强化氧化对石煤钙化焙烧提钒的影响

李昌林,周向阳,王辉,张太康,李劼,欧星,江小舵

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:研究石煤钙化焙烧参数对提钒效果的影响,确定合理的焙烧参数:当焙烧温度为950 ℃,焙烧时间3 h,碳酸钙添加量为质量分数6%时,石煤焙烧料中钒的浸出率为63%。在此基础上研究增强氧化对提钒效果的影响,比较通空气和添加MnO2这2种情况下提钒的效果。用化学物相分析和钒价态分析等技术探讨加强氧化提高钒浸出率的原因。空气通入速度为0.48 L/h时,钒的浸出率为69%;MnO2添加量(质量分数)为3%时,钒浸出率为68%。研究结果表明,加强氧化后矿石的结构被破坏,V5+含量提高,生成更多易溶于酸的钒酸钙类物质。

关键词:钙化焙烧;钒;石煤;氧化

中图分类号:TF841.3 文献标志码:A 文章编号:1672-7207(2011)01-0007-04

Effect of oxidation on vanadium extraction from stone coal with calcified roasting

LI Chang-lin, ZHOU Xiang-yang, WANG Hui, ZHANG Tai-kang, LI Jie, OU Xing, JIANG Xiao-duo

(School of Metallurgical Science and Engineering, Central south university, Changsha 410083, China)

Abstract: The calcified roasting condition for vanadium extraction from stone coal was studied. Under the condition of 950 ℃, roasting 3 h, CaCO3 addition 6% (mass fraction), the subsequent vanadium leaching efficiency of about 63% can be obtained. On the base of the same condition, effect of air sparging and MnO2 addition on vanadium extraction was investigated. The reason why oxidation can improve vanadium leaching was investigated through phase and valence state of vanadium analysis. Results show that vanadium leaching efficiency of 69% can be obtained with air sparging speed of 0.48 L/h and 68% with MnO2 addition of 3%. It is found that oxidation is effective to destroy the ore structure and increase the percentage of V5+ in calcine, and more calcium vanadate compounds is generated, which easily responds to acid leaching.

Key words: calcified roasting; vanadium; stone coal; oxidation

钒是一种重要的金属,广泛应用于冶金、航空航天、电子、化工、医药等各个领域行业[1-3]。地壳的元素中,钒的含量位居第22位。钒常与其它矿物共生,常见的含钒矿物有:钒钾铀石、钒云母、铅钒矿、钒铜铅矿、钒钛磁铁矿、绿硫钒石和石煤。我国石煤资源丰富,储量为1.18亿t (以五氧化二钒计),占钒总储量的87%[4-6]。从20世纪70年代起,许多厂家研发了一系列从石煤中提取钒的工艺,如钠化焙烧-水浸工艺和钙化焙烧-酸浸工艺。钠化焙烧-水浸是最早实现工业化的石煤提钒工艺,其原理是在高温和氯化钠作用下,将石煤中的钒氧化转变为可溶性的钒酸钠,经水浸后形成含钒溶液。该工艺虽流程简便,但钒的提取率低,对环境污染严重[7-9]。与钠化焙烧-水浸工艺相比,钙化焙烧-酸浸工艺具有高效、清洁的特点。钙化焙烧过程中低价钒氧化为五价钒,与钙剂生成钒酸钙,钒酸钙与酸反应后将钒浸出。可见,强化石煤中低价钒的氧化,是提高钒收率的有效途径[10-13]。本文研究了通空气和添加MnO2强化氧化的方法对钒浸出效率的影响,采用化学物相分析和钒价态分析技术分析了强化氧化提高钒浸出率的原因。

1 实验

1.1 实验原料

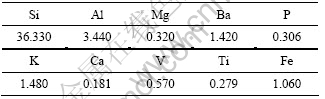

实验所用石煤来自湖南湘西。主要成分如表1所示,该石煤中V2O5的含量(质量分数)为1.02%。实验用试剂:硫酸、碳酸钙、氧化钙、二氧化锰、硫酸亚铁铵、尿素、高锰酸钾、亚硝酸钠、N-苯基邻氨基苯甲酸,均为分析纯。

表1 石煤主要化学成分(质量分数)

Table 1 Chemical analysis results of main composition of stone coal %

1.2 实验过程

矿石破碎后筛分,取粒度小于150 μm的矿粉做焙烧实验原料。将矿粉与适量的水和添加剂混匀制成粒径为15~20 mm的料球,在100 ℃下烘12 h后,置于电炉中在一定温度下焙烧相应时间。焙烧的料球经冷却粉碎后置于质量浓度为5%的硫酸溶液中搅拌浸出,焙烧效果用浸出率表征。浸出过程工艺参数为:浸出液固比1.5?1,浸出温度为20 ℃,浸出时间为3 h,搅拌速度为200 r/min;浸出反应完毕后抽滤,并用清水洗2遍,洗涤液加入到浸出液中一起计算浸出率。

1.3 分析与检测

采用高锰酸钾氧化—硫酸亚铁铵滴定法测定矿石和溶液中的钒含量;依据文献[14]中的方法测定石煤焙烧料中钒的价态及在各相的分布。

2 结果与讨论

2.1 焙烧条件的确定

影响焙烧效果的主要因素是焙烧温度、焙烧时间和钙剂添加量。

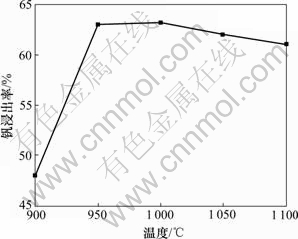

焙烧温度对焙烧效果和钒的浸出效果有很大影响。如图1所示,恒定焙烧时间为3 h,碳酸钙添加量(相对于石煤质量)为10%,当焙烧温度从900 ℃提高到950 ℃时,焙烧料的钒浸出率逐渐提高,在焙烧温度为950~1 000 ℃时,钒的浸出率达到最大值63%;继续提高焙烧温度,浸出率开始下降。实验结果说明,在950~1 000 ℃焙烧时有利于矿石结构改变、生成易被酸浸出的钒酸钙;但若温度继续升高,则导致形成低熔点硅酸钙类化合物,使钒不易被硫酸浸出[15-16]。

图1 温度对钒浸出率的影响

Fig.1 Effect of roasting temperature on vanadium leaching

焙烧时间对钒浸出效率的影响如图2所示。当焙烧温度为950 ℃,碳酸钙添加量(质量分数,下同)为10%,焙烧3 h时,钒浸出率达63%;继续延长焙烧时间,浸出率仅提高1%~2%。从能源等方面综合考虑,焙烧时间宜选择3 h。

图2 焙烧时间对钒浸出率的影响

Fig.2 Effect of roasting time on vanadium leaching

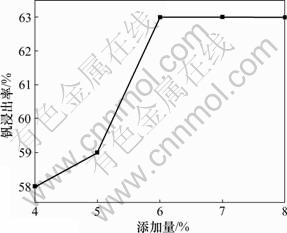

图3所示为碳酸钙添加量与钒浸出效率之间的关系。实验焙烧温度和时间分别为950 ℃和3 h。结果表明,钒的浸出率随碳酸钙的加入量增大而提高,当碳酸钙添加量为6%时,钒浸出率为63%,继续增加碳酸钙的添加量,钒的浸出率保持不变。

以上实验表明,合适的焙烧条件为:焙烧温度为950 ℃,焙烧时间为3 h,碳酸钙添加量为6%。

图3 CaCO3对钒浸出率的影响

Fig.3 Effect of CaCO3 addition on vanadium leaching

2.2 强化氧化对钒浸出效果的影响

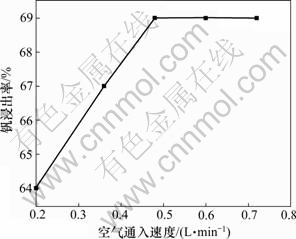

在固定碳酸钙加入量(质量分数)、焙烧温度和焙烧时间分别为6%,950 ℃和3 h时,研究强化氧化对钒浸出效果的影响。图4所示为焙烧料的钒浸出率随空气通入速度的变化情况。当空气通入速度小于0.48 L/min时,钒浸出率随空气通入速度增大而提高;空气通入速度大于0.48 L/min后,继续提高空气通入速度对提高浸出率作用不明显。空气通入速度为0.48 L/min时,钒浸出率可达69%。

图4 通气速率对钒浸出率的影响

Fig.4 Effect of air flow velocity on vanadium leaching

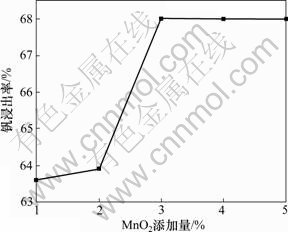

图5所示为MnO2加入量对焙烧料钒浸出效果的影响。从图5可以看出:随着MnO2的加入,焙烧料的浸出率提高,MnO2添加量达到3%时,浸出率达到68%;若增加MnO2添加量,则浸出率不再增加。MnO2强化提钒效果的原因,可能是由于随着温度升高,MnO2释放氧气,增加氧化气氛,强化了低价钒的氧化[17]。

图5 MnO2添加量对钒浸出率的影响

Fig.5 Effect of MnO2 addition on vanadium leaching

焙烧料中五价钒的含量分析结果表明:加强氧化后,更多的低价钒氧化为高价钒,通空气可以使焙料中五价钒的含量由83.33%提高到91.67%,添加MnO2可以使焙料中五价钒的含量由83.33%提高到91.80%,加强氧化后更多的五价钒可以转化为钒酸钙,从而提高焙料中钒的浸出率。

石煤中的含钒矿物分为3相,即氧化铁相、云母相和难熔硅酸盐相。氧化铁相比较容易被破坏,其中的钒可以被质量浓度为30%的盐酸于90 ℃,45 min内浸出;云母相不能被盐酸有效破坏,只有在质量浓度为20%以上的氢氟酸中才能完全溶解它;难熔硅酸盐更难被溶解,只有熔融的过氧化钠可将其完全分 解[14]。钙化焙烧可以破坏石煤中的一部分云母相,使得该相中的钒被盐酸浸出,因此,可通过盐酸浸出焙料所得的浸出率,间接反映钙化焙烧对石煤物相的破坏作用。本实验采用盐酸浸出的方法来研究不同条件下钙化焙烧对石煤物相的破坏作用,焙料的浸出条件是:盐酸的质量浓度为30%,浸出温度为90 ℃,浸出时间为45 min。3种钙化焙烧条件为:非强化氧化、强化氧化,通入空气速率为0.48 L/min和添加质量分数为3%的MnO2。所得焙料在上述条件下钒的浸出率分别为67.82%,72.95%和73.05%。

从上面的分析可知,通空气和添加MnO2均可以强化低价钒的氧化,加强矿石结构的破坏,从而提高焙料的钒浸出率。MnO2的加入会使焙料中钒的浓度略微降低,随后的钒浸出率也相应低于通空气焙烧料。

3 结论

(1) 焙烧料的钒浸出率随温度的升高先增高后降低,在950~1 000 ℃时达到最大浸出率。焙烧时间的延长有利于得到高的浸出率,但焙烧时间超过3 h后的浸出率提高效果不明显。适度增加碳酸钙可以得到更好的浸出率,当碳酸钙添加量超过6%后浸出率不再提高。

(2) 通空气和添加MnO2可以提高焙料中钒的浸出率,当空气通入速度为0.48 L/h时,钒的浸出率可以提高6%;添加质量分数为3%的MnO2时,浸出率可提高5%。

(3) 通空气和添加MnO2均可以强化低价钒的氧化,加强矿石结构的破坏,从而提高焙料的钒浸出率。

参考文献:

[1] Carreon M A, Guliants V V. Phase transformations in mesostructured vanadium-phosphorus-oxides[J]. Catalysis Today, 2003, 78(1/4): 303-310.

[2] Monakhov I N, Khromov S V, Chernousov P I, et al. The flow of vanadium-bearing materials in industry[J]. Metallurgist, 2004, 48(7/8): 381-385.

[3] LAN Yao-zhong, LIU Jin. Review of vanadium processing in China[J]. Engineer Sciences, 2005, 3(3): 58-62.

[4] HE Dong-sheng, FENG Qi-ming, ZHANG Guo-fan, et al. An environmentally-friendly technology of vanadium extraction from stone coal[J]. Minerals Engineering, 2007, 20(12): 1184-1186.

[5] Moskalyk R R, Alfantazi A M. Processing of vanadium: a review[J]. Minerals Engineering, 2003, 16(9): 793.

[6] ZHOU Xiang-yang, LI Chang-lin, LI Jie, et al. Leaching of vanadium from carbonaceous shale[J]. Hydrometallurgy, 2009, 99(1/2): 97-99

[7] LI Hao-ran, FENG Ya-li, LIANG Jing-long, et al. Vanadium recovery from clay vanadium mineral using an acid leaching method[J]. Rear Metals, 2008, 27(2): 116-120.

[8] ZENG Li, LI Qing-gang, XIAO Lian-sheng. Extraction of vanadium from the leach solution of stone coal using ion exchange resin[J]. Hydrometallurgy, 2009, 97(3/4): 194-197.

[9] LI Min-ting, WEI Chang, FAN Gang, et al. Extraction of vanadium from black shale using pressure acid leaching[J]. Hydrometallurgy, 2009, 98(3/4): 308-313.

[10] 冯其明, 何东升, 张国范, 等. 石煤提钒过程中钒氧化和转化对钒浸出的影响[J]. 中国有色金属学报, 2007, 17(8): 1348-1352.

FENG Qi-ming, HE Dong-sheng, ZHANG Guo-fan, et al. Effect of vanadium oxidation and conversion on vanadium leaching in extraction process of vanadium from stone coal[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1348-1352.

[11] 陈铁军, 邱冠周, 朱德庆. 石煤提钒焙烧过程钒的价态变化及氧化动力学[J]. 矿冶工程, 2008, 28(3): 64-67.

CHEN Tie-jun, QIU Guan-zhou, ZHU De-qing. Valence variation and oxidation kinetics of vanadium during vanadium- bearing stone coal roasting[J]. Mining and Metallurgical Engineering, 2008, 28(3): 64-67.

[12] 黄可龙, 刘素琴, 仲晓玲, 等. 一种从石煤钒矿中提钒的焙烧工艺: CN 101215647[P]. 2008-07-09.

HUANG Ke-long, LIU Su-qin, ZHONG Xiao-ling, et al. A process of extracting vanadium from stone coal: CN 101215647[P]. 2008-07-09.

[13] 李中军. 五氧化二钒与氧氯化锆的湿法提取研究[D]. 郑州: 郑州大学, 2006: 4-11.

LI Zhong-jun. Wet metallurgical extraction of vanadium pentoxide and zirconium oxychloride[D]. Zhengzhou: Zhengzhou University, 2006: 4-11.

[14] 李连仲. 岩石矿物分析[M]. 北京: 地质出版社, 1991: 611.

LI Lian-zhong. Analysis of rock and ore[M]. Beijing: Geology press, 1991: 611.

[15] 马胜芳, 张光旭. 钙化焙烧粘土钒矿提钒过程的研究Ⅰ焙烧工艺的研究[J]. 稀有金属, 2007, 31(6): 813-817.

MA Sheng-fang, ZHANG Guang-xu. Leaching process of vanadium from argillaceous vanadium ore using calcified roasting study on roasting technology[J]. Chinese Journal of Rare Metals, 2007, 31(6): 813-817.

[16] 李静, 李朝建, 吴雪文, 等. 提钒焙烧工艺及机理探讨[J]. 湖南有色金属, 2007, 23(6): 7-11.

LI Jing, LI Zhao-jian, WU Xue-wen, et al. Technology of roasting process on extraction of vanadium from stone coal and mechanism discussion[J]. Hunan Nonferrous Metal, 2007, 23(6): 7-11.

[17] 谭柱中, 梅光贵, 李维健, 等. 锰冶金学[M]. 长沙: 中南大学出版社, 2004: 20-21.

TAN Zhu-zhong, MEI Guang-gui, LI Wei-jian, et al. Metallurgy of manganese[M]. Changsha: Central South University Press, 2004: 20-21.

(编辑 张曾荣)

收稿日期:2009-10-24;修回日期:2010-03-01

基金项目:国家自然科学基金资助项目(50974136);中南大学大学生创新性实验项目(LD09155);湖南省研究生科研创新项目(CX2009B037)

通信作者:周向阳(1969-),男,湖南长沙人,博士,教授,从事冶金工艺及功能材料研究;电话:0731-88836329;E-mail: zxy13908482918@163.com