Trans. Nonferrous Met. Soc. China 22(2012) s84-s88

Hot deformation behavior of Hastelly C276 superalloy

LU Yan-ling1, LIU Jin-xi1, 2, LI Xiao-ke1, LIANG Jian-ping1, LI Zhi-jun1, WU Guan-yuan1, ZHOU Xing-tai1

1. Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai 201800, China;

2. College of Mechatronics and Automobile Engineering, Chongqing Jiaotong University, Chongqing 400074, China

Received 9 July 2012; accepted 15 August 2012

Abstract: Hot tensile behavior of C276 superalloy was studied in the deformation temperature range of 650-750 °C with the strain rate range of 0.35-35 mm/s. The results show that deformation temperature and strain rate both have significant influence on the flow stress. The flow stress decreases with the increase of deformation temperature, while increases with the increase of strain rate. The deformation of C276 superalloy exhibits dynamic recovery feature in the case of deformation temperature of 700 °C. However, when the deformation temperature increases to 750 °C, dynamic recrystallization behavior may occur. The flow stress of C276 alloy during hot deformation process can be characterized by Zener-Hollomon parameter including the Arrhenius term and the deformation activation energy is 327.66 kJ/mol. Therefore, a scientific basis is provided for the reasonable choice of processing parameters of C276 superalloy.

Key words: C276 superalloy; hot tension deformation; flow stress; constitutive equation

1 Introduction

Hastelloy C276 alloy is a Ni-Cr-Mo wrought alloy that is generally considered a versatile corrosion- resistant alloy. C276 alloy is also an improved wrought version of alloy C in which it usually doesn’t need to be solution heat-treated after welding and has vastly improved fabricability [1]. Due to its good high temperature strength, resistance to neutron radiation, and perfect anti-oxidation ability, it has been widely used in the field of chemical, oil, nuclear industry and so on in the last four decades.

In the program of the fourth generation of advanced nuclear energy systems-Thorium Molten Salt Reactor (TMSR), Hastelloy C276 alloy was selected as a candidate material for molten salt high-temperature experimental circuit. Previous study on this kind of material was mainly focused on the microstructure, oxidation resistance and the mechanism of corrosion resistance [2-5]. However, there was little research related to the deformation behavior of high temperature tensile deformation of C276 alloy. MAO et al [6] studied the tensile properties of C276 at 500-650 °C, and the results show that C276 alloy has yield stress flow behavior and good plasticity at high temperature. But the highest working temperature of TMSR experimental circuit is about 700 °C, so it is necessary to study the tensile properties at higher temperature.

Recently, finite element (FE) simulation has become one of the most important and effective methods for analyzing material deformation processing. As we know, the value of flow stress has significant influence on the simulation accuracy. Flow stress is one of the basic parameter to material plastic deformation depending on the deformation temperature, strain rate and chemical composition. Hot deformation processing is generally used for C276 super alloy because of its high deformation stress [2,3].

In this work, effect of the deformation temperature, strain rate and strain on the flow stress is analyzed to illustrate the mechanical behavior of C276 super alloy. The activation energy for deformation of hot tensile C276 alloy is calculated. Besides, the deformation mechanisms are proposed through the activation energy under different deformation parameters. Finally, constitutive equation of C276 alloy described by Zener-Hollomon parameter is established so as to optimize the processing parameters.

2 Experimental

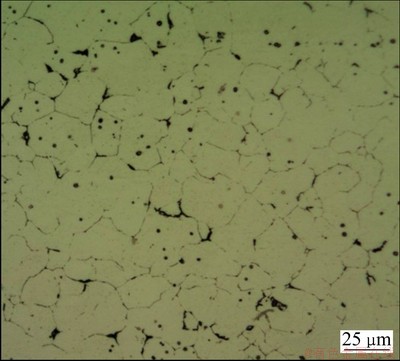

The materials used in this work were from the solid-solution state plates with thickness of 6 mm. The chemical composition (mass fraction) is as follows: Ni 57.48%, Cr 15.49%, Mo 15.45%, Fe 6.41%, W 3.57%, Mn 0.55%, V 0.236%, Co 0.0099%, Si 0.069%, C 0.009 4%, P 0.002%, S 0.0018%. The as-received micro-structure of the C276 alloy consisting of γ phase and a small amount of carbide phase is illustrated in Fig. 1. It can be seen that the microstructure contains fine equiaxed-shaped γ grains having grain size of about 30 μm.

Fig. 1 Original optical microstructure of C276 superalloy

Tensile specimens with 180 mm in length and 40 mm in width were machined from C276 plate. According to Chinese Standard Database GB4338—2006 “Method of hot tensile test for metals”, hot tensile deformation behavior of C276 alloy was carried out on a Shimadzu AG-X/250 testing machine. The test temperature ranged from 650 °C to 750 °C and strain rates were kept at 0.35 mm/s, 3.5 mm/s and 35 mm/s, respectively. The samples were heated to the setting temperature at the heating rate of 10 °C/s and held for 10 min. Three samples were employed to obtain average data of mechanical properties.

3 Results and discussion

3.1 True stress—true strain curve

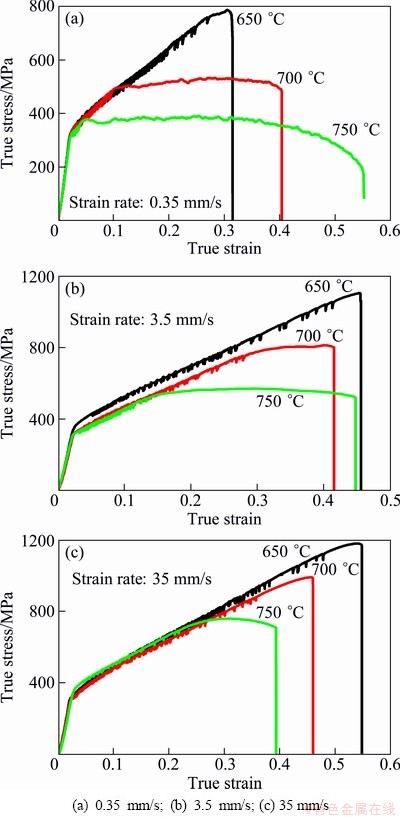

True stress—true strain curves of C276 alloy under different deformation temperatures and strain rates are shown in Fig. 2. From Fig. 2, it can be seen that flow stress increases rapidly with increasing strain in the initial stage of deformation, and as the strain continues to increase until the alloy rupture occurs. At the same deformation temperature, the flow stress increases with increasing strain rate. When the temperature is 650 °C and the deformation rate is 0.35 mm/s, the peak stress is 785 MPa. When the strain rate increases to 35 mm/s, the peak stress increases to 1177 MPa. The reasons for these results are as follows: Firstly, heating time is not enough for material softening; Secondly, the density of dislocations increases with increasing strain rate, which can enhance the degree of hardening. At the same strain rate, the flow stress decreases with increasing temperature. For example, when the strain rate is 3.5 mm/s and the temperature is 650 °C, the peak stress is 1104 MPa; when the temperature increases to 750 °C, the peak value of stress is reduced to 570 MPa. This is because the higher the temperature, the greater the dynamic recovery and recrystallization driving force, and the sooner the softening, reducing the resistance to deformation. This indicates that deformation temperature and strain rate are two important factors that affect the alloy flow stress.

Fig.2 True stress—true strain curves for C276 alloy at different temperatures and strain rates

It is also can be seen from Fig. 2 that when the temperature is 700 °C, the strain rate is 0.35 mm/s or 3.5 mm/s, true stress—true strain curve shows the steady-state flow stress characteristics, that is, in the given temperature and strain rate, stress is a fixed value, and true stress—strain curve is close to a horizontal line. There is cross-slip with the increasing of deformation strain, and the degree of softening is also enhanced. This also improves dislocations capacity to overcome the resistance, making a dynamic balance between softening and strain hardening, so dynamic recovery occurs. At the temperature of 750 °C, the curve reaches peak stress with the increase of strain. With the increase of the strain, austenite in the alloy will appear dynamic recrystallization. This results in the gradually disappearance of dislocations, and dynamic softening greater than the work hardening; curve appears downward trend. So alloy dynamic recrystallization may occur.

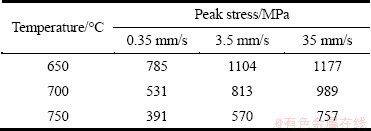

The measured peak stresses under different conditions are presented in Table 1.

Table 1 Peak stresses of C276 alloy at different deformation temperatures and strain rates

3.2 Constitutive equation

High temperature deformation of the metal is a hot activation process. Strain rate and deformation temperature have important effects on the flow stress, and the relationship can be depicted by Arrhenius equation[7-10]:

(1)

(1)

where  is the strain rate; A and α are constants; σ is the stress peak value; n is the strain constant; Q is the deformation activation energy; R is the mole gas constant; T is the deformation temperature.

is the strain rate; A and α are constants; σ is the stress peak value; n is the strain constant; Q is the deformation activation energy; R is the mole gas constant; T is the deformation temperature.

For the strain value smaller than 0.8 (ασ<0.8), there is

(2)

(2)

For the strain value higher than 1.2 (ασ>1.2) , there is

(3)

(3)

where A1, A2 and β are constants. The relationship of α, β and n can be written as α=β/n.

Equations (4) and (5) can be calculated by Eqs. (2) and (3):

(4)

(4)

(5)

(5)

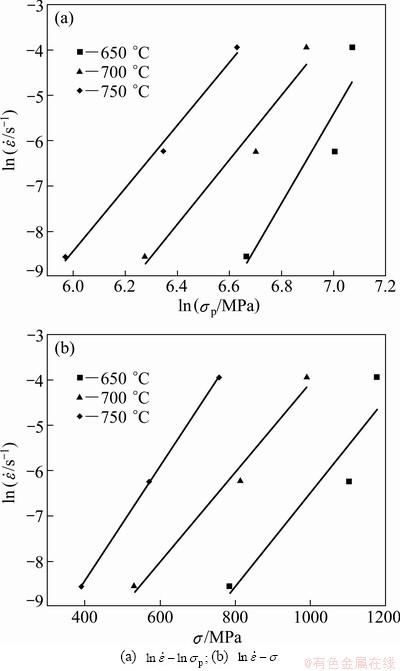

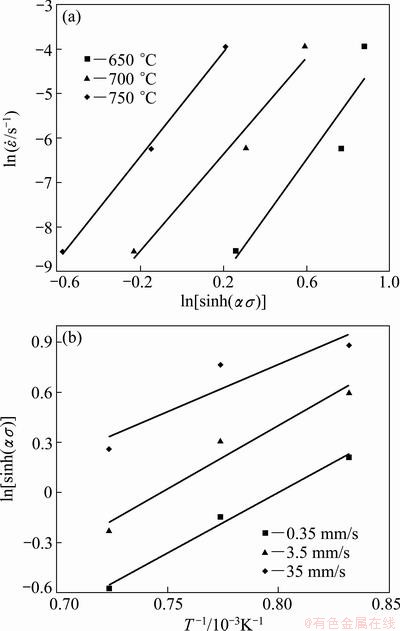

By using regressive method, two curves of  and

and  are obtained, n and β are the slopes of the curve, respectively, as shown in Figs. 3(a) and (b).

are obtained, n and β are the slopes of the curve, respectively, as shown in Figs. 3(a) and (b).

Fig. 3 Relationship between strain rate and peak stress of C276 alloy

It can be seen that the linear relationship is consistent with the experimental data at each temperature. By taking the average of the slope of lines in Figs. 3(a) and (b), we can obtain: n=7.9476, β=0.0109, so α=β/n=0.0109/7.947=0.00137.

Then Eq. (6) can be obtained from taking logarithm of Eq. (1):

(6)

(6)

Assuming that Q and T are independent, Eq. (7) can be obtained from taking differentiation of Eq (6):

(7)

(7)

where  and

and are slopes of the relation curves of

are slopes of the relation curves of  and

and  , respectively, as shown in Figs. 4(a) and (b). Using the slope value calculated in Figs. 4(a) and (b) by Eq. (7), Q value is 327.66 kJ/mol.

, respectively, as shown in Figs. 4(a) and (b). Using the slope value calculated in Figs. 4(a) and (b) by Eq. (7), Q value is 327.66 kJ/mol.

Fig. 4 Relationship between peak stress and strain rate, deformation temperature of C276 alloy

The relationship between strain rate and temperature in process of hot deformation can be expressed as Zener-Hollomon parameter [11]:

(8)

(8)

Then Eq. (9) can be obtained from putting Eq. (1) into Eq. (8):

(9)

(9)

Then Eq. (10) can be obtained from taking logarithm of Eq. (9):

(10)

(10)

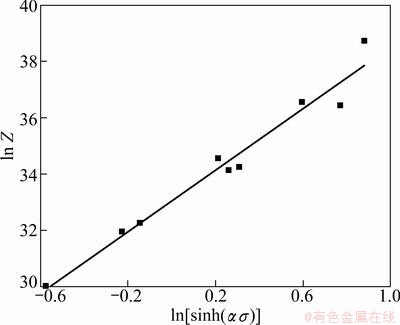

Z can be obtained by substitution of the Q value in Eq. (9), the relationship between lnZ and  is shown in Fig. 5. ln A=33.0707, n=5.487, and A=2.3×1014.

is shown in Fig. 5. ln A=33.0707, n=5.487, and A=2.3×1014.

ln Z and ln[sinh(ασ)] meet a linear relationship, and correlation coefficient is 0.96. So this model can describe the flow stress behavior of the C276 alloy deformation.

Fig. 5 Relationship between ln[sinh(ασ)] and ln Z parameter of C276 superalloy

The constitutive equation can be obtained from putting α, Q, A, n into Eq. (1):

Equation (11) can be obtained based on Eq. (7) and the definition of hyperbolic sine function as follows:

(11)

(11)

Therefore, the flow stress constitutive equation can be expressed as:

In order to validate the calculation results, we use the following formula to calculate the relative error of the flow stress:

=0.759%

=0.759%

4 Conclusions

1) Deformation temperature and strain rate have significant effects on the flow stress of C276 superalloy. The flow stress decreases with increasing the deformation temperature and increases with the increase of strain rate.

2) The strain—stress curve of C276 superalloy has an obvious peak value when the deformation temperature is 750 °C, and the deformation mechanism is mainly dynamic recrystallization. However, when the temperature is 700 °C, the strain—stress curve becomes steady, and the deformation of C276 superalloy exhibits a dynamic recovery feature.

3) According to Zener-Hollomon, the constitutive equation of C276 superalloy is as follows:

4) Deformation activation energy value of C276 superalloy is 327.66 kJ/mol.

References

[1] Haynes International. Hastelloy C-276 Alloy [R]. Houston: Haynes International, 2002.

[2] MA Yan, LU Dao-gang, MAO Xue-ping,ZHANG Li-yin, CAI Jun. Microstructure analysis of stress rupture performance of Hastelloy C-276 alloy [J]. Rare Metal Materials and Engineering, 2007(3): 23-25. (in Chinese)

[3] GE Xin-sheng, WU Lei, ZHANG Hai-bo, CUI Jun. The effect of sensitizing on corrosion resistance of alloy C276 and its recovery [J]. Pressure Vessel, 2007(3): 23-25. (in Chinese)

[4] HE Feng, TANG Bin, LAN Hua. Welding of nickel based alloy C276 [J]. Installation, 2005(5): 41-42. (in Chinese)

[5] RAGHAVAN M, BERKOWITZBJ, SCA N-LONJC. Electron microscopic analysis of heterogeneous precipitates in Hastelloy C276 [J]. Metallurgic Transaction, 1982, 13: 979-983.

[6] MAO Xue-ping, WANG Gang, ZHANG Li-yin. High temperature tensile properties of nickel based alloy C276 [J]. Journal of Power Engineering, 2009, 29(7): 699-702. (in Chinese)

[7] JONAS J J, SELLARS C M, TEGART W J, MC G. Strength and structure under hot-working conditions [J]. Int Metiall Reviews, 1969, 3: 1-24.

[8] POIRIER J P. High temperature plastic deformation of the crystals [M]. GUAN De-lin. Dalian: Dalian University of Science and Technology Press, 1989: 52-54. (in Chinese)

[9] LUO Feng-hua, YIN Zhi-min, ZUO Tie-yong. Hot deformation behavior of CuZn(Cr,Zr) alloys [J]. The Chinese Journal of Nonferrous Metals, 2000, 10(1): 12-16. (in Chinese)

[10] SHI H, McLAREN A J, SELLARS C M, SHAHANI R, BOLINGBROKE R. Constitutive equations for high temperature flow stress of aluminum alloys [J]. Materials Science and Technology, 1997, 13(3): 210-216.

[11] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel [J]. J Appl Phys, 1944, 15(1): 22-32.

C276合金的热变形行为

陆燕玲1,刘锦溪1, 2,李肖科1,梁建平1,李志军1,吴冠原1,周兴泰1

1. 中国科学院 上海应用物理研究所,上海 201800;

2. 重庆交通大学 机电与汽车工程学院,重庆 400074

摘 要:采用万能材料试验机,研究C276高温合金在变形温度650~750 °C、变形速度0.35~35 mm/s条件下的高温拉伸变形行为,分析了变形温度、变形速率对C276合金变形行为的作用及影响规律。结果表明:变形温度和变形速率对合金流变应力有显著影响,流变应力随着变形温度的升高而降低,随着变形速率的提高而增大。在温度为700 °C、应变速率为0.35 mm/s和3.5 mm/s 时,曲线呈现出明显的稳态流变应力特征,合金变形机制以动态回复为主;在温度为750 °C时,随着应变量的增加,合金内发生动态再结晶。利用Zener-Hollomon参数建立了C276合金的变形抗力模型, 求得变形激活能为327.66 kJ/mol。

关键词:C276合金;高温拉伸变形;流变应力;本构方程

(Edited by HE Yun-bin)

Foundation item: Project (XDA02000000) supported by the Strategic Priority Research Program of the CAS; Projects (2010CB934501, 2010CB934503) supported by the National Basic Research Program of China; Project (11JC1414900) supported by Science and Technology Commission of Shanghai Municipality, China; Projects (11005148, 50904044) supported by the National Natural Science Foundation of China

Corresponding author: LU Yan-ling; Tel: +86-21-39194767; Fax: +86-21-39194539; E-mail: luyanling@sinap.ac.cn