文章编号:1004-0609(2010)06-1189-06

钎焊及时效过程中化学镀Ni-P与Sn-3.5Ag的界面反应

黄明亮1, 2,柏冬梅1, 2

(1. 大连理工大学 材料科学与工程学院,大连 116024;

2. 大连理工大学 辽宁省先进连接技术重点实验室,大连 116024)

摘 要:研究磷含量为6.5%(质量分数)的化学镀Ni-P薄膜与Sn-3.5Ag钎料合金之间的润湿行为,以及Sn-3.5Ag/Ni-P焊点在钎焊和时效过程中的界面反应。结果表明:250 ℃时,直径为(2.3±0.06) mm的Sn-3.5Ag焊球在化学镀Ni-6.5%P薄膜上钎焊后得到的润湿角约为44?,铺展率约为67%;焊点界面由Ni3Sn4 IMC层、及较薄的Ni-Sn-P过渡层构成Ni3P晶化层;钎焊过程中界面Ni3Sn4 IMC的生长速率与钎焊时间t1/3呈线性关系;时效过程中界面Ni3Sn4 IMC及富P层的生长速率与时效时间t1/2呈线性关系。

关键词:化学镀Ni-P薄膜;Sn-3.5Ag钎料;界面反应;钎焊;时效

中图分类号:TQ153.2 文献标志码:A

Interfacial reactions between Sn-3.5Ag solder and electroless Ni-P during soldering and aging

HUANG Ming-liang1, 2, BAI Dong-mei1, 2

(1. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

2. Key Laboratory of Liaoning Advanced Welding and Joining Technology,Dalian University of Technology, Dalian 116024, China)

Abstract: The wetting behavior of Sn-3.5Ag solder on the electroless Ni-P film with 6.5% P (mass fraction) during soldering and the interfacial reactions between Sn-3.5Ag solder and electroless Ni-6.5% P during soldering and aging were investigated. The results show that the wetting angle is about 44? and the spreading coefficient is about 67% using the solder balls with diameter of (2.3±0.06) mm at 25 ℃. The soldering interface are composed of a Ni3Sn4 IMC layer, a thinner Ni-Sn-P layer and a Ni3P crystallization layer between Sn-3.5Ag solder and electroless Ni-P. The growth kinetics of the interfacial IMC Ni3Sn4 during soldering follows a linear relation with cubic root of soldering time. The growth kinetics of interfacial IMC Ni3Sn4 and P-enriched layer during aging obeys a linear relation with square root of aging time.

Key words: electroless Ni-P film; Sn-3.5Ag solder; interfacial reaction; soldering; aging

随着电子封装技术的发展,电子产品的集成度越来越高,焊点尺寸越来越小。焊点作为器件的连接材料,担负着机械、电路连接以及热交换等任务,其在服役过程中的可靠性也越来越受到关注[1]。微电子互连的可靠性依赖于多种因素,其中钎料合金/焊盘UBM(Under bump metallization)界面反应所形成的金属间化合物(Intermetallic compound,IMC)对焊点可靠性的影响最为重要[2]。金属间化合物层的形成是构成可靠性机械连接的必要条件,而其在服役过程中的过快生长会降低焊点的热疲劳寿命和可靠性[3-4]。

Sn-3.5Ag合金具有优异的力学性能,已在某些电子产品中获得广泛应用。Sn-3.5Ag共晶温度为221 ℃,远高于传统Sn-Pb合金的(183 ℃),同时,Sn-3.5Ag钎料中Sn含量也远高于传统Sn-Pb钎料中的Sn含量。高的钎焊温度和高的Sn含量使Sn-3.5Ag在钎焊过程中界面反应加快,生成的界面金属间化合物的种类、形态、生长速度也有很大差别。因此,高Sn含量的Sn-3.5Ag钎料在钎焊和服役过程中界面反应引起的可靠性问题成为研究者关注的热点。近年来,化学镀 Ni-P作为优异的钎焊阻挡层材料,在微电子封装工业中得到广泛的应用[5-6]。化学镀Ni-P薄膜中含有一定的P元素,在钎焊和服役过程中,P元素与Ni、Sn元素之间并不发生化学反应,导致界面上富P层的析出。此外,化学镀Ni-P是非晶薄膜,Ni-P薄膜的成分对界面反应过程中焊点界面结构变化产生的影响比较复杂[7-9]。所以,研究化学镀Ni-P薄膜与Sn-3.5Ag合金之间的界面反应及其对焊点可靠性影响具有重要的意义。本文作者主要研究了P含量为6.5%(质量分数)的化学镀Ni-P薄膜与Sn-3.5Ag焊球在钎焊和时效过程中的界面反应及界面IMC的生长规律。

1 实验

实验中将L2铝(w(Al)>99.60%,w(Cu)≤0.05%,w(Mg)≤0.03%,w(Mn)≤0.03%,w(Fe)≤0.35%,w(Si)≤0.25%,w(Ti)≤0.03%,其他不大于0.03%(质量分数)切割成2 mm×1 mm×1.5 mm的小片,预磨抛光后,进行化学镀Ni-P薄膜制备,经扫描电镜(SEM)测得Ni-P镀层厚度约6 μm,能谱(EDX)测定其磷含量为6.5%(质量分数)。将纯度99.95%的Sn和99.9%的Ag丝在500 ℃的真空炉中熔炼4 h得到Sn-3.5Ag钎料合金,冷却后切割成质量为(48±1) mg的小块,然后,熔化成直径为(2.3±0.06) mm的焊球。

在Sn-3.5Ag焊球表面涂覆一层RMA钎剂,放置于化学镀Ni-P薄膜上,同时放入预先加热到250 ℃的加热炉中,焊球融化时形始计时,反应时间分别为5、10和30 min。将钎焊5和30 min的试样在150 ℃的空气中时效,时效时间分别为50,100,150和200 h。将钎焊及时效后的试样垂直放在直径20 mm的塑料管中,用环氧树脂进行冷镶嵌。对镶嵌好的样品进行预磨和抛光后,用92%乙醇-5%硝酸-3%盐酸的溶液腐蚀,在扫描电镜下观察焊点横截面微观组织和生成的界面IMC晶粒的形貌。

2 结果与分析

2.1 Sn-3.5Ag焊球在化学镀Ni-P薄膜上的钎焊润湿行为

钎焊过程中,钎料在母材表面上的润湿、流动对钎焊的成功与否起到关键的作用。对于润湿行为的表征,通常有两种方法:一是测量钎料的润湿角,二是测量钎料的铺展面积并用铺展系数来表征。

润湿角的大小由Yung-Dupre公式得到:

式中:γSF、γIF和γLF分别为基体/钎剂、IMC/钎料及钎料/钎剂之间的表面张力。从式(1)可以看出,当γSF较小或γSF-γIF较大时,对应的润湿角较小,小的润湿角有利于钎料的钎接。

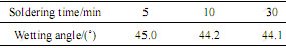

在液态下钎料在本身重力的作用下,在基体横向上会发生流动。表1所列为Sn-3.5Ag/Ni-P在250 ℃钎焊不同时间的润湿角。由表1可以看出,润湿角的大小随着钎焊时间的延长而略有减小,总体上变化不大。测量得到的润湿角接近44?,这与MA和SUHLING等[10]使用W2000A助焊剂在Cu板上得到的润湿角相近。

表1 Sn-3.5Ag与Ni-P薄膜钎焊的润湿角

Table 1 Wetting angle between Sn-3.5Ag and Ni-P plating

对于铺展系数的测定,通过GB/T 11364—2008的试验方法进行,通过以下公式计算

式中:K为铺展系数;H为钎料在基体表面铺展后的高度的数值(mm);D为与钎料体积相等的球体的直径(mm),D=1.24V1/2,V为实验中使用的钎料的质量与密度的比值。

表2所列为Sn-3.5Ag/Ni-6.5%(质量分数)P在 250 ℃钎焊不同时间的铺展系数。由表2可以看出,铺展系数随着钎焊时间的延长略有增大,钎焊30 min后的铺展系数较钎焊5 min时的铺展系数增加2%,但总体变化不大,铺展系数约为67%,这与润湿角的测量结果基本一致。

表2 Sn-3.5Ag与Ni-P层钎焊的铺展系数

Table 2 Spreading coefficients between Sn-3.5Ag and Ni-P plating

2.2 钎焊过程中Sn-3.5Ag/Ni-6.5P的界面反应

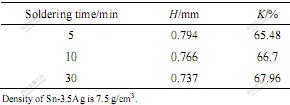

图1所示为Sn-3.5Ag焊球与化学镀Ni-6.5P薄膜在250 ℃下钎焊不同时间后界面Ni3Sn4 IMC的SEM像。从图1可以看出,钎焊5 min后,Ni3Sn4 IMC主要呈现小颗粒状,同时有少量较粗大的条状晶粒;钎焊10 min后,Ni3Sn4 IMC小颗粒长大,较粗大的条状晶粒也比钎焊5 min时多,且在Ni3Sn4 IMC表面附着一些细小颗粒,通过EDX确认为Ag3Sn粒子;钎焊30 min后,粗大的棱面状颗粒成为Ni3Sn4 IMC的主要形貌特征,大块的Ni3Sn4 晶粒尺寸约为6 μm,同时Ni3Sn4 表面附着的Ag3Sn颗粒也有所增加,局部Ag3Sn长成细条状。由此可见,钎焊过程中,界面Ni3Sn4金属间化合物的尺寸随着液态钎料与Ni-P薄膜反应时间延长而逐渐变大,而相应的晶粒数则减少。KIM和TU[11]研究认为,这种晶粒的粗化受从UBM到界面的扩散流及由于晶粒曲率半径不同引起的熟化流控制。从钎焊5~10 min的形貌可以看出,IMCs的生长符合晶粒粗化机制。HE等[12]研究认为,棱面状Ni3Sn4 IMC形成的主要原因是由于Ni3Sn4相存在界面能的各向异性。大的棱面状晶粒是由多个相邻具有相同结晶取向的晶粒粗化形成。在长时间的钎焊过程中,界面Ni3Sn4 IMC形成连线层,从UBM到界面的扩散流受到抑制,而熟化流控制了Ni3Sn4 IMC的生长,因此,形成了大的具有相同结晶取向的晶粒和不同结晶取向的小晶粒共存的形貌特征。

图1 Sn-3.5Ag/Ni-6.5P在250℃钎焊不同时间后界面Ni3Sn4 IMC的SEM像

Fig.1 SEM images of Ni3Sn4 IMC at interface of Sn-3.5Ag/Ni-6.5P soldering at 250 ℃ for different times: (a) 5 min; (b) 10 min; (c) 30 min

图2所示为Sn-3.5Ag焊球与化学镀Ni-P薄膜在250 ℃钎焊不同时间的横截面的SEM像。扫描电镜形貌与能谱分析表明,IMC层主要由Ni3Sn4 IMC、Ni3P晶化层及较薄的Ni-Sn-P过渡层构成。在Ni3Sn4 IMC相中未检测到P元素,通常认为P元素不参与反应,当Ni-P层中的Ni消耗,富P层则形成Ni3P晶化层[7-9]。由于Ni3P具有多孔的细晶结构,会大大影响到Ni元素通过此层的扩散,在某些区域Ni的扩散较大,因此形成不同形状和厚度的Ni3Sn4 IMC层[12]。钎焊5 min时,在Ni-P薄膜表面形成了连续的Ni3Sn4 IMC;随着钎焊时间的延长,界面Ni3Sn4 IMC呈现为颗粒状;当钎焊30 min时,Ni3Sn4 IMC颗粒进一步长大,形成棱面状。

图2 在250℃钎焊不同时间后Sn-3.5Ag/Ni-6.5P横截面的SEM像

Fig.2 SEM images of cross-section of Sn-3.5Ag/Ni-6.5P interface during soldering at 250 ℃ for different times: (a) 5 min; (b) 10 min; (c) 30 min

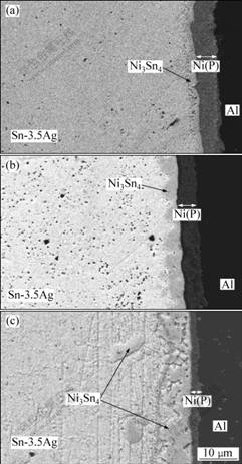

图3所示为钎焊不同时间后的Ni3Sn4 IMC平均厚度与钎焊时间(ts)的关系。由图3可见,钎焊5 min后,IMC平均厚度为2.3 μm;钎焊10 min后,IMC平均厚度为3.2 μm;而钎焊30 min后,IMC平均厚度达到3.8 μm。通过拟合可知,Ni3Sn4 IMC厚度与钎焊时间ts1/3呈线性关系,表明随着钎焊时间的延长,IMC的厚度增加速度减缓。

图3 IMC厚度与钎焊时间ts1/3的关系

Fig.3 Thickness of IMC as function of cubic root of soldering time

2.3 时效过程中Sn-3.5Ag/Ni-6.5P界面IMC的生长行为

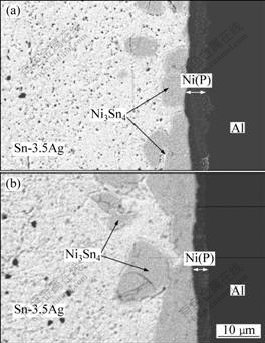

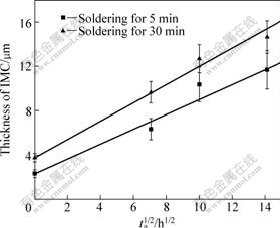

图4所示分别为250 ℃钎焊5 min和30 min的Sn-3.5Ag/Ni-6.5P焊点在150 ℃下时效200 h后横截面的SEM像。扫描电镜形貌与能谱分析表明,时效200 h后,钎焊界面层仍由Ni3Sn4 IMC、Ni3P晶化层及较薄的Ni-Sn-P过渡层构成,时效过程未改变焊点的界面结构。由于时效过程中,钎料和Ni-P层之间发生元素的相互扩散,Ni3Sn4 IMC、Ni3P晶化层及较薄的Ni-Sn-P过渡层持续不断生长。从图2可以看出,钎焊5 min时未时效焊点中界面IMC层的平均厚度约为2 μm,小于Sn-3.5Ag/Cu在250 ℃下钎焊5 min焊点中界面IMC层的平均厚度[13],这主要是由于相对于CuNi(P)的扩散更弱些,使得IMC的生长较慢[7-9];时效100 h后,界面Ni3Sn4 IMC的平均厚度达到10 μm;时效200 h后,界面Ni3Sn4 IMC的平均厚度达到11.7 μm。IMC的生长可能与Ni3P的晶化有关,因为在时效过程中,Ni3P的厚度不断增加,致使IMC处形成内应力,促使Ni3P中形成微裂纹或由于柯肯达尔效应引起的孔洞[7-9, 14],这些缺陷为Ni向界面进一步扩散形成IMC提供了短路扩散的途径。对于钎焊30 min的焊点时效200 h后,Ni3Sn4 IMC层的平均厚度达到14.6 μm,界面IMC出现较大的颗粒。图5所示为Ni3Sn4 IMC的生长速率与时效时间的对应关系。通过分析可知,IMC的生长速率与ta1/2呈线性关系。在150 ℃下时效时,界面Ni3Sn4 IMC在钎焊5 min的焊点中的生长速率为1.11×10-8 m/s1/2,而界面Ni3Sn4 IMC在钎焊30 min的焊点中的生长速率为1.37×10-8 m/s1/2。两种生长速率相差不大,这主要是因为IMC的生长是由元素的扩散行为控制的。钎焊后焊点中IMC的厚度相差不大,元素的扩散路径基本相同,因此,观察到相接近的Ni3Sn4 IMC生长速率。本研究中IMC的生长速率与HUANG等[15]研究Sn-3.5Ag/Ni-P钎焊30~60 s后时效过程中界面IMC的生长速率1.63×10-8 m/s1/2接近。

图4 Sn-3.5Ag/Ni-6.5P时效后的横截面的SEM像

Fig.4 SEM images of cross-section of Sn-3.5Ag/Ni-6.5P interface after aging: (a) Soldering at 250 ℃ for 5 min, then aging at 150 ℃ for 200 h; (b) Soldering at 250 ℃ for 30 min then aging at 150 ℃ for 200 h

图5 150 ℃时Ni3Sn4 IMC厚度与时效时间ta1/2的关系

Fig.5 Relationship between thickness of Ni3Sn4 IMC and square root of aging time at 150 ℃

2.4 时效过程中界面富P层的生长行为

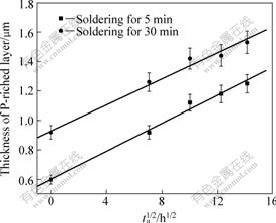

图6所示为在250 ℃下分别钎焊5和30 min后焊点在150 ℃下时效0~200 h界面富P层的生长厚度。从图6可以看出,在150 ℃下时效后,富P层的厚度与时效时间ta1/2呈线性关系,表明富P层的生长满足抛物线规律且受扩散控制。钎焊5 min的焊点中富P层在时效过程中的生长速率为7.92×10-10 m/s1/2,钎焊30 min的焊点中富P层在时效过程中的生长速率为7.36×10-10 m/s1/2。HUANG等[15]在Sn-3.5Ag/Ni-P钎焊30~60 s后时效过程中得到的富P层的生长速率为2.10×10-9 m/s1/2,经比较可知本研究中得到的富P层生长速率均比HUANG等得到的富P层的生长速率小,这主要是由于本实验中钎焊时间长(5~30 min),导致界面IMC及富P层的厚度均大于HUANG等[15]钎焊30~60 s得到的界面IMC及富P层的厚度,本实验中较厚的界面IMC的出现使时效过程中Ni-P层中的Ni向Sn-3.5Ag钎料中扩散的阻力增大,导致富P层的生长速率较低。

图6 150 ℃时富P层厚度与时效时间的关系

Fig.6 Relationship between thickness of P-riched layer as function of square root of aging time at 150 ℃

3 结论

1) 直径为(2.3±0.06) mm的Sn-3.5Ag焊球与化学镀Ni-6.5%P薄膜在250 ℃钎焊5~30 min得到的润湿角约为44?,铺展率约为67%。

2) 250 ℃下钎焊5~30 min,Sn-3.5Ag/ Ni-P焊点中界面由成分为Ni3Sn4的IMC层、Ni3P晶化层及较薄的Ni-Sn-P过渡层构成。随钎焊时间的延长,Ni3Sn4 IMC晶粒逐渐长大,钎焊5 min时以小颗粒为主,钎焊30 min后,颗粒粗化,出现尺寸约6 μm的棱面状Ni3Sn4 IMC晶粒。Ni3Sn4 IMC生长速率与钎焊时间ts1/3呈线性关系。钎焊10 min后,也观察到在Ni3Sn4表面附着Ag3Sn相。

3) 250 ℃下钎焊5和30 min的Sn-3.5Ag/ Ni-P焊点在150 ℃下时效200 h后,界面层仍由Ni3Sn4 IMC层、Ni3P晶化层及较薄的Ni-Sn-P过渡层构成。时效过程中Ni3Sn4 IMC的生长与时间ta1/2呈线性关系。界面Ni3Sn4 IMC在钎焊5 min的焊点中的生长速率为1.11×10-8 m/s1/2,而在钎焊30 min的焊点中的生长速率为1.37×10-8 m/s1/2。

4) 250 ℃下钎焊5和30 min的Sn-3.5Ag/Ni-P焊点在150 ℃下时效过程中,界面富P层的生长速率与时效时间ta1/2呈线性关系。钎焊5 min的焊点中界面富P层的生长速率为7.92×10-10 m/s1/2,钎焊30min的焊点中界面富P层的生长速率为7.36×10-10 m/s1/2。

REFERENCES

[1] 中国电子学会生产技术学分会丛书编委会组. 微电子封装技术[M]. 合肥: 中国科学技术大学出版社, 2005.

Series Edit Committee of China Electronics Academy of Manufacture and Technology. Micro-electronics packaging technology[M]. Hefei: University of Science and Technology of China Press, 2005.

[2] 宣大荣. 无铅焊接?微焊接技术分析与工艺设计[M]. 北京: 电子工业出版社, 2005.

XUAN Da-rong. Lead-free welding?micro-welding technology analysis and technics design[M]. Beijing: Electronic Industry Press, 2005.

[3] 金玉丰, 王志平, 陈 兢. 微系统封装技术概论[M]. 北京: 科学出版社, 2006.

JIN Yu-feng, WANG Zhi-ping, CHEN Jin. Microsystem packaging technology[M]. Beijing: Science Press, 2006.

[4] MA H T, SUHLING J C. A review of mechanical properties of lead-free solders for electronic packaging [J]. Jounal of Materials Science, 2009, 44: 1141-1158.

[5] 刘 曦, 高加强, 胡文彬. 化学镀Ni-P合金在电子工业中的应用[J]. 电镀与精饰, 2006, 28(1): 30-34.

LIU Xi, GAO Jia-qiang, HU Wen-bin. Application of electroless Ni-P alloys in electronics industry[J]. Plating and Finishing, 2006, 28(1): 30-34.

[6] JANG J W, KIM P G, TU K N, FREAR D R, THOMPSONP. Solder reaction-assisted crystallization of electroless Ni-P under bump metallization in low cost flip chip technology[J]. Journal of Applied Physics, 1999, 85: 8456-8463.

[7] CHEN C J, LIN K L. The reaction between electoless Ni-Cu-P deposition and 63Sn-37Pb flip chip solder bumps during reflow[J]. Journal of Electronic Materials, 2000, 29: 1007-1014.

[8] HUNG K C, CHAN Y C, TANG C W. Correlation between Ni3Sn4 intermetallics and Ni3P due to solder reaction-assisted crystallization of electrolee Ni-P metallization in advanced packages[J]. Journal of Materials Research, 2000, 15: 2534-2539.

[9] HUNG K C, CHAN Y C. Study of Ni3P growth due to solder reaction-assisted crystallization of electroless Ni-P metallization[J]. Journal of Materials Science Letters, 2000, 19: 1755-1757.

[10] 李 松. 电子封装焊料润湿性的研究[D]. 武汉: 华中科技大学, 2006: 12.

LI Song. Wetting dynamics of solders in SMT[D]. Wuhan: Huazhong University of Science and Technology, 2006: 12.

[11] KIM H K, TU K N. Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening[J]. Physical Review B, 1996, 53: 16027-16034.

[12] HE Min, LAU Wee-hua, QI Guo-jun, CHEN Zhong. Intermetallic compound formation between Sn-3.5Ag solder and Ni-based metallization during liquid state reaction[J]. Thin Solid Films, 2004, 462/463: 376-383.

[13] 于大全. 电子封装互连无铅钎料及其界面问题研究[D]. 大连: 大连理工大学, 2004.

YU Da-quan. Development of lead free solder and its interfacial issues in electronics packaging[D]. Dalian: Dalian University of Technology, 2004.

[14] ZENG K, TU K N. Six cases of reliability study of Pb-free solder joints in electroic packing technology[J]. Materials Science and Engineering Report, 2002, 38(1): 55-105.

[15] HUANG M L, LOEHER T, MANESSIS D, BOETTCHER L, OSTMANN A, REICHL H. Morphology and growth kinetics of intermetallic compounds in solid-state interfacial reaction of electroless Ni-P with Sn-based lead-free solders[J]. Journal of Electronic Materials, 2006, 35: 181-188.

__________________________________

基金项目:国家科技支撑计划资助项目(2006BAE03B02-2);国家自然科学基金资助项目(U0734006,50811140338);教育部高校博士点基金资助项目(20070141062)

收稿日期:2009-07-15;修订日期:2010-01-05

通信作者:黄明亮,教授,博士;电话:0411-84706595;E-mail:huang@dlut.edu.cn

(编辑 龙怀中)