文章编号:1004-0609(2014)10-2519-06

化学镀非晶态Ni-P镀层的摩擦与磨损性能

孔德军1, 2,王进春1,刘 浩1

(1. 常州大学 机械工程学院,常州 213164;

2. 常州大学 江苏省材料表面科学与技术重点实验室,常州 213164)

摘 要:采用化学镀方法在5052铝合金表面制备一层非晶态Ni-P镀层,用扫描电镜、能谱仪、X射线衍射仪等对Ni-P镀层形貌、化学成分和物相进行分析和表征。通过磨损试验测试其摩擦因数和磨损性能,并对其磨损机理进行分析。结果表明:化学镀非晶态Ni-P镀层由直径为10~50 μm原子团簇组成,能够完全覆盖基体,镀层表面显微硬度为370.5HV;镀层与基体结合较好,其厚度为20 μm左右;Ni-P镀层主要由Ni和P组成,其中Ni原子结合能为853.34 eV,P原子结合能为133.02 eV;镀层摩擦因数为0.4556,磨损质量损失减少83.5%,其磨损形式为磨粒磨损;镀层摩擦区边缘发生裂纹萌生和扩展,产生脆性剥落,镀层未被磨穿,Ni-P镀层的抗磨损性能较好。

关键词:Ni-P镀层;5052铝合金;摩擦因数;磨损性能

中图分类号:U177.2;TG115.5 文献标志码:A

Friction and wear properties of amorphous Ni-P coating prepared by electroless plating

KONG De-jun1, 2, WANG Jin-chun1, LIU Hao1

(1. College of Mechanical Engineering, Changzhou University, Changzhou 213164, China;

2. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164, China)

Abstract: Amorphous Ni-P coating was prepared on the surface of 5052 aluminum alloy by electroless plating, the morphologies, compositions and phases of the coating were analyzed and characterized with SEM, EDS and XRD, respectively. The friction coefficients and wear performances of Ni-P coating and 5052 aluminum alloy were investigated with wear test, the wear resistance mechanism of Ni-P coating was discussed. The results show that Ni-P coating by chemical plating is composed of atom clusters with the diameter of 10-50 μm, which can cover the substrate completely; the surface micro-hardness is 370.5HV. Ni-P coating is well bonded with the substrate, and the coating thickness is about 20 μm. Ni-P coating is composed of Ni and P atoms, in which the bonding energy of Ni atom is 853.34 eV, while that of P atom is 133.02 eV. The friction coefficient of Ni-P coating is 0.4556, the wear mass loss decreases by 83.5% compared with that of the substrate, and the wear mechanism is abrasive wear. The micro-crack initiation and propagation are produced and peeled at the wear edge, and the coating is not worn out, showing good wear performances.

Key words: Ni-P coating; aluminum alloy 5052; friction coefficient; wear performance

5052铝合金属于Al-Mg系合金,具有良好的抗蚀性、强度较低、塑性高、成形性能优良等特点[1],广泛应用于航空、航天、兵器等行业,是制造“大飞机”所必备的高品质铝合金材料,可以制作旋翼、螺旋桨、壁板、起落架支柱以及火箭锻环等。但由于5052铝合金硬度仅有60~80HB,其耐磨性能较差,且工艺上不可以通过热处理进行强化[2]。虽然铝合金中Mg元素有一定的固溶强化作用,但铝合金的硬度不高,目前,铝合金主要采用阳极氧化和化学镀方法进行表面强化处理[3-5]。阳极氧化大多采用硫酸溶液,形成的氧化膜孔洞较大,表面粗糙度值也比较大,降低了氧化膜质量[6]。化学镀Ni-P镀层是铝合金比较理想的表面改性技术之一,可以提高基体材料的耐蚀性、耐磨性和硬度等性能[7]。但是在铝合金表面进行化学镀的预处理工艺流程比较繁琐,而且每道工序都需要进行彻底清洗,避免上道工序的残液带入下一道工序,影响Ni-P镀层的表面质量。目前化学镀Ni-P镀层的研究主要集中在制备工艺、镀液和形成机理等方面,对Ni-P非晶态形成机理[8-10]、工艺参数[11]、摩擦性能[12]等进行大量试验与研究,其目的在于提高其表面硬度,改善其耐腐蚀性能[13],但是对于5052铝合金化学镀Ni-P镀层的摩擦与磨损研究尚未见报道。在此,本文作者采用化学镀方法在5052铝合金表面制备Ni-P镀层,通过SEM、EDS和XRD等手段分析了其表面-界面形貌、化学元素组成和物相,测试了其摩擦与磨损试验性能,为改善5052铝合金的摩擦磨损性能提供了实验依据。

1 实验

试验材料为5052铝合金板材,其化学成分如下(质量分数,%):Si≤0.25,Cu≤0.10,Mg 2.2~2.8,Zn≤0.10,Mn≤0.10,Cr 0.15~0.35,Fe≤0.40,Al余量。镀Ni-P镀层步骤:预处理→施镀。预处理分为除油和酸浸蚀:1) 采用不含碱性除油液在50~70 ℃下浸泡10 min后,用热水清洗;2) 室温下用质量分数为3%的硝酸溶液浸蚀30 s,取出放入镀液中施镀。化学镀Ni-P的主要原料如下:硫酸镍25~30 g/L,次磷酸钠30~40 L,柠檬酸钠60~65 L,用NH4Cl(100g/L)调节pH=8.0,采用数字式温度表设定镀槽液温上下限,通过蒸汽电磁阀实施蒸汽加热镀液温度,自动控制镀槽温度为80~85 ℃,时间1 h,即得试验所需试样。用HXD-1000型显微硬度仪测量Ni-P镀层显微硬度,测试参数如下:载荷200 N,持续时间10 s。通过JSM-6360LA型扫描电镜观察了Ni-P镀层磨损前后的表面形貌,并用其配置的电子能谱仪进行化学成分分析。在Thermo ESCALAB 250型X射线光电子能谱仪上进行XPS分析,X射线激发源:单色Al Kα (hv=1486.6 eV),功率:150 W,X射线束斑:500 μm,能量分析器固定透过能:30 eV。在HSR-2M型高速往复摩擦磨损试验机上分析Ni-P镀层干磨损性能,对磨件为d 4 mm淬火钢球,试验载荷为5 N,盘试样转速为500 r/min,运行时间为120 min,运行长度为5 mm,运行速度为500 r/min。

2 结果与分析

2.1 镀层表面与界面形貌

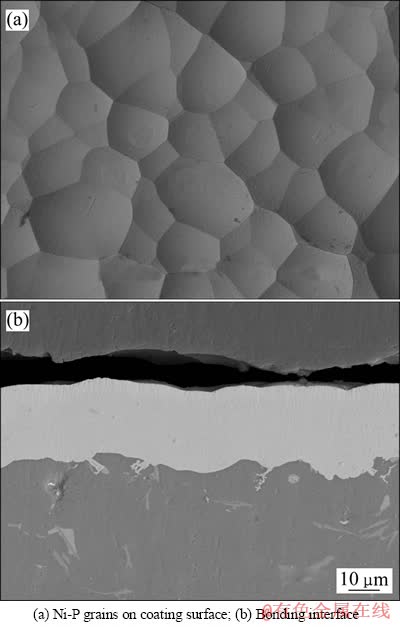

Ni-P镀层表面形貌如图1(a)所示,是由直径10~50 mm的颗粒组成,其形状近似球形,以原子团簇形式沉积在基体表面。镀层表面存在一些微细的凹坑,是由于夹杂在金属Ni之间的P原子向镀层表面扩散,与此同时,邻近金属Ni原子在热效应作用下,填充了原先P原子所在的位置,导致镀层的体积变化所致[14]。由于Ni和P原子在化学镀过程中是一个随机堆积的过程,因此,镀层是以非晶态的形式存在的。进行热处理后,镀层由非晶态转化为晶体,晶粒开始重新形核和排列,可以提高其显微硬度。图1(b)所示为Ni-P镀层结合界面形貌,镀层厚度比较均匀,约为20 mm,界面之间没有出现空隙和断层现象。镀层与基体部分形成了波峰与波谷的接触形式,增大了接触面积,提高了镀层对基体的吸附力[14]。用显微硬度仪测得Ni-P镀层显微硬度为352.6HV,由此可见,Ni-P镀层提高了5052铝合金基材表面显微硬度,有利于提高其耐磨性能。

图1 Ni-P镀层表面与界面形貌

Fig. 1 Morphologies of Ni-P coating surface and interface

2.2 镀层的XPS分析

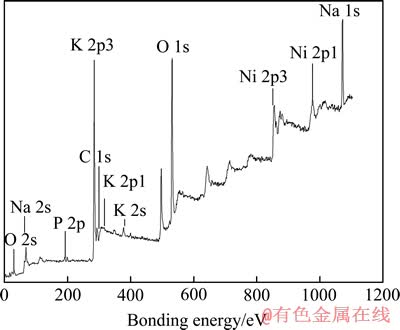

利用Thermo ESCALAB 250型X射线光电子能谱仪对Ni-P镀层进行XPS能谱分析,其测试参数如下:X射线激发源:单色Al Kα (hv=1486.6 eV),功率150 W,X射线束斑500 μm,能量分析器固定透过能为30 eV。Ni-P镀层表面的XPS全谱如图2所示,由图2可以看出,Ni-P镀层表面存在P 2s、Ni 2p、O 2s、O 1s、Na 2s、Na 1s、C 1s、K 2p等峰,这说明镀层主要由Ni和P两种元素组成。

图2 Ni-P镀层表面的XPS全谱

Fig. 2 XPS full scan spectra of Ni-P coating surface

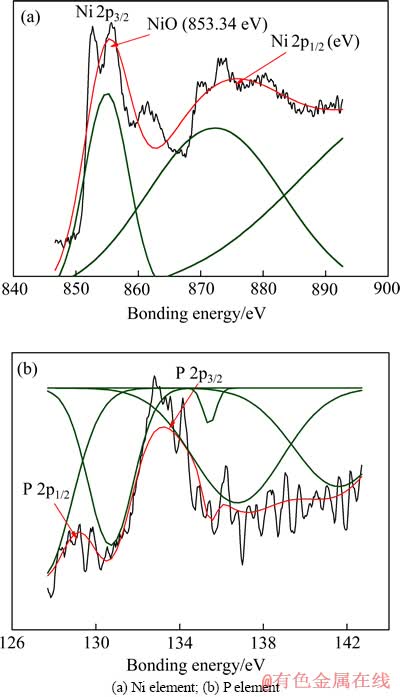

图3所示为Ni和P元素的XPS谱。Ni元素的XPS光电子线位置为Ni 2p1/2(874.0 eV),Ni 2p3/2在853.34 eV处出现结合能峰,其半峰高宽(FWHM)为3.54 eV,以NiO的形式存在,Ni为金属态。P元素的XPS光电子线位置为P 2p1/2,P 2p1/2在133.02 eV处出现结合能峰,其半峰高宽(FWHM)为2.34 eV,P的存在形式为单质态。

图3 Ni-P镀层表面元素Ni和P的XPS谱

Fig. 3 XPS narrow scan analysis of Ni and P elements on Ni-P surface

2.3 镀层的摩擦因数

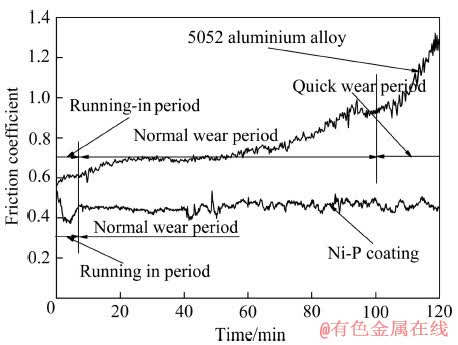

图4所示为基体和Ni-P镀层的摩擦因数与时间的关系曲线。由图4可以看出,基体摩擦因数远大于Ni-P镀层的摩擦因数,说明Ni-P镀层对降低铝合金基体的摩擦因数效果比较明显。其原因是由于基体硬度较低,容易产生粘着磨损,增大了表面粗糙度,引起摩擦因数增大。图4中5052铝合金基体摩擦因数与时间关系曲线,分为如下3个阶段:1) 磨合期。在磨合初期,5052铝合金表面存在着一层显微硬度比较高的氧化膜,对磨件与基体之间是点接触,此时摩擦因数表现为最小。磨合时间大约5min左右,摩擦因数随着时间增加而增大,由0.565增加到0.613。2) 正常磨损期。时间为95 min,摩擦因数由0.611增加到0.925。此阶段的表面实际接触面为氧化膜,且随着磨损的正常进行,表面磨损加剧,摩擦因数随时间增加而增大,其变化趋势也增大。3) 急剧磨损阶段。5052铝合金氧化膜磨损后表面显微硬度较低,表面粗糙度值增大,摩擦因数由0.919迅速增大到1.228,此时表面磨损进入非正常磨损阶段。Ni-P镀层摩擦因数与时间关系的变化曲线,只有两个阶段:1) 磨合期。在磨合初期,对磨件与镀层接触面主要是Ni-P镀层表面不平的硬质点,此时摩擦因数表现为一个比较大的值,且随着磨损试验的进行,镀层摩擦表面愈来愈光滑,摩擦因数出现了下降趋势。由于Ni-P镀层显微硬度达到某个很高的数值,磨损发生在Ni-P颗粒和对磨件之间,使得摩擦因数变大,然后达到一个稳定值。由于镀层表面微观尺寸相对不平整,加上载荷压力作用,镀层与对磨件摩擦接触面增大,摩擦因数由0.533下降到0.374后,又上升至0.468。2) 正常磨损期,摩擦因数在经过磨合期即达到稳定,镀层微观表面趋于平滑,实际接触面积增大,磨损速度逐渐减慢,摩擦因数逐渐减小,直至相对稳定,在0.431~ 0.498之间波动,波动范围趋向稳定。虽然40 min后磨摩擦因数出现波动,但摩擦因数始终维持在0.45左右,没有急剧增加,仍然趋于稳定,由此可见,Ni-P镀层表现出良好的减摩效果。

图4 基体和Ni-P镀层的摩擦因数与时间关系

Fig. 4 Relationship between friction coefficient and time for substrate and Ni-P coatings

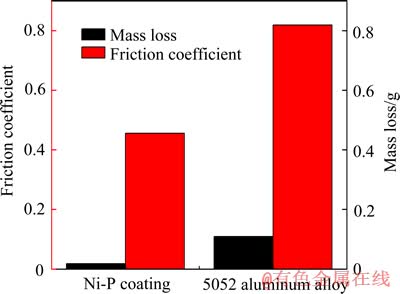

图5所示为Ni-P镀层与基体平均摩擦因数和磨损质量损失比较。由图5可知,在磨损期内基体摩擦因数平均值为0.8188,且摩擦因数变化较大,表面磨损质量损失为0.1092 g,这是铝合金基体磨损性较低的一个主要原因。Ni-P镀层在磨损期内摩擦因数平均值为0.4556,约为基材的55.64%,表面磨损质量损失为0.018 g,磨损率减少83.5%。这表明高硬度的Ni-P具有良好的减摩和抗磨损性能,有效地保护了5052铝合金基体,同时改善了其表面摩擦与磨损性能,提高了基体的使用寿命。

图5 Ni-P镀层与基体平均摩擦因数和磨损质量损失比较

Fig. 5 Comparison of average friction coefficients and wear loss mass between Ni-P coatings and substrate

2.4 镀层磨损后表面形貌

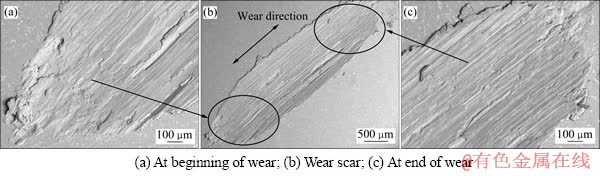

图6所示为5052铝合金基体磨损后的表面形貌。由于基体硬度较低,对磨件容易磨削其表层,磨损后表面呈现出相当多的塑性变形、切削和擦伤的痕迹。磨损表面平行于滑动方向的犁沟宽度约为1000 mm,深度约为105 mm,这是由于对磨件表面硬质凸起磨屑刻划作用形成的[15]。基体磨损方式以磨粒磨损为主,还存在轻微剥落磨损。

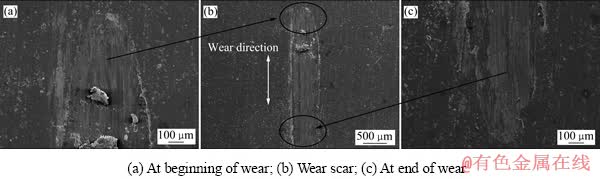

磨损后Ni-P镀层表面形貌如图7所示。可以看到磨损表面比较平整,仍存在犁沟,但与图6中基体相比,已经变得非常浅,其犁沟宽度约为500 mm,深度约为25 mm。其磨损机制为轻微磨粒磨损。

图6 5052铝合金基体磨损后表面形貌

Fig. 6 Surface morphologies of 5052 aluminum alloy after wear test

图7 Ni-P镀层磨损后表面形貌

Fig. 7 Surface morphologies of Ni-P coating after wear test

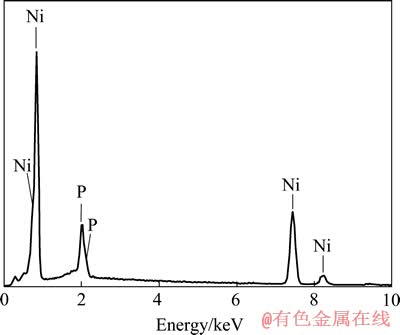

对磨损后表面进行能谱分析,如图8所示,其质量分数为P 5.81%、Ni 94.19%,磨痕处未出现对磨件的化学元素。这说明微区裂纹没有深入基体,镀层未被磨破,只在表面产生裂纹,没有发生粘着磨损现象。

图8 磨损后Ni-P镀层能谱分析

Fig. 8 EDS analysis of Ni-P coating after wear test

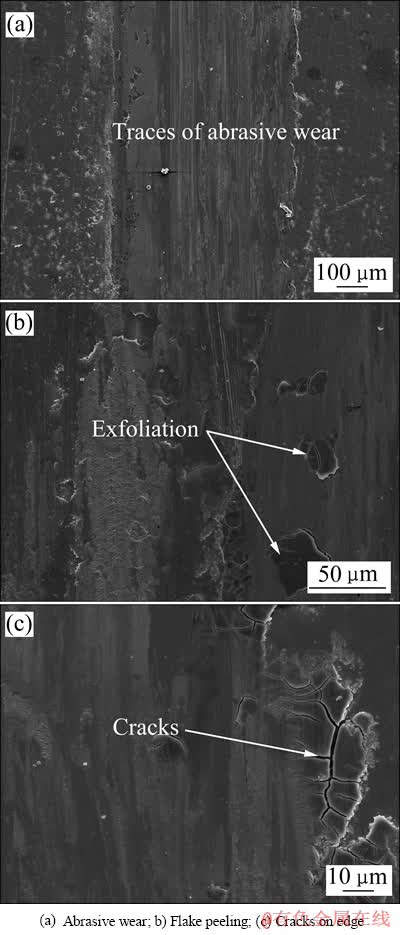

Ni-P镀层磨损后表面形貌如图9所示,磨损后表面由摩擦区和两端片状剥落区组成,其磨损表现为3种形式。1) 摩擦区表面呈现较深的微切削犁沟,表面呈现被轻微碾压和磨粒磨损的痕迹,如图9(a)所示,可见镀层已产生了一定的塑性变形,其塑韧性较好。2) 两端片状剥落区出现了裂纹,部分磨损片状剥落,可观察到明显的颗粒剥落(剥层)和犁沟(磨粒磨损)现象(见图9(b))。其磨损量由在摩擦区磨粒磨损产生的犁屑和两端片状剥落区疲劳磨损产生的片状剥落构成。由此可见,Ni-P镀层磨损形式主要表现为磨粒磨损、裂纹萌生和扩展以及脆性剥落等。3) 在磨损的边缘出现了裂纹(见图9(c)),可解释为在磨粒犁削作用下边缘微区表面拉应力增大,产生局部剥落及边缘裂纹。

图9 Ni-P磨损后镀层表面磨损形式

Fig. 9 Wear forms of Ni-P coating after wear test

3 结论

1) 化学镀制备的非晶态Ni-P镀层以原子团簇形式沉积在基体表面,Ni原子结合能为853.34 eV,其存在形式为金属态,P原子结合能为133.02 eV,其存在形式为氧化态。

2) Ni-P镀层的摩擦因数为0.4556,约为基材的55.64%,有效地改善了5052铝合金表面摩擦性能。

3) 非晶态Ni-P镀层表面显微硬度为370.5HV,与铝合金基体相比,磨损质量损失减少83.5%,其磨损形式主要表现为磨粒磨损、裂纹萌生和扩展以及脆性剥落。

REFERENCES

[1] QIN Tie-nan, MA Li-qun, YAO Yan, NI Cong, ZHAO Xiang-yu, DING Yi. An in situ measure method to study deposition mechanism of electroless Ni-P plating on AZ31 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(12): 2790-2797.

[2] HE Mi-na, LI Fu-guo, WANG Zhi-gang. Forming limit stress diagram prediction of aluminum alloy 5052 based on GTN model parameters determined by in situ tensile tes [J]. Chinese Journal of Aeronautics, 2011, 24(3): 378-386.

[3] 孔德军, 王进春, 刘 浩. 7475铝合金阳极氧化膜表面-界面组织和特征[J]. 中国有色金属学报, 2014, 24(7): 1744-1751.

KONG De-jun, WANG Jin-chun, LIU Hao. Surface-interface structures and characteristics of anodic oxidation film on 7475 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1744-1751.

[4] 刘建华, 刘 洲, 于 美, 李松梅, 陈高红. 3种溶液体系下铝合金阳极氧化膜的性能[J]. 中国有色金属学报, 2012, 22(7): 2032-2039.

LIU Jian-hua, LIU Zhou, YU Mei, LI Song-mei, CHEN Gao-hong. Properties of aluminum alloy anodic films formed in three kinds of solutions[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2032-2039.

[5] 胡永俊, 熊 玲, 蒙继龙. 钨含量对铝合金化学镀Ni-W-P硬度和耐磨性的影响[J]. 中国有色金属学报, 2007, 17(5): 737-742.

HU Yong-jun, XIONG Ling, MENG Ji-long. Effect of content of tungsten on hardness and wear resistance of electroless Ni-W-P plating on aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 737-742.

[6] 李永星, 于 美, 刘建华, 李松梅, 陈高红. 电压加载下己二酸铵对2024-T3铝合金阳极氧化膜的封闭研究[J]. 航空学报, 2011, 32(7): 1326-1335.

LI Yong-xing, YU Mei, LIU Jian-hua, LI Song-mei, CHEN Gao-hong. Sealing of ammonium adipate on anodic oxide film of aluminium alloy 2024-T3 under voltage loading[J]. Acta Aeronautica et Astronautica Sinica, 2011, 32(7): 1326-1335.

[7] 孙 华, 马洪芳, 刘科高, 刘 义. 前处理工艺对铝基Ni-P化学镀层性能的影响[J]. 化工学报, 2010, 61(12): 3200-3204.

SUN Hua, MA Hong-fang, LIU Ke-gao, LIU Yi. Influence of pretreatment on property of electroless plating of Ni-P on aluminum surface[J]. Chemical Industry and Engineering Society of China, 2010, 61(12): 3200-3204.

[8] 于维平, 段淑贞. 电沉积Ni-P非晶态合金的初期结构及形成机理[J]. 材料研究学报, 1996, 10(4): 419-422.

YU Wei-ping, DUAN Shu-zhen. Initial structure of electro-depositing Ni-P amorphous alloy and its formation mechanism[J]. Chinese Journal of Materials Research, 1996, 10(4): 419-422.

[9] 张启富, 涂抚洲. 非晶态镍磷合金电沉积机理的研究[J]. 电镀与涂饰, 2001, 20(1): 1-6, 11.

ZHANG Qi-fu, TU Fu-zhou. Studies on the mechanism of amorphous nickel-phosphorus alloy electrode position[J]. Electroplating & Finishing, 2001, 20 (1): 1-6, 11.

[10] 涂抚洲, 蒋汉派. 电镀非晶态镍磷合金的研究[J]. 电镀与涂饰, 1998, 17(3): 10-15.

TU Fu-zhou, JIANG Han-ying. Study of amorphous Ni-P alloy electroplating[J]. Electroplating and Finishing, 1998, 17(3): 10-15.

[11] RAFI U, GUO Cai-yu, XU Liang, HUANG Yu-ting, QU Xuan-hui. Fabrication and thermal stability of Ni-P coated diamond powder using electroless plating[J]. International Journal of Minerals Metallurgy and Materials, 2011, 18(4): 479-486.

[12] 孔德军, 付贵忠. 5052铝合金表面化学镀Ni-P涂层组织与性能[J]. 中国有色金属学报, 2012, 22(5): 1360-1364.

KONG De-jun, FU Gui-zhong. Microstructure and properties of Ni-P coatings prepared by chemical plating on surface of 5052 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1360-1364.

[13] 刘 仙, 班春燕. 化学镀Ni-P合金工艺及镀层耐蚀性的研究[J]. 钢铁研究, 2002, 128(5): 35-38.

LIU Xian, BAN Chun-yan. Study on electroless Ni-P alloy technology and corrosion resistance of coating[J]. Research on Iron and Steel, 2002, 128(5): 35-38.

[14] 任富忠, 高家诚, 谭 尊. 热处理对短碳纤维表面镍磷涂层形貌和结构的影响[J]. 功能材料, 2010, 41(5): 866-869.

REN Fu-zhong, GAO Jia-cheng, TAN Zun. Influence of heat treatment for nickel-phosphorous coatings morphology and structure on the short carbon fibers[J]. Journal of Functional Materials, 2010, 41(5): 866-869.

[15] 彭成章, 朱玲玲. 电沉积Ni-P/纳米Al2O3复合镀层的摩擦磨损与耐铝液侵蚀性能[J]. 中国有色金属学报, 2010, 20(6): 1177-1182.

PENG Cheng-zhang, ZHU Ling-ling. Tribological properties and erosion resistance of electroplated Ni-P/nano-Al2O3 composite coatings to aluminum liquid[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1177-1182.

(编辑 龙怀中)

基金项目:常州市应用基础研究计划项目(CJ20110019);常州市知识产权计划推进项目(CK20120003)

收稿日期:2013-09-10;修订日期:2014-07-10

通信作者:孔德军,副教授,博士;电话:0519-83290205;E-mail: kong-dejun@163.com