J. Cent. South Univ. Technol. (2008) 15(s1): 369-373

DOI: 10.1007/s11771-008-382-3

Laboratory research on rheological behavior and characterization of ultraviolet aged asphalt

WU Shao-peng(吴少鹏), ZHU Guo-jun (朱国军), CHEN Zheng (陈 筝), LIU Zhi-fei (刘至飞)

(Key Laboratory of Silicate Materials Science and Engineering of Ministry of Education, Wuhan University of Technology, Wuhan 430070, China)

Abstract: The influence of aging on the evolution of structural, morphological and rheological properties of neat asphalt was investigated by Fourier transform infrared (FTIR), atomic force microscopy (AFM) and dynamic shear rheometer (DSR), respectively. Asphalt was suffered under 20 W/m2 of UV radiant intensity and under the condition of aging time(0, 48, 96 and 144 h)with film thickness of 100 μm and film thickness of 50, 100, 200 and 500 μm after aging for 120 h, respectively, at certain UV radiant intensity 20 W/m2. Rheological results tested by DSR exhibit higher the complex shear (stiffness) modulus (G*) and lower phase angle (δ), compared to the virgin at the same test condition. The compositions analysis of asphalt before and after aging show an increase of carbonyl and sulfoxides, while a decrease of aromatic functional groups. With the increase of the component of asphaltene, obvious agglomerates of asphalten appear in neat asphalt surfaces after aging.

Key words: ultraviolet (UV) aging asphalt; rheological behavior; chemical microstructure; morphology evolutions

1 Introduction

Various accelerated aging tests have been made to simulate the practical degradation[1-7]. For example, the short-term aging is addressed by the rolling thin film oven (RTFO) test, which simulates the aging of asphalt mixture during mixture production, laying and compaction, while the long-term aging is done by the pressure aging vessel (PAV) test under the condition of high pressure and temperature, to stimulate the aging of asphalt pavement in service. Such aging procedures are believed to be caused mainly by thermal degradation from its simulation condition. In real environment, the aging of the asphalt concrete in service involves a set of complex physicochemical processes and solar radiation, especially UV radiation, which can be absorbed dramatically by asphalt and resulting in the aging of asphalt as well. However, it has been ignored by traditional laboratory aging tests. Therefore, much attention has been paid to the laboratory aging tests with UV radiation. TRAXLER[4] used actinic light to simulate the photochemical aging of asphalt. After that, MONTEPARA et al found that the volatilization, oxidation and polymerization of the asphalt happened due to UV radiation aging. Later, AIREY[7] reported that the standard procedures using RTFO followed by PAV, had different aging effects compared with those obtained from the photodegradation process. The aging results obtained by the latter could not fully be reproduced by the former.

An experimental study of rheological behavior and characterization of UV aged asphalt was made by laboratory simulation. The neat asphalt was subjected to the short-term aging regime by RTFO, which was then followed by the UV radiation at different aging times and different asphalt films. An investigation was carried out to explore the effects of different times and films on structural, morphological, chemical and rheological properties of asphalt. As a desired test method that was comparable with solar exposure, UV radiation oven test was focused on and the effects of film thickness from which UV radiation can affect on the properties of asphalt were also investigated.

2 Materials and experimental

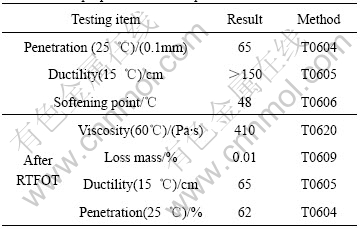

Asphalt AH70 used in this study was from Koch Asphalt Co.Ltd, China. The basic properties are listed in Table 1. The neat asphalt was utilized during the short- term aging by polling thin film oven (RTFO) for duration of 75 min at 163 ℃ and air flow of 4 L/min according to test specification ASTM D2872. The UV radiation oven accelerated aging test was applied to investigating the photodegradation behavior of asphalt specimens[8-9].

Table1 Basic properties of neat asphalt AH70

The UV radiation oven tests were performed on specimens that had already subjected to RTFO aging. The exposure intensity of the UV lamping of the radiation oven was set at a constant value of 20 W/m2 with the wavelength of 360 nm. The specimens were irradiated for 0, 48, 96 and 144 h at an integrated ultraviolet irradiation of 0, 3.46, 6.92 and 10.37 MJ/m2, which is equivalent to those of outdoor natural exposure for different time. The temperature was set at 60 ℃, which is in agreement with the surface temperature of asphalt pavement in summer.

The thickness of the asphalt film that will be subjected to UV aging would be of great importance because the induced aging depth in the asphalt layer was considered to be limited at a certain level. Therefore, the test of UV aging needs a fairly thin asphalt film if possible. Furthermore, the asphalt collected after UV aging must have a certain quantity for the following test items, i.e. AFM test, FTTR test and DSR test. Obviously, very thin film turns out to be difficult to collect and a huge area is needed to spread the required amount of asphalt in that case. With a comprehensive consideration of the above analyses, four asphalt specimens with film thicknesses of 50, 100, 200 and 500 μm were considered. It is known that the UV radiation oven test consists of both UV aging and thermal aging. To distinguish the thermal aging from this combination, a natural ventilated oven test was also considered. Such a test condition is similar to that of the UV radiation oven test just without UV radiation.

To obtain a desired thickness of asphalt film, the procedure is described as follows: approximately 5 g of asphalt sample after RTFO was diluted by carbon disulfide to form a mixture of 15 g to 25 g. The mixture was deposited onto a glass plate that was placed horizontally. After the evaporation of the organic solvent at room temperature, asphalt specimens with the thickness of 50, 100, 200 and 500 μm and time of 0, 48, 96 and 144 h were achieved by selecting the suitable sizes of the plates. The required sizes can be determined by the volume of used asphalt and the target film thickness.

AFM (DI Nanoscope TV with Nanoscope 5.12648 software, American Veeco Company) was applied to investigate the morphology of asphalt. A hot liquid drop of asphalt (130 ℃) was carefully placed on a 10 mm×10 mm×1 mm glass slide, then cooled to ambient temperature for AFM observation. Height and Z-images were scanned using an etched silicon probe. Cantilever was 125 nm long with curvature radius of 5-10 nm and height of 15-20 nm. The drive frequency was 260 kHz and the drive amplitude was 56 mW.

A thermo Nicolet Model Nexus FTIR-Raman spectrophotometer loaded with Omnic 6.2 software was used to acquire FTIR spectra by weight solutions of asphalt prepared in carbon disulfide. All samples were obtained by using KBr cell, a 0.1 mm path length sample. Spectra were recorded using the following settings: number of scans 32, gain 1, apodization weak and resolution 4. The Salt plates and windows of sealed cells were KBr. The resolution in wave number ranged from 4 000 to 400 /cm-1.

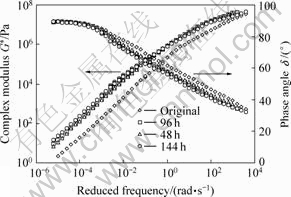

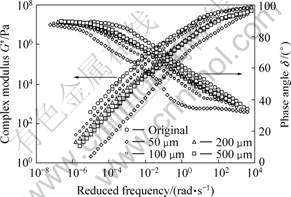

A DSR (MCR101, Anton Paar, made in German) was used to measure dynamic shear rheological properties of asphalt specimens by means of complex modulus and phase angle. Measurements were conducted at 10-80 ℃ and a frequency range from 0.1-100 rad/s. Based on the test data obtained from various temperatures and frequencies, the time-temperature superposition principle (TTSP) was used to construct master curves for complex modulus G* and phase angle δ, which would provide a fundamental analysis for aging effects on asphalt. When temperature is lower than 35 ℃, a 2 mm gap and an 8 mm diameter stainless steel plates were used; At higher temperature, a 1 mm gap and a 25 mm diameter stainless steel plates were used. All of the tests were conducted under strain-controlled mode and the applied strain was kept within the linear viscoelastic range.

3 Results and discussion

3.1 Morphology evolutions

Figs.1(a) and (b) show the AFM two images of AH70 before and after aging, Figs.1(c) and (d) show the AFM three images of AH70 before and after aging, respectively. It can be seen that bee structure appears in

Fig.1 AFM two-dimensional-images and three-dimensional images of AH70: (a) Orginal two-dimensional image of AH70; (b) Aged two-dimensional image of AH70; (c) Orginal three-dimensional image of AH70; (d) Aged three-dimensional image of AH70

both images, and the bee size becomes bigger after aging. On the contrary, bee structure is less, but continued complanate structure appears in the AFM image of AH70 before aging (Fig.1(c)). After aging, Fig.1(d) shows that a large number of bee structure increases, while many of them are larger than those in corresponding original AH70. According to Loeber’s report, the appearance of bee structure is due to the asphaltene micelles in asphalt. Obviously, the appearance of more asphalenes with large molecular mass resulted in larger bee structures.

3.2 Chemical structure analyses

Functional groups determined by FTIR can reveal the types of compounds in these samples. The spectra of the investigated asphalt UV aging obtained by FTIR are shown in Figs.2-3. The strong peaks within 1 458- 1 377 cm-1 region are typical C—H bonding vibrations in aliphatic chains. The characteristic absorption peak around 1 690-1 720 cm-1 is attributed to carbonyl compounds (C=O), and detailed check of the wavenumbers indicates that C=O comes from the ester structure (normally in the 1 710-1 695 cm-1 region). Besides this C=O absorption peak, it also shows a distinctive peak at 1 700 cm-1, which is due to the absorption of asymmetrical C=O stretching in carboxylic dimer. The weak peak at 1 600 cm-1 is assigned as C=C stretching in aliphatic chains. In 1 000-1 050 cm-1 region, this absorption peak (1 030 cm-1) is induced by the stretch absorption of sulphoxides (S=O) and commonly applied to the characterization of the evolutions of the chemical structures of aged asphalt.

It shows FTIR spectra of asphalt specimens after UV aging for different time (0 to144 h) and thickness (50 to 500 μm), in which the absorption peaks at 1 030 and

Fig.2 FT-IR spectra of asphalt specimens aging different time

Fig.3 FT-IR spectra of asphalt specimens aging different thicknesses

1 700 cm-1 are highlighted. As an indicator of degree UV aging, the peak absorbance at 1 700 cm-1 and 1 030 cm-1 changes with the aging of samples and the variation of thickness. With respect to UV radiation oven test, the peak absorbance at 1 700 cm-1 and 1 030 cm-1 decreases the sample thickness increases from 50 to 500 μm, which means the existence of more carbonyl groups and sulphoxides, thus reflecting more oxidation reaction happens in asphalt samples with relatively thin thickness. The peak of carbonyl and sulphoxides indices in Fig.3 can give more details about these changes discussed above. The obvious absorbance peak can be observed from the asphalt sample at 500 μm, while a peak appears at 100 μm and the most strongest at 50 μm. As a comparison, the different aging time of the carbonyl and sulphoxides of the samples are from 0 to 144 h, very close to the different aging thicknesses in Fig.2. At the same time its peaks also decreases with the aging time from 144 h to 0 h. The condition of 100 μm for different time is at 60 ℃, while an integrated ultraviolet irradiation is from 0 to 10.37 MJ/m2. It seems that aging at long time is similar to aging at thin thickness with UV radiation in terms of changed carbonyl groups and sulphoxides.

3.3 Rheological properties

Figs.4-5 present the muster curves of complex modulus and phase angle obtained by asphalt samples UV radiation oven test involving various asphalt aging time and film thicknesses. The reference temperature for all muster curves is 25 ℃. It can be observed that aging induced hardening has a significant effect on asphalt rheological properties. As shown in Fig.5, the complex modulus G* increases gradually and the phase angle δ reduces with the increase of frequency; further increase of the aging time makes G* increase gradually and the phase angle δ reduce at the same frequency. The change in phase angle then tends to be constant at low frequency. If original sample is selected as the reference value, in the same aging condition, UV radiation aging at 50 μm thickness is the most remarkable, followed by 100 μm thickness; the effect of the 500 μm thickness seems to be similar to that of the 200 μm thickness. It can be further confirmed that the asphalt becomes stiffer thin than thick thickness aging, especially for those samples with relatively thin film under 100 μm. From this point, increasing the thickness of the asphalt binders, even if only slightly, will improve the durability of prevention of photodegradation of in-depth asphalt.

Fig.4 Influence of different aging time on complex modulus and phase angle

Fig.5 Influence of different film thicknesses on complex modulus and phase angle

It is apparent that the film thickness of 100 μm is a critical value. When the film thickness is smaller than this value, the aging effect caused by UV radiation is much more pronounced. The reason may be that the aging depth is limited to an extent below the film surface. As a result, the actual fraction of aged asphalt in the collected specimens becomes smaller. Such a small amount of aged asphalt fraction can reflect the changes of rheological properties at a certain extent. The effect of UV radiation is dominant, particularly when the film thickness is less than 100 μm.

4 Conclusions

1) The increase of aging time and the decrease of thickness film both can result in a growth of the bee structure of asphalt during aging process.

2) Photodegradation effect decreases with the increase of the thickness of asphalt film, especially when the film thickness is less 100 μm, and the aging time has a distinct influence on the properties of aged asphalt.

References

[1] WU Shao-peng, PANG Ling, MO Lian-tong, et al. Ultraviolet and thermal aging of pure bitumen-comparison between laboratory simulation and natural exposure aging[J]. Road Materials and Pavement Design, 2008, 9: 103-113. (in Chinese)

[2] HVEEM F N, ZUBE E, SKOG J. Proposed new tests and specifications for paving grade asphalts[J]. Proc Assn Asphalt Paving Technol, 1963, 32: 247-327.

[3] AIREY G D. State of the art report on aging test methods for bituminous pavement materials[J]. The International Journal of Pavement Engineering, 2003, 4(3): 165-176.

[4] TRAXLER R N. Durability of asphalt cements[J]. Proc Assn Asphalt Paving Technol, 1963, 32: 44-58.

[5] JIME′NEZ-MATEOS J M, QUINTRO L C, RIAL C. Characterization of petroleum bitumens and their fractions by thermogravimetric analysis and differential scanning calorimetry[J]. Fuel, 1996, 75: 1691-1700.

[6] AL-SAMMERRAI F, AL-SAMMERRAI D. The use of thermogravimetry and NMR spectroscopy in the attempted identification of the source of babylonian building asphalt[J]. Thermochim Acta, 1987, 115: 181-188.

[7] AIREY G D. Rheological properties of styrene butadiene styrene polymer modified road bitumens[J]. J Fuel, 2003, 82(14): 1709-1719.

[8] JTJ 052—2000, Standard test methods of bitumen and bituminous mixtures for highway engineering[S]. (in Chinese)

[9] AASHTO TP31—94, Standard test for determining the fatigue life of compacted hot-mix asphalt (HMA) subjected to repeated flexural bending T321-03[S].

(Edited by CHEN Can-hua)

Foundation item: Project(200631800076) supported by 2006 West Science and Technology Project of the Department of Transportation

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: WU Shao-peng, Doctor; Tel: +86-027-87162595; E-mail: wusp@whut.edu.cn