文章编号:1004-0609(2013)S1-s0500-05

热处理对Ti-45Nb丝材微观组织和拉伸性能的影响

刘彦昌1, 2,朱宝辉1, 2,赵洪章1,王培军1,陈睿博1,王晓平1,曾卫东2

(1. 宁夏东方钽业股份有限公司 钛材分公司,石嘴山 753000;

2. 西北工业大学 材料学院,西安 710072)

摘 要:研究Ti-45Nb钛合金丝材在不同温度真空热处理后的显微组织和拉伸性能。结果表明:热处理温度对Ti-45Nb合金丝材的微观组织有明显的影响,但对丝材的拉伸性能影响不大。随着温度的升高,丝材的晶粒不断长大,拉伸强度整体下降,伸长率和断面收缩率略有增大。800 ℃时样品微观组织均匀细小且强塑性匹配最好;热处理温度相同时,不同规格丝材的微观组织差别不明显。随着丝材直径的减小,其拉伸强度有所提高,伸长率变化不大,但断面收缩率略有降低。经过800 ℃固溶处理后,丝材的组织均匀性得到明显的改善。实验还发现,通过热处理提高Ti-45Nb合金丝材强度的效果不明显,但通过增加合金中的O含量可以较为明显的提高合金强度。

关键词:Ti-45Nb;钛合金;丝材;热处理;拉伸性能;微观组织

中图分类号:TG146.2 文献标志码:A

Influence of heat treatment on microstructures and tensile properties of Ti-45Nb wires

LIU Yan-chang1, 2, ZHU Bao-hui1, 2, ZHAO Hong-zhang1, WANG Pei-jun1, CHEN Rui-bo1, WANG Xiao-ping1, ZENG Wei-dong2

(1. Titanium Materials Sub-company, Ningxia Orient Tantalum Industry Co., Ltd., Shizuishan 753000, China;

2. School of Materials Science and Engineering, Northwestern, Polytechnical University, Xi’an710072, China)

Abstract: The microstructures and tensile properties of Ti-45Nb wires produced by vacuum annealing heat treatment at various temperatures and sizes were studied. The results show that the effects of the temperatures of the vacuum annealing heat treatment on the microstructures of the wires are obvious while on the tensile properties are slight. With increasing temperature, the grains of the wires grow bigger, and the tensile strength trends to decrease while the elongation and reduction area both increase slightly. The microstructures after the vacuum annealing heat treatment of the wires are fine and uniform and better adoption of strength and plasticity is reached at 800 ℃. The microstructures do not change obviously under annealing at the same temperature, with decreasing diameter of the wires, the tensile strengths increase, the elongation does not change much, the reduction area decreases slightly. The uniformity of microstructures of the wires improves obviously after solution treatment at 800 ℃. The improvement of the tensile strength of the wires by heat treatment is not obvious, but the tensile strength is greatly increased by increasing the oxygen content of the alloy.

Key words: Ti-45Nb; titanium alloy; wire; heat treatment; tensile properties; microstructures

Ti-45Nb合金是一种单相β钛合金,在航空、航天、化工防腐、生体医用和超导领域都表现出优异的综合性能。该合金在航空航天领域主要用于复合材料及钛合金结构的铆接,于1974年列入AMS4982规范,2007年修订为AMS4982D。在化工防腐方面,其耐蚀性能与纯铌的相当,比纯钛高一个数量级,但是其价格和密度比纯钛的高很多,所以只能少量地用在特殊环境中,如湿法冶金、板道系统、低压氧化等某些工作条件恶劣的部位。在生体医用方面该合金在国外已有应用,但在国内尚属空白。另外,该合金是最重要的低温合金超导材料,应用于民用领域的核磁共振扫描仪(NMR)、核磁共振成像(MRI),强电磁场领域的高能物理的加速器、探测器、等离子体磁约束、超导储能超导电机等。Ti-45Nb合金的产品类型主要以棒丝材为主,该合金丝材在退火状态下具有良好加工性能,冷成型性能与纯钛相当[1-5, 10]。

本文作者研究不同规格的Ti-45Nb合金丝材的热处理工艺,比较丝材在热处理后的微观组织和拉伸性能。

1 实验

实验所用材料为经过熔炼、锻造、轧制、拉拔制备的d 2.5、3.0、3.5、4.0和5.0 mm的Ti-45Nb合金丝材。

对d5.0 mm的丝材在650、700、750、800、850和900 ℃进行不同温度的真空退火处理,比较其显微组织变化及其在700、800和900 ℃下的拉伸性能;对d 2.5、3.0、3.5和4.0 mm不同规格的丝材在700和800 ℃下进行热处理,测试其拉伸性能,并比较 800 ℃下其显微组织的变化;退火处理均在真空退火炉中进行,保温时间均为1 h;对d 2.5 mm的丝材于800 ℃进行不同时间的固溶处理,并比较其显微组织的变化。按照GB/T228标准准备拉伸试样,在INSTRON 4505电子万能试验机上进行拉伸试验,使用Leica MM-6金相显微镜观察其显微组织。

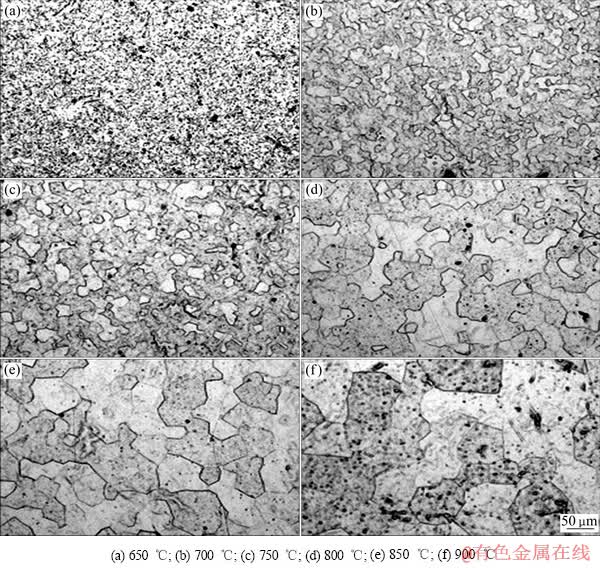

图1 不同退火温度下d 5 mm Ti-45Nb丝材的微观组织

Fig. 1 Microstructures of d 5 mm Ti-45Nb wires at different annealing temperatures

2 结果与讨论

2.1 热处理温度对Ti-45Nb丝材微观组织的影响

图1所示为d 5.0 mm Ti-45Nb丝材在不同温度下进行真空热处理后的显微组织。可以看出,随着退火温度的升高,其晶粒尺寸不断长大。在650 ℃退火后,再结晶开始形核, 在700和750 ℃时,加工态组织基本消除,但再结晶尚未完成,两种温度下晶粒尺寸差别不大,在800 ℃时晶粒继续长大,再结晶比较充分,微观组织为完全再结晶等轴组织,晶粒尺寸较为均匀,850 ℃时晶粒已经开始明显长大,900 ℃时晶粒发生了异常长大。

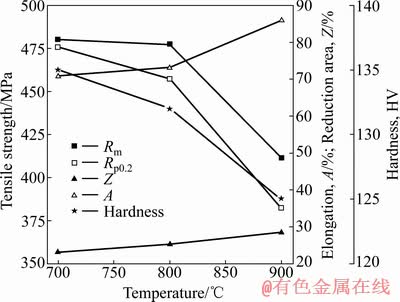

图2是对d 5.0 mm的丝材在700、800和900 ℃下真空退火后力学性能的比较。由图可见,随着温度的升高,丝材的抗拉强度和屈服强度整体下降,伸长率和断面收缩率在800和900 ℃时的变化不大,可满足紧固件用材的要求,抗拉强度均在560 MPa以上,屈服强度均在450 MPa以上,但在900 ℃时的拉伸性能与其相比均有明显降低,已不能满足紧固件用的标准。丝材的硬度也随着温度的升高而降低。

图2 d 5.0 mm Ti-45Nb丝材真空热处理后的力学性能

Fig. 2 Mechanical properties of d 5.0 mm Ti-45Nb wires after vacuum annealing heat treatment

综上所述,在试验温度下,Ti-45Nb丝材在800 ℃进行真空退火可以得到最好的组织性能匹配。

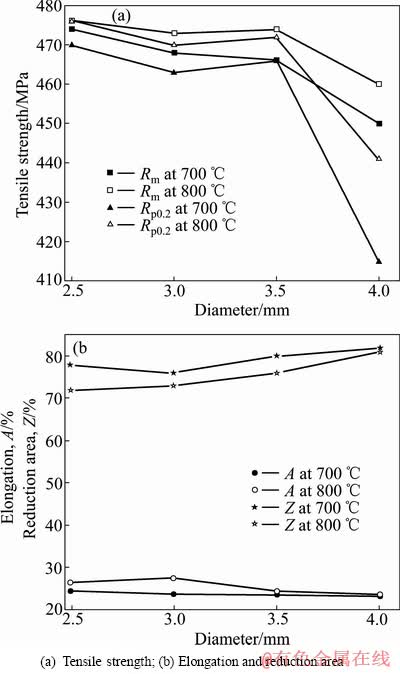

2.2 不同规格Ti-45Nb丝材真空热处理后的拉伸性能

不同规格Ti-45Nb丝材真空热处理后的拉伸性能如图3所示。由图可见,随着丝材直径的减小,其抗拉强度及屈服强度升高,伸长率变化不大,但断面收缩率略有降低。当丝材直径小于3.5 mm时,其拉伸性能变化较小,而d 4.0、3.5、3.0和2.5 mm丝材的拉伸强度变化较为明显,因为在丝坯规格相同的情况下,细晶强化对d 4.0 mm丝材不如对直径小于3.5 mm丝材的作用明显。随着丝材直径的减小,真空退火温度对丝材拉伸性能的影响减小。总体来说,所有丝材在800 ℃退火后的强塑性匹配比700 ℃退火的好。

图3 不同直径Ti-45Nb丝材真空热处理后的拉伸性能

Fig. 3 Tensile properties of Ti-45Nb wires with different diameters after vacuum annealing heat treatment

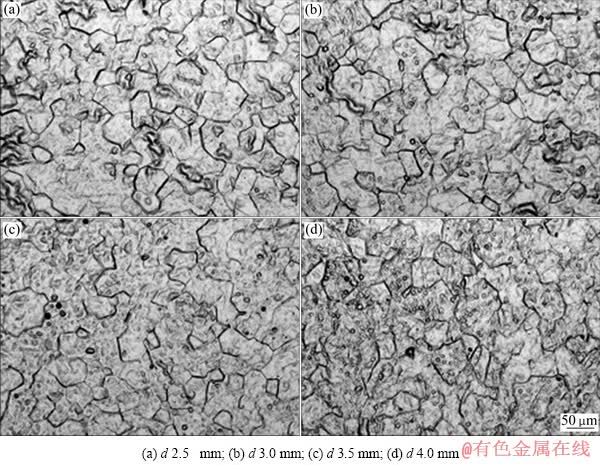

2.3 不同规格Ti-45Nb丝材真空热处理后的显微组织

图4所示为4种不同规格(d 2.5、3.0、3.5和4.0 mm) Ti-45Nb丝材的显微组织。热处理制度为(800 ℃,1 h, FC)。由图4可见,4种规格丝材退火后的晶粒均呈等轴状,晶界明显,再结晶比较充分,其晶粒尺寸随丝材尺寸的变化不明显。但组织的均匀性较差,需要 通过调整加工工艺进行改善[7]。

2.4 固溶处理对Ti-45Nb丝材显微组织的影响

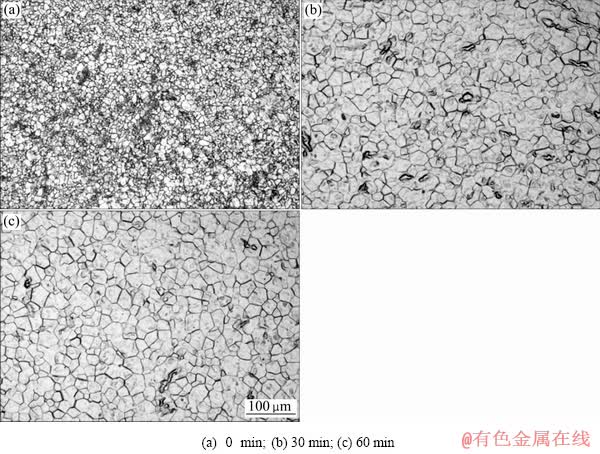

固溶处理过程中发生的静态再结晶可以改善丝材微观组织的均匀性[5],图5所示为d 2.5 mm丝材的原始加工态组织和经800 ℃固溶处理30和60 min后的微观组织。可以看出,固溶处理后材料发生了明显的静态再结晶,加工态的不均匀组织得到了明显的改善。

丝材在800 ℃进行固溶热处理30和60 min后,组织没有明显的变化,未发现明显的晶粒粗化。因此,可以在此温度和时间范围内对丝材进行固溶处理。

图4 不同规格Ti-45Nb丝材真空退火后的显微组织

Fig. 4 Microstructures of Ti-45Nb wires with different diameters after vacuum annealing heat treatment at 800 ℃ for 1 h

图5 d 2.5 mm Ti-45Nb丝材经800 ℃固溶处理后的显微组织

Fig. 5 Microstructures of d 2.5 mm Ti-45Nb wires withr solution heat treatment at 800 ℃ for different time

2.5 不同氧含量Ti-45Nb丝材真空热处理后的拉伸性能

Ti-45Nb合金为纯β合金,该合金无法通过固溶处理和时效的方式进行强化,只能通过细晶强化和固溶强化来实现,间隙元素O也可以提高钛合金的室温抗拉强度[1]。如上所述,该合金的细晶强化作用已经显现,但还无法完全满足紧固件用材的要求,说明该合金固溶强化效果不明显,这是由于间隙元素O含量过低,形成的晶格畸变有限。固溶强化效果与合金的成分关系紧密,将合金中的O含量由原来的0.04%调整为约0.08%(质量分数),在不改变加工工艺的情况下,测试d 4.0 mm丝材的拉伸性能,结果如表1所列。与原有的成分丝材相比,增加O含量后的合金的拉伸性能变化较为明显,拉伸强度均增加40~50 MPa,塑性有所下降。可见增加间隙元素O的含量,可以显著增加晶格畸变强化效果。调整后该合金可同时作为超导用材和紧固件用材[6-8]。

表1 不同氧含量Ti-45Nb丝材真空退火后的室温拉伸性能

Table 1 Room temperature tensile properties of Ti-45Nb wires after vacuum annealing with different O content

3 结论

1) 热处理温度对Ti-45Nb合金丝材的微观组织有明显的影响,随着温度的升高,晶粒尺寸不断长大,在800 ℃形成完全再结晶的等轴组织。

2) 热处理温度对Ti-45Nb合金丝材的拉伸性能影响不大,随着温度的升高,丝材的抗拉强度和屈服强度下降,伸长率和断面收缩率略有增大,其硬度也随着温度的升高而降低,800 ℃热处理的强塑性匹配最好。

3) 在相同的热处理温度下,随着丝材直径的减小,其抗拉强度和屈服强度有所提高,伸长率变化不大,但断面收缩率略有降低。

4) 通过(800 ℃,60 min)固溶处理,丝材的组织均匀性得到明显的改善。

5) 通过热处理提高Ti-45Nb合金丝材的拉伸强度效果不明显,在相同的加工工艺和热处理制度下,通过调整合金成分,特别是间隙元素O的含量,可以较为显著的提高合金强度。

REFERENCES

[1] 《稀有金属材料加工手册》编辑组. 稀有金属材料加工手册[M]. 北京: 冶金工业出版社, 1984: 27-44.

Editorial Group. Pocessing handbook of rare metal materials [M]. Beijing: Metallurgical Industry Press, 1984: 27-44.

[2] 张喜燕,赵永庆,白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005: 80-95.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Cheng-guang. The application of titanium alloy [M]. Beijing: Chemical Industry Press, 2005: 80-95.

[3] GODLEY R, STAROSVETSKY D, GOTMAN I. Corrosion behavior of a low modulus β-Ti-45%Nb alloy for use in medical implants [J]. Journal of Materials Science: Materials in Medicine, 2006, 17: 63-67.

[4] 张宝昌. 有色金属及其热处理[M]. 西安: 西北工业大学出版社, 1993: 35-38.

ZHANG Bao-chang. Nonferrous metal and heat treatment [M]. Xi’an: Northwestern Polytechnical University Press, 1993: 35- 38.

[5] 草道英武. 金属钛及应用[M]. 程 敏, 赵克德, 译. 北京: 冶金工业出版社, 1989: 155-157.

HIDETEKE K. Metallic titanium and its application [M]. CHENG Min, ZHAO Ke-de, transl. Beijing: Metallical Indystry Press, 1989: 155-157.

[6] 赵庆云, 刘风雷, 刘华东. 世界先进航空紧固件进展[J]. 航空制造技术, 2009, 10(3): 54-56.

ZHAO Qing-yun, LIU Feng-lei, LIU Hua-dong. Development of advanced aeronautic manufacturing technology [J]. Aeronatic Manufacturing Technology, 2009, 10(3): 54-56.

[7] 张 奕, 郑永健, 唐晓东, 付宝全, 王 虎, 雷锦文. 变形率和热处理制度对Nb47Ti合金显微组织的影响[J]. 中国有色金属学报, 2010, 20(S1): s331-s335.

ZHANG Yi, ZHENG Yong-jian, TANG Xiao-dong, FU Bao-quan, WANG Hu, LEI Jin-wen. Effect of deformation rate and heat treatment on microstructure of Nb47Ti alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s331-s335.

[8] 李建峰, 张平祥, 刘向宏, 李金山, 冯 勇, 王天成, 杜社军, 刘维涛. 磁体用NbTi超导体的研究进展[J]. 材料导报, 2009, 23(2): 90-93.

LI Jian-feng, ZHANG Ping-xiang, LIU Xiang-hong, LI Jin-shan, FENG Yong, WANG Tian-cheng, DU She-jun, LIU Wei-tao. Research advancces in NbTi superconduct for magnet application [J]. Materials Review Issn, 2009, 23(2): 90-93.

[9] 商国强, 王新南, 唐 斌, 朱知寿, 寇宏超, 张丰收, 常 辉. 紧固件用Ti45Nb合金丝材的性能评价[J]. 中国有色金属学报, 2010, 20(S1): s70-s74.

SHANG Guo-qiang, WANG Xin-nan, TANG Bin, ZHU Zhi-shou, KOU Hong-chao, ZHANG Feng-shou, CHANG Hui. Property evaluation of Ti-45Nb alloy wires used in fasterner [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s70-s74.

[10] 国际钽铌研究中心. 钽铌译文集[M]. 刘贵材, 娄燕雄, 译. 长沙: 中南大学出版社, 2009: 180-186.

International Research Center of Tantalum and Niobium. Translation of tantalum and niobium [M]. LIU Gui-cai, LOU Yan-xiong, transl. Changsha: Central South University Press, 2009: 180-186.

(编辑 方京华)

基金项目:宁夏东方钽业股份有限公司资助项目(SJ07-13-2)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:刘彦昌,工程师; 电话:0952-2098907;E-mail: yanchang.liu@163.com