to the liquid phase by diffusion through solid grain. With further increasing holding time, these new formed liquid droplets inside grains became spheroidal in appearance with reduction of solid-liquid interfacial energy [8].

Fig. 8 Optical micrographs of as-cast AM60B magnesium alloys treated by compression and then isothermally held at 580 °C for 10 min (a), 20 min (b), 40 min (c) and 80 min (d)

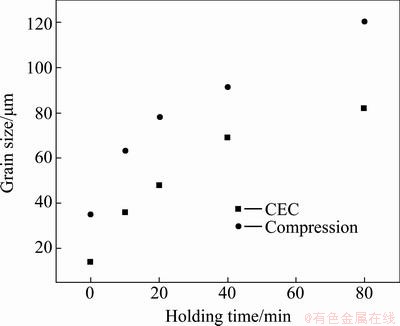

Fig. 9 Plot of solid grain size as function of holding time

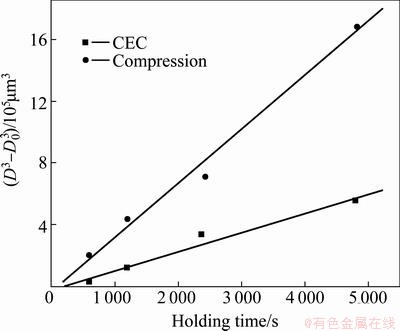

Figure 9 shows that the results from the grain size as a function of the holding time in the semi-solid state for CEC and compression formed AM60B magnesium alloys. As shown in Fig. 9, with the increase in holding time, grain coarsening occurred both in CEC and compression formed AM60B magnesium alloys during partial remelting. However, grain size in the compression formed alloy was larger than that in the CEC formed alloy. For many diffusion controlled coarsening system, including solid-liquid mixtures, coarsening kinetics can be described by the equation:

(5)

(5)

where D and D0 are the final and initial grain sizes, respectively; t is the isothermal holding time; K is a coarsening rate constant; n is the power exponent. It is generally believed that n is 3 for volume diffusion- controlled coarsening, n is 4 for grain boundary diffusion controlled coarsening, and n is 2 for interfacial reaction-controlled coarsening [8]. Many studies investigating solid-liquid coarsening of metals in the semi-solid state generally reported an exponent of n=3 [5,6,10]. To evaluate coarsening kinetics of CEC and compression formed AM60B magnesium alloy during partial remelting, it was assumed in the present study that coarsening was controlled by diffusion in the liquid and was cubic, i.e. n=3. The cubic coarsening rate constant, K in Eq. (5) is given experimentally by the gradient of the best fit straight lines shown in Fig.10, and was 121 and 348 μm3/s for CEC and compression formed samples partially remelted at 580 °C respectively.

Fig. 10 Plot of solid grain size cubed as function of holding time for AM60B magnesium alloys treated by CEC and compression partially remelted at 580 °C for different holding time

During the CEC and compression process, internal strain energy was stored in the form of crystal lattice distortion, dislocation multiplication and vacancies, which provided the driving force for subsequent recovery and recrystallization. Compared Fig. 6(a) with Fig. 6(b), it was indicated that the alloy formed by larger equivalent strains gave a finer recrystallized grain size. The larger the degree of deformation is, the greater the overall grain boundary and sub-grain boundary area are. This led to greater potential for the development of recrystallization nuclei, and therefore a finer recrystallized grain size. Increasing the amount of deformation increased the driving force for recrystallization, since a heavily deformed sample contained more stored energy necessary for the recrystallization process. During partial remelting, coalescence and Ostwald ripening generally control grain coarsening [10]. Coalescence and Ostwald ripening operated simultaneously and independently as soon as liquid was formed. However, the relative contribution of coalescence and Ostwald ripening to grain coarsening also maintained a matter of controversy [16]. In accordance with our observations, there was a limitation to the role of diffusion because of thin liquid film in the early stage of partial remelting (Fig. 6). Under this condition, coalescence mainly controlled the grain coarsening, which led to rapid particle growth. With increasing holding time, liquid fraction increased and therefore the liquid film was thicker. Ostwald ripening was thought to be the dominant mechanism for coarsening in the semi-solid state. Compared Fig. 6(a) with Fig. 6(b), it can be found that the liquid formation rate of CEC formed alloy was faster than that of compression formed alloy. The reason might be analyzed as follows: during reheating, the liquation of eutectic firstly occurred at grain boundaries with high distortion energy [20]. Compared with compression formed alloys, because of severe deformation during CEC, CEC formed alloys have higher distortion energy, which enhances the rate of liquation. The liquid formation rate determines the thickness of liquid film, which further determines the mechanism of grain growth in the semi-solid state. As for CEC formed alloys, because of high liquid formation rate, relatively thick liquid films surrounding solid particles reduce the contribution of coalescence ripening to the total coarsening mechanism. Therefore, as expected, a lower coarsening rate was obtained in the CEC formed alloy.

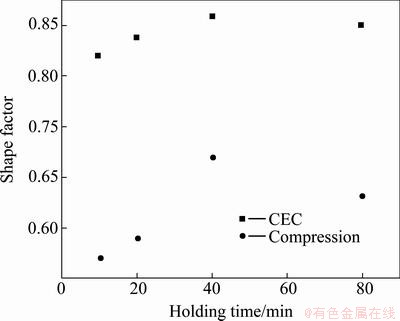

Figure 11 shows the shape factor plotted as a function of holding time at 580 °C. The change of shape factor both in CEC and compression formed AM60B magnesium alloys almost followed the same tendency. With increasing the holding time, the shape factor increased rapidly. For example, with increasing the holding time from 10 min to 40 min, the shape factor in CEC formed alloy increased from 0.82 to 0.86 and the shape factor in compression formed alloy increased from 0.62 to 0.72. Two possible explanations were proposed for the higher shape factor value obtained in the CEC formed alloy. The first was that Ostwald ripening mechanism driven by the presence of variable curvature on the surface of each grain contributed to a large extent to grain spheroidization. In other words, Ostwald ripening mechanism promoted the spheroidization of grains. Second, more likely explanation was that fine and homogeneous recrystallized grains were ontained in the CEC formed alloy. During partial remelting, it was easy for these fine and homogeneous recrystallized grains to be surrounded by liquid. However, in the compression, due to limited stored energy, “bimodal” microstructure which includes coarse and fine grains, resulted in irregular grains during partial remelting. Therefore, the grains of CEC formed alloy were more spheroidal in appearance than those of compression formed alloy under the same isothermal holding conditions. It is of interest to note that further increase in holding time resulted in a slight reduction in shape factor. This can be attributed to coalescence, which led to the formation of irregular grains for long isothermal holding.

Fig. 11 Plot of solid shape factor as function of holding time

3.3 Thixoforming and mechanical properties of thixoformed AM60B magnesium alloy

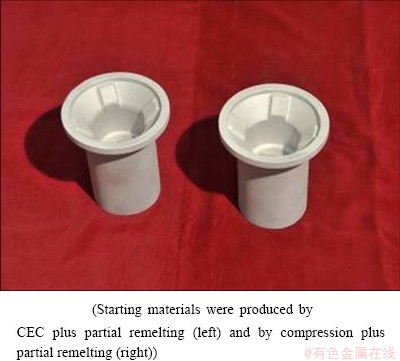

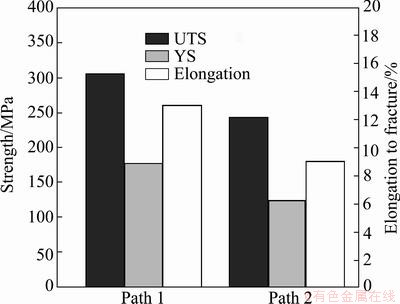

Figure 12 presents photographs of successfully thixoformed components. The components of starting materials were AM60B magnesium alloy produced by the SIMA route (CEC plus partial remelting and compression plus partial remelting). The trial results indicated that the thixoformed components had a very good surface and no problem was experienced in filling the lateral walled sections. Each tensile value was the average of at least three measurements. The results show that the ultimate tensile strength (UTS), yield strength (YS) and elongation of thixoformed AM60B alloy produced by CEC plus partial remelting were 305 MPa, 176 MPa and 13%, respectively (Fig. 13). The UTS, YS and elongation of thixoformed AM60B alloy produced by the compression plus partial remelting were 242 MPa, 123 MPa and 9%, respectively (Fig. 13). The larger the degree of deformation is, the greater the overall grain boundary and subgrain boundary are. This led to greater potential for the development of recrystallisation nuclei, and therefore a finer recrystallized grain size when reheating. Another effect of CEC on alloy was that misorientation of sub-grain boundaries may increase, leading to an increase in the amount of stored energy in the alloy and increased driving force towards recrystallisation [36,37]. Recrystallization was favorable for improving the grain structure of the CEC formed billet. Once it is heated to semi-solid temperature range, ideal, fine semi-solid structures are produced, in which completely globular solid grains have a small number of intragranular liquid droplets [38,39]. Such microstructures, with spheroids of solid in a liquid matrix, are ideal for thixoforging.

Fig. 12 Photos of successfully thixoformed AM60B magnesium components

Fig. 13 Tensile mechanical properties of components thixoformed from starting materials produced by path 1 CEC plus partial remelting and by path 2 compression plus partial remelting

4 Conclusions

1) After cyclic extrusion compression, fine and homogeneous recrystallized grains were obtained in AM60B alloy. However, the microstructure of compression processed AM60B alloy was nonuniform with a bimodal grain size distribution.

2) During the partial remelting, the alloy treated by CEC exhibits ideal, fine microstructures, in which completely spheroidized grains contain little entrapped liquid. While the grains of AM60B alloy treated by compression are spheroidized to some extent but the previous irregular shape is still obvious. As holding time increases, grain coarsening occurs both in CEC and compression formed alloys during the partial remelting. The cubic coarsening rate constants, K, were 121 and 348 μm3/s for CEC and compression formed samples partially remelted at 580 °C, respectively.

3) The AM60B alloy treated by CEC plus partial remelting is more suitable for thixoforming. Ultimate tensile strength, yield strength and elongation of thixoformed AM60B alloy produced by CEC plus partial remelting are 305 MPa, 176 MPa and 13%, respectively. The UTS, YS and elongation of thixoformed AM60B alloy produced by the compression plus partial remelting are 242 MPa, 123 MPa and 9%, respectively.

References

[1] CHEN Q, SHU D Y, HU C K, ZHAO Z D, YUAN B G. Grain refinement in an as-cast AZ61 magnesium alloy processed by multi-axial forging under the multitemperature processing procedure [J]. Materials Science and Engineering A, 2012, 541: 98–104.

[2] GENG L, ZHANG H W, LI H Z, GUAN L N, HUANG L J. Effects of Mg content on microstructure and mechanical properties of SiCp/Al-Mg composites fabricated by semi-solid stirring technique [J]. Transactions of Nonferrous Metals Society of China, 2010, 10: 1851-1855.

[3] ZHAO Z D, CHEN Q, HU C K, HUANG S H, WANG Y Q. Near-liquidus forging, partial remelting and thixoforging of an AZ91D+Y magnesium alloy [J]. Journal of Alloys and Compounds, 2009, 485: 627–636.

[4] CHEN Zhen-hua, LIU Jun-wei, CHEN Ding, YAN Hong-ge. Deformation mechanisms, current status and development direction of superplastic magnesium alloys[J].The Chinese Journal of Nonferrous Metals, 2008, 18(2): 193-202. (in Chinese)

[5] CHEN Q, SHU D Y, ZHAO Z D, ZHAO Z X, WANG Y B, YUAN B G. Microstructure development and tensile mechanical properties of Mg–Zn–RE–Zr magnesium alloy [J]. Materials and Design, 2012, 40: 488–496.

[6] SU G H, CAO Z Y, LIU Y B, WANG Y H, ZHANG L, CHENG L R. Effects of semi-solid isothermal process parameters on microstructure of Mg-Gd alloy [J]. Transactions of Nonferrous Metals Society of China ,2010, 20(s2): s402-s406

[7] TZIMAS E, ZAVALIANGOS A. Evolution of near-equiaxed microstructure in the semisolid state [J]. Materials Science and Engineering A, 2000, 289 (1-2): 228-240.

[8] LUO S J, CHEN Q, ZHAO Z D. An investigation of microstructure evolution of RAP processed ZK60 magnesium alloy [J]. Materials Science and Engineering A, 2009, 501: 146–152.

[9] ZHAO Z D, CHEN Q, CHAO H Y, HUANG S H. Microstructural evolution and tensile mechanical properties of thixoforged ZK60-Y magnesium alloys produced by two different routes [J]. Materials and Design, 2010, 31: 1906–1916.

[10] ZHAO Z D, CHEN Q, WANG Y B, SHU D Y. Microstructural evolution of an ECAE-formed ZK60-RE magnesium alloy in the semi-solid state [J]. Materials Science and Engineering A, 2009, 506: 8–15.

[11] ATKINSON H V. Modelling the semisolid processing of metallic alloys [J]. Progress Materials Science, 2005, 50 (3): 346-352.

[12] ZHAO Z D, CHEN Q, WANG Y B, SHU D Y. Effect of predeformation on semi-solid microstructure of ZK60+RE magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 535-539.

[13] ZHAO Z, FAN Z T, JIANG W M, DONG X P. Microstructural evolution of Mg9AlZnY alloy with vibration in lost foam casting during semi-solid isothermal heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s768-s773

[14] CHEN Q, YUAN B G, ZHAN G Z, SHU D Y, HU C K, ZHAO Z D, ZHAO Z X. Microstructural evolution during reheating and tensile mechanical properties of thixoforged AZ91D-RE magnesium alloy prepared by squeeze casting-solid extrusion[J]. Materials Science and Engineering A, 2012, 537: 25–38.

[15] CHEN Q, ZHAO Z D, ZHAO Z X, HU C K, SHU D Y. Microstructure development and thixoextrusion of magnesium alloy prepared by repetitive upsetting-extrusion [J]. Journal of Alloys and Compounds, 2011, 509: 7303–7315.

[16] LUO S J, CHEN Q, ZHAO Z D. Effects of processing parameters on the microstructure of ECAE-formed AZ91D magnesium alloy in the semi-solid state [J]. Journal of Alloys and Compounds, 2009, 477: 602–607.

[17] JI Z S, HU M L, SUGIYAMA S, YANAGIMOTO J. Formation process of AZ31B semi-solid microstructures through strain-induced melt activation method [J]. Materials Characterization, 2008, 59: 905-911.

[18] ZHAO Z D, CHEN Q,TANG Z J, HU C K. Microstructural evolution and tensile mechanical properties of AM60B magnesium alloy prepared by the SIMA route [J]. Journal of Alloys and Compounds, 2010, 497: 402–411.

[19] ZHANG L, CAO Z Y, LIU Y B. Microstructure evolution of semi-solid Mg-14Al-0.5Mn alloys during isothermal heat treatment [J].Transactions of Nonferrous Metals Society of China, 2010, 20: 1244-1248.

[20] CHEN Q, LUO S J, ZHAO Z D. Microstructural evolution of previously deformed AZ91D magnesium alloy during partial remelting [J]. Journal of Alloys and Compounds, 2009, 477: 726–731.

[21] ZHAO Z D, CHEN Q, WANG Y B, SHU D Y. Effect of predeformation on semi-solid microstructure of ZK60+RE magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 535-539.

[22] CHENG Y S, CHEN Q, HUANG Z Q, HUANG S H. Microstructure evolution and thixoextrusion of AZ91D magnesium alloy produced by SSTT [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s739-s743.

[23] ATKINSON H V, BURKE K, VANEETVELD G. Recrystallisation in the semi-solid state in 7075 aluminium alloy [J]. Materials Science and Engineering A, 2008, 490: 266-276.

[24] ASHOURI S, NILI-AHMADABADI M, MORADI M, IRANPOUR M. Semi-solid microstructure evolution during reheating of aluminum A356 alloy deformed severely by ECAP [J]. J Alloys Compounds, 2008, 466: 67-72.

[25] HU Y, HE B L, YAN H. Rheological behavior of semi-solid Mg2Si/AM60 magnesium matrix composites at steady state [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s883-s887

[26] CHEN Q, ZHAO Z X, SHU D Y, ZHAO Z D. Microstructure and mechanical properties of AZ91D magnesium alloy prepared by compound extrusion [J]. Materials Science and Engineering A, 2011, 528: 3930–3934.

[27] ZHAO Zu-de, CHEN Qiang, KANG Feng, SHU Da-yu. Microstructural evolution and tensile mechanical properties of thixoformed AZ91D magnesium alloy with the addition of yttrium [J]. Journal of Alloys and Compounds, 2009, 482: 455–467.

[28] ZHAO Z D, CHEN Q, HU C K, SHU D Y. Microstructure and mechanical properties of SPD-processed an as-cast AZ91D+Y magnesium alloy by equal channel angular extrusion and multi-axial forging [J]. Materials and Design, 2009, 30: 4557–4561.

[29] KLEINER S, BEFFORT O, UGGOWITZER P J. Microstructure evolution during reheating of an extruded Mg-Al-Zn alloy into the semisolid state [J]. Scripta Materialia, 2004, 51: 405-410.

[30] FENG X M, AI T T. Microstructure evolution and mechanical behavior of AZ31 Mg alloy processed by equal-channel angular pressing [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 293-298.

[31] ZHAO Z D, CHEN Q, HUANG S H, KANG F, WANG Y B. Microstructure and tensile properties of AM50A magnesium alloy prepared by recrystallisation and partial melting process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1630–1637.

[32] MA Y L, PAN F S, ZUO R L, ZHANG J,YANG M B. Effects of heat-treatment on microstructure of wrought magnesium alloy ZK60 [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 1888-1891.

[33] ZHAO Zu-de, CHEN Qiang, TANG Ze-jun, WANG Yan-bin, NING Hai-qing. Microstructure evolution and mechanical properties of Al2O3sf/AZ91D magnesium matrix composites fabricated by squeeze casting [J]. Journal of Materials Science, 2010, 45: 3419–3425.

[34] SONG D, MA A B, JIANG J H,LIN P H,YANG D H. Corrosion behavior of ultra-fine grained industrial pure Al fabricated by ECAP [J]. Transactions of Nonferrous Metals Society of China, 2009, 19:1065-1070.

[35] ZHAO Z D, CHENG Y S, CHEN Q, WANG Y B, SHU D Y. Reheating and thixoforging of ZK60+RE alloy deformed by ECAE [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 178–182.

[36] ZHAO Z D, CHEN Q, CHAO H Y, HU C K, HUANG S H. Influence of equal channel angular extrusion processing parameters on the microstructure and mechanical properties of Mg–Al–Y–Zn alloy [J]. Materials and Design, 2011, 32: 575-583

[37] ZHAO Z D, CHEN Q, YANG L, SHU D Y, ZHAO Z X. Microstructure and mechanical properties of Mg-Zn-Y-Zr alloy prepared by solid state recycling [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 265–271.

[38] ZHANG Q Q, CAO Z Y, LIU Y B, WU J H, ZHANG Y F. Study on the microstructure evolution and rheological parameter of semi-solid Mg-10Al-4Zn alloys [J]. Materials Science and Engineering A, 2008, 478: 195-200.

[39] YANG M B, PAN F S, CHENG R J, SHEN J. Effects of holding temperature and time on semi-solid isothermal heat-treated microstructure of ZA84 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 566-572.

王丽萍,姜文勇,陈 添,冯义成,周洪宇,赵思聪,梁镇强,朱 言

哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040

摘 要:通过应变诱导熔化激活法制备半固态AM60B镁合金,并研究其组织演变。分别采用往复挤压-镦粗(CEC法)和传统压缩预成形铸态AM60B镁合金,并在半固态区间部分重熔和触变成形。结果表明,CEC态镁合金的粗晶组织消失,出现细小晶粒组织,但是压缩态合金的粗晶和再结晶晶粒共存。在局部重熔过程中,CEC态合金获得理想的细晶组织,完全球化的晶粒被液相均匀包裹。在压缩态合金中,多边形晶粒在一定程度上球化,但是之前不规则的形状仍然明显存在。CEC加上二次重熔触变成形的AM60B镁合金,其力学性能优于压缩态加上二次重熔触变成形的镁合金的。

关键词:镁合金;组织;力学性能;触变成形;部分重熔;往复挤压;半固态

(Edited by YANG Hua)

Foundation item: Project (12511069) supported by Department of Education of Heilongjiang Province, China; Project (201210214008) supported by Training Programs of Innovation and Entrepreneurship for Undergraduates, China

Corresponding author: CHEN Tian; Tel: +86-18304639120; E-mail: cq60suo@163.com

DOI: 10.1016/S1003-6326(12)61743-9