文章编号:1004-0609(2009)06-1032-06

热暴露对Ti60合金性能及断裂行为的影响

贾蔚菊,曾卫东,俞汉清,周义刚

(西北工业大学 材料科学与工程学院 凝固技术国家重点实验室,西安 710072)

摘 要:采用光学显微镜和扫描电镜观察分析了Ti60合金热暴露前后拉伸试样的显微组织、断裂方式及其断口形貌。结果表明:Ti60合金塑性对试样表面富氧层较为敏感,带有富氧层的试样塑性较低;热暴露前后试样断裂方式发生变化,未经热暴露的试样,断裂起源于试样中心部位,断面凹凸不平,为典型的韧窝型断裂;毛坯热暴露断口上呈现出大量的解理小平面,也可以观察到韧窝形貌,为混合型断口;试样热暴露后,裂纹起源于试样表面,在微观断口上除了断裂小平面外,还有大量的撕裂棱,表现为断裂沿着α片层界面扩展的特征;在高温长时间暴露过程中,氧除了污染试样表面,还会溶解在基体中形成脆性富氧层,这是影响Ti60合金热稳定性能的重要原因。

关键词:高温钛合金;热稳定性能;富氧层;断口形貌

中图分类号:TG 146.4 文献标识码: A

Effect of thermal exposure on properties and

fracture behaviors of Ti60 alloy

JIA Wei-ju, ZENG Wei-dong, YU Han-qing, ZHOU Yi-gang

(State Key Laboratory of Solidification Processing, School of Materials Science and Engineering,

Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The tensile properties of Ti60 titanium alloy after high temperature exposure were investigated. The variation and morphologies of fracture for Ti60 titanium alloy after exposure were analyzed. The results show that the tensile properties of the unexposured specimens at room and high temperature can meet the specification. After thermal exposure, the strength of the specimens increases but the ductility decreases. The dominant damage mechanism changes after thermal exposure. Before exposure, the crack initiates near the center of the specimens, and the fractographs exhibits honeycomb morphology. After thermal exposure, a brittle oxygen-riched subsurface layer forms, the crack initiates on the surface of the tensile specimens, the fracture is hybrid fracture of dimple and quasi-cleavage, and the fracture facet shows the characteristic of lamellar along α platelet colony. During long-term high temperature exposure, the oxygen absorbed in alloy, except for forming oxidation layer, dissolves into the matrix and forms the surface oxygen-enriched layer which becomes an important factor of decreasing the thermal stability of Ti60 alloy.

Key words: high temperature titanium alloy; thermal stability; oxygen-enriched layer; fracture morphology

航空发动机用钛构件的工作环境集高温、高压、高负载于一体,对材料要求极其苛刻,因此,世界各国都在竞相发展600 ℃高温钛合金,用来制造高推比发动机的压气机轮盘、叶片和机匣等,可明显减轻发动机质量、提高发动机推重比[1]。高温钛合金的开发主要为Ti-Al-Sn-Zr-Mo-Si近α型体系[2],较为典型的有英国的IMI834[3]、美国的Ti1100[4]、俄罗斯的BT36[5]、中国的Ti60[6]及Ti600[7]等,其中IMI834合金已经在EJ200和TRENT800等发动机上得到了成功应用[8]。

热强性与热稳定性是高温钛合金的一对主要矛盾。强调热强性而忽视热稳定性或强调热稳定性而忽视热强性均不能使合金真正满足设计的要求而获得使用。从目前看来,合金热强性可以达标,因此较突出的是合金的热稳定性问题[9]。热稳定性表征了材料在高温长时作用下保持塑性和韧性的能力,是高温钛合金的一个重要力学性能指标,对于保证高温钛合金部件的高温长期使用可靠性具有重要的意义。

本研究的Ti60合金是在IMI834合金基础上加入一定含量的β稳定元素Ta及较高含量的Si元素设计而成的。这种合金的优点是具有较高的热强性能,但与其它高温钛合金一样,Ti60合金的热稳定性不够理想[10]。高温钛合金热稳定性包括组织稳定性和表面稳定性两方面。本文作者主要研究在热暴露前后合金拉伸性能的变化及其断口形貌特征,探索其变化规律及其断裂机制。

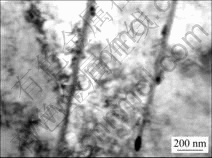

1 实验

实验用原材料是由宝钛集团提供的d120 mm×500 mm的棒材,原材料经反复镦拔后,改锻成d150 mm的棒材,最后采用常规锻造获得直经为d200 mm的饼材,其显微组织如图1所示,为典型的等轴组织。试验所用试样均沿饼材弦向采用线切割切取。室温拉伸、高温拉伸和热稳定试样的工作直径均为d5 mm,标距有效长度为25 mm的标准试样。热暴露实验是在箱式电炉中600 ℃温度下保温100 h后进行室温拉伸。合金的拉伸断口形貌在SUPRATM 55型扫描电子显微镜下进行观察和分析。

图1 Ti60合金轴的显微组织

Fig.1 Microstructure of Ti60 alloy

2 结果与分析

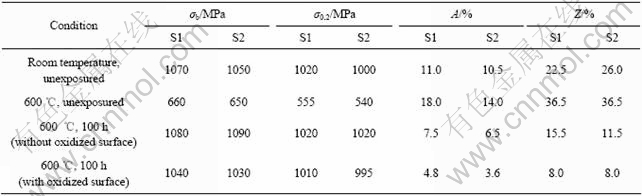

2.1 热暴露前后的拉伸性能

表1所列为Ti60合金在热暴露前后试样1(S1)和2(S2)的拉伸性能数据。从表1中可以看出,合金经过毛坯热暴露以后,试样抗拉强度(σb)和屈服强度(σ0.2)较室温拉伸试样有所提高,伸长率(A)和断面收缩率(Z)有所下降;而试样热暴露以后,强度较室温拉伸略有降低,同时塑性明显降低。这是因为毛坯热暴露去除了表面富氧层的影响,但经过高温长时间暴露以后,组织内部会有硅化物及有序脆性相析出[11],从而提高了合金强度,降低了具塑性。而试样热暴露所用试样内部同样存在硅化物及有序相的析出,不同的是在试样表面带有脆性富氧层。这层脆性层容易诱发细微裂纹,导致试样过早断裂,使其强度有所降低,同时塑性明显下降。对比毛坯热暴露和试样热暴露以后合金的延伸率和面缩可见,表面氧化是影响合金热稳定性的重要原因。

表1 Ti60合金不同条件下的拉伸性能

Table 1 Tensile properties of Ti60 alloy under different conditions

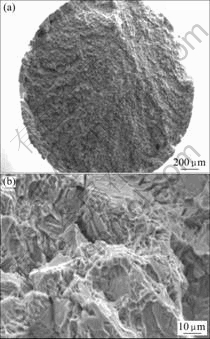

2.2 热暴露前的断口形貌

图2所示为未经热暴露的室温拉伸试样的宏观和微观断口形貌。由图2可看出,从宏观断口上可以看到,断面凹凸不平,呈粗颗粒状,有明显的颈缩,边缘是与拉伸轴线约成45?方向的剪切唇;从微观组织来看,断口上有明显的撕裂棱,具有“蜂窝”状特征,为典型的韧窝型断口。

图2 未经热暴露试样断口形貌

Fig.2 Fracture morphologies of alloy without thermal exposure: (a) Macro morphology; (b) Micro morphology

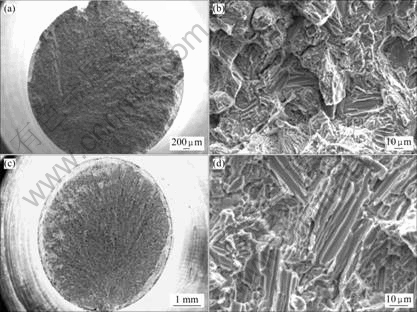

2.3 热暴露后的断口形貌

图3所示为经热暴露以后的拉伸断口形貌。由图3(a)可见,毛坯热暴露试样,宏观断口较平整,裂纹起源位置偏中心部位,存在向外发散的纹路,颈缩较小。在图3(b)上可以观察到大量的断裂小平面,小平面上有光亮的撕裂棱,局部可见韧窝形貌,属于混合型断口。由图3(c)和(d)可看出,裂纹明显起源于试样表面,微观断口可以观察到解理小平面,还可以看到大量的长条状断裂平面,经对比分析发现,这些长条状断面与合金显微组织中片层状α相对应,可见断裂是沿片层状α相进行的。造成这种现象的原因与热暴露后合金表面氧化和内部组织的变化有关系。

图3 热暴露后试样的断口形貌

Fig.3 Macro ((a), (c)) and micro ((b), (d)) morphologies of alloy after thermal exposure: (a), (b) Specimens removed oxidized surface; (c), (d) Specimens with oxygen-riched scale on surface

试样热暴露所用试样与毛坯热暴露试样相比,其表面带有污染层,这层脆性层容易诱发细微裂纹,在拉伸过程中,α脆性层优先崩裂,裂纹从表层向试样内部扩展,这就使得宏观上观察到裂纹源区位于试样表面的。另外,当裂纹向组织内部扩展时,优先沿着组织中的薄弱部位发展,从而改变了正常的拉伸断裂机制,形成与拉伸断口不同的断口形貌。

在近α高温钛合金中,Si的含量一般为0.1% ~ 0.5% (质量分数),现存的高温钛合金中,几乎都含有Si,一般认为,Si能够增加强度并提高蠕变阻力,但过高的Si含量会形成硅化物,影响合金的塑性。研究表明[12],Si和硅化物对IMI834合金的室温拉伸塑性有明显的影响,且对于带有氧化层的试样,其塑性对硅含量的敏感性比去除氧化表面的试样更为强烈,当Si含量大于0.1%时,其塑性明显下降。在Ti60合金中,Si以两种状态存在,即Si固溶于基体中和以硅化物的形态析出,而硅化物的析出类型和分布特征则主要取决于合金的成分和热处理制度。本研究结果发现,硅化物主要在片层α间的残余β相中及沿晶界析出,如图4所示。在α片层内不同方向的滑移带被阻挡在α片层界面上的硅化物处,易于在那里产生应力集中,诱发空洞和裂纹的形成。这些部位就是组织中的薄弱地带,富氧层中的细微裂纹会优先选择这些路径扩展,从而使断口形貌表现出断裂沿α片层进行的特征,这种现象也在IMI834中存在[13],同时合金塑性下降,如表1所列。

图4 合金中α和β相界面析出硅化物的形貌

Fig.4 Morphology of bright field of silicide precipitation at interlayer of α and β phases boundaries

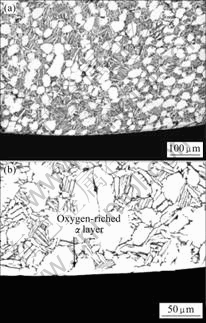

由表1可看出,Ti60合金经过热处理后,其室温及高温拉伸性能,即强度与塑性均良好。但毛坯热暴露以后,强度较室温拉伸试样有所提高,伸长率和断面收缩率有所下降;而试样热暴露以后,强度较室温拉伸略有降低,同时塑性明显降低。其原因是,Ti60合金在600 ℃,100 h热暴露过程中,表面氧化和内部组织变化共同影响着拉伸性能[14]。钛合金热暴露后除产生氧化外,在钛的晶格间隙中可溶解10%的稳定α相的氧,并形成富氧α层[15](见图5)。

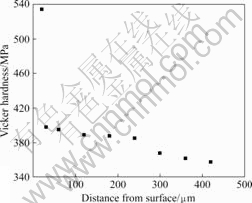

图5(a)所示为未经热暴露的试样表层的形貌。图5(b)所示为试样经过600 ℃,100 h热暴露后试样表面的形貌。图5(a)中,试样显微组织由白色的初生α相和条状的转变β组成。图5(b)中在试样表层以下一定距离几乎全是白色的α相,即富氧α层,如图中箭头所示。对经过热暴露的试样从表面向内部测量显微硬度,其结果如图6所示。研究表明[16],富氧α层的厚度与加热温度和保温时间有关,随着加热温度的升高和保温时间的延长,富氧α层的深度增加,表面显微硬度逐步提高,距离表面越远,显微硬度值的增长越小。从图6中可以看出,该合金表层硬度非常高,随着距表层距离的增大,硬度急剧降低之后,逐渐降低至基体硬度,是符合规律的。

图5 热暴露前后试样的表面形貌

Fig.5 Surface morphologies of specimen: (a) Before exposure; (b) Exposured at 600 ℃ for 100 h

图6 Ti60合金经600 ℃氧化后硬度随深度的变化

Fig.6 Change of Vicker hardness with depth of oxygen riched α layer of Ti60 titanium alloy oxidized at 600 ℃

由于热暴露过程中试样表面污染形成的富氧α层,此层硬度高、塑性低,受力时容易导致表面开 裂[17]。图7所示为没有污染层(图7(a))和带污染层(图7(b))的试样经过拉伸以后的表面状态。从图7中可以清楚看出,前者试样表面光滑,后者则出现了无数深浅不等、疏密不一的细微裂纹。试样表面富氧层引发的细微裂纹,进行拉伸实验时,这些细微裂纹向试样内部发展,随着拉伸变形的增加,裂纹不断向内扩展,当试样承受的拉伸应力超过材料允许应力时,试样将会发生断裂。本实验毛坯热暴露是经过机加后去除了表面富氧层的影响,但基体内部组织的变化仍然影响合金的热稳定性能,塑性有所降低。而试样热暴露所用试样表面带有污染层,在拉伸过程中,α脆性层首先崩裂,裂纹从表层向试样内部扩展,改变了正常的拉伸断裂机制,从而塑性明显下降。由此可以认为,氧的表面污染是影响热稳定性能的重要原因。

图7 拉伸试样的表面形貌

Fig.7 Surface morphologies of tensile specimen: (a) Without exposure; (b) Exposured at 600 ℃ for 100 h

另外,由试样的断口形貌可以看出,未经热暴露和毛坯热暴露的试样断裂源偏向于试样的中心位置,而试样热暴露的断裂起源于试样表面。未经热暴露的试样,断裂形貌为韧窝型断口,经过热暴露后断口形貌发生变化,毛坯热暴露断口可以观察到解理小平面,也有大量的韧窝特征,为混合型断口,试样热暴露断口形貌,除了断裂小平面外,可以观察到大量的撕裂棱,表现为断裂沿着α片层界面扩展的特征。造成这种现象的原因一方面是由于热暴露以后,试样表面氧污染层起到一定的缺口效应,改变了正常的拉伸断裂机制与断裂方式,使拉伸断裂时由正常情况下的从试样中心部位起源转变为从表面起源,促使裂纹的萌生或发展;另一方面是由于组织内部原因,Ti60为近α型高温钛合金,在高温长时间暴露过程中大量有序相和硅化物在界面处析出,使滑移被阻挡在相界处,易于产生应力集中,诱发空洞和裂纹的形成,使得界面处成为组织内部的薄弱环节,裂纹则优先沿着相界面扩展,从而形成了断裂沿片层界面扩展的特征。

3 结论

1) Ti60合金经过毛坯热暴露以后,强度较室温拉伸试样有所提高,伸长率和断面收缩率有所下降;试样热暴露以后,强度较室温拉伸略有降低,同时塑性明显降低。

2) 室温拉伸试样断裂起源于试样中心位置,断口形貌为韧窝型断裂;毛坯热暴露断口可观察到解理小平面,也有大量的韧窝特征,为混合型断口;试样热暴露以后,裂纹源位于试样的表面,微观断口上除了看到解理小平面以外,显著的特征是断裂沿片层α相界面扩展,这是由于在片层α界面处第二相的析出 所致。

3) 试样热暴露后在试样表层形成脆性富氧层,富氧层内容易引发细微裂纹,在拉伸过程中富氧层起到一定的缺口作用,导致试样过早断裂。试样表面形成的脆性富氧层是Ti60合金热暴露后塑性下降的重要原因之一。

REFERENCES

[1] 蔡建明, 李臻熙, 马济民, 黄 旭, 曹春晓. 航空发动机用600 ℃高温钛合金的研究与发展[J]. 材料导报, 2005(1): 50?53.

CAI Jian-ming, LI Zhen-xi, MA Ji-min, HUANG Xu, CAO Chun-xiao. Research and development of 600 ℃ titanium alloy for aeroengine[J]. Materials Review, 2005(1): 50?53.

[2] 赵永庆. 高温钛合金研究[J]. 钛工业进展, 2001(1): 33?39.

ZHAO Yong-qing. The research of high temperature titanium alloy[J]. Titanium Industry Progress, 2001(1): 33?39.

[3] BLENKINSOP P A. Development in high temperature alloys [C]// L?TJERING G, ZWICKER U, BUNK W. 5th World Conference on Titanium. Obserurel: Deutsche Gesellschaft fur Metallkunde, 1984: 2323?2332.

[4] BANIA P J. Ti-1100: A new high temperature titanium alloy [C]// LACOMBE P, TRICOT R, B?RANGER G. 6th World Conference on Titanium. Paris: Les Editions de Physique, 1988: 825?830.

[5] TETYUKHIN V, LEVIN I, LLYENKO V, BILIBINA E, USOVA T, PADYKOVA N. Heat resistant titanium alloys with enhanced, heat resistance, thermal stability[C]// 8th World Conference on Titanium. Brimingham, UK: Cambridge University Press, 1996: 2430?2437.

[6] 张尚洲, 徐惠忠, 刘子全. 碳含量对Ti-60合金时效过程中硅化物的影响[J]. 材料研究学报, 2005, 19(5): 499?505.

ZHANG Shang-zhou, XU Hui-zhong, LIU Zi-quan. Effect of carbon on siliside precipitates during ageing of Ti-60 titanium alloy[J]. Chinese Journal of Materials Research, 2005, 19(5): 499?505.

[7] 洪 权, 戚运莲, 赵永庆, 杨冠军. 加工工艺对Ti600合金板材组织性能的影响[J]. 稀有金属材料与工程, 2005, 34(8): 1334?1337.

HONG Quan, QI Yun-lian, ZHAO Yong-qing, YANG Guan-jun. Effect of rolling process on microstructure and properties of Ti600 alloy plates[J]. Rare Metal Materials and Engineering, 2005, 34(8): 1334?1337.

[8] 段 锐, 蔡建明, 李臻熙. 初生α相含量对近α钛合金TG6拉伸性能和热稳定性的影响[J]. 航空材料学报, 2007, 27(3): 17?22.

DUAN Rui, CAI Jian-ming, LI Zhen-xi. Effect of primary α phase volume fraction on tensile property and thermal stability of near-alpha TG6 titanium alloy[J]. Journal of Aeronautical Materials, 2007, 27(3): 17?22.

[9] 惠松骁, 张 翥, 萧今声, 袁冠森. 高温钛合金热稳定性研究进展—Ⅰ. 组织稳定性[J]. 稀有金属, 1999, 23(2): 125?130.

HUI Song-xiao, ZHANG Zhu, XIAO Jin-shen, YUAN Guan-sen. Progress of research on thermal stability of high-temperature titanium alloys—Ⅰ. Metallurgical stability[J]. Chinese Journal of Rare Metals, 1999, 23(2): 125?130.

[10] 萧今声, 许国栋. 提高高温钛合金性能的途径[J]. 中国有色金属学报, 1997, 17(4): 97?105.

XIAO Jin-shen, XU Guo-dong. Several ways to improve mechanical properties of high-temperature Ti-based alloys[J]. The Chinese Journal of Nonferrous Metals, 1997, 17(4): 97?105.

[11] 储茂友, 惠松骁, 张 翥, 沈剑韵. BT25y高温钛合金固溶处理及热暴露过程中硅化物的析出机制[J]. 电子显微学报, 2004, 23(2): 168?171.

CHU Mao-you, HUI Song-xiao, ZHANG Zhu, SHEN Jian-yun. Precipitation mechanism of silicide in BT25y titanium alloy in solution treatment and thermal exposure[J]. Journal of Chinese Electron Microscopy Society, 2004, 23(12): 168?172.

[12] 张 均, 李 东. 高温钛合金中的α2相[M]. 沈阳: 东北大学出版社, 2002: 8.

ZHANG Jun, LI Dong. The α2 phase in the high temperature titanium[M]. Shenyang: Northeast University Press, 2002: 8.

[13] 崔文芳, 边为民, 罗国珍, 洪 权, 周 廉. 热暴露对IMI834近α高温钛合金组织和拉伸性能的影响[J]. 航空材料学报, 1997(4): 15?20.

CUI Wen-fang, BIAN Wei-min, LUO Guo-zhen, HONG Quan, ZHOU Lian. Effect of thermal exposure on the microstructures and tensile properties of near-α high temperature titanium alloy IMI834 [J]. Journal of Aeronautical Materials, 1997(4): 15?20.

[14] 周义刚. Ti-679合金热稳定性的研究[J]. 金属学报, 1980, 16(3): 302?307.

ZHOU Yi-gang. An investigation on the thermal stability of Ti-679 alloy[J]. Acta Metallurgica Sinica, 1980, 16(3): 302?307.

[15] CHRISTOPH L, MANFRED P, DIRK W, KAYSSER W A. Influence of long-term annealing on tensile properties and fracture of near-α titanium alloy Ti-6Al-2.75Sn-4Zr-0.4Mo- 0.45Si[J]. Metall Mater Trans A, 1996, 27: 1709?1717.

[16] 朱知寿, 王新南, 吴崇周, 储俊鹏. 钛合金富氧α层的形成与测定方法研究[J]. 稀有金属快报, 2007, 26(12): 24?28.

ZHU Zhi-shou, WANG Xin-nan, WU Chong-zhou, CHU Jun-peng. Study on formation and detection of rich-oxygen α layer in titanium alloy[J]. Rare Metals Letters, 2007, 26(12): 24?28.

[17] SRINADH K V S, SINGH V. Oxidation behaviour of the near α-titanium alloy IMI 834[J]. Mater Sci, 2004, 27(4): 347?354.

基金项目:国家重点基础研究发展计划资助项目(2007CB613807);新世纪优秀人才支持计划资助项目(NCET-07-0696)

收稿日期:2008-09-05;修订日期:2009-01-05

通讯作者:曾卫东,教授,博士;电话:029-88494298;E-mail: zengwd@nwpu.edu.cn

(编辑 李艳红)