HRXRD analysis for YBa2Cu3O7-x deposited on {001} LaAlO3

ZHANG Hua, YANG Jian, WANG Shu-ming, LIU Hui-zhou

General Research Institute for Nonferrous Metals, Beijing 100088, China

Received 22 December 2010; accepted 31 May 2011

Abstract: YBa2Cu3O7-x (YBCO) superconducting film was fabricated on {001} LaAlO3 (LAO) substrate by pulse laser deposition (PLD), and its microstructure was examined by high resolution X-ray diffraction technology (HRXRD), such as pole figure, rocking curve, reciprocal space mapping. The results show that the YBCO crystalline alignment is almost {001}YBCO//{001}LAO, á100?YBCO//á100?LAO besides 2% {001}YBCO//{001}LAO, á110?YBCO//á100?LAO. The out-plane alignment of YBCO is some spreading (the breadth is 0.75°). There are 90°±0.65°á110? twin domains in the film, which is caused by the high local stress and stress difference between á100? and á010? during the tetragonal to orthorhombic phase transition.

Key words: YBa2Cu3O7-x; crystalline alignment; twin domain; phase transition; superconducting film

1 Introduction

MBa2Cu3O7-x (where M is yttrium or a rare earth element) film has a good prospect to produce microwave passive components due to its very low loss in microwave field [1-3]. However, the critical current density in a—b plane is greatly influenced by the weak link [4-5], and the critical temperature is very sensitive to crystalline lattice modifications induced by compositional changes or strain [6]. The film’s superconducting ability is, therefore, affected by its microstructure, such as crystalline alignment, large angle grain boundary, domain structure, micro crack, crystalline structure [7]. Thus, we should analyze the microstructure carefully.

As the pulsed laser deposition (PLD) offers numerous advantages: including film stoichiometry close to the target, low contamination level, high deposition rate and non-equilibrium processing, it is one of the most convenient methods to obtain YBa2Cu3O7-x (YBCO) thin film [8-9]. In the present study, the YBCO superconducting film (450 nm in thickness) is grown on {001} LaAlO3 (LAO) by PLD. The crystalline microstructure and alignment about both substrate and film are analyzed by high resolution X-ray diffraction (HRXRD) technology systematically.

2 Experimental

YBCO film was deposited on {001} LAO substrate (5 mm×10 mm) by PLD. The laser (wavelength 248 nm, repetition rate 10 Hz, energy density 2.5 J/cm2) was used to ablate materials from rotating stoichiometric target. Substrate was attached with silver paste to the stainless steel (SS) tape, which was placed opposite to the target with a distance of 60 mm in a vacuum chamber. When the base pressure of the chamber achieved 3×10-4 Pa, the YBCO was deposited at the referential deposition temperature of 780 °C with the oxygen pressure of 25 Pa. After deposition, the oxygen pressure in the cavity was increased to 8×104 Pa and the temperature was reduced to 480 °C and kept for 30 min. Finally, the film was cooled naturally.

The microstructure was analyzed by HRXRD technology, such as pole figure, rocking curve and reciprocal space map (RSM). The measurements were carried out in a Panalytical X’ Pert MRD diffractometer equipped with four-circle goniometer and monochromator, using Cu Kα radiation (40 kV, 40 mA).

3 Results and discussion

3.1 Orientation relationship

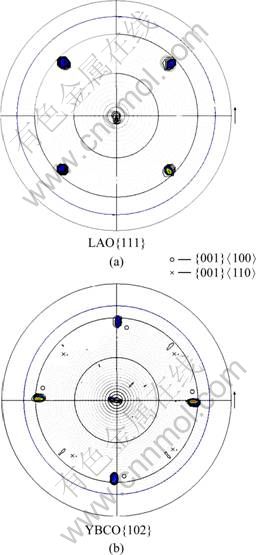

The LAO {111} and YBCO {102} pole figures were measured to reveal the crystalline orientation relationship between LAO and YBCO generally, and the results are shown in Fig. 1. LAO {111} pole plots are at ψ=54.7°, φ=45°, 135°, 225°, 315° (ψ: the azimuth angle of the pole plot; φ: the rotation angle of the pole plot), and YBCO {102} pole plots are at the ψ=54.7°, φ=0°, 45°, 90°, 135°, 180°, 225°, 270°, 315° respectively. It can be deduced that the orientation relationships are {001}YBCO//{001}LAO, á100?YBCO//á100?LAO and {001}YBCO//{001}LAO, á110?YBCO// á100?LAO. The first orientation relationship is absolute majority due to the lowest lattice mismatch, and the second is just 2% calculated from the integrated area and pole intensity.

3.2 Out-plane alignment

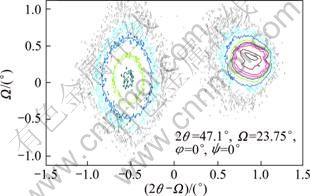

The RSM around YBCO {006}/LAO {002} was measured to study the out-plane alignment deeply, and the result is shown in Fig. 2. The YBCO {006} plot spreads along the Ω axis obviously (the breadth is almost 0.75°), which means the out-plane alignment of the YBCO film is some spreading. As the plot does not spread along the 2θ-Ω axis, we can deduce that there is no micro strain in the film. The LAO {002} plot is splitting along the Ω axis, which means that there are domains with different out-plane orientations in the LAO. It can be deduced that the out-plane alignment spreading of the YBCO is caused by the substrate’s domain structure.

Fig. 1 LAO {111} (a) and YBCO {102} (b) pole figures

Fig. 2 RSM around YBCO{006}/LAO{002}

The YBCO {006} peak is at (46.55°, 24.00°) (2θ, Ω), and LAO {002} is at (47.94°, 24.45°). The axial lattice constant c of YBCO film is 11.69 ? according to the 2θ value of {006} plot and the Bragg equation (2dsin θ=λ), which is close to that of YBa2Cu3O7 (11.684 ?, JCPDS: 89-6049). The miscutting angle value (the crystalline orientation deviates from the surface normal) is 0.5° for LAO, which is 0.2° for YBCO film (deduced from the Ω value of the plots). It means that the c-axes of the YBCO crystalline grains tend to the normal direction of LAO surface, although the mismatch energy of the YBCO film is the lowest when it is along LAO (001) axis. It may be affected by the growing direction of or the surface energy during deposition process.

3.3 In-plane alignment

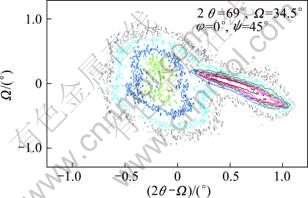

The RSM around YBCO {206} and LAO {202} was measured to learn detailed information about in-plane microstructure, which is shown in Fig. 3. The spreading of LAO {202} peak along the 2θ-Ω axis is caused by the instrumental broadening as the slit system and asymmetrical X-ray diffraction geometry were selected in the experiment. What is more, the instrumental broadening is serious especially when the sample is monocrystalline (i.e. we still chose this diffraction geometry, considering the low intensity of YBCO {206} plot). It can be deduced from the map that the YBCO á100? is closely parallel to the LAO á100?. There is no obvious in-plane alignment splitting among the domains in the LAO according to the LAO {202} plot. However, there are two splitting peaks with equal intensity and near 2θ value around YBCO {206}, and the Ω distance between them is about 0.4°. Unfortunately, it is difficult to ascertain the possible reason (such as multi-domains, multi-phases) for the splitting here due to the higher instrumental broadening and lower resolution.

Fig. 3 RSM around YBCO {206} and LAO {202}

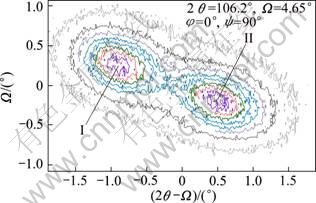

Therefore, in order to analyze the reason of YBCO {206} plot’s splitting, the RSM around YBCO {038} and {308} (crystalline plane with higher Miller index) was measured, as shown in Fig. 4. There are two peaks with the equal intensity and integrated area in Fig. 4. The positions are at (48.70°, 105.387°) (I) and (48.25°, 106.724°) (II) (Ω, 2θ) respectively. It can be deduced that I is {038} plot and II is {308} plot. It means that there are two in-plane alignment types with equal proportion and nearly 90° included angle in plane. The result is similar to what shown in Ref. [10], in which it was defined as 90° á110? twin domain.

Fig. 4 RSM around YBCO {038} and {308}

The intersection RSMs for YBCO {038} and {308} (namely, the Ω direction is vertical to the above RSM) were measured respectively and shown in Fig. 5, from which we can find that each one has two symmetrical splitting peaks: I is at (52.92°, 105.387°, 48.2°, 90°) (Ω, 2θ, φ, ψ), II is at (52.46°, 105.387°, 48.2°, 90°) , III is at (53.58°, 106.724°, 48.65°, 90°) , and IV is at (53.16°, 106.724°, 48.65°, 90°). The four peaks constitute a shape X in the reciprocal space, and the intensities of them are almost equal. The Ω distances between I and II, III and IV are about 0.46° and 0.42°, respectively.

Fig. 5 Intersection RSMs for YBCO {038} (a) and {308} (b)

3.4 Discussion

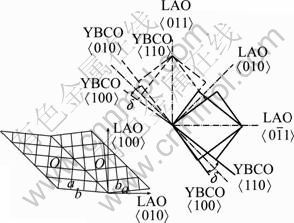

From the above discussion, the in-plane alignments of YBCO twin domains can be deduced, which is shown in Fig. 6. The twin boundary is along YBCO á110?, which is parallel to the LAO á110?. Both the YBCO á100? and á010? are along but not parallel strictly to the LAO á100?, and there is a distortion angle (δ) between them, which is ±0.65° in the present study (calculated according to the trigonometry of spherical triangles).

The twin domains have also been found in the YBCO monocrystal block [11], which was considered to be caused by the phase transition. During the film depositing at higher temperature firstly, the crystalline structure is tetragonal (T), with a=b=3.86 ?. After deposition, the film was annealed around 480 °C for 30 min, with the oxygen pressure increased to 8×10 4 Pa. In the annealing period, the oxygen in the crystal cell rises and rearranges in the basal Cu-O planes [12], which causes the changes in the unit cell symmetry (losing D4há001? symmetry operation). The tetragonal phase transits to the orthorhombic (O) (T-O phase transition), with lattice constants of a and b changing from 3.86 ? to 3.82 ? and 3.88 ? respectively [13]. Then, the strain, 1.04% extrusion along the orthorhombic á100? direction and -0.52% compressing along á010? direction, will be generated in the tetragonal grain. The local stress values can become quite large with the T-O phase transition, and it is the same as the stress difference between á100? and á010? [14]. Therefore, the 90° á110? twin domain structure has to be generated in order to release the stress in the crystalline grain or keep it equivalent along every direction. Due to the difference between lattice constants a and b, the micro distortion angle will generate between a and b axes of the twinned crystalline grains [15].

Fig. 6 In-plane alignments of 90°±δ {110} twin domains

The twin domain has two opposite influences on the superconducting ability: limiting the critical current density because of its weak link and improving the critical current due to its magnetic flux pinning effect [16-17]. Therefore, the twin domain structure should be paid more attention to analyzing and designing.

4 Conclusions

1) The orientation relationships between YBCO and LAO are: {001}YBCO//{001}LAO, á100?YBCO//á100?LAO and {001}YBCO//{001}LAO, á110?YBCO//á100?LAO, and the second one is just about 2%.

2) The out-plane alignment of YBCO is some spreading (0.75° along omega axis), which is caused by the domain structure in the LAO substrate. The c–axes of YBCO crystalline grains tend to the normal direction of LAO surface.

3) The in-plane alignment is multifold. There are 90°±0.65° á110? twin domains in the YBCO film, although the YBCO á100? or á010? is closely parallel to the LAO á100?. The twin domain structure is caused by the high local stress and stress difference between á100? and á010? during the T-O phase transition.

References

[1] ZHAO Xin-jie, LI Lin, LEI Chong, TIAN Yong-jun. High temperature superconducting thin films for microwave filters [J]. Science in China: Series A, 2002, 45: 1183-1191.

[2] BUSCHOW K H J, CAHN R W, FLEMINGS M C, IISCHNER B, KRAMER E J, MAHAJAN S, VEYSSIERE P. Encyclopedia of materials: Science and technology [M]. 2nd ed. Amsterdam: Elsevier, 2002: 1-9.

[3] SHI Li-bin, ZHENG Yan, REN Jun-yuan, LI Ming-biao, ZHANG Guo-hua. Strain effect on microwave surface resistance of YBa2Cu3O7-δ/LaAlO3 and Tl2Ba2CaCu2O8/LaAlO3 high temperature superconducting thin films [J]. Acta Physica Sinica, 2008,57(2): 1183-1189.

[4] CUI Da-fu, LI Chun-ling, MA Kun, ZHOU Yue-liang, LIU Yan-wei, CHEN Zheng-hao, MA Jian-wei, LI Lin. Raman spectroscopy of laser ablated BaTiO3/YBa2Cu3O7-x thin film bilayer structure [J]. Appl Phys Lett, 1996, 68: 750-752.

[5] VILLARD C, KOREN G, COHEN D, POLTURAK E, THRANE B, CHATEIGNIER D. ab-plane anisotropy of transport properties in unidirectionally twinned YBa2Cu3O7-δ films [J]. Phys Rev Lett, 1996, 28: 3913-3916.

[6] SALLUZZO M, ARUTA C, AUSANIO G, AGOSTINOA D. Effect of strain on the structure and critical temperature in superconducting Nd-dpoed YBa2Cu3O7-δ [J]. Physical Review B, 2002, 66: 184518-1-184518-6.

[7] ZHENG Li-zhen, SUN Ji-jun, ZHAO Bai-ru, XU Bo, LI Jin-wei, YIN Bo, ZHU Chuan-feng, BAI Chun-li. Microstructure and superconductivity of ultrathin YBa2Cu3O7-δ films [J]. Chinese Physics Letters, 1995, 12: 625-628.

[8] SINGH R K, KUMAR D. Pulsed laser deposition and characterization of high-Tc YBa2Cu3O7-x superconducting thin films [J]. Materials Science and Engineering R, 1998, 22: 113-185.

[9] ZHANG Hua, YANG Jian, LIU Hui-zhou, FENG Xiao-liang, WANG Shu-ming. Study of YBCO superconducting layer using pulse laser deposition for coated conductor [J]. Journal of Functional Materials, 2010, 41(3): 428-431. (in Chinese)

[10] FEWSTER P F. X-ray diffraction form low-dimensional structures [J]. Semiconductor Science and Technology, 1993, 8: 1915-1934.

[11] SARIKAYA M, STERN E A. Local structural variations in YBa2Cu3O7-x [J]. Phys Rev B, 1988, 37: 9373-9381.

[12] KHACHATURYAN A G, MORRIS J W. Ordering and decomposition in the high-temperature superconducting compound YBa2Cu3Ox [J]. Phys Rev Lett, 1987, 59: 2776-2779.

[13] BROTZ J, FUESS H, HAAGE T, ZEGENHAGEN J. Controlled modification of interfacial strain and twinning in YBa2Cu3O7-δ films on vicinal SrTiO3 (001) [J]. Phys Rev B, 1998, 57: 3679-3682.

[14] CALDWELL W A, TAMURA N, CELESTRE R S, MACDOWELL A A, PADMORE H A, GEBALLE T H, KOSTER G, BATTERMAN B W, PATEL J R. Shear at twin domain boundaries in YBa2Cu3O7-x [J]. Phys Rev Lett, 2004, 92: 216105-216109.

[15] SANDIUMENGE F, SANTISO J, FIGUERAS A. X-ray study of the three-dimensional orientation of mixed a/c-oriented YBa2Cu3Qx films on (100)-SrTiO3 substrates by metalorganic chemical vapor deposition [J]. J Appl Phys, 1994, 76: 2951-2953.

[16] CHAN S W. Nature of grain boundaries as related to critical currents in superconducting YBa2Cu3O7 [J]. J Phys Chem Sol, 1994, 55: 1415-1432.

[17] CHOPRA M, CHAN S W, MENG R L, CHU C W. Y2BaCuO5 addition and its effects on critical currents in large grains of YBa2Cu3O7-δ: A quantitative microstructural study [J]. J Mater Res, 1996, 11: 1616-1626.

{001} LaAlO3衬底上沉积

YBa2Cu3O7-x薄膜的HRXRD研究

张 华, 杨 坚, 王书明, 刘慧舟

北京有色金属研究总院,北京100088

摘 要:采用脉冲激光沉积技术(PLD)在{001} LaAlO3(LAO)衬底上生长YBa2Cu3O7-x(YBCO)薄膜,并通过极图、摇摆曲线以及倒易空间图谱等高分辨X射线衍射技术(HRXRD)对其微结构进行表征。结果表明,YBCO薄膜的晶粒取向主要为{001}YBCO//{001}LAO, á100?YBCO//á100?LAO,但还有2%的{001}YBCO//{001}LAO, á110?YBCO// á100?LAO 取向。摇摆曲线结果表明,YBCO的面外取向有一定的漫散(宽度为0.75°);薄膜面内存在90°±0.65° á110? 孪晶畴结构,主要是由四方到正交的相变过程中较大的局部应力以及á100?和á010?方向应力差异引起的。

关键词:YBa2Cu3O7-x;晶粒取向;孪晶畴;相变;超导薄膜

(Edited by YANG Hua)

Foundation item: Project (50972019) supported by the National Natural Science Foundation of China; Project (2011CBA00105) supported by the National Basic Research Program of China

Corresponding author: YANG Jian; Tel: +86-10-82241256; Fax: +86-10-62376971; E-mail: yangjian@grinm.com

DOI: 10.1016/S1003-6326(11)61102-3