文章编号:1004-0609(2015)10-2642-07

动态塑性变形下AZ31镁合金的孪生特征

娄 超1,张喜燕2,任 毅2

(1. 重庆交通大学 交通土建工程材料国家地方联合工程实验室,重庆 400074;

2. 重庆大学 材料科学与工程学院,重庆 400044)

摘 要:沿热轧退火态AZ31镁合金轧制方向进行室温动态塑性变形,采用场发射扫描电子显微镜研究 孪生的变体类型及结构特征。结果表明:在

孪生的变体类型及结构特征。结果表明:在 孪生机制主导塑性变形的初级阶段(ε<8%),AZ31镁合金中大部分晶粒内部仅产生一种

孪生机制主导塑性变形的初级阶段(ε<8%),AZ31镁合金中大部分晶粒内部仅产生一种 孪生变体或变体对,所以孪晶结构呈彼此平行状,将晶粒分割成片层组织;这种片层组织的厚度随着应变量的增加而减小,从5.55 μm减小到2.49 μm;少数晶粒形核产生不同的

孪生变体或变体对,所以孪晶结构呈彼此平行状,将晶粒分割成片层组织;这种片层组织的厚度随着应变量的增加而减小,从5.55 μm减小到2.49 μm;少数晶粒形核产生不同的 孪生变体,且这种晶粒的数量随着塑性变形量的增大而增加;当ε>8%,孪生体积分数接近饱和,位错滑移成为镁合金主要的变形机制。

孪生变体,且这种晶粒的数量随着塑性变形量的增大而增加;当ε>8%,孪生体积分数接近饱和,位错滑移成为镁合金主要的变形机制。

关键词:镁合金;动态塑性变形;孪生变体;变形机制

中图分类号:TG146.2 文献标志码:A

Twinning characteristic of AZ31 magnesium alloy during dynamic plastic deformation

LOU Chao1, ZHANG Xi-yan2, REN Yi2

(1. National and Local Joint Engineering Laboratory of Traffic Civil Engineering Materials,

Chongqing Jiaotong University, Chongqing 400074, China;

2. School of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: Both variant type and structure characteristic of  twinning in the as-rolled AZ31 magnesium alloy subjected to dynamic plastic deformation at room temperature along the rolling direction were investigated. The results show that at the stage of twinning-dominated deformation (ε<8%), mostly a

twinning in the as-rolled AZ31 magnesium alloy subjected to dynamic plastic deformation at room temperature along the rolling direction were investigated. The results show that at the stage of twinning-dominated deformation (ε<8%), mostly a  twin variant or a twin variant pair is activated in the grain of AZ31 magnesium alloy, leading to a parallel twin lamellar structure. The lamellar thickness decreases significantly from 5.55 μm to 2.49 μm with increasing the strain. Meanwhile, different

twin variant or a twin variant pair is activated in the grain of AZ31 magnesium alloy, leading to a parallel twin lamellar structure. The lamellar thickness decreases significantly from 5.55 μm to 2.49 μm with increasing the strain. Meanwhile, different  variant pairs also generate in some grains, and the number of these grains increases with increasing the plastic strain. When the plastic strain is greater than 8%, the volume fraction of twins almost saturates and dislocation slips dominate the later deformation.

variant pairs also generate in some grains, and the number of these grains increases with increasing the plastic strain. When the plastic strain is greater than 8%, the volume fraction of twins almost saturates and dislocation slips dominate the later deformation.

Key words: magnesium alloy; dynamic plastic deformation; twinning variant; deformation mechanism

镁合金是实际工程应用中最轻的金属结构材料, 在交通、电子通信、航空航天和国防军工等各个领域的应用日益广泛。但是,由于具有特殊的密排六方结构,镁合金的独立滑移系统非常有限,导致其室温条件下极差的成形性[1-6]。对于形变镁合金中常见的几种孪生类型来说, 孪生被认为是更易被激活、协调变形能力更强的变形机制。

孪生被认为是更易被激活、协调变形能力更强的变形机制。 孪生具有极性特征,即只能沿一个形变方向切变,所以机械加工过程中,镁合金会形成强烈的基面织构,从而使其力学性能表现出各向异性[7-9]。同时,复杂的孪生与位错滑移的交互作用能够有效提高或降低材料的强度与塑性。例如,孪晶界能够阻碍位错滑移,在界面附近形成位错塞积,从而提高材料的强度;孪晶界面可以作为储存位错的滑移面从而改善材料塑性[10-11]。对于热轧镁合金来说,在特定的变形方式(压缩变形方向垂直于晶格c轴)下,晶粒内部会形核平行的

孪生具有极性特征,即只能沿一个形变方向切变,所以机械加工过程中,镁合金会形成强烈的基面织构,从而使其力学性能表现出各向异性[7-9]。同时,复杂的孪生与位错滑移的交互作用能够有效提高或降低材料的强度与塑性。例如,孪晶界能够阻碍位错滑移,在界面附近形成位错塞积,从而提高材料的强度;孪晶界面可以作为储存位错的滑移面从而改善材料塑性[10-11]。对于热轧镁合金来说,在特定的变形方式(压缩变形方向垂直于晶格c轴)下,晶粒内部会形核平行的 孪晶片层结构,这种现象与激活的孪晶变体类型有关。通过分子动力学模拟,发现当这种孪晶片层间距小于2.9 nm时,镁合金的力学性能得到明显改善[12]。所以,研究密排六方金属的孪生方式,特别是孪生变形过程中激活的孪晶变体类型,对于了解孪晶片层组织结构以及设计材料的微观结构甚至是宏观力学性能都具有非常重要的意义。

孪晶片层结构,这种现象与激活的孪晶变体类型有关。通过分子动力学模拟,发现当这种孪晶片层间距小于2.9 nm时,镁合金的力学性能得到明显改善[12]。所以,研究密排六方金属的孪生方式,特别是孪生变形过程中激活的孪晶变体类型,对于了解孪晶片层组织结构以及设计材料的微观结构甚至是宏观力学性能都具有非常重要的意义。

高应变速率变形能够促进镁合金的 孪生活动[13-14],但对于相关变形下的微观孪生特征却鲜见报道。本文作者对动态塑性变形下不同变形量的AZ31镁合金的显微组织结构进行分析,通过研究微观孪生结构的演变过程,分析激活的孪生变体类型,来了解高应变速率下

孪生活动[13-14],但对于相关变形下的微观孪生特征却鲜见报道。本文作者对动态塑性变形下不同变形量的AZ31镁合金的显微组织结构进行分析,通过研究微观孪生结构的演变过程,分析激活的孪生变体类型,来了解高应变速率下 孪生行为特征。

孪生行为特征。

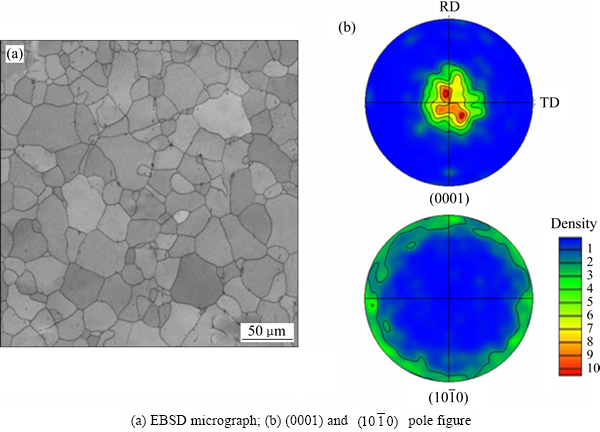

1 实验

本实验中选用420 ℃下保温3 h均匀化处理后的商用AZ31镁合金热轧坯板(成分为Al 2.95%,Zn 0.94%,Mn 0.41%,Si 0.18%,Ce 0.05%,Mg余量,质量分数)。图1所示为热轧退火态AZ31镁合金的微观结构特征。由图1可知,初始板材的显微组织中并无孪晶存在,晶粒尺寸分布较均匀,利用截线法判断材料平均晶粒度约为34 μm(见图1(a))。与大多数轧制镁合金一样,板材具有明显的基面织构,即{0001}基面几乎平行于板材轧面(见图1(b))。

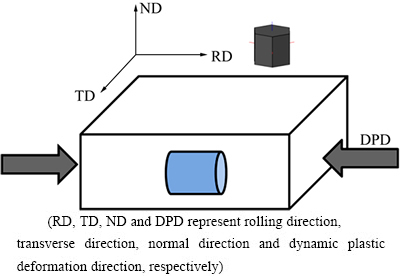

在本实验中,采用动态塑性变形(Dynamic plastic deformation,DPD)来制备样品。在板材上沿轧制方向切取圆柱样品(直径为8 mm,高度为12 mm),样品的取向示意图如图2所示。在室温条件下,利用Instron Dynatup 8120型落锤冲击试验机对样品进行单道次打击变形,应变速率约为1×103 /s。利用模具限制样品的变形量,得到应变量为2.1%、4.3%、6.5%和8.3%的样品。变形后沿RD-ND面剖开,以便于后续的显微组织观察以及织构分析。

利用商用镁合金抛光液AC 2(丹麦STURERS公司生产)室温下电解抛光60s(抛光电压为20V),之后用配备了电子背散射衍射(EBSD)探头的FEI Nova400型FEG-SEM场发射扫描电子显微镜对样品进行EBSD实验分析。当EBSD数据采集完成后,利用HKL Channel5商业软件包对样品进行常规分析。常规分析包括晶粒的取向以及相关的分析、织构组分、晶粒尺寸分布、晶界取向差分布等。

图1 热轧退火态AZ31镁合金的微观结构特征

Fig. 1 Microstructural characteristics of as-rolled AZ31 alloy sheet (RD and TD represent rolling direction and transverse direction, respectively)

图2 DPD实验的样品取向示意图

Fig. 2 Schematic diagram of sample orientations used for DPD testing

2 结果与讨论

2.1 微观结构演变

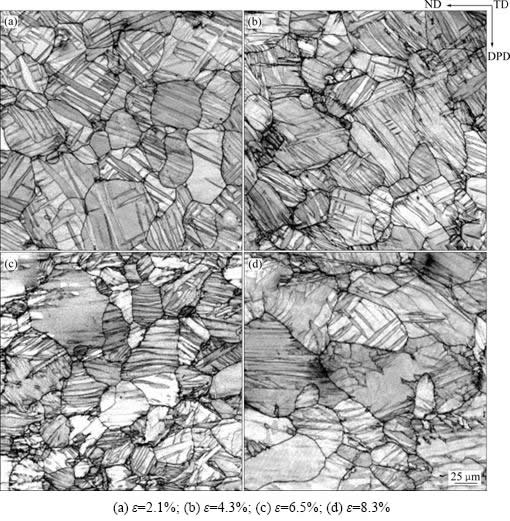

图3所示为不同应变量下样品的EBSD像。

变形后的晶粒内部只产生 一种孪晶形式。在变形初期,即应变量较小时,大量的

一种孪晶形式。在变形初期,即应变量较小时,大量的 孪晶被激活,并且绝大多数晶粒内部的孪晶形貌是彼此平行的,从而导致晶粒内部形成片层结构。随着应变量的增加,不规则的孪生形貌开始出现,这是由于平行结构的孪晶不断生长导致相遇合并。

孪晶被激活,并且绝大多数晶粒内部的孪晶形貌是彼此平行的,从而导致晶粒内部形成片层结构。随着应变量的增加,不规则的孪生形貌开始出现,这是由于平行结构的孪晶不断生长导致相遇合并。

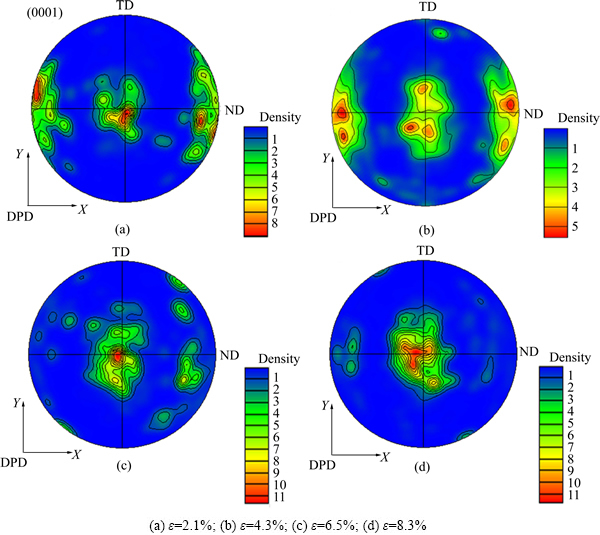

图4所示为不同应变量下AZ31镁合金的(0001)极图。对于垂直于晶体结构的c轴的单轴压缩变形,孪生部分的c轴都会偏转到近似平行于载荷的方向,从而形成孪生织构(见图4)。随着应变量的增加, 孪晶形核后的生长其体积分数会增加。大量的数据统计得出,2.1%、4.3%、6.5%和8.3%这4种应变量样品的孪生体积分数分别是26%、44%、62%和74%。所以,不同应变量下孪生织构密度的区别是基于不同的孪生体积分数。当应变量大于8%时,初始态的基面织构(即c轴平行于ND)几乎完全转变成变形后的孪生织构(即c轴平行于载荷方向,见图4(d))。

孪晶形核后的生长其体积分数会增加。大量的数据统计得出,2.1%、4.3%、6.5%和8.3%这4种应变量样品的孪生体积分数分别是26%、44%、62%和74%。所以,不同应变量下孪生织构密度的区别是基于不同的孪生体积分数。当应变量大于8%时,初始态的基面织构(即c轴平行于ND)几乎完全转变成变形后的孪生织构(即c轴平行于载荷方向,见图4(d))。

图3 不同应变量下AZ31镁合金的EBSD像

Fig. 3 EBSD images of AZ31 samples with different strains

图4 不同应变量下AZ31镁合金的(0001)极图

Fig. 4 (0001) pole figures of AZ31 samples with different strains

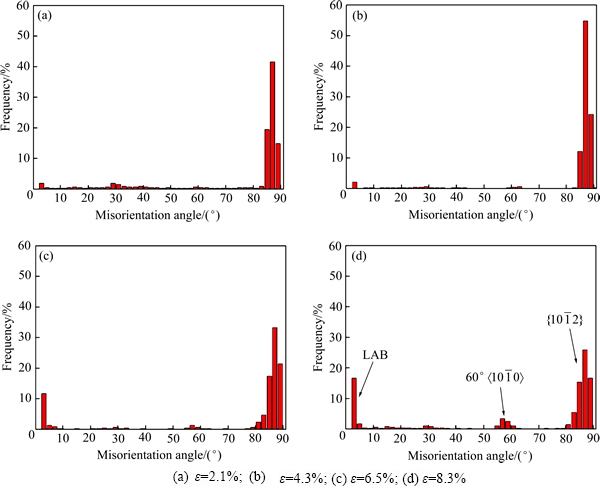

图5所示为各样品的取向差角分布图。从图5可以看出,在塑性变形初期, 孪晶大量形核,80°~90°的角度峰随着应变量的增加而急剧升高;当应变量大于4%后,这个峰值由于形核孪生的生长合并而降低。对于镁合金来说,两种

孪晶大量形核,80°~90°的角度峰随着应变量的增加而急剧升高;当应变量大于4%后,这个峰值由于形核孪生的生长合并而降低。对于镁合金来说,两种 孪生变体生长相遇可以形成几种关系界面:属于同一变体对的两个变体交互作用会形成0°或7.4°

孪生变体生长相遇可以形成几种关系界面:属于同一变体对的两个变体交互作用会形成0°或7.4° 取向关系界面;属于不同变体对的变体形成60°

取向关系界面;属于不同变体对的变体形成60° 或60.4°

或60.4° 取向关系界面。后两者的取向很接近,所以在EBSD分析中较难分辨。当压缩方向垂直于晶格c轴时,绝大多数晶粒内部只产生一种

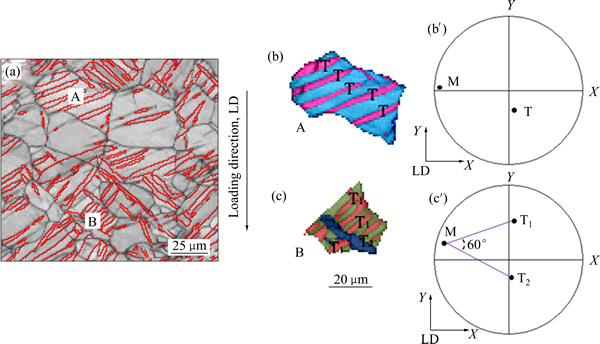

取向关系界面。后两者的取向很接近,所以在EBSD分析中较难分辨。当压缩方向垂直于晶格c轴时,绝大多数晶粒内部只产生一种 孪生变体或变体对,所以在同一晶粒内形成的孪晶形貌是彼此平行的[15],如图6中的晶粒A;当继续加载时,80°~90°的角度峰逐渐降低,而7.4°

孪生变体或变体对,所以在同一晶粒内形成的孪晶形貌是彼此平行的[15],如图6中的晶粒A;当继续加载时,80°~90°的角度峰逐渐降低,而7.4° 关系界面的密度增加,导致0°~10°的角度峰迅速增加。同时,一些晶粒形核了两种不同的

关系界面的密度增加,导致0°~10°的角度峰迅速增加。同时,一些晶粒形核了两种不同的 孪生变体(见图6(c))。所以图5中60°角度峰随着应变的增加而缓慢升高。另外,在晶界处的位错堆积以及孪晶内部高密度的位错塞积也是小角界面(<5°)迅速增加的原因之一。

孪生变体(见图6(c))。所以图5中60°角度峰随着应变的增加而缓慢升高。另外,在晶界处的位错堆积以及孪晶内部高密度的位错塞积也是小角界面(<5°)迅速增加的原因之一。

2.2 孪晶片层结构的演变

在低温动态塑性变形下,Cu的孪晶片层尺寸会随着变形量的增加而减小[16];而镍合金HASTELLOY C-2000通过表面剧烈塑性变形(S2PD)后,从中心到打击表面,即从应力集中较弱的区域到应力集中较大的区域,孪晶片层尺寸是逐渐减小的[17]。作为室温塑性变形下镁合金主要的形变机制, 孪生的形核生长改变了材料的显微组织形貌,形成大量的孪晶片层结构(见图3)。

孪生的形核生长改变了材料的显微组织形貌,形成大量的孪晶片层结构(见图3)。

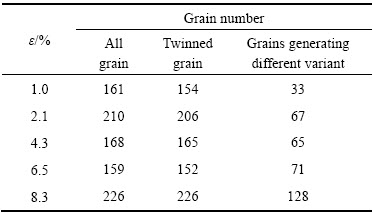

利用截线法对片层厚度进行统计,目的是分析应变过程对于显微组织形貌演变的影响。为了确保统计的有效性,对1%、2.1%、4.3%、6.5%和8.3% 5个变形量的样品进行大量的晶粒统计,结果如表1所列。在统计的晶粒中,绝大多数晶粒都发生孪生,极少量的晶粒由于取向偏离基面织构较大而没有发生孪生。

图5 不同应变量下AZ31镁合金的取向差角分布图

Fig. 5 Misorientation angle distribution maps of AZ31 samples with different strains (Peaks at 86° and 60° indicate  twins and 60°

twins and 60° relationship, and LAB indicates low angle boundaries with misorientation angle less than 5°)

relationship, and LAB indicates low angle boundaries with misorientation angle less than 5°)

图6 应变为4.3%样品的EBSD成像图以及晶粒A和晶粒B的结构示意图及相应的晶体取向分布

Fig. 6 Microstructure(a) of DPD sample with ε=4.3% and sketch maps of grains A(b) and B(c) and crystallographic orientations of grains A(b′) and B(c′), respectively (M represents grain matrix. T, T1 and T2 represent activated  twin variants; red lines indicating

twin variants; red lines indicating  twin boundaries)

twin boundaries)

表1 孪生晶粒的统计结果

Table 1 Statistical results of number of twinned grains

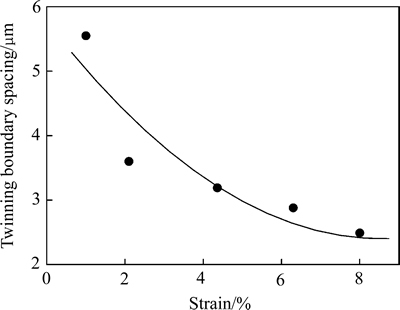

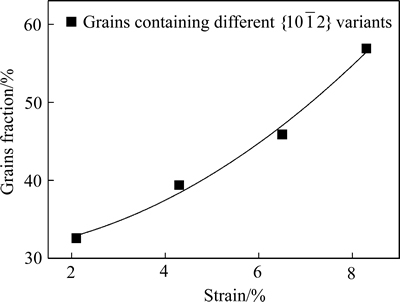

图7所示为不同应变量下样品平均孪晶片层尺寸的分布。从图7可以看出,平均片层厚度由ε=1%时的5.55 μm减少到ε=8.3%时的2.49 μm。从统计数据可以看出,孪生片层厚度随着应变的增加而减少。但是由于孪生体积分数不断增加,孪生机制对塑性变形的贡献也会逐渐减小。当应变超过8%时,平行的孪生片层形貌变得不规则,并且由于孪晶之间的交互作用,孪晶界的比例也明显降低(见图5)。当应变达到11.4%时,晶体中几乎很难再发现孪生片层结构[18]。

当 孪生主导变形时,大量平行孪生带的形核将晶粒划分成片层结构。这种显微组织形貌的演变明显与孪生的形核和生长机制有直接的关系[19]。一般来说,孪生片层厚度会随着孪晶的不断形核而减少,随着孪晶的生长而不断增长。与孪生的生长相比,孪生的形核需要更大的应力作用才能发生,所以随着应力的增加,已形核的孪晶的生长要比新孪晶的形核更容易。从图7中曲线的变化趋势来看,在塑性变形的初期阶段,大量的孪晶形核导致片层厚度的急剧下降;每个晶粒中孪生的形核数量与晶粒本身的体积有关[20],孪晶的生长导致晶粒基体体积减小,所以随着应变量的增加,新晶粒的形核变得更加困难。同时,生长孪晶的合并也导致片层数量的减少,所以在孪晶主导变形的后期变形阶段(ε>4%),片层厚度的降低趋势趋于平缓的原因是孪晶形核受到抑制。

孪生主导变形时,大量平行孪生带的形核将晶粒划分成片层结构。这种显微组织形貌的演变明显与孪生的形核和生长机制有直接的关系[19]。一般来说,孪生片层厚度会随着孪晶的不断形核而减少,随着孪晶的生长而不断增长。与孪生的生长相比,孪生的形核需要更大的应力作用才能发生,所以随着应力的增加,已形核的孪晶的生长要比新孪晶的形核更容易。从图7中曲线的变化趋势来看,在塑性变形的初期阶段,大量的孪晶形核导致片层厚度的急剧下降;每个晶粒中孪生的形核数量与晶粒本身的体积有关[20],孪晶的生长导致晶粒基体体积减小,所以随着应变量的增加,新晶粒的形核变得更加困难。同时,生长孪晶的合并也导致片层数量的减少,所以在孪晶主导变形的后期变形阶段(ε>4%),片层厚度的降低趋势趋于平缓的原因是孪晶形核受到抑制。

图7 不同应变量下样品的孪生片层厚度的统计结果

Fig. 7 Statistical results of lamellar thickness of DPD AZ31 alloys with different strains

2.3 不同 孪生变体的判定

孪生变体的判定

如前所述,当晶粒内部形核两种不同的 孪晶变体时,它们之间会形成60°

孪晶变体时,它们之间会形成60° 或60.4°

或60.4° 的取向关系。通过EBSD数据的分析,可以鉴别出形核两种变体的晶粒。对每一种变形量样品中产生不同

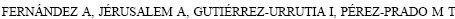

的取向关系。通过EBSD数据的分析,可以鉴别出形核两种变体的晶粒。对每一种变形量样品中产生不同 变体的晶粒数量所占分数进行统计,结果如图8所示。尽管这种晶粒在每个样品中的数量很少,但是从图8中可以发现,形核不同

变体的晶粒数量所占分数进行统计,结果如图8所示。尽管这种晶粒在每个样品中的数量很少,但是从图8中可以发现,形核不同 孪生变体的晶粒数量随着应变量的增大而增加。由于早期形核的

孪生变体的晶粒数量随着应变量的增大而增加。由于早期形核的 孪生变体生长后的体积分数较大,抑制新形核变体的生长,导致它们协调塑性变形能力有限。由于这种新形核的变体的数量较少,体积分数较小,使其与早期形核变体生长相遇后形成的60°

孪生变体生长后的体积分数较大,抑制新形核变体的生长,导致它们协调塑性变形能力有限。由于这种新形核的变体的数量较少,体积分数较小,使其与早期形核变体生长相遇后形成的60° 关系界面的百分比较小。所以,尽管随着应力增加仍有新的孪生产生,但它们已经无法对镁合金的塑性变形起到太大的作用。

关系界面的百分比较小。所以,尽管随着应力增加仍有新的孪生产生,但它们已经无法对镁合金的塑性变形起到太大的作用。

图8 形核两种不同 孪晶变体的晶粒数量所占分数

孪晶变体的晶粒数量所占分数

Fig. 8 Number fraction of grains generating two different  variants

variants

3 结论

1) 当热轧退火AZ31镁合金垂直于晶格c轴进行动态塑性变形时,大量 孪晶被激活。由于大部分晶粒内部仅仅产生一种

孪晶被激活。由于大部分晶粒内部仅仅产生一种 孪生变体或变体对,所以它们之间彼此平行,将晶粒分割成片层组织。

孪生变体或变体对,所以它们之间彼此平行,将晶粒分割成片层组织。

2) 孪生机制主导塑性变形的初级阶段(ε<8%)。在这一阶段,片层厚度随着应变量的增加而减小,从5.55 μm减小到2.49 μm。而片层结构尺寸的演变与变形过程中孪生活动有着直接的关联。当ε<4%时,积极的孪生形核导致片层厚度急剧降低;当ε>4%时,由于孪生的生长以及初始晶粒体积的减少,新的孪生形核受到抑制,导致片层厚度的降低趋势趋于平缓。

3) 随着应变量的增加,仍有新的孪晶产生,但由于其数量少,体积分数小,导致其对镁合金的塑性变形贡献有限。所以当应变量继续增大(ε>8%)时,位错滑移将会取代 孪生,成为镁合金主要的变形机制。在这一阶段,孪生片层结构基本消失,孪生体积分数接近饱和。

孪生,成为镁合金主要的变形机制。在这一阶段,孪生片层结构基本消失,孪生体积分数接近饱和。

REFERENCES

[1] BARNETT M R. Twinning and the ductility of magnesium alloys Part Ⅰ: “Tension” twins[J]. Materials Science and Engineering A, 2007, 464(1/2): 1-7.

[2] BARNETT M R. Twinning and the ductility of magnesium alloys Part Ⅱ: “Contraction” twins[J]. Materials Science and Engineering A, 2007, 464(1/2): 8-16.

[3] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHENG Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[4] YOO M H. Slip, twinning, and fracture in hexagonal close- packed metals[J]. Metallurgical Transactions A, 1981, 12(3): 409-418.

[5] 丁文江, 靳 丽, 吴文祥, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 21(10): 2371-2381.

DING Wen-jiang, JIN Li, WU Wen-xiang, DONG Jie. Texture and texture randomization of wrought Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2371-2381.

[6] 郭 飞, 张丁非, 杨绪盛, 蒋璐瑶, 潘复生. 大应变热轧过程中AZ31镁合金显微组织及织构变化[J]. 中国有色金属学报, 2015, 25(1): 14-21.

GUO Fei, ZHANG Ding-fei, YANG Xu-sheng, JIANG Lu-yao, PAN Fu-sheng. Microstructure and texture evolution of AZ31 magnesium alloy during large strain hot rolling[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 14-21.

[7] del VALLE J A, CARRENO F, RUANO O A. Influence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling[J]. Acta Materialia, 2006, 54(16): 4247-4259.

[8] LOU C, ZHANG X Y, WANG R H, LIU Q. Mechanical behavior and microstructural characteristics of magnesium alloy containing  twin lamellar structure[J]. Journal of Materials Research, 2013, 28(5): 733–739.

twin lamellar structure[J]. Journal of Materials Research, 2013, 28(5): 733–739.

[9] 卢立伟, 赵 俊, 刘龙飞, 王 尧, 刘天模. 冷锻及再结晶退火对挤压态AZ31镁合金组织的影响[J]. 中国有色金属学报, 2014, 24(12): 2969-2977.

LU Li-wei, ZHAO Jun, LIU Long-fei, WANG Yao, LIU Tian-mo. Influence of cold forging and recrystallization annealing on microstructure of extruded AZ31 magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 2969-2977.

[10] LU K, LU L, SURESH S. Strengthening materials by engineering coherent internal boundaries at the nanoscale[J]. Science, 2009, 324: 349-352.

[11] LU L, CHEN X, HUANG X, LU K. Revealing the maximum strength in nanotwinned copper[J]. Science, 2009, 323: 607-610.

[12] SONG H Y, LI Y L. Effect of twin boundary spacing on deformation behavior of nanotwinned magnesium[J]. Physics Letters A, 2012, 376(4): 529-533.

[13] DUDAMELL N V, ULACIA I,  , YI S, BOHLEN J, LETZIG D, HURTADO I, PEREZ-PRADO M T. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature[J]. Acta Materialia, 2011, 59(18): 6949-6962.

, YI S, BOHLEN J, LETZIG D, HURTADO I, PEREZ-PRADO M T. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature[J]. Acta Materialia, 2011, 59(18): 6949-6962.

[14] LOU C, ZHANG X Y, DUAN G L, TU J, LIU Q. Characteristics of different  twin variants in magnesium alloy during room temperature dynamic plastic deformation[J]. Journal of Materials Research, 2013, 28(14): 1885-1890.

twin variants in magnesium alloy during room temperature dynamic plastic deformation[J]. Journal of Materials Research, 2013, 28(14): 1885-1890.

[15] HONG S G, PARK S H, LEE C S. Role of  twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy[J]. Acta Materialia, 2010, 58: 5873-5885.

twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy[J]. Acta Materialia, 2010, 58: 5873-5885.

[16] XIAO G H, TAO N R, LU K. Microstructures and mechanical properties of a Cu-Zn alloy subjected to cryogenic dynamic plastic deformation[J]. Materials Science and Engineering A, 2009, 513/514: 13-21.

[17] SHAW L L, ORTIZ A L, VILLEGAS J C. Hall-Petch relationship in a nanotwinned nickel alloy[J]. Scripta Materialia, 2008, 58: 951-954.

[18] LOU C, ZHANG X Y, WANG R H, LIU Q. Characteristics of  twin lamellar structure in magnesium alloy during room temperature dynamic plastic deformation[J]. Journal of Materials Science & Technology, 2014, 30(1): 41-46.

twin lamellar structure in magnesium alloy during room temperature dynamic plastic deformation[J]. Journal of Materials Science & Technology, 2014, 30(1): 41-46.

[19]  . Three-dimensional investigation of grain boundary-twin interactions in a Mg AZ31 alloy by electron backscatter diffraction and continuum modeling[J]. Acta Materialia, 2013, 61:7679-7692.

. Three-dimensional investigation of grain boundary-twin interactions in a Mg AZ31 alloy by electron backscatter diffraction and continuum modeling[J]. Acta Materialia, 2013, 61:7679-7692.

[20] CAPOLUNGO L, MARSHALL P E, MCCABE R J, BEYERLEIN I J, TOME C N. Nucleation and growth of twins in Zr: A statistical study[J]. Acta Materialia, 2009, 57: 6047-6056.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51071183, 50890170)

收稿日期:2015-03-23;修订日期:2015-07-13

通信作者:娄 超,讲师,博士;电话:023-62650387;E-mail: louchao84@163.com