Flow behavior and microstructure evolution during

hot compression of TA15 titanium alloy

XU Wen-chen(徐文臣), SHAN De-bin(单德彬), YANG Guo-ping(杨国平), L? Yan(吕 炎)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 28 July 2006; accepted 15 September 2006

Abstract: The samples of TA15 titanium alloy were hot compressed in the temperature range of 550-1 000 ℃ at constant strain rate from 0.01 s-1 to 1.0 s-1. The flow behavior and microstructural evolution during hot deformation of TA15 alloy were investigated, based on which the hot working parameters of TA15 alloy were selected. The results show that with the increase of deformation temperature and decrease of stain rate, the flow stress decreases gradually, but the magnitude of stress drop varies with the increase of temperature in different temperature intervals. According to the flow stress and deformation microstructure, the deformation behavior can be classified into three types as working hardening(550-600 ℃, α+β phase), dynamic recrystallization (650-900 ℃, α+β phase) and dynamic recovery(950-1 000 ℃, β phase). The main softening mechanism is dynamic recrystallization(DRX) of α phase in α+β phase zone and dynamic recovery(DRV) of β phase in β phase zone. As the stain rate decreases dynamic recrystallization of α phase proceeds more adequately in α+β zone and the β subgrains of dynamic recovery have the tendency to grow in β zone. The reasonable temperature for warm forming of TA15 alloy is in the range of 600-700 ℃, which has been verified by warm spinning experiment of tube workpieces.

Key words: TA15 titanium alloy; microstructure evolution; hot compression; dynamic recrystallization; dynamic recovery

1 Introduction

Due to their exceptional properties such as high specific strength, creep resistance and corrosion resistance, titanium alloy is widely used in aeronautics, astronautics and chemical industry[1-4]. TA15 titanium alloy is a near-α alloy similar to Russia alloy Ti-6Al-2Zr-1Mo-1V(BT20) with good hot-working plasticity of α+β alloy and nice weldability of α alloy, which is mainly used to manufacture sheet bank, sectional bar and forging workpiece[5]. However, because of low plasticity and high strength TA15 titanium alloy is very difficult to form at ambient temperature. Therefore, it is necessary to study the deformation behavior of TA15 alloy, by which the mechanism of hot deformation may be revealed and the process parameters may be optimized. Currently the hot deformation characteristics of as-cast TA15 alloy have been investigated, but there is little report available on hot deformation behavior of as-forged TA15 alloy[6-7].

The objective of the present paper is to study the flow behavior and microstructure evolution under different hot working conditions, analyze the influence of process parameters on deformation behavior and determine the proper hot deformation parameters of TA15 titanium alloy by hot compression experiments conducted on a Gleeble-1500 hot simulator. Considering that most titanium alloy workpieces are produced by as-rolled or as-forged billet, the as-rolled bar of TA15 alloy is adopted as experimental material. The research has systematically indicated the deformation mechanism, which lays a sound foundation on plastic working of as-rolled or as forged TA15 alloy.

2 Experimental

Hot rolled TA15 alloy bar used in the experiments was produced by Baoji Nonferrous Metal Works in China, whose actual chemical composition is shown as follows: 6.60%Al, 2.31%V, 1.70%Mo, 2.20%Zr, 0.06%Fe and balance Ti. The specimens of 8 mm in diameter and 12 mm in height were spark machined from the hot-rolled bar. The hot compression experiments were carried out at strain rates of 0.01, 0.1 and 1 s-1 and temperatures from 550 to 1 000 ℃ at intervals of 50 ℃ within the compression amount of 65%. The specimens were resistance heated to deformation temperatures with heating ratio of 2.5 ℃/s and homogenized for 180 s at the onset of hot compression. The load-stroke curves obtained from the compression tests on Gleeble-1 500 hot simulator are converted into true stress—true strain curves by standard equations for true stress and true strain calculation. The hot compression specimens were sectioned parallel to the pressing direction to examine the microstructure characteristic using optical microscopy (OM) and transmission electronic microscopy (TEM). Specimens for optical metallography were etched with a solution which consisted of 3%HF-10%HNO3-H2O.

3 Results and discussion

3.1 Stress and strain behavior

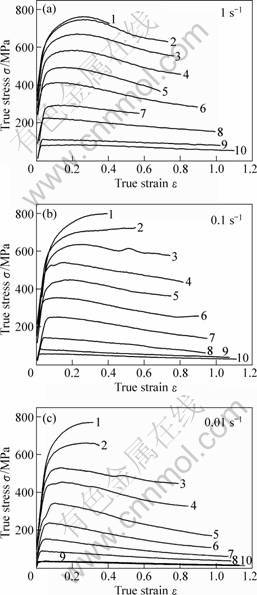

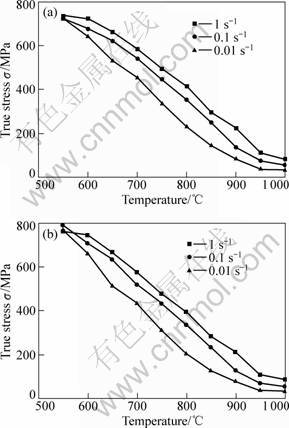

The measured true stress—strain curves for TA15 alloy show a very strong dependence on temperature and strain rate, as illustrated in Figs.1 and 2. In general, the flow stress decreases with the increase of temperature and decrease of strain rate, which is analogous to that found in hot working of conventional α/β titanium alloys[8-10]. However, the magnitude of stress drop varies with the increase of temperature in different temperature regions. As shown in Fig.2, flow stress decreases slowly at 550-600 ℃ and quickly at over 600 ℃, especially at high strain rate of 1 s-1. When the temperature increases over 850 ℃, the decrease of the flow stress becomes slow again. Until the temperature (>950 ℃) approaches the β phase transition point(at 970-980 ℃) the flow stress changes slightly with the growth of temperature.

Fig.1 True stress—strain curves of TA15 alloy at different strain rates and temperature: 1—500 ℃; 2—600 ℃; 3—650 ℃; 4—700 ℃; 5—750 ℃; 6—800 ℃; 7—850 ℃; 8—900 ℃; 9—950 ℃; 10—1 000 ℃

Fig.2 Variation of flow stress with temperature at strain of: (a) ε=0.15; (b) ε=0.3

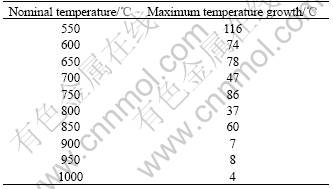

In addition, many flow stress curves exhibit flow softening, especially at high strain rates and low temperatures. There are some sources to contribute to flow softening in hot deformation, which include deformation heating, dynamic recovery, dynamic recrystallization and phase transformation[11-12]. In the hot compression of TA15 alloy, the adiabatic heating is more remarkable at relatively higher strain rate and lower deformation temperature. Table 1 gives the temperature growth of specimen surface measured by thermal couple fixed on the specimens at strain rate 1 s-1, and the central temperature growth is higher than the surface, which leads to the decrease of flow stress at the later stage of hot compression under the conditions of low temperature or high strain rate.

Table 1 Temperature growth relative to nominal temperature at deformation degree of 65% and strain rate of 1 s-1 during hot compression

After eliminating the influence of deformation heat effect at high stain rates ( ≥1 s-1), the flow behavior can be classified into three types as work hardening, dynamic recrystallization and dynamic recovery according to the flow stress curves. In 550-600 ℃ the flow stress increases with the increase of strain in a large strain range and no distinct peak value of flow stress exists, suggesting that the deformation mechanism is dominated by work-hardening. From 650 to 900 ℃ the flow stress decreases gradually after it reaches maximal value, which indicates that dynamic recrystallization (DRX) occurs in the temperature region. In 950-1 000 ℃ the flow stress approaches steady state and nearly remains at constant values, which shows the characteristic of dynamic recovery (DRV).

≥1 s-1), the flow behavior can be classified into three types as work hardening, dynamic recrystallization and dynamic recovery according to the flow stress curves. In 550-600 ℃ the flow stress increases with the increase of strain in a large strain range and no distinct peak value of flow stress exists, suggesting that the deformation mechanism is dominated by work-hardening. From 650 to 900 ℃ the flow stress decreases gradually after it reaches maximal value, which indicates that dynamic recrystallization (DRX) occurs in the temperature region. In 950-1 000 ℃ the flow stress approaches steady state and nearly remains at constant values, which shows the characteristic of dynamic recovery (DRV).

3.2 Microstructure evolution

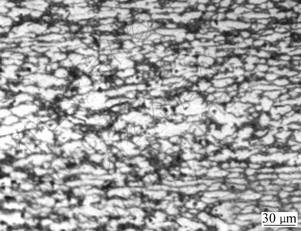

Deformation temperature has obvious effect on the

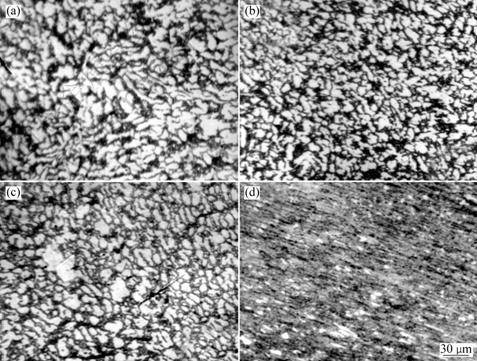

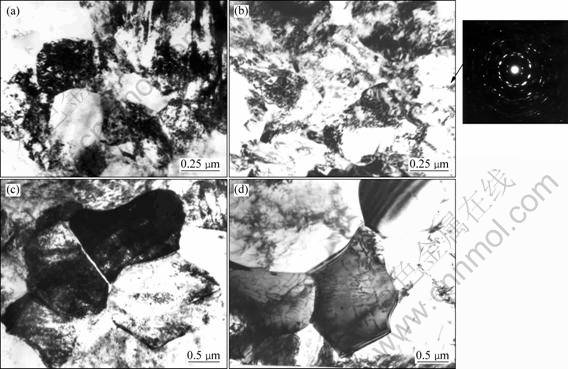

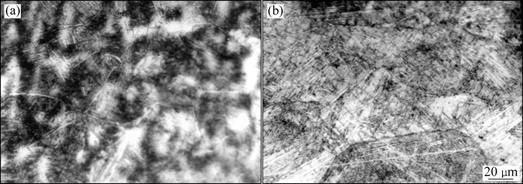

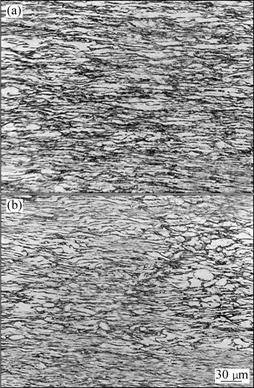

hot deformation microstructure of TA15 titanium alloy. Fig.3 displays the initial as-rolled microstructure, and Fig.4 gives the optical micrographs of microstructure at various deformation temperatures with deformation degree of 65% and strain rate of 1 s-1. As can be seen in Fig.3, the initial microstructure mainly consists of α phase, among which lies small quantity of transformed β phase microstructure. When compressed below 600 ℃, the microstructural morphology are typical plastic deformation microstructure of bar-shaped or striped state (Fig.4(a)). At 650 ℃ large quantity of coarse deformed α strips are broken into equiaxed grains (Fig.4(b)). When the temperature reaches 800 ℃, the content of prior α microstructure starts to reduce because of the α→β phase transformation(Fig.4(c)). After the temperature is increased up to 950 ℃, β transformation microstructure is in the majority among which only a few residual α grains remains or even prior α phase nearly vanishes, which means that β phase becomes matrix microstructure ((Fig.4(d)). According to the observation of hot compression microstructure, it could be considered that when the temperature is below 950 ℃, the hot deformation zone lies in α+β phase, and when the temperature is over 950 ℃ the deformation zone lies in β phase, because the adiabatic heating can be neglected at 950 ℃ and β phase transformation is nearly not affected by adiabatic heating at present deformation conditions. Meanwhile, the microstructure of hot deformation is easily influenced by strain rate. Fig.5 gives the TEM photographs of hot deformation microstructure at different strain rates in α+β phase region, and Fig.6 shows the optical microstructure in β phase region. As shown in Fig.5, when deformed at 650 ℃ there is DRX phenomenon occurred in α phase microstructure (Figs.5(a, b)), but only partial DRX takes place and there are still large quantity of elongated grains in the deformation microstructure(Fig.4(b)). As strain rate increases deformation heat effect strengthens progressively, which contributes to DRX of α phase. When the temperature rises to 800 ℃, the microstructure shows obvious DRX characteristic of α phase (Figs.5(c and d)). As strain rate declines the DRX grain grows gradually, which means that the DRX is fully developed with the decrease of strain rate. At the temperature of 1 000 ℃ β subgrains with straight boundaries are readily observed (Fig.6(a)), thus demonstrating that dynamic recovery(DRV) has occurred. It can be seen that the β subgrains have the tendency to grow as the stain rate decreases in β region (Figs.6(a and b)).

Fig.3 Initial as-rolled microstructure of TA15 titanium alloy

Fig.4 Microstructures of hot compressed TA15 alloy at different temperatures with deformation degree of 65% and strain rate of 1 s-1: (a) 550 ℃; (b) 650 ℃; (c) 800 ℃; (d) 950 ℃

Based on the above study, it can be concluded that in low temperature zone of α+β phase DRX of α phase is the main softening mechanism, and in β phase zone dynamic softening is controlled by DRV of β phase. With the increase of deformation temperature in high temperature zone of α+β phase there is a tendency of α→β phase transformation occurring which makes the main dynamic softening mechanism convert from DRX of α phase to DRV of β phase, by which it can be explained that as the temperature grows in the high temperature zone of α+β phase the decrease of flow stress becomes slow gradually after rising to peak value (Fig.1).

Fig.5 TEM micrographs of hot compression microstructure at deformation degree of 65%: (a) t=650 ℃,  =1 s-1; (b) t=650 ℃,

=1 s-1; (b) t=650 ℃,  =0.01 s-1; (c) t=800 ℃,

=0.01 s-1; (c) t=800 ℃,  =1 s-1; (d) t=800 ℃,

=1 s-1; (d) t=800 ℃,  =0.01 s-1

=0.01 s-1

Fig.6 OM micrographs of hot compression microstructure at deformation degree of 65%: (a)  =1 s-1, t=1 000 ℃; (b)

=1 s-1, t=1 000 ℃; (b)  =0.01 s-1, t=1 000 ℃

=0.01 s-1, t=1 000 ℃

4 Warm forming temperature of TA15 titanium alloy

The experimental research indicates that the suitable hot deformation temperature of TA15 alloy is between 900 and 1 000 ℃ due to low flow stress and small variation rate of flow stress in the temperature region (Fig.2). But for some local plastic forming processes in which plastic deformation concentrates on a small zone, such as sheet bending and flow forming, it is feasible to use warm forming process of TA15 alloy in 600-700 ℃ where the deformation resistance reduces quickly, dynamic softening characteristic starts to occur and material plasticity is improved, which can not only decrease deformation temperature but also prevent hydrogenation and surface oxidization during hot forging of titanium alloy in high temperature.

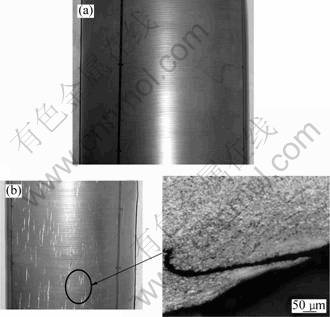

To verify whether or not the warm forming temperature of TA15 alloy is feasible, tube spinning experiment was carried out on a spinning machine with two rollers. The initial tube billets were machined from hot-rolled bars of TA15 alloy and heat treated by recrystallization annealing. The workpieces were spun in two temperature ranges, i.e. 550-580 ℃ and 600-680 ℃, with equal reduction rate. Fig.7 gives the macrographs of spinning parts and Fig.8 shows the spinning microstructure at the last pass. When the spinning temperature is in 600-680 ℃ the tubular workpiece is well spun with smooth surface (Fig.7(a)), the microstructure is deformed uniformly and fiber microstructure comes into being along deformation direction (Fig.8(a)). When the spinning temperature is below 580 ℃, surface crack occurs on spun parts and the spun microstructure is not subject to homogeneous deformation (Fig.7(b)). There are residual undeformed α grains distributed in the spun microstructure (Fig.8(b)). The reason is that as the temperature is lower than 600 ℃ TA15 alloy has no enough plasticity, which causes work hardening that cannot be counteracted by dynamic softening, thus leading to surface cracking of tube workpieces. The spinning experiments suggest that the warm forming temperature ranges obtained by hot compression tests is reasonable.

Fig.7 Spun tubular workpieces in different temperature ranges: (a) 600-680 ℃; (b) 550-580 ℃

Fig.8 Optical micrographs of spinning microstructure at last pass: (a) 600-680 ℃; (b) 550-580 ℃

5 Results

1) With the increase of deformation temperature and decrease of stain rate, flow stress declines gradually, but the magnitude of stress drop varies with the increase of temperature in different temperature regions.

2) At 550-1 000 ℃ the deformation behavior could be classified into three types as work hardening, dynamic recrystallization(DRX) and dynamic recovery (DRV). At 550-600 ℃(α+β phase) the deformation mechanism is dominated by work-hardening. At 650-900 ℃(α+β phase), DRX of α phase controls dynamic softening of TA15 alloy. In the temperature between 950 and 1 000 ℃ (β phase), DRV of β phase is the main softening mechanism. In α+β phase zone, DRX is fully developed with the reduce of strain rate. In β phase zone the subgrains of DRV have the tendency to grow as strain rate declines.

3) The warm forming temperature range of TA15 alloy is in 600-700 ℃, which has been verified by spinning experiment of tubular workpieces.

References

[1] BOYER R R. An overview on the use of titanium alloy in the aerospace industry[J]. Mater Sci Eng A, 1996, 213: 103-114.

[2] DING R, GUO Z X, WILSON A. Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing[J]. Mater Sci Eng A, 2002, 327: 233-245.

[3] SEMIATIN S L, SEETHARAMAN V, WEISS I. Hot workability of titanium and titanium aluminide alloys-an overview[J]. Mater Sci Eng A, 1998, 243: 1-24.

[4] LI Xiao-li, LI Miao-quan. Microstructure evolution model based on deformation mechanism of titanium alloy in hot forming[J]. Trans Nonferrous Met Soc China, 2005, 15(4): 749-753.

[5] PENG Yan-ping, ZENG Fan-chang, WANG Jun-jie. Development application and feature of titanium alloys in foreign aviation industry[J]. Journal of Materials Engineering, 1997, (10): 3-6.(in Chinese)

[6] HONG Quan, ZHANG Zhen-qi. Hot deformation behavior of Ti-6Al-2Zr-1Mo-1V alloy[J]. Journal of Aeronautical Materials, 2001, 21(1): 10-12.(in Chinese)

[7] HONG Quan, ZHANG Zhen-qi, ZHAO Yong-qing. Hot compressive deformation behaviors of Ti-6Al-2Zr-1Mo-1V alloy and its plastic flow equation[J]. Journal of Guangdong Non-ferrous Metals, 2001, 11(2): 129-133.(in Chinese)

[8] LI L X, LOU Y, YANG L B. Flow stress behavior and deformation characteristics of Ti-3Al-5V-5Mo compressed at elevated temperatures[J]. Mater Design, 2002, 23, 451-457.

[9] LIU Y, BAKER T N. Deformation characteristics of IMI685 titanium alloy under β isothermal forging conditions[J]. Mater Sci Eng A, 1995, 197: 125-131.

[10] ROBERTSON D G, MCSHANE H B. Analysis of high temperature flow stress of titanium alloys IMI550 and Ti-10V-2Fe-3Al during isothermal forging[J]. Materials Science and Technology, 1998, 14: 339-345.

[11] PU Z J, WU K H, SHI J. Development of constitutive relationships for the hot deformation of boron microalloying TiAl-Cr-V alloys[J]. Mater Sci Eng A, 1995, 192/193: 780-787.

[12] LAASRAOUI A, JONAS J J. Prediction of steel flow stresses at high temperatures and strain rates[J]. Metall Trans A, 1992, 22: 1545-1558.

(Edited by CHEN Can-hua)

Corresponding author: XU Wen-chen; Tel: +86-451-86416221; E-mail: xuwc_76@hit.edu.cn