Trans. Nonferrous Met. Soc. China 22(2012) s465-s471

Hot deformation behavior of in-situ TiBw/Ti6Al4V composite with novel network reinforcement distribution

ZHANG Yu-zi, HUANG Lu-jun, LIU Bao-xi, GENG Lin

National Key Laboratory for Precision Heat Processing of Metals, Harbin Institute of Technology, Harbin 150001, China

Received 28 August 2012; accepted 25 October 2012

Abstract: TiB whiskers reinforced Ti6Al4V (TC4) alloy matrix composite (TiBw/Ti64) was fabricated by in-situ reactive hot pressing. The high temperature deformation behavior of the composite was studied by hot compression tests carried out in the temperature range of 900-1100 °C and strain rate range of 0.001-10 s-1. The results show that the flow stress of the composite decreases with the increase of temperature and the decrease of strain rate. At strain rate of 10 s-1, discontinuous yielding followed by flow oscillations can be observed, especially in the β phase region. Constitutive equations were constructed based on the peak flow stresses of the stress—strain curves in α+β phase region and β phase region, respectively. Activation energies for the plastic deformation were also calculated in different temperature ranges according to the constitutive equations, namely, 822.3 kJ/mol in α+β phase region and 209.4 kJ/mol in β phase region. The deformed morphologies of the reinforcement network microstructure and the matrix microstructure greatly depend on the deformation regions and parameters.

Key words: titanium matrix composites (TMCs); TiB whiskers; Ti6Al4V alloy; hot deformation; constitutive equation; network microstructure

1 Introduction

Titanium and titanium alloy matrix composites reinforced with ceramic whiskers/particles are attractive to researchers because of their considerable potential for improving properties and service temperature. Moreover, titanium matrix composites (TMCs) can be widely applied in aerospace and other areas in terms of their high specific strength and modulus and good corrosion resistance [1-4]. As for the matrix, Ti6Al4V alloy is a competitive candidate due to an excellent combination of mechanical properties as one typical α+β alloy. TiB whiskers (TiBw) are always chosen as the reinforcement for TMCs owing to their high modulus, good chemical stability and similar coefficient of thermal expansion to titanium matrix [5-7]. In particular, discontinuously reinforced titanium matrix composites (DRTMCs) fabricated by powder metallurgy are sought-after due to their potential of superior and isotropic properties and low cost [5-8]. However, the bottleneck problem of the extreme brittleness of titanium alloy matrix composites fabricated by conventional powder metallurgy (such as reaction hot pressing (RHP)) highly constrained their further investigation and their applications. It is significant that a novel 5%TiBw/Ti6Al4V composite with network reinforcement distribution was successfully designed and fabricated by reaction hot pressing in the previous works [8,9]. This composite exhibits a superior combination of strengthening effect and toughening effect, which overcomes the bottleneck problem of extreme brittleness of titanium alloy matrix composites fabricated by the conventional powder metallurgy.

On the basis of the previous works [8,9], the objective of this work is to investigate the hot deformation behavior of the novel composite by analyzing the stress—strain curves, construct constitutive equations, and observe the microstructural evolution under different hot compression parameters in order to promise its industrial practice in the future. Earlier researchers did similar work to TiBw reinforced Ti6Al4V matrix composite with a homogenous microstructure. For example, SEN and RAMAMURTY [10] studied the influence of a minor B element addition on the hot deformation behavior of Ti6Al4V alloys. POLETTI et al [11] investigated the hot deformation of Ti6Al4V modified with 1% B (mass fraction) and 0.1% C (mass fraction) using the compression tests. However, the microstructure and mechanical property evolutions of the homogenous microstructure must be totally different from that of the novel network microstructure TiBw reinforcement in this work. Therefore, it is especially significant to investigate the hot deformation behavior of the novel composite with a network microstructure.

2 Experimental

2.1 Materials

The material used in this experiment was 5%TiBw (volume fraction) reinforced Ti6Al4V alloy composites. The raw components consisted of spherical Ti6Al4V alloy powders with a size range of 180-220 μm and the hexagonal prismatic TiB2 powders with a size range of 1-8 μm. The measured composition (in mass fraction, %) of Ti6Al4 alloy was 6.42 Al, 4.12 V, 0.18 Fe, 0.024 Si, 0.12 O, 0.013 C, 0.011 N, 0.004 H, balance Ti. The mixed powders after low energy ball milling process were hot pressed at 1200 °C for 1 h in a vacuum atmosphere under a pressure of 20 MPa. During the hot pressing process, TiB whiskers were in-situ synthesized around the large spherical titanium alloy matrix particles by the reaction between TiB2 and Ti. The β transus temperature for this material was measured to be about 995 °C.

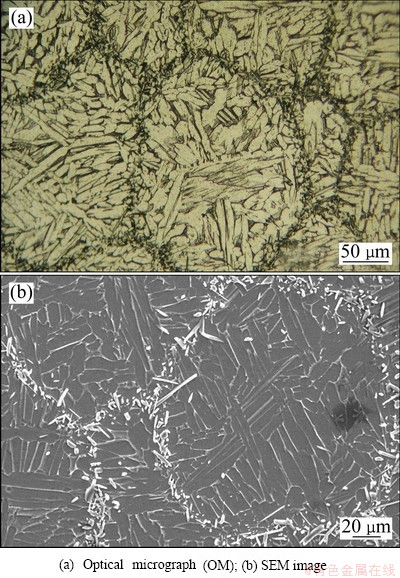

Figure 1 shows the microstructures of the 5%TiBw/ Ti6Al4V composite with network reinforcement distribution after reaction hot pressing. As seen from Fig. 1, the matrix Ti6Al4V alloy exhibits the lamellar α colonies in coarse prior β grains and narrow β phase layers between the lamellar α phase. The TiBw reinforcements in the composite are located at the boundary between the adjacent original spherical Ti6Al4V alloy particles forming a network microstructure.

2.2 Experimental procedures

Isothermal compression tests in the temperature range of 900-1100 °C and strain rate range of 0.001-10 s-1 were performed using a Gleeble-1500D machine. The cylindrical specimens with diameter of 8 mm and height of 12 mm were prepared by wire-cutting machine. After hot compression to a reduction of 60% in height, the specimens were water-quenched immediately to keep the high temperature microstructure. The deformed specimens were cut along their axis parallel to the direction of compression, mechanically ground and polished for metallographic observations by optical microscopy (OLYPUS PEM-3).

Fig. 1 Micrographs of 5%TiBw/Ti6Al4V composite with network reinforcement distribution

3 Results and discussion

3.1 Stress—strain curves

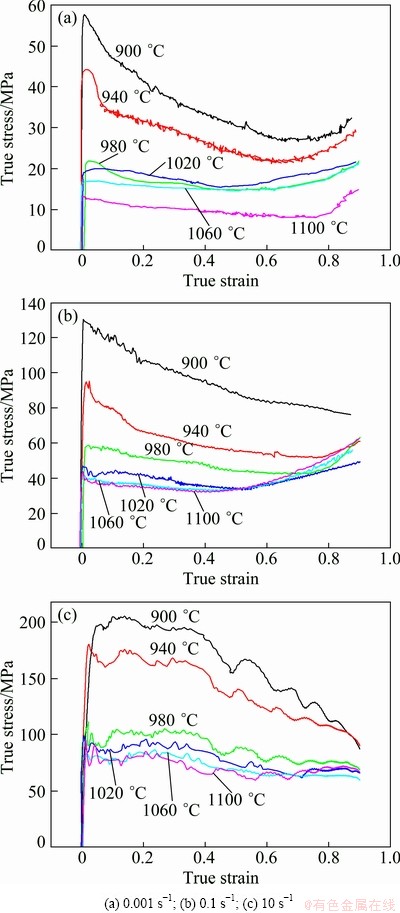

The stress—strain curves for 5%TiBw/Ti6Al4V network-structured composite hot compressed under different conditions are shown in Fig. 2. It can be seen that all the flow curves exhibit peak flow stresses, which are more apparent at lower temperatures and lower strain rates. Higher peak flow stresses are observed at lower temperatures and higher strain rates. After reaching the peak flow stress, the curves display a declining tendency corresponding to flow softening which is more remarkable at lower temperatures (α+β phase region) than higher temperatures (β phase region). Then, all the curves attain steady-state flow stresses that gradually maintain plateau or change slightly with increasing true strain, which can be attributed to the balance of hardening and softening in the composite. At the high strain rate of 10 s-1, discontinuous yielding and dramatic oscillation of flow stresses can be seen from all the curves of Fig. 2(c).

Fig. 2 True stress—true strain curves for 5%TiBw/Ti6Al4V composite during hot compression at different temperatures and different strain rates

3.2 Constitutive equations

Making reference to our previous work on studying the hot deformation of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy [12], the constitutive equation proposed by SELLARS and TEGART [13,14] was used in the present work to simulate the flow stress stages and calculate the activation energies of the composite according to peak flow stresses for the plastic deformation at different compression parameters including temperature, strain rate and strain. The equation can be expressed as

(1)

(1)

where F(σ) is a function of applied stress with the following possible forms:

F(σ)=σn for ασ<0.8 (2)

F(σ)=exp(βσ) for ασ>1.2 (3)

F(σ)=[sinh(ασ)n] for all values of σ (4)

α=β/n (5)

In the above formulas, α, n and A are constants; Q is the activation energy of the deformation; R is the gas constant; is the strain rate; and T is the absolute temperature.

is the strain rate; and T is the absolute temperature.

The relationship between T and  can be also defined through Zener-Hollomon parameter (Z) according to the following relation [15] in place of Eq. (1):

can be also defined through Zener-Hollomon parameter (Z) according to the following relation [15] in place of Eq. (1):

(6)

(6)

By inserting Eq. (2) and Eq. (3) into Eq. (1), two forms of strain rate ( ) can be described as

) can be described as

(7)

(7)

(8)

(8)

where B1 and B2 are new constants.

Therefore, two constitutive equations were constructed in the two ranges of temperature respectively, namely, 900 °C≤t≤980 °C and 1020 °C≤t≤1100 °C.

When 900 °C≤t≤980 °C, after taking the nature logarithm to both sides of Eq. (7) and Eq. (8), two new linear equations can be obtained:

(9)

(9)

(10)

(10)

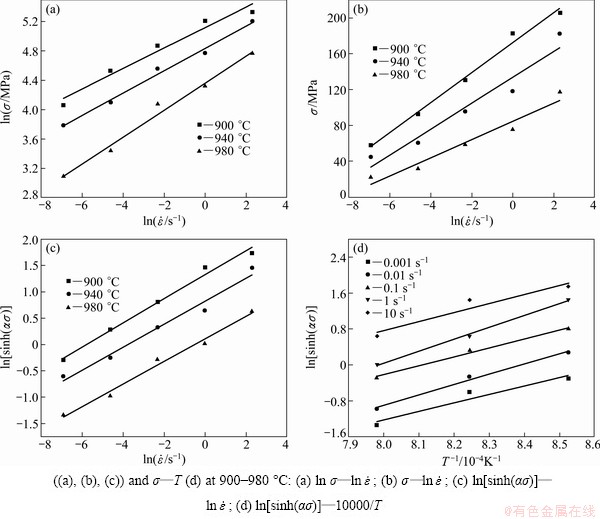

Then, ln σ—ln and σ-ln

and σ-ln plots are presented in Figs. 3(a) and (b), respectively, by inserting true stress—true strain data into Eq. (9) and Eq. (10). Figures 3(a) and (b) show the two plots in linear relationship approximately. The stress exponent n can be calculated by inversing the slope of the curve in Fig. 3(a) while the inverse of the slope of the curve in Fig. 3(d) represents parameter β.

plots are presented in Figs. 3(a) and (b), respectively, by inserting true stress—true strain data into Eq. (9) and Eq. (10). Figures 3(a) and (b) show the two plots in linear relationship approximately. The stress exponent n can be calculated by inversing the slope of the curve in Fig. 3(a) while the inverse of the slope of the curve in Fig. 3(d) represents parameter β.

In α+β phase region, the value of stress exponent n is estimated to be about 6.38263 in the limited strain rate range of 0.001-10 s-1, and parameter β is about 0.075603. Parameter α(α=β/n) is then calculated to be around 0.0118451.

For all variables of flow stress:

(11)

(11)

(12)

(12)

Equation (13) can be drawn by taking nature logarithm to Eq. (11) as

(13)

(13)

According to Eq. (13), the plots in patterns of ln[sinh(ασ)]—ln and ln[sinh(ασ)]—10000/T are obtained after inserting true data as shown in Figs. 3(c) and (d) where T and

and ln[sinh(ασ)]—10000/T are obtained after inserting true data as shown in Figs. 3(c) and (d) where T and  are considered to be constants, respectively. Both of the two plots show a linear relationship approximately. Similarly, the stress exponent n2 and activation energy Q can be obtained by inversing respective slope of the plot in Figs. 3(c) and (d). Various activation energies (Q) on the basis of different parameters calculated from the two plots (Figs. 3(c) and (d)) are listed in Table 1.

are considered to be constants, respectively. Both of the two plots show a linear relationship approximately. Similarly, the stress exponent n2 and activation energy Q can be obtained by inversing respective slope of the plot in Figs. 3(c) and (d). Various activation energies (Q) on the basis of different parameters calculated from the two plots (Figs. 3(c) and (d)) are listed in Table 1.

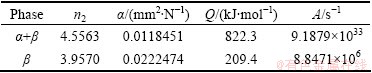

Table 1 Experimental constants obtained from hot deformation data of TiBw/Ti6Al4V composite

In the same way, the above parameters can be obtained in the temperature range from 1020 °C to 1100 °C as listed in Table 1.

By inserting these results into Eq. (12), the flow stress in the two phase regions can be expressed as

1) When 900 °C ≤ t ≤ 980 °C and Z= exp[822.3/(RT)],

exp[822.3/(RT)],

σ=84.423ln{[Z/(9.1879×1033)]1/4.5563+{[Z/(9.1879×1033)]2/4.5563+12/4.556323}1/2};

2) When 1020 °C≤ t ≤1100 °C and Z= exp[209.4/(RT)]

exp[209.4/(RT)]

σ=44.949ln{[Z/(8.8471×106)]1/3.957+{[Z/(8.8471×106)]2/3.957+12/4.556323}1/2}

In α+β phase region, the stress exponent n2 is estimated to be about 4.5563 in the strain rate range of 0.001-10 s-1. The apparent activation energy calculated from the above plot is 822.3 kJ/mol, which is much higher than that of Ti6Al4V alloy (501 kJ/mol) [16], which indicates that the TiBw reinforcements distributed surrounding the Ti6Al4V particles in the composite effectively inhibit the movement of dislocations.

In β phase region, the value of stress exponent n2 is estimated to be about 3.9570 in the strain rate range of 0.001-10 s-1. The apparent activation energy estimated from the above plot is 209.4 kJ/mol, which is higher than that for self diffusion in β-Ti (153 kJ/mol) [12].

3.3 Deformation microstructures

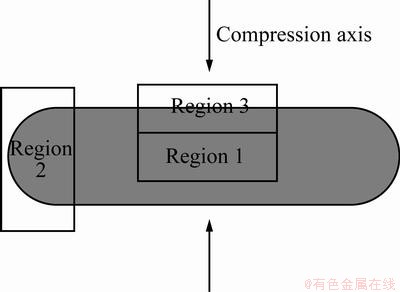

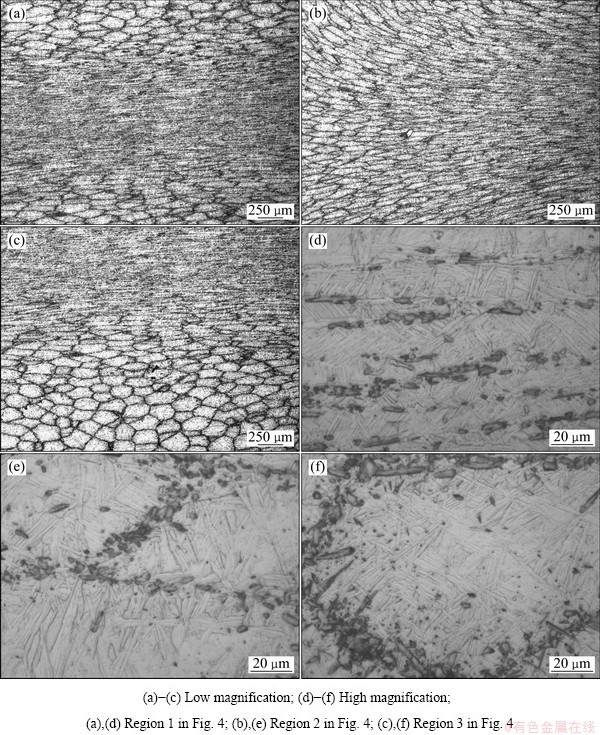

The schematic diagram of three different observation regions on the deformed specimen is presented in Fig. 4. According to Fig. 4, Fig. 5 shows these three deformation regions of the specimen deformed at 1060 °C and 0.001 s-1 corresponding to different microstructures. From Fig. 5(a), region 1 of about 1.5 mm width is the region of the maximum plastic strain called deformation center region during the hot compression. In this area, original spherical Ti6Al4V particles were torn and crushed dramatically to broken ones connected to each other. Besides, from Fig. 5(d), the TiB whiskers broke up to smaller particles, arranging perpendicularly to the compression axis. Accordingly, the ratio of length to diameter decreased. From Fig. 5(b), in region 2 of the deformed sample, the spherical Ti6Al4V particles distorted to a large extent and became elongated. From Fig. 5(c), in region 3, i.e., the least strain region, spherical Ti6Al4V particles deformed a little and generally retained initial shape. From Figs. 5(d)-(f), it can be seen that all the regions in the matrix turned to lath martensite.

Fig. 3 Linear fitting relationship of σ— ((a), (b), (c)) and σ—T (d) at 900-980 °C

((a), (b), (c)) and σ—T (d) at 900-980 °C

Fig. 4 Schematic diagram showing three observation regions of deformed specimen

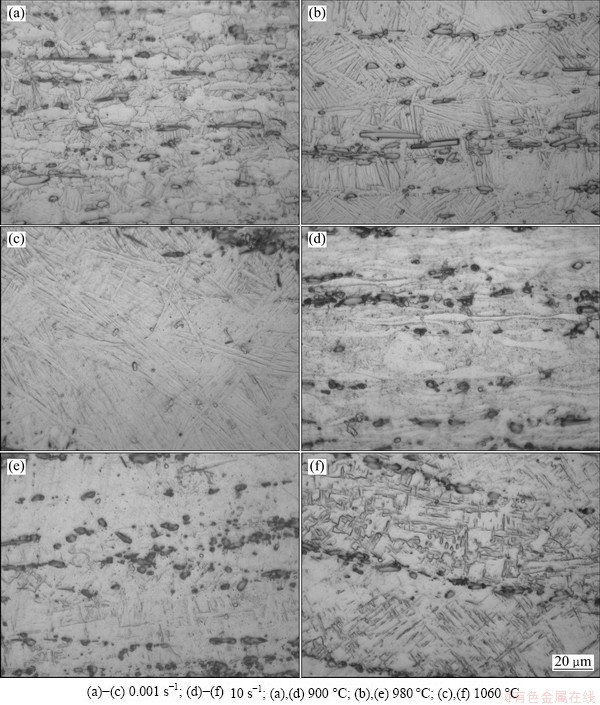

The typical optical micrographs of the specimens tested at different temperatures and strain rates are shown in Fig. 6. From Figs. 6(a) and (d), it can be seen that at 900 °C and 0.001 s-1, primary α transformed into β phase partially and the globularization of the retained prior α phase was observed resulting from enough time for transformation. In contrast, at 10 s-1, primary α laths kinked and transformed into β phase only to a smaller extent because the deformation time was too short to accomplish much phase transformation. From Figs. 6(b) and (e), at 980 °C (below β transus temperature), low and high strain rates, all of the matrix transformed to martensite, which suggested that the hot deformation promoted α phase transforming to β phase, leading to more volume of β phase in the composite. At 1060 °C (above β transus temperature), the martensite size decreased with increasing strain rate and became finer.

Fig. 5 Optical micrographs of specimens deformed at 1060 °C and 0.001 s-1

Fig. 6 Optical micrographs of TiBw/Ti6Al4V specimens deformed at different temperatures and strain rates

4 Conclusions

1) The flow stress of TiBw/Ti6Al4V composite with the network microstructure decreases with the increase of temperature and the decrease of strain rate. At the strain rate of 10 s-1, discontinuous yielding followed by flow oscillations can be observed, especially in β phase region.

2) In α+β phase region, the activation energy of 822.3 kJ/mol is much higher than that of Ti6Al4V alloy, demonstrating the TiB whiskers and the special network microstructure as impediments in the composite during the hot deformation. In β phase region, the activation energy of 209.4 kJ/mol is much higher than that of β-Ti self diffusion.

3) Constitutive equations are constructed on the basis of peak stresses.

4) The microstructures of specimens greatly depend on the conditions of the hot deformation. Different deformation regions correspond to various micro- structures of the composite.

References

[1] HUANG L J, GENG L, LI A B, YANG F Y, PENG H X. In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing [J]. Scripta Materialia, 2009, 60(11): 996-999.

[2] TJONG S C, MAI Y W. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites [J]. Composite Science and Technology, 2008, 68(3-4): 583-601.

[3] ZHANG Ke-min, ZOU Jian-xin, LI Jun, YU Zhi-shui, WANG Hui-ping. Synthesis of Y2O3 particle enhanced Ni/TiC composite on TC4 Ti alloy by laser cladding [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1817-1823.

[4] LI Jian-kang, YANG Yan-ging, YUAN Mei-ni, LUO Xian, LI Li-li. Effect of properties of SiC fibers on longitudinal tensile behavior of SiC(f)/Ti-6Al-4V composites [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 523-530.

[5] XIAO Lu, LU Wei-jie, YANG Zhi-feng, QING Ji-ning, ZHANG Di, WANG Min-min, ZHU Feng, JI Bo. Effect of reinforcements on high temperature mechanical properties of in situ synthesized titanium matrix composites [J]. Materials Science and Engineering A, 2008, 491(1-2): 192-198.

[6] MORSI K, PATEL V V. Processing and properties of titanium–titanium boride (TiBw) matrix composites—A review [J]. Journal of Materials Science, 2007, 42(6): 2037-2047.

[7] MA Z Y, TJONG S C, GEN L. In-situ Ti-TiB metal-matrix composite prepared by a reactive pressing process [J]. Scripta Materialia, 2000, 42(4): 367-373.

[8] HUANG L J, GENG L, PENG H X, ZHANG J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture [J]. Scripta Materialia, 2011, 64(9): 844-847.

[9] HUANG L J, GENG L, WANG B, XU H Y, KAVEENDRAN B. Effects of extrusion and heat treatment on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composite with a network architecture [J]. Composites: Part A, 2012, 43(3): 486-491.

[10] SEN I, RAMAMURTY U. High-temperature plastic deformation behavior of B-modified Ti-6Al-4V alloys: Temperature and strain rate effects [J]. Metallurgical and Materials Transactions A, 2010, 41(11): 2959-2969.

[11] POLETTI C, WARCHOMICKA F, DEGISCHER H P. Local deformation of Ti6Al4V modified 1 wt% B and 0.1 wt% C [J]. Material Science and Engineering A, 2010, 527(4-5): 1109-1116.

[12] HUANG L J, GENG L, LI A B, WANG G S, SHI L. Constitutive equation and hot deformation characteristic of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy with equiaxed microstructure [J]. Rare Metals, 2007, 26: 88-93.

[13] BRUSCHI S, POGGIO S, QUADRINI F, TATA M E. Workability of Ti-6Al-4V alloy at high temperatures and strain rates [J]. Materials Letter, 2004, 58(27-28): 3622-3629.

[14] SUN Yu, ZENG Wei-dong, ZHAO Yong-qing, HAN Yuan-fei, MA Xiong. Intelligent method to develop constitutive relationship of Ti-6Al-2Zr-1Mo-1V alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1457-1461.

[15] LI A B, HUANG L J, MENG Q Y, GENG L, CUI X P. Hot working of Ti-6Al-3Mo-2Zr-0.3Si alloy with lamellar α+β starting structure using processing map [J]. Materials and Design, 2009, 30(5): 1625-1631.

[16] QU Y H, SUN J K, MENG X J. Research and development of isothermal forging of titanium alloys [J]. Titanium Industry Progress, 2006, 23(1): 6-9. (in Chinese).

新型网状增强体分布的原位自生TiBw/Ti6Al4V复合材料的热变形行为

张煜梓,黄陆军,刘宝玺,耿 林

哈尔滨工业大学 金属精密热加工国级重点实验室,哈尔滨 150001

摘 要:通过原位自生反应热压法制备出TiB晶须增强Ti6Al4V(TC4)合金基复合材料(TiBw/Ti64)。通过热压缩实验研究这种新型复合材料的高温变形行为,变形温度区间为900~1100 °C,变形应变速率区间为0.001~10 s-1。结果显示,该复合材料的流变应力随变形温度的升高与应变速率的降低而降低。当应变速率达到10 s-1时,出现了非连续屈服与流变失稳现象,特别是在β相区变形时,这种现象更加明显。根据应力—应变曲线上获得的峰值流变应力,分别获得了α+β双相区与单一β相区的流变应力方程。根据流变应力方程,获得了α+β双相区塑性变形激活能为822.3 kJ/mol,单一β相区塑性变形激活能为209.4 kJ/mol。增强体网状组织结构与基体组织结构变形形态较大程度上取决于变形区域与变形参数。

关键词:钛基复合材料(TMCs);TiB晶须;Ti6Al4V合金;热变形;流变应力方程;网状组织结构

(Edited by CHEN Wei-ping)

Foundation item: Projects (51101042, 51271064) supported by the National Natural Science Foundation of China; Project (HIT. NSRIF. 201131) supported by the Fundamental Research Funds for the Central Universities; Projects (2012T50327, 2011M500653) supported by the 5th-class Special Financial Grant and the 50th-class General Financial Grant from the China Postdoctoral Science Foundation; Project supported by the Provincial Heilongjiang Postdoctoral Science Foundation, China

Corresponding author: HUANG Lu-jun; Tel: +86-451-86418836; E-mail: ljhuanghit@yahoo.com.cn

DOI: 10.1016/S1003-6326(12)61747-6