文章编号: 1004-0609(2006)05-0805-06

Ti(C, N)基金属陶瓷刀具的切削性能

石增敏1, 郑 勇2, 刘文俊1, 3, 袁 泉1

(1. 三峡大学 机械与材料学院, 宜昌 443002;

2. 南京航空航天大学 材料科学与技术学院, 南京 210016;

3. 华中科技大学 塑性成形模拟及模具技术国家重点实验室, 武汉 470074)

摘 要: 利用真空烧结工艺和表面氮化处理工艺制备纳米复合Ti(C, N)基金属陶瓷可转位刀片和功能梯度可转位刀片, 并对刀片的切削性能进行分析。 结果表明: 切削正火态45#钢、 淬火态45#钢和奥氏体不锈钢时, 与YT15、 YG8、 TN20相比, 制备的刀具皆表现出较优的切削性能和较高的耐磨性, 表面经氮化处理后, 刀具的表面硬度提高了HRA2.2, 大幅度提高了刀具的抗热冲击性能。 具有梯度结构的金属陶瓷刀片切削正火钢、 铸铁和不锈钢时的切削性能比无梯度结构金属陶瓷刀片的切削性能优良, 具有更高的耐磨性。

关键词: Ti(C, N)基金属陶瓷; 功能梯度可转位刀片; 切削性能; 耐磨性 中图分类号: TG506

文献标识码: A

Cutting performance of Ti(C, N)-based cermet tools

SHI Zeng-min1, ZHENG Yong2, LIU Wen-jun1, 3, YUAN Quan1

(1. College of Mechanical and Material Engineering, China Three Gorges University,Yichang 443002, China;

2. College of Materials Science and Technology,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

3. Sate Key Laboratory of Plastic Forming Simulation and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The nano-composite Ti(C, N)-based cermet indexable tools and functionally gradient Ti(C, N)-based cermet indexable tools were prepared by vacuum sintering process and surface heat-treatment process with hot isostatic pressing (HIP) in nitrogen, respectively, and the newly fabricated cermet cutting tools were tested by continuous turning. The results show that, comparing to the cemented carbide YT15, YG8 and cermet TN20, the newly fabricated cermet tools exhibit better performance and higher wear resistance during cutting the normalized medium carbon steel, quenched medium carbon steel and austenite stainless steel. The surface hardness of the post-treated cermets increases, and the thermal shock resistance is substantially improved. The cutting property of the cermet tools with gradient structure is much better than that without gradient structure.

Key words: nano-composite Ti(C, N)-based cermet; functionally gradient indexable insert; cutting performance; wear resistance

Ti(C, N)基金属陶瓷刀具因其具有较高的硬度、 耐磨性、 红硬性以及优良的化学稳定性和极低的摩擦系数而受到国内外普遍关注[1-4], 已在日本和瑞典等国家得到了成功的应用。 为进一步提高金属陶瓷材料的性能和延长其使用寿命, 在此方面的研究和应用也日益增多。 纳米尺寸合成是提高金属陶瓷性能的有效途径, 纳米复合金属陶瓷通过添加一定量纳米粉和晶粒长大抑止剂真空烧结就可得到组织致密、 晶粒细小的烧结体, 从而使其力学性能得到大幅度提高[5-8]。 有人研究了金属陶瓷表面氮化处理技术, 预烧结成形后直接在氮气中处理来获得具有表面梯度结构的材料, 以获得比涂层材料更优的表面性能[9 -13 ]。 已有研究表明, 氮化处理后材料的表面抗塑性变形能力和耐磨性提高了[10, 11 ]。 而进行真空烧结成形的纳米复合金属陶瓷表面氮化处理时, 可在不降低材料抗弯强度的基础上, 提高材料表面的硬度, 降低材料表面与金属间的摩擦系数[5, 6]。 本文作者利用真空烧结工艺和表面氮化处理工艺制备了高韧性的纳米复合Ti(C, N)基金属陶瓷刀片和功能梯度金属陶瓷刀片, 并与通用刀具进行了对比切削实验, 对刀具的切削性能进行了分析。 这对于利用纳米复合和氮化处理技术进一步提高金属陶瓷性能及其推广应用具有重要的理论和参考价值。

1 实验

自制刀片的成分配比33%TiC-10%TiN-32%Ni-16%Mo-6.9%WC-1.5%C-0.6%Cr3C2(质量分数), TiC粉和TiN粉由纳米粉和微米粉复合而成, 纳米粉与微米粉的质量比为2∶8, 利用同种成分同时制备纳米复合金属陶瓷刀片和功能梯度金属陶瓷刀片。 混合粉经球磨36h后烘干, 掺入成形剂, 冷压成形, 压制力为270MPa, 试样成形后进行真空烧结和表面氮化处理。 真空烧结设备为ZT-60-20型真空烧结炉, 烧结温度为1420℃, 保温时间60min; 氮化处理在美国ABB公司生产的QIH-6型热等静压炉进行, 烧结温度为1150℃, 采用N2-Ar混合气体为流体介质, 介质压力为100MPa, 保温保压时间为1h。 用JSM-5600LV型扫描电镜观察自制刀片的组织形貌。

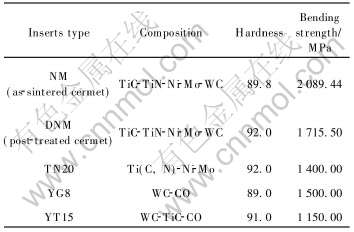

切削实验在CA6140普通车床上进行, 刀片型号为SNUN150416, 安装角度为θr=75°, γ0=0°, α0=5°, λs=-3°。 采用干车削方式。 测量过渡后刀面即刀尖的磨损值VC来衡量刀具的耐磨性, 磨钝标准取VCmax=0.8mm。 自制刀片氮化处理前后力学性能的变化及对比刀片的成分及性能指标如表1所列。

表1 实验用刀片成分及其性能指标

Table 1 Component and mechanical properties of used inserts

实验用被切削材料的状况: 正火态45#钢棒料, 硬度为HRC21; 淬火态45#钢棒料, 硬度为HRC52~53; 灰铸铁HT200棒料, 硬度为HB225~240; 奥氏体不锈钢1Cr18Ni9Ti棒料, 硬度为HB187。

2 结果及分析

2.1 组织结构

真空烧结和烧结后再经氮化处理试样的SEM像如图1所示。 由图1(a)可知, 真空烧结后的纳米复合金属陶瓷由典型的芯-壳结构和金属粘结相组成, 黑芯-白壳结构是黑色芯部周围围绕着灰色环形相, 黑色芯部是Ti(C, N)固溶体, 环形相为富W和Mo的(Ti, W, Mo)(C, N)固溶体, 部分环形相具有内环形相和外环形相。 细小的白芯-灰壳结构, 白芯为在固相烧结阶段形成的(W, Mo, Ti)(C, N)固溶体, 灰壳是在液相阶段形成的重元素Mo、 W含量较低的(W, Mo, Ti)(C, N) [5-7, 14, 15]。

由图1(b)可看出, 氮化处理后, 金属陶瓷表面区的显微组织发生了明显变化, 在距表面区域约20μm的区域中, 晶粒明显细化, 小颗粒硬质相所占的体积分数增加, 内环形相基本消失, 在距表面3~10μm的范围内, 几何形状与粘结相相近的白色富W、 Mo相明显增多。 研究[9, 13]表明: 在N2气氛条件下, 金属陶瓷表面区N的活度比基体内部N的高, 促进了基体内部合金元素的扩散, 在表面区域内形成梯度分布, 富W、 Mo环型相不断溶解, W、 Mo原子向材料内部扩散, Ti原子向材料表面扩散。 由于扩散在材料表面形成了富Ti和N的硬化层, 紧贴硬化层形成了一层Ni含量相对较高的过渡层。 且由于大颗粒的溶解, 使得晶粒细化, 提高了材料表面的硬度。 基体内硬质相颗粒由于氮化温度较低而未出现长大和过度溶解现象, 因而材料的抗弯强度只是略有降低。

图1 金属陶瓷刀片材料的表面显微组织SEM像

Fig.1 SEM images of surface zones of newly fabricated metal cermets

2.2 抗热冲击性

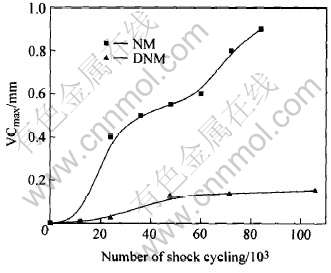

本研究以正火态45#钢棒料为被切削材料, 轴向铣3个均匀分布的槽(10mm×10mm), 切削参数为vC=219.8m/min, f=0.1mm/r, ap=0.5mm, 采用外圆断续车削的方式, 通过检验相同冲击次数下刀具的磨损量来对比检验刀具的抗冲击性。 自制刀片在不同冲击次数下的磨损曲线如图2所示。

图2 金属陶瓷刀具的冲击切削实验曲线

Fig.2 Interrupted cutting curves of newly fabricated metal cermets

由图2可看出, 在相同的冲击次数条件下, 经过氮化处理后刀片(DNM)的刀尖磨损量较未经氮化处理刀片(NM)的刀尖磨损量低7倍左右, 可见表面氮化处理可极大提高刀具的抗热冲击性能。

2.3 耐磨性

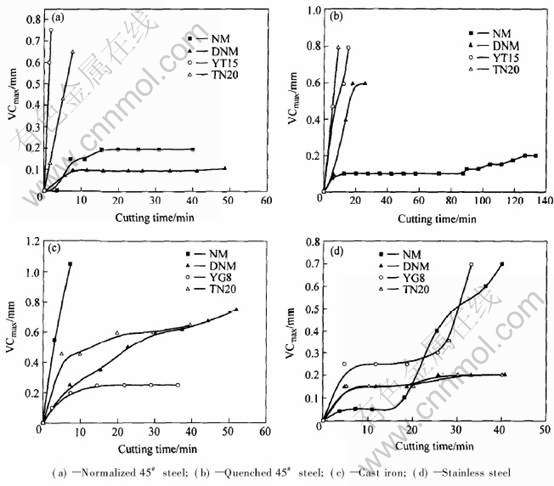

图3(a)所示为自制刀片与YT15、 TN20切削正火态45#钢的磨损过程对比曲线。 切削参量为vC=323m/min, f=0.5mm/r, ap=0.5mm。 图3(b)所示为自制刀片与YT15、 TN20切削淬火态45#钢的磨损过程对比曲线, 切削参量为vC=47.2m/min, f=0.1mm/r, ap=0.5mm。 图3(c)所示为自制刀片与YG8、 TN20切削铸铁的磨损过程对比曲线。 切削参量为vC=80m/min, f=0.3mm/r, ap=0.5mm。 图3(d)所示为自制刀片与YG8、 TN20切削奥氏体不锈钢的磨损过程对比曲线。 切削用量为vC=62.8m/min, f=0.5mm/r, ap=0.5mm。

图3 硬质合金刀片的切削性能对比

Fig.3 Comparison of cutting performance of different cemented carbides

由图3(a)可以看出, YT15、 TN20皆在很短的时间内达到了磨钝标准, 相比之下, 自制刀片表现出较好的耐磨性。 在同样的切削时间内, 自制刀片经氮化处理后刀尖的耐磨性提高了2倍。

由图3(b)可以看出, 切削淬火钢时自制刀片NM表现出非常优异的切削性能, 在切削时间为133min时, 刀尖的最大磨损量VCmax=0.2mm; 氮化处理后, 刀片的耐磨性下降, 且以崩刃形式失效。 而刀片的耐用度都比较短, YT15的耐用度为14min, TN20的耐用度为8min。

由图3(c)可以看出, 在选用的切削量下切削铸铁时, 自制刀片NM、 DNM及TN20的耐磨性低于YG8刀片的。 DNM刀片与NM刀片相比, 刀具的耐用度提高了约10倍, 30min后, 刀片的耐磨性与TN20相似。

由图3(d)可以看出, 切削不锈钢的初始16min内, NM表现出较好的耐磨性和使用性能, NM刀片的磨损量为DNM、 TN20磨损量的1/3, 为YG8磨损量的1/5; 随切削时间的延长, NM刀片的磨损加剧, 但NM刀片的使用寿命是YG8的1.3倍。 DNM刀片在切削不锈钢时的磨损性能同TN20的相似。

3 讨论

高温时金属陶瓷刀具表面的塑性变形主要是由于粘结相Ni的扩散活跃, 易产生动态恢复, 而低碳硬质相抑止了这种动态恢复使得材料得以强化, 同时固溶在粘结相中的氮也能抑止这种动态恢复[16]。 因此表面氮化处理可显著抑止刀具表面的高温变形, 大大提高刀具表面的高温强度, 提高了刀具的表面抗塑性变形力[10, 11]。 且表面硬度的提高降低了刀具后刀面与被切削材料间的摩擦系数, 因此断续切削时可降低切削力和切削温度, 使得刀具表面承受的拉、 压热应力降低, 提高了刀具表层的抗疲劳能力, 因此刀具的抗热冲击性能得到大幅度提高。

切削正火态45#钢, 氮化处理后DNM刀片的耐磨性要明显优于未氮化处理NM刀片的, 刀尖的耐磨性提高了2倍, 可知经过氮化处理可较大程度地提高刀尖的耐磨性。 YT15和TN20刀片在切削正火态45#钢的过程中, 都有火花飞溅现象, 且TN20刀片的积屑瘤现象严重, 积屑瘤几乎将整个刀尖覆盖, 工件表面的光洁度较差, 可见YT15和TN20刀片的切削过程中具有较高的切削温度。 这说明自制刀片在同样切削条件下, 与正火态45#钢具有更低的摩擦系数, 切削力和切削温度要远小于YT15和TN20的。 可见自制刀片高速大切削量连续切削正火态45#钢时, 具有较优异的切削性能。

切削淬火钢时, NM刀片的优势更加突出。 在选定的切削用量下, TN20和YT15都是在极短的时间内失效, 从淬火钢的对比切削过程也可得出此结论。 TN20和YT15切削淬火钢时的切削阻力很大, 导致刀片的耐用度较低; 纳米复合金属陶瓷NM刀片的切削阻力相对较小, 且刀片的韧性较大, 因此在切削淬火钢时表现出较优异的耐磨性, 刀片的耐用度也较大。

切削淬火钢时, 氮化处理刀片DNM的耐磨性远低于NM刀片的, 刀片的失效形式为崩刃, 从而导致刀尖急剧磨损, 但与TN20和YT15相比, 要略好一些。 氮化处理后刀片表面层的Ni含量减少, 使得DNM刀片的表层韧性下降、 脆性增加。 同时, 在氮化处理过程中, 表面层合金元素含量的变化可能导致硬质相和粘结相间的界面应力发生变化, 且N由刀具表层向基体内部的扩散, 表面粘结相的减少致使在硬质相和粘结相的界面产生微裂纹, 使得硬质相和粘结相的界面结合力下降。 在加工淬火钢时, 刀片和工件间的切削阻力和切削温度远高于切削其他材料时的切削阻力和切削温度, 切屑的形成和流走对刀尖产生了非常大的剪切作用, 硬质相和粘结相的界面微裂纹在剪切力的作用下扩展, 在刀具表面形成较大的裂纹, 从而导致了刀具的崩刃失效。

灰铸铁的组织特点是金属基体加游离的石墨, 切削铸铁时, 刀具的切削变得不连续, 在石墨处可认为刀具处于空程状态, 在金属基体处, 刀具才发生切削, 刀具的实际切削过程为断续切削过程, 对刀刃产生了较大的热冲击。 且切削时, 切屑的断裂是从石墨处开始的不规则断裂连续深入到已加工的表面以下, 切削金属层频繁的无规则断裂对刀具亦会产生冲击。 表面氮化处理较大程度地提高了刀具表面的抗热冲击性能, 因此DNM刀片在切削铸铁时的耐磨性要优于NM刀片的。 切削30min后, DNM刀片的磨损性能同TN20的相似, 这可能是由于刀尖表面氮化层被磨损掉。 但与YG8相比, 氮化处理刀片DNM切削铸铁时的切削性能仍然较差。 可见自制刀片不适合于大切削用量下铸铁的切削。

奥氏体不锈钢的晶体结构为fcc结构, 与金属陶瓷的晶体结构相同, 且合金元素与刀具材料相似, 切削高温使得切屑底层的合金元素扩散活跃, 因此在切削高温作用下, 刀屑界面的亲和力很大, 刀屑界面的元素固溶现象较其他材料的严重。 表面氮化处理后, 由于刀具表面氮化层的Ni含量降低, 且刀具表面层低碳硬质相对粘结相Ni的动态恢复且有较大的抑止作用, 降低了刀屑界面元素的固溶, 因此在切削奥氏体不锈钢时, DNM刀片表现出较优异的耐磨性。 切削不锈钢时, DNM刀片的耐磨性与TN20刀片的相似, DNM的表面硬度与TN20刀片的相同, 硬度的提高使得刀片的耐磨性提高。

4 结论

1) 表面氮化处理可大幅度提高刀具的抗热冲击性能, 切削正火态45#钢、 灰铸铁和奥氏体不锈钢时, 在选用切削用量的范围内, 表面氮化处理可提高刀片的耐磨性。

2) 高速连续切削正火态45#钢、 淬火态45#钢和奥氏体不锈钢时, 自制刀具与通用刀具相比具有优异的切削性能和较高的适配性和耐磨性。

3) 切削铸铁时, 表面氮化处理后刀具的耐磨性有较大程度的提高, 其耐磨性略优于TN20的。 但与YG8刀具相比, 自制刀具的切削性能较差。

REFERENCES

[1]Ettmayer P, Kolaska H, Lengauer W, et al. Ti(C, N) cermets-metallurgy and properties[J]. Refractory Metals & Hard Materials, 1995,13(6): 343-351.

[2]Viatte T, Bolognini S, Gutard T, et al. Investigation into the potential of a composite combining toughness and plastic deformation resistance[J]. Refractory Metals & Hard Materials, 1999, 17(1-3): 79-89.

[3]DErrice G E, Bugliosi S, Cuppini D, et al. A study of cermets wear behaviour[J]. Wear, 1997, 203-204: 242-246.

[4]Bolognini S, Feusier G. High temperature mechanical behaviour of Ti(C, N)-Mo-Co cermets[J]. Refractory Metals & Hard Materials, 1998, 16(4-6): 257-268.

[5]郑勇. 细晶粒Ti(C, N)基金属陶瓷复合材料的研究[D]. 武汉: 华中科技大学, 2002.

ZHENG Yong. Research on a Composite of Fine Grained Ti(C, N)-based Cermet[D]. Wuhan: Huazhong University of Science and Technology, 2002.

[6]刘文俊. 热等静压(HIP)在细晶粒金属陶瓷制备中的应用[D]. 武汉: 华中科技大学, 2003.

LIU Wen-jun. The Application of Hot Isostatic Processing on a Composite of Fine Grained Ti(C, N)-based Cermets[D]. Wuhan: Huazhong University of Science and Technology, 2003.

[7]ZHENG Yong, XIONG Wei-hao, LIU wen-jun, et al. Effect of nano addition on the microstructures and mechanical properties of Ti(C, N)-based cermets[J]. Ceramics International, 2005, 31(1): 165-170.

[8]刘文俊, 郑勇, 游敏. 烧结温度对细晶粒Ti(C, N)基陶瓷组织和性能的影响[J]. 三峡大学学报, 2003, 25(2): 114-117.

LIU Wen-jun, ZHENG Yong, YOU Min. Influence of sintering temperature on microstructure and property of Ti(C, N)-based cermets[J]. Journal of China Three Gorges University, 2003, 25(2): 114-117.

[9]Zackrisson J, Rolander U, Wein G, et al. Microstructure of the surface zone in a heat treated cermet material[J]. Int J Refr Met Hard Mater, 1998,16(4-6): 315-322.

[10]Zackrission J, Rolander U, Jansson B, et al. Microstructure and performance of a cermet material heated-treaded in nitrogen[J]. Acta Mater, 2000, 48(17): 4281-4291.

[11]Knigshofer R, Eder A, Lengauer W, et al. Growth of the graded zone and its impact on cutting perfor-mance in high-pressure nitrogen modified functionally gradient hardmetals[J]. Journal of Alloys and Compounds, 2004, 366(1-2): 228-232.

[12]郑勇, 熊惟皓, 宗校军, 等. Ti(C, N)基金属陶瓷功能梯度材料的制备[J]. 粉末冶金技术, 2002, 20(4): 195-199.

ZHENG Yong, XIONG Wei-hao, ZONG Xiao-jun, et al. Processing of functionally graded Ti(C, N)-based cermets[J]. Powder Metallurgy Technology, 2002, 20(4): 195-199.

[13]郑勇, 熊惟皓, 宗校军, 等. Ti(C, N)基金属陶瓷表面氮化处理后的表面组织结构及形成机理[J]. 硅酸盐学报, 2003, 31(3): 262-267.

ZHENG Yong, XIONG Wei-hao, ZONG Xiao-jun, et al. Surface microstructure and forming mechanism of Ti(C, N)-based cermet heat-treated in nitrogen[J]. Journal of the Chinese Ceramics Society, 2003, 31(3): 262-267.

[14]LI Chen-hui, XIONG Wei-hao, YU Li-xin. Evolution of Ti(C, N)-based cermet microstructures[J]. Trans Nonferrous Met Soc China, 2002, 12(2): 214-217.

[15]ZHENG Yong, XIONG Wei-hao, YOU Min, et al. Microstructural evolution and characteristics during sintering of submicron Ti(C, N)-based cermet[J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1424-1429.

[16]张箐. Ti(C, N)基金属陶瓷的高温力学性能[J]. 硬质合金, 1995, 12(3): 187-189.

ZHANG Qing. The mechanical behavior of Ti(C, N)-based cermet under high temperature[J]. Cemented Carbide, 1995, 12(3): 187-189.

基金项目: 国家自然科学基金资助项目(50104006); 湖北省政府新世纪人才工程基金资助项目(2003-31); 三峡大学青年科学基金联合资助项目(KJA0456)

收稿日期: 2005-08-01; 修订日期: 2005-03-20

通讯作者: 郑 勇, 教授,博士; 电话:025-84895790; E-mail: shzm@ctgu.edu.cn

(编辑李艳红)