Microstructure evolution and mechanical properties of

extruded Mg-12Zn-1.5Er alloy

WANG Qing-feng, LI Han, LI Shu-bo, WANG Zhao-hui, DU Wen-bo

School of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China

Received 25 September 2010; accepted 20 December 2010

Abstract: The microstructure and mechanical properties of the cast and extruded Mg-12Zn-1.5Er alloys were investigated. The I-phase observed in the cast Mg-12Zn-1.5Er alloy was broken during hot extrusion. The microstructure of the alloy was refined due to the dynamic recrystallization, and the equiaxed grains have size in the range of 2-5 μm. Moreover, a great deal of nano-scale particles precipitate in the recrystallized grains. Compared with the cast one, the extruded alloy shows a great improvement on the mechanical properties as the result of refined microstructure, the dispersed I-phase and the fine precipitates. The ultimate tensile strength and the yield tensile strength of this extruded alloy are 359 and 318 MPa, respectively.

Key words: Mg-Zn-Er alloy; extrusion; microstructure; mechanical property

1 Introduction

As the lightest metallic structural materials, magnesium alloys have been received a great attention in the last decade because of their good potential for use in automotive and aerospace applications[1]. However, magnesium alloys generally exhibit moderate strength with limited ductility at room temperature due to their HCP structure[2]. Thus, a novel strengthening method should be applied to improving the mechanical properties of the magnesium alloys. The icosahedral quasicrystalline phase (I-phase) has many unique properties such as conspicuous hardness, high thermal-stability, high corrosion-resistant and low surface energy[3]. As a second phase, the I-phase is stable and against the microstructure coarsening at elevated temperature due to the low interfacial energy and it has a great effect on improving the mechanical properties of the wrought magnesium alloys[4-5]. LI et al[6-7] reported that the cast Mg-Zn-Er alloy strengthened by the I-phase exhibited high tensile strength and good creep-resistant property.

The microstructure refinement is one of the most important ways to enhance the mechanical properties of the magnesium alloys, such as the commercial wrought Mg-Zn and Mg-Al-Zn alloys[8-10]. The dynamic recrystallization occurred during hot deformation plays an important role in refinement the microstructures of the magnesium alloys[11]. SINGH et al[4-5] and YUAN et al[12-13] have introduced the hot extrusion process to prepare Mg-Zn-Y and Mg-Zn-Gd alloys, and these alloys exhibited excellent mechanical properties.

In the present work, the cast Mg-Zn-Er alloy was extruded at 673 K, and the effect of the hot extrusion on microstructures and mechanical properties of the alloy were investigated.

2 Experimental

An alloy ingot with a normal composition of Mg-12Zn-1.5Er (mass fraction, %) was prepared from pure Mg, pure Zn and Mg-Er master alloys by using a graphite crucible in an electric resistance furnace under the protection of an anti-oxidizing flux. The melt was poured into a steel mold, and cooled down in the atmosphere.

Then, part of the ingots were extruded at 673 K with an extrusion ratio of 10. The microstructure analysis was performed by X-ray diffraction (XRD) with Cu Kα radiation, scanning electron microscopy (SEM, HITACHI S-450) equipped with energy dispersive spectroscopy (EDS), and transmission electron microscopy (TEM, JEM-2000FX, JEOL). The TEM specimens were prepared by electro-polishing and finally ion beam milling at an angle of incidence less than 10°.

3 Results and discussion

3.1 Microstructure of cast Mg-12Zn-1.5Er alloy

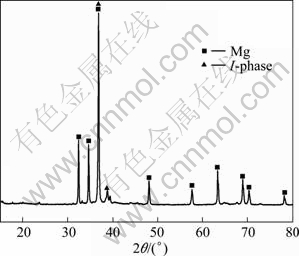

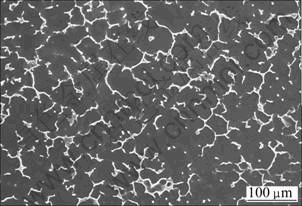

The XRD pattern of the cast alloy is shown in Fig.1. It reveals that the alloy mainly consists of two kinds of phases. One is the α-Mg, the other is I-phase. The I-phase in the cast Mg-Zn-Er alloy has previously been reported by LI et al[6]. No other phases are detected within the sensitivity limit of XRD. The SEM image of the cast alloy is shown in Fig.2. It can be seen that the alloy is composed of the primary α-Mg matrix and eutectic pockets. The eutectic pockets is mainly located in the interdendritic region. The mean grain size of the cast alloy is 50-80 μm.

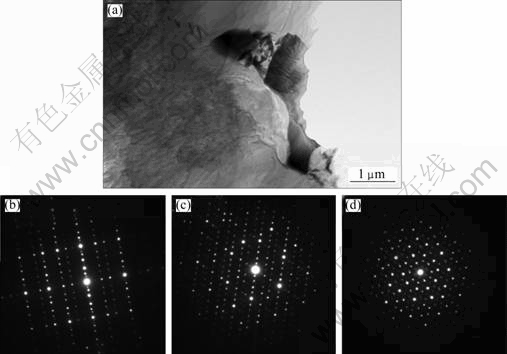

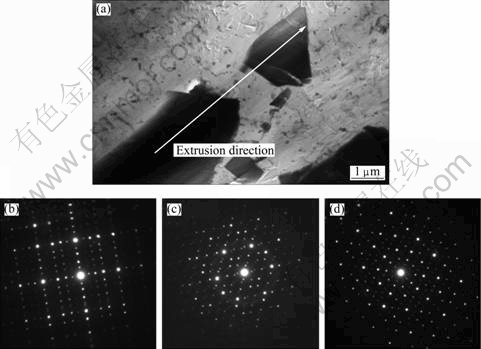

To further confirm the existence of the I-phase, TEM observation was conducted for the cast Mg-12Zn-1.5Er alloy. Figure 3. shows the TEM image and the corresponding selected area diffraction pattrens (SADP) of the I-phase. In Figs.3(b)-(d), the SADPs obtained from the eutectic lamellar phase suggest that these eutectic pockets have 2-, 3-, 5-fold symmetries, respectively. It is a distinct characteristic of the icosahedral quasicrystalline phase (I-phase)[2].

Fig.1 XRD pattern of cast Mg-12Zn-1.5Er alloy

Fig.2 SEM image of cast Mg-12Zn-1.5Er alloy

Fig.3 Bright field TEM image of I-phase of cast alloy (a) and SADPs corresponding to I-phase with 2-fold (b), 3-fold (c) and 5-fold (d) symmetries

3.2 Microstructure of extruded alloy

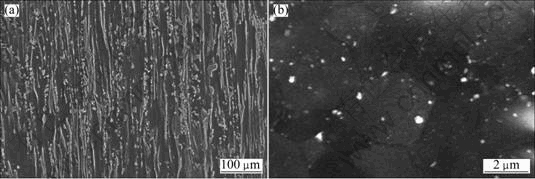

The SEM images of the extruded Mg-12Zn-1.5Er alloy along the extrusion direction are shown in Fig.4. The eutectic pockets observed in the cast alloy are sharply broken and then distributed along the extrusion direction during hot extrusion, as shown in Fig.4(a). After hot extrusion, the grains are unequiaxed crystals with size of 2-5 μm, as shown in Fig.4(b). This indicates that a dynamic recrystallization (DRX) takes place. Furthermore, many nano-scale particles are precipitated in both matrix and at grain boundaries during hot extrusion.

In order to investigate the broken I-phase and the microstructure evolution of the extruded alloy, TEM was performed. Figure 5 shows the TEM micrograph of the broken I-phases, and the corresponding selected area electron diffraction (SAED) patterns. The coarse I-phase in the cast alloy is crushed during the hot extrusion process, and these broken particles distribute near the initial location of the I-phase that is formed in the cast alloy, as seen in Fig.5. Furthermore, no cavity or crack is observed at the I-phase/α-Mg interface in the extruded alloy, although the strength and plasticity of the I-phase are different from those of the matrix. The broken interfaces are also completely healed by the thermally activated process in Mg-Zn-Y alloys[2].

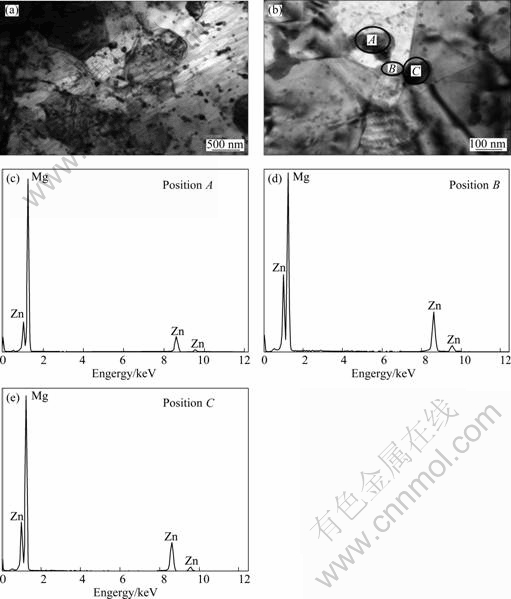

Dynamic recrystallization can be classified into either continuous or discontinuous recrystallization. The dynamic recrystallization process that occurred in this alloy during the hot extrusion was continuous recrystallization. The DRX process occurred at the boundaries of original grains. The recrystallized grains grew greatly through the migration of grain boundaries during the hot deformation process. Figures 6(a) and (b) show that the subgrains are formed, and then the low-angle grain boundary transforms to high-angle grain boundary through absorbing the dislocations. At last, these subgrains become DRX grains. In addition, many fine particles with size of 50-100 nm precipitate in the matrix. The EDS analysis suggests that nano-scale Mg-Zn precipitates exist, which is different from that observed in the Mg-Zn-Y and Mg-Zn-Gd based alloys[5, 14]. However, fine and stable precipitates cannot only act as nucleation site for recrystallization but also restrict the growth of the recrystallized grain by pinning the grain boundaries. In conclusion, this extruded alloy with the formation of the nano-scale precipitate shows finer microstructure compared with the other alloys.

Fig.4 SEM images of extruded alloy along extrusion direction

Fig.5 Bright field TEM image of I-phase of extruded alloy (a) and SADPs corresponding to I-phase with 2-fold (b), 3-fold (c) and 5-fold (d) symmetries

Fig.6 TEM images (a, b) and EDS results (c, d, e) of extruded alloy

3.3 Mechanical properties of alloys

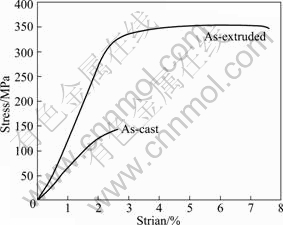

The stress—strain curves of the cast and the extruded alloys at room temperature are shown in Fig.7. It can be seen that the mechanical properties at room temperature are improved greatly after hot extrusion. The extruded alloy exhibits the highest yield stress of 318 MPa and ultimate tensile strength of 359 MPa at room temperature.

Fig.7 Stress—strain curves of cast and extruded alloys at room temperature

The enhanced tensile properties of the extruded alloy are attributed to the following factors, such as distribution of the broken I-phase particles and the grain refinement.

The primary strengthening phase in the extruded alloy is the I-phase. The high symmetry and quasiperiodicity of quasicrystal phase ensure a good atomic match at the interface between this quasicrystal phase and the matrix[2]. Therefore, the interfacial energy between the I-phase and matrix is so low that the binding energy between the matrix and this phase is very high[2]. It is different from that between the Mg17Al12 phase and the matrix in the AZ91 alloys[15]. Because of the high binding energy, it is difficult to form voids that lead to deformation failure but easy to load transfer from the matrix to the I-phase effectively during plastic deformation[16]. Moreover, hot extrusion process makes the I-phase break and distribute along the extrusion direction so that the strength of the extruded alloy is further improved by more effective obstacles to dislocation movement.

Tensile strength has been improved greatly after hot extrusion, especially for the yield tensile stress. One of the most important factors is the refinement of the microstructure. During the hot extrusion process, the DRX occurs, and it plays an important part in refining the microstructure of the alloy. The grain size is reduced to 2-5 μm in the extruded alloy. Meanwhile, the spherical Mg-Zn particles with size of 50-100 nm precipitate in the matrix during the hot extrusion and strengthen the alloy by impeding the movement of the dislocations. In magnesium alloys, the precipitate acts as a nucleation site for recrystallized grains and/or prevents the grain growth by pinning effect. Therefore, the alloy with precipitates shows finer grain structures compared with the alloy without precipitates[17]. As stated above, the extruded alloy shows good tensile properties compared with the cast one due to the refined microstructure, the dispersed I-phase and the fine precipitates.

4 Conclusions

1) The extruded alloy exhibits yield tensile strength of 318 MPa and ultimate tensile strength of 359 MPa, which are much higher than those of the as-cast alloy. The excellent tensile properties of the extruded Mg-12Zn-1.5Er alloy are mainly attributed to the strengthening mechanisms due to the dispersed I-phase particles, fine precipitates and grain refinement.

2) After hot extrusion, the α-Mg matrix grains are significantly refined due to the dynamic recrystallization, the eutectic I-phase in the as-cast alloy is broken and almost distributed along the extrusion direction, and then fine Mg-Zn phase with nano-size is precipitated.

References

[1] SCHUMANN S, FRIEDRICH H. Current and future use of magnesium in the automobile industry [J]. Materials Science Forum, 2003, 419-422: 51-56.

[2] BAE D H, KIM S H, KIM D H, KIM W T. Deformation behavior of Mg-Zn-Y alloys reinforced by icosahedral quasicrystalline particles [J]. Acta Materialia, 2002, 50: 2343-2356.

[3] PIERCE F S, POON S J, GUO Q. Electron localization in metallic quasicrystals [J]. Science, 1993, 261: 737-739.

[4] SINGH A, NAKAMURA M, WATANABE M, KATO A, TSAI A P. Quasicrystal strengthened Mg-Zn-Y alloys by extrusion [J]. Scripta Materialia, 2003, 49: 417-422.

[5] SINGH A, WATANABE M, KATO A, TSAI A P. Microstructure and strength of quasicrystal containing extruded Mg-Zn-Y alloys for elevated temperature application [J]. Materials Science and Engineering A, 2004, 385: 382-396.

[6] LI Jian-hui, DU Wen-bo, LI Shu-bo, WANG Zhao-hui. Icosahedral quasicrystalline phase in an as-cast Mg-Zn-Er alloy [J]. Rare Metals, 2009, 28: 297-301.

[7] LI Jian-hui, DU Wen-bo, LI Shu-bo, WANG Zhang-hui. Tensile and creep behaviors of Mg-5Zn-2.5Er alloy improved by icosahedral quasicrystal [J]. Materials Science and Engineering A, 2010, 527: 1255-1259.

[8] MABUCHI M, CHINO Y, IWASAKI H, AIZAWA T, HIGASHI K. The grain size and texture dependence of tensile properties in extruded Mg-9Al-1Zn [J]. Materials Transactions, 2001, 42: 1182-1188.

[9] SOMEKAWA H, MUKAI T. High strength and fracture toughness balance on the extruded Mg-Ca-Zn alloy [J]. Materials Science and Engineering A, 2007, 459: 366-370.

[10] MENDIS C L, OH-ISHI K, KAWAMURA Y, HONMA T, KAMADO S, HONO K. Precipitation-hardenable Mg-2.4Zn- 0.1Ag-0.1Ca-0.16Zr (at.%) wrought magnesium alloy [J]. Acta Materials, 2009, 57: 749-760.

[11] ZHANG Jing, MA Qi, PAN Fu-sheng. Effects of trace Er addition on the microstructure and mechanical properties of Mg-Zn-Zr alloy [J].Materials and Design, 2010, 31: 4043-4049.

[12] YUAN Guang-yin, LIU Yong, DING Wen-jiang, LU Chen. Effects of extrusion on the microstructure and mechanical properties of Mg-Zn-Gd alloy reinforced with quasicrystalline particles [J].Materials Science and Engineering A, 2008, 474: 348-354.

[13] LIU Yong, YUAN Guang-yin, DING Wen-jiang, LU Chen. Deformation behavior of Mg-Zn-Gd-based alloys reinforced with quasicrystal and Laves phases at elevated temperatures [J]. Alloys and Compounds, 2007, 472: 160-165.

[14] LIU Yong, YUAN Guang-yin, LU Chen, DING Wen-jiang. Stable icosahedral phase in Mg-Zn-Gd alloy [J]. Scripta Materialia, 2006, 55: 919-922.

[15] LIU Y Z, WANG Q D, DING W J, ZENG X Q, ZHU Y P. Fracture behavior of AZ91 magnesium alloy[J].Materials Letters, 2000, 44: 265-268.

[16] ZHENG Ming-yi, QIAO Xiao-guang, XU Shi-wei, GAN Wei-min. Effect of hot extrusion on microstructure and mechanical properties of quasicrystal-reinforced Mg-Zn-Y alloy [J].Transactions of Nonferrous Metals Society of China, 2005, 15: 715-721.

[17] SOMEKAWA H, SINGH A, MUKAI T. Microstructure evolution of Mg-Zn binary alloy during a direct extrusion process [J]. Scripta Materialia, 2009, 60: 411-414.

挤压Mg-12Zn-1.5Er镁合金的微观组织演变及力学性能

王庆峰, 李 晗, 李淑波, 王朝辉, 杜文博

北京工业大学 材料科学与工程学院,北京100124

摘 要:研究铸造及挤压Mg-12Zn-1.5Er合金的显微组织及力学性能。结果表明:铸造Mg-12Zn-1.5Er合金中的I相在挤压过程中被破碎,并且动态再结晶伴随着挤压过程发生,导致合金组织进一步细化。合金的晶粒为等轴晶,其平均晶粒尺寸为2-5 μm;并且观察到大量的纳米级颗粒在动态再结晶晶粒中析出;与铸造合金相比,挤压合金的力学性能明显提高,这是因为组织细化、准晶强化及纳米级颗粒的析出强化;挤压合金的抗拉强度、屈服强度分别为359 MPa和318 MPa。

关键词:Mg-Zn-Er合金;挤压;微观组织;力学性能

(Edited by LI Xiang-qun)

Foundation item: Project (2007CB613706) supported by the National Basic Research Program of China; Project (PHR200906101) supported by Innovation Project for Talents of the Beijing Municipal Education Commission, China; Project (00900054R7001) supported by Innovation Project for Team of the Beijing Municipal Education Commission, China

Corresponding author: DU Wen-bo; Tel: +86-10-67392917; Fax: +86-10-67392917; E-mail: duwb@bjut.edu.cn

DOI: 10.1016/S1003-6326(11)60796-6