放电等离子体烧结WC-Co,WC-Co-Cr3C2和WC-Co-TaC金属陶瓷的显微组织和力学性能

来源期刊:中国有色金属学报(英文版)2016年第10期

论文作者:P. SIWAK D. GARBIEC

文章页码:2641 - 2646

关键词:等离子体烧结;金属陶瓷;碳化铬;碳化钽;力学性能

Key words:spark plasma sintering; cermet; chromium carbide; tantalum carbide; mechanical properties

摘 要:通过添加Cr3C2和TaC晶粒长大抑制剂,采用等离子体烧结技术制备WC-Co金属陶瓷。采用扫描电镜、X射线衍射、密度测定、硬度测试、断裂韧性测试和弹性模量测试技术表征放电等离子烧结体。在相同的工艺参数下,与不添加WC-Co抑制剂的金属陶瓷进行了比较。结果表明,添加Cr3C2 和 TaC抑制剂能提高WC-Co金属陶瓷的硬度和断裂韧性,且添加Cr3C2的陶瓷其晶粒生长抑制性能比添加TaC的更好。WC-5Co-2Cr3C2金属陶瓷的最佳硬度和断裂韧性分别为HV30 (2105±38)和(8.3±0.2) MPa·m1/2。

Abstract: Spark plasma sintering was successfully used to produce WC-Co cermets with the addition of Cr3C2 and TaC grain growth inhibitors. The spark plasma sintered compacts were investigated by scanning electron microscopy, X-ray diffraction analysis, density measurements, hardness tests, fracture toughness tests and elastic modulus tests. The results were compared with an inhibitor-free WC-Co cermet consolidated under the same process parameters. By using Cr3C2 and TaC additives, it is possible to improve the hardness and fracture toughness of WC-Co cermets, but Cr3C2 has better grain growth inhibition property than that of TaC. The best combination of hardness (HV30 (2105±38)) and fracture toughness ((8.3±0.2) MPa·m1/2) was obtained by the WC-5Co-2Cr3C2 cermet.

Trans. Nonferrous Met. Soc. China 26(2016) 2641-2646

P. SIWAK1, D. GARBIEC2

1. Poznan University of Technology, Institute of Mechanical Technology, 3 Piotrowo street, 60-965 Poznan, Poland;

2. Metal Forming Institute, 14 Jana Pawla II street, 61-139 Poznan, Poland

Received 13 October 2015; accepted 15 April 2016

Abstract: Spark plasma sintering was successfully used to produce WC-Co cermets with the addition of Cr3C2 and TaC grain growth inhibitors. The spark plasma sintered compacts were investigated by scanning electron microscopy, X-ray diffraction analysis, density measurements, hardness tests, fracture toughness tests and elastic modulus tests. The results were compared with an inhibitor-free WC-Co cermet consolidated under the same process parameters. By using Cr3C2 and TaC additives, it is possible to improve the hardness and fracture toughness of WC-Co cermets, but Cr3C2 has better grain growth inhibition property than that of TaC. The best combination of hardness (HV30 (2105±38)) and fracture toughness ((8.3±0.2) MPa·m1/2) was obtained by the WC-5Co-2Cr3C2 cermet.

Key words: spark plasma sintering; cermet; chromium carbide; tantalum carbide; mechanical properties

1 Introduction

Several studies [1-3] have concentrated on the relationship between the microstructure and properties of the cutting zone in industrial applications. WC-Co cermets are mostly used for machining, mining, cutting and drilling tools as well as wear resistance parts. They consist of hard WC embedded in ductile Co [4-7]. Increasing the WC fraction and/or decreasing the WC grain size can increase hardness and wear resistance, while fracture toughness can increase with increasing the Co content and/or WC grain size [7,8]. That is why WC-Co cermets with 5%-10% Co are the most promising materials offering a very good balance of hardness and fracture toughness [8]. Furthermore, it is important to control the growth of WC grains. This is achieved by using grain growth inhibitors. In cemented carbides the most commonly used grain growth inhibitors are Cr3C2 [9], TaC [10,11], TiC [11], VC [10] and NbC [12]. Besides, the addition of grain growth inhibitors are also very useful to improve fracture toughness [12]. MAHMOODAN et al [10] proved that additions of 0.6% TaC and 0.7% VC to WC-10Co cermets increase hardness by 24% and fracture toughness by 35% over that of inhibitor-free sintered compacts. The same relationship was confirmed by other authors. SU et al [8] demonstrated that an addition of 0.4% TaC to WC-9Co increases hardness from HV30 927 to HV30 1124. Hardness increased from HV30 1420 to HV30 1604 and HV30 1915 by adding a set of WC-6Co inhibitors: TaC-NbC and TiC-TaC-NbC, respectively [11]. The same effect was observed by  et al [9], where an addition of 1% Cr3C2 to WC-12Co cermets increased hardness from HV30 1503 to HV30 1668 for conventional sintering and from HV30 1847 to HV30 1872 for spark plasma sintering (SPS).

et al [9], where an addition of 1% Cr3C2 to WC-12Co cermets increased hardness from HV30 1503 to HV30 1668 for conventional sintering and from HV30 1847 to HV30 1872 for spark plasma sintering (SPS).

WC-Co cermet densification has been accomplished by such processes as conventional sintering [13], hot pressing [14], hot isostatic pressing [15], microwave sintering [16,17], high-frequency induction sintering [18,19] and spark plasma sintering. In particular, the SPS technique, which has the advantages of rapid heating and cooling, short holding time and controllable high pressure over conventional PM methods, has attracted more and more attention in investigations of cemented carbides [20,21]. That is why in this work we report the results on the sintering of WC-Co cermets with an addition of a high content of Cr3C2 and TaC grain growth inhibitors. The goal of the work was to produce WC-Co cermets by spark plasma sintering and study the effect of Cr3C2 and TaC additives on the densification, microstructure and some mechanical properties of the obtained sintered compacts.

2 Experimental

Submicrocrystalline WC (99.95%, particle size ~200 nm), microcrystalline Co (particle size ~4 μm), microcrystalline Cr3C2 (99.9%, particle size ~6 μm) and microcrystalline TaC (99.9%, particle size ~3 μm) were used as the starting materials. The morphology and EDS analysis of the powders were examined by scanning electron microscopy using a Vega 5135 (Tescan, USA) microscope with an energy dispersive X-ray spectrometer. The WC and Co, WC, Co and Cr3C2, WC, Co and TaC powders were mechanically mixed for 5 h using our own construction mixer similar to Turbula shaker-mixer. The prepared WC-5%Co, WC-5%Co- 2%Cr3C2 and WC-5%Co-2%TaC powder mixtures were densified by spark plasma sintering using an HP D 25-3 furnace (FCT, Germany). The sintering temperature of 1500 °C was reached at the heating rate of 600 °C/min. The pressure level on the specimens was kept constant at 50 MPa throughout the sintering process. The vacuum level of the sintering chamber was set at 5 Pa. After 5 min holding time, the sintered compacts were rapidly cooled to room temperature.

The consolidated material densities were measured following the Archimedes’ method. Vickers hardness measurements were carried out using a hardness tester FV-700 (Future-Tech, Germany) by applying a load of 294.2 N for 7 s. The fracture toughness (KIC) was calculated based on the crack length measured from the corner of the indenter made by Vicker’s indentation using Eq. (1) [22]:

(1)

(1)

where HV30 is the Vickers hardness measured under a load of 294.2 N and  is the total length of cracks initiated from the corners of the indenter. The studies of the indentation elastic modulus (EIT) were carried out using a nanoindentation tester Picodentor HM500 (Fischer, Germany). The Vickers indenter was used under a load of 0.3 N applied for 5 s. The X-ray structural studies were performed by an Empyrean diffractometer (PANalytical, Netherdlands) using Cu Kα radiation with an Ni filter and stepping working mode. The Scherrer method was used to estimate the average WC crystallite size. The microstructure of the sintered materials was observed on polished cross-sectioned surfaces by scanning electron microscopy using an Inspect S (FEI, Netherlands) microscope.

is the total length of cracks initiated from the corners of the indenter. The studies of the indentation elastic modulus (EIT) were carried out using a nanoindentation tester Picodentor HM500 (Fischer, Germany). The Vickers indenter was used under a load of 0.3 N applied for 5 s. The X-ray structural studies were performed by an Empyrean diffractometer (PANalytical, Netherdlands) using Cu Kα radiation with an Ni filter and stepping working mode. The Scherrer method was used to estimate the average WC crystallite size. The microstructure of the sintered materials was observed on polished cross-sectioned surfaces by scanning electron microscopy using an Inspect S (FEI, Netherlands) microscope.

3 Results and discussion

Figure 1 shows the second electron SEM micrographs of the starting powders. It can be seen from Fig. 1 that the WC and TaC powder particles were spherical in shape and significantly agglomerated. The Co and Cr3C2 powder particles were generally rounded and slightly agglomerated. The EDS analyses showed that only the main peaks corresponding to the basic elements were clearly visible. This means that no contaminations were detected above the EDS detection limit.

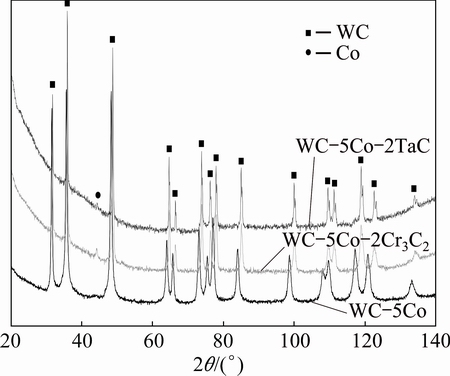

Figure 2 shows the typical XRD patterns of the spark plasma sintered WC-Co cermets. In all cases, WC-5Co, WC-5Co-2Cr3C2 and WC-5Co-2TaC were composed of WC and Co phases. The only one low diffraction peak of Co (111) was visible at 2θ of ~44°. No Cr3C2 or TaC phases were detected in the X-ray diffraction analysis in the obtained sintered compacts, as in Refs. [10,11]. No diffraction peaks for the sub-carbide W2C were present, thus spark plasma sintering does not lead to any compositional changes or transformations. However, in the XRD spectra there is a clearly visible shift in WC peaks toward a higher 2θ value. This is most likely caused by a deformation of the crystal structure during spark plasma sintering with grain growth inhibitors, which affects the position of the diffraction peaks.

Figure 3 shows the backscattered electron SEM images of the obtained WC-5Co, WC-5Co-2Cr3C2 and WC-5Co-2TaC sintered compacts. The microstructure observations allowed the authors to highlight the ceramic and the binder distribution. The bright and grey contrast phases are the WC ceramic and Co binder, respectively. The WC particles have a multi-angular shape. The black areas correspond to pores. Larger pores were observed only in the WC-5Co-2Cr3C2 specimen. This may be due to the higher viscosity of the liquid phase containing Cr3C2 and the lower capability to fill the porosities. The same effect was observed by SUN et al [23]. In contrast, only small pores, which cannot disappear during the SPS process, were observed in the inhibitor-free and TaC-containing specimens. This is due to the fact that the TaC addition has little effect on decreasing the viscosity of the liquid phase during sintering [10]. The WC grains estimated using the Scherrer method show a size of 47 nm for the inhibitor-free and 26 and 38 nm for the specimens containing Cr3C2 and TaC, respectively. This means that Cr3C2 has better grain growth inhibition property than TaC.

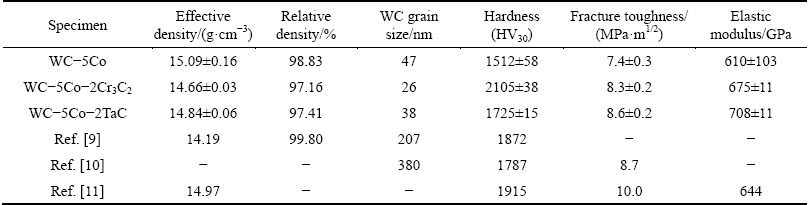

Table 1 shows the values of density, hardness, fracture toughness and elastic modulus of the WC-Co inhibitor-free and WC-Co-containing grain growth inhibitors spark plasma sintered compacts, compared with the literature data. However, a direct comparison of other authors’ results with the obtained values is hampered due to the various contents of Co binder and grain growth inhibitors in each paper.

All the obtained spark plasma sintered cermets show densification above 97% of theoretical density. The inhibitor-free specimen has the highest relative density, near 99%. The cermet with the Cr3C2 addition has the highest porosity. The cermet with the TaC addition has a little bit lower porosity. The obtained density measurement results confirmed the microstructure observations.

Fig. 1 Second electron SEM images and EDS analysis results of starting powders

Fig. 2 XRD patterns of spark plasma sintered compacts

Fig. 3 Backscattered SEM images of spark plasma sintered WC-5Co (a), WC-5Co-2Cr3C2 (b) and WC-5Co-2TaC (c) compacts

Based on the results presented in Table 1, WC- 5Co-2Cr3C2 has the highest hardness (HV30 2105±38), 39% higher than that of the inhibitor-free specimen and 22% higher than that of the specimen containing 2% TaC. The WC-5Co-2TaC specimen has 14% higher hardness than the WC-5Co cermet. Moreover, the obtained WC-5Co-2Cr3C2 specimen has higher hardness than the cermets fabricated by  et al [9], MAHMOODAN et al [10] and MERWE et al [11], where the hardness is below HV30 2000.

et al [9], MAHMOODAN et al [10] and MERWE et al [11], where the hardness is below HV30 2000.

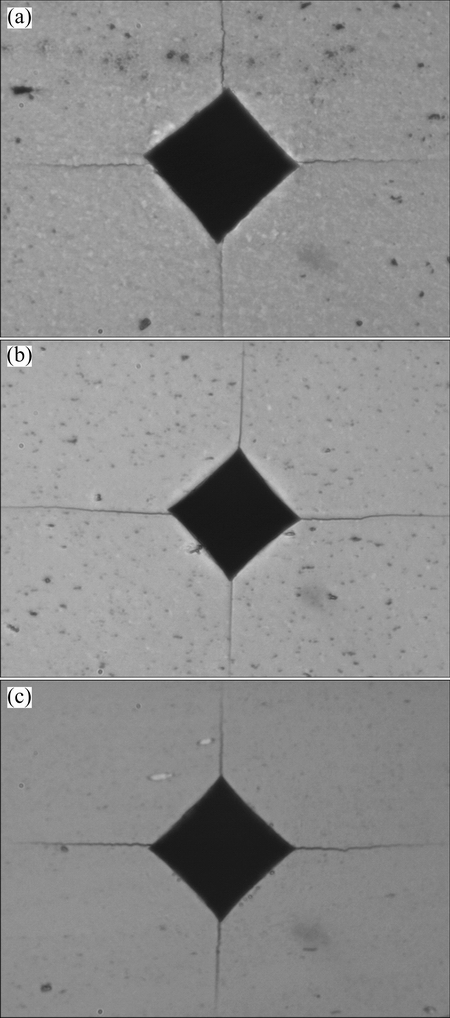

Figure 4 shows the LM micrographs of Vickers indentations of the obtained specimens. There were cracks near the indents made by the Vickers indentation load and the crack paths were straight. The measured crack lengths were used to calculate the fracture toughness of all the specimens. The obtained sintered compacts with grain growth inhibitor addition were characterized by a higher fracture toughness than that of the inhibitor-free cermet. WC-5Co was characterized by KIC ~7.4 MPa·m1/2, but the cermets with inhibitor addition have KIC above 8 MPa·m1/2, wherein the WC-5Co-2TaC has the highest fracture toughness (8.6 MPa·m1/2), 15% higher than that of the WC-5Co cermet. This improvement was achieved by choosing suitable spark plasma sintering conditions and appropriate performance of Cr3C2 and TaC as grain growth inhibitors during sintering. A similar effect after proper selection of the sintering conditions was obtained by MAHMOODAN et al [24]. However, KIC of the obtained sintered compacts was lower than that of the fracture toughness reported by other authors presented in Table 1. Mainly, it is a result of low Co binder content in the obtained specimens, regarding the cermets fabricated by  et al [9], MAHMOODAN et al [10] and MERWE and SACKS [11].

et al [9], MAHMOODAN et al [10] and MERWE and SACKS [11].

Table 1 Properties of fabricated spark plasma sintered compacts compared with literature data

Fig. 4 Vickers indentation of spark plasma sintered WC-5Co (a), WC-5Co-2Cr3C2 (b) and WC-5Co-2TaC (c) compacts

The indentation elastic moduli of the inhibitor-free cemented carbide were 610 GPa and 675 GPa for cermet with Cr3C2 addition. The TaC-containing specimen shows the highest EIT of 708 GPa, 16% higher than that of the inhibitor-free cemented carbide, about 5% higher than that of the specimen with the Cr3C2 addition and 10% higher than that of the cermet fabricated by MERWE et al [11]. This follows that the presence of this inhibitor has an improving effect on elasticity.

4 Conclusions

The rapid consolidation of WC-Co, WC-Co-Cr3C2 and WC-Co-TaC hard materials was accomplished using spark plasma sintering. Nearly fully dense cermets were obtained. It is obviously indicated that both Cr3C2 and TaC additives improve the hardness and fracture toughness of the obtained sintered compacts. The lack of inhibitors causes grain growth and deterioration of the mechanical properties. With 2% Cr3C2 addition in the WC-5Co, the hardness is HV30 2105 and fracture toughness is 8.3 MPa·m1/2, which are 39% and 10% higher than those of the inhibitor-free WC-5Co cermet consolidated under the same process parameters, respectively.

References

[1] KROLCZYK G, LEGUTKO S, NIESLONY P, GAJEK M. Study of the surface integrity microhardness of austenitic stainless steel after turning [J]. Technical Gazette, 2014, 21: 1307-1311.

[2] MARUDA R, LEGUTKO S, KROLCZYK G, HLOCH S, MICHALSKI M. An influence of active additives on the formation of selected indicators of the condition of the Z10CrNi18-8 stainless steel surface layer in MQCL conditions [J]. International Journal of Surface Science and Engineering, 2015, 9: 452-465.

[3] KROLCZYK G, NIESLONY P, LEGUTKO S, STOIC A. Microhardness changes gradient of the duplex stainless steel (DCS) surface layer after dry turning [J]. Metalurgija, 2014, 53: 529-532.

[4] LIU Wen, SONG Xiao-yan, WANG Kai, ZHANG Jiu-xing, ZHANG Guo-zhen, LIU Xue-mei. A novel rapid route for synthesizing WC-Co bulk by in situ reactions in spark plasma sintering [J]. Materials Science and Engineering A, 2009, 499: 476-481.

[5] LIU Wen-bin, SONG Xiao-yan, ZHANG Jiu-xing, YIN Fu-xing, ZHANG Guo-zhen. A novel route to prepare ultrafine-grained WC-Co cemented carbides [J]. Journal of Alloys and Compounds, 2008, 458: 366-371.

[6] MD RAIHANUZZAMAN R, JEONG T S, GHOMASHCHI R, XIE Z H, HONG S J. Characterization of short-duration high-energy ball milled WC-Co powders and subsequent consolidations [J]. Journal of Alloys and Compounds, 2014, 615: 564-568.

[7] KIM Hwan-cheol, SHON In-jin, YOON Jin-kook, DOH Jung-mann. Consolidation of ultra fine WC and WC-Co hard materials by pulsed current activated sintering and its mechanical properties [J]. International Journal of Refractory Metals and Hard Materials, 2007, 25: 46-52.

[8] SU Wei, SUN Ye-xi, YANG Hai-lin, ZHANG Xian-qi, RUAN Jian-ming. Effects of TaC on microstructure and mechanical properties of coarse grained WC-9Co cemented carbides [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1194-1199.

[9]  L, BORRELL A, SALVADOR M D, GUTIERREZ-GONZALEZ C F. Sliding wear behavior of WC-Co-Cr3C2-VC composites fabricated by conventional and non-conventional techniques [J]. Wear, 2013, 307: 60-67.

L, BORRELL A, SALVADOR M D, GUTIERREZ-GONZALEZ C F. Sliding wear behavior of WC-Co-Cr3C2-VC composites fabricated by conventional and non-conventional techniques [J]. Wear, 2013, 307: 60-67.

[10] MAHMOODAN M, ALIAKBARZADEH H, GHOLAMIPOUR R. Sintering of WC-10%Co nano powder containing TaC and VC grain growth inhibitors [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 1080-1084.

[11] van der MERWE R, SACKS N. Effect of TaC and TiC on the friction and dry sliding wear of WC-6wt.%Co cemented carbides against steel counterfaces [J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 94-102.

[12] GENGA R M, AKDOGAN G, WESTRAADT J E, CORNISH L A. Microstructure and material properties of PECS manufactured WC-NbC-Co and WC-TiC-Ni cemented carbides [J]. International Journal of Refractory Metals and Hard Materials, 2015, 49: 240-248.

[13]  P, BARTHA L, PORAT R, BERGER S, ROSEN A. Solid or liquid phase sintering of nanocrystalline WC/Co hardmetals [J]. Nanostructured Materials, 1998, 10: 245-255.

P, BARTHA L, PORAT R, BERGER S, ROSEN A. Solid or liquid phase sintering of nanocrystalline WC/Co hardmetals [J]. Nanostructured Materials, 1998, 10: 245-255.

[14] JIA Cheng-chang, SUN Lan, TANG Hua, QU Xuan-hui. Hot pressing of nanometer WC-Co powder [J]. International Journal of Refractory Metals and Hard Materials, 2007, 25: 53-56.

[15] WEI Chong-bin, SONG Xiao-yan, ZHAO Shi-xian, ZHANG Li, LIU Wen-bin. In-situ synthesis of WC-Co composite powder and densification by sinter-HIP [J]. International Journal of Refractory Metals and Hard Materials, 2010, 28: 567-571.

[16] BAO Rui, YI Jian-hong, PENG Yuan-dong, ZHANG Hao-ze, LI Ai-kun. Decarburization and improvement of ultra fine straight WC-8Co sintered via microwave sintering [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 853-857.

[17] BAO Rui, YI Jian-hong. Effect of sintering atmosphere on microwave prepared WC–8wt.%Co cemented carbide [J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 315-321.

[18] KIM Hwan-cheol, OH Dong-young, SHON In-jin. Sintering of nanophase WC-15vol.%Co hard metals by rapid sintering process [J]. International Journal of Refractory Metals and Hard Materials, 2004, 22: 197-203.

[19] KIM Hwan-cheol, OH Dong-young, JIANG Guo-jian, SHON In-jin. Synthesis of WC and dense WC-5vol.%Co hard materials by high-frequency induction heated combustion [J]. Materials Science and Engineering A, 2004, 368: 10-17.

[20] RUMMAN R, SIE Z H, HONG S J, GHOMASHCHI R. Effect of spark plasma sintering pressure on mechanical properties of WC-7.5wt% nano Co [J]. Materials and Design, 2015, 68: 221-227.

[21] ZHAO Shi-xian, SONG Xiao-yan, WEI Chong-bin, ZHANG Li, LIU Xue-mei, ZHANG Jiu-xing. Effects of WC particle size on densification and properties of spark plasma sintered WC-Co cermet [J]. International Journal of Refractory Metals and Hard Materials, 2009, 27: 1014-1018.

[22] SCHUBERT W D, NEUMEISTER H, KINGER G, LUX B. Hardness to toughness relationship of fine-graded WC-Co hardmetals [J]. International Journal of Refractory Metals and Hard Materials, 1998, 16: 133-142.

[23] SUN Lan, YANG Tian-en, JIA Cheng-chang, XIONG Ji. VC, Cr3C2 doped ultrafine WC-Co cemented carbides prepared by spark plasma sintering [J]. International Journal of Refractory Metals and Hard Materials, 2011, 29: 147-152.

[24] MAHMOODAN M, ALIAKBARZADEH H, GHOLAMIPOUR R. Microstructural and mechanical characterization of high energy ball milled and sintered WC-10wt%Co-xTaC nano powders [J]. International Journal of Refractory Metals and Hard Materials, 2009, 27: 801-805.

P. SIWAK1, D. GARBIEC2

1. Poznan University of Technology, Institute of Mechanical Technology, 3 Piotrowo street, 60-965 Poznan, Poland;

2. Metal Forming Institute, 14 Jana Pawla II street, 61-139 Poznan, Poland

摘 要:通过添加Cr3C2和TaC晶粒长大抑制剂,采用等离子体烧结技术制备WC-Co金属陶瓷。采用扫描电镜、X射线衍射、密度测定、硬度测试、断裂韧性测试和弹性模量测试技术表征放电等离子烧结体。在相同的工艺参数下,与不添加WC-Co抑制剂的金属陶瓷进行了比较。结果表明,添加Cr3C2 和 TaC抑制剂能提高WC-Co金属陶瓷的硬度和断裂韧性,且添加Cr3C2的陶瓷其晶粒生长抑制性能比添加TaC的更好。WC-5Co-2Cr3C2金属陶瓷的最佳硬度和断裂韧性分别为HV30 (2105±38)和(8.3±0.2) MPa·m1/2。

关键词:等离子体烧结;金属陶瓷;碳化铬;碳化钽;力学性能

(Edited by Xiang-qun LI)

Corresponding author: P. SIWAK; E-mail: piotr.siwak@put.poznan.pl

DOI: 10.1016/S1003-6326(16)64390-X