Rheological behavior of continuous roll casting process of aluminum alloy

来源期刊:中南大学学报(英文版)2005年第6期

论文作者:湛利华 钟掘 李晓谦 黄明辉

文章页码:629 - 634

Key words:aluminum alloy; continuous roll casting; simulation; rheological behavior; constitutive relation

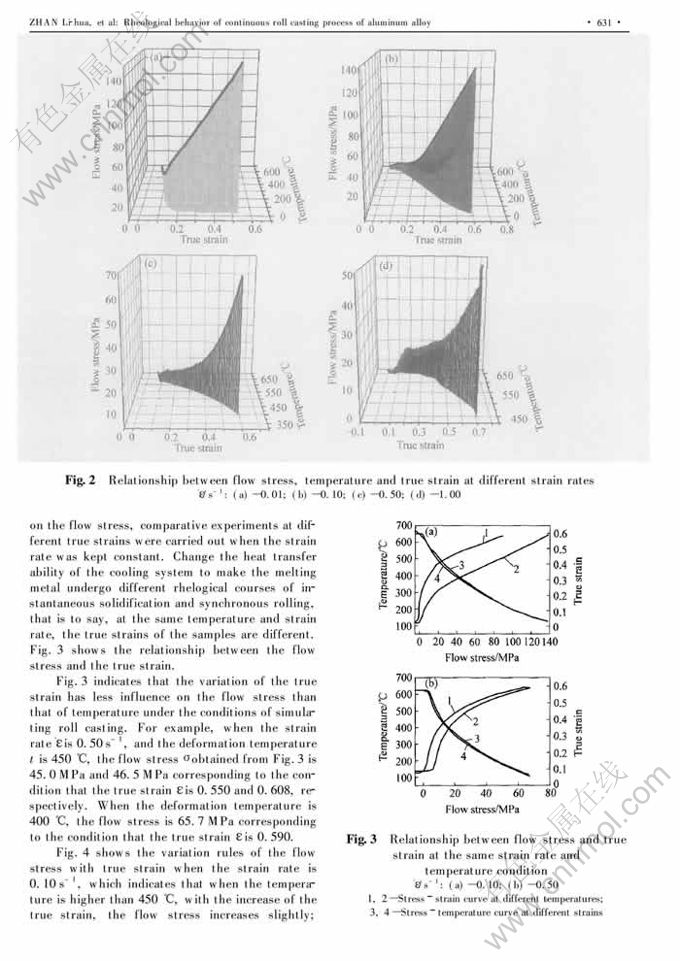

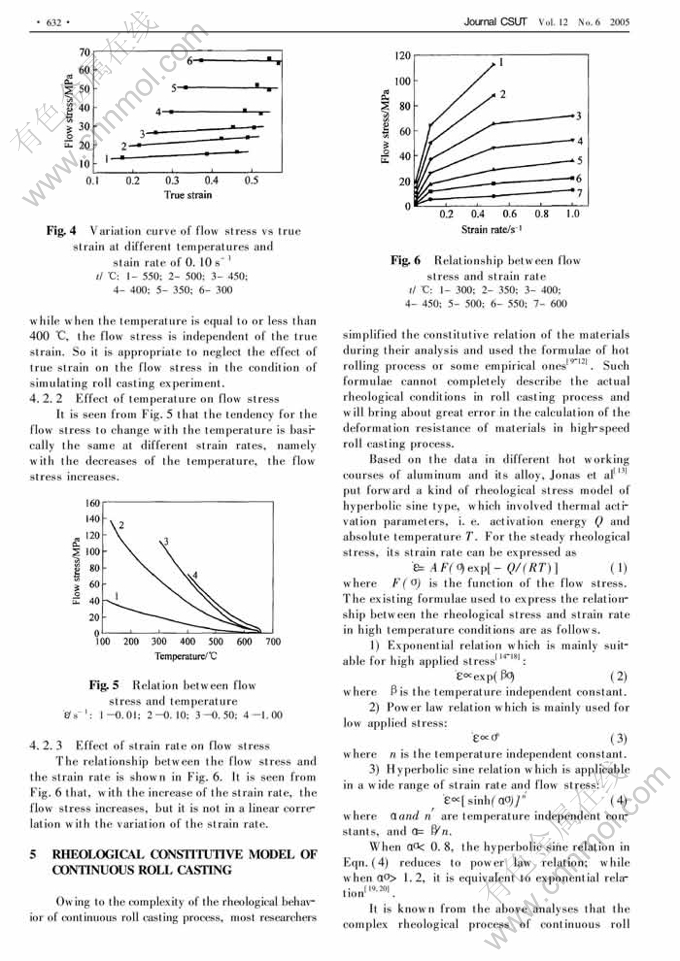

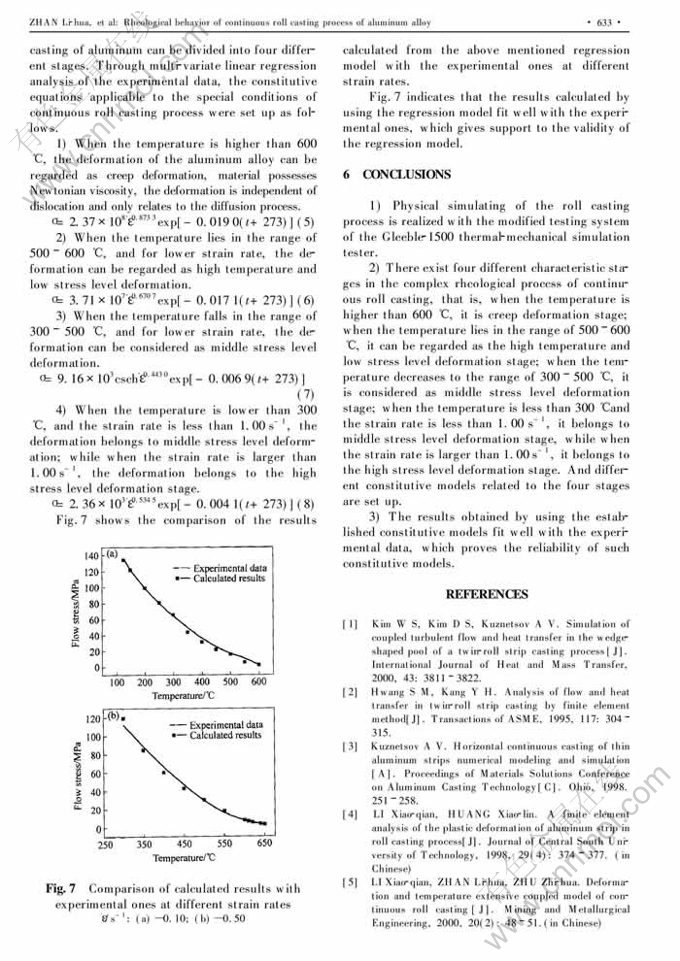

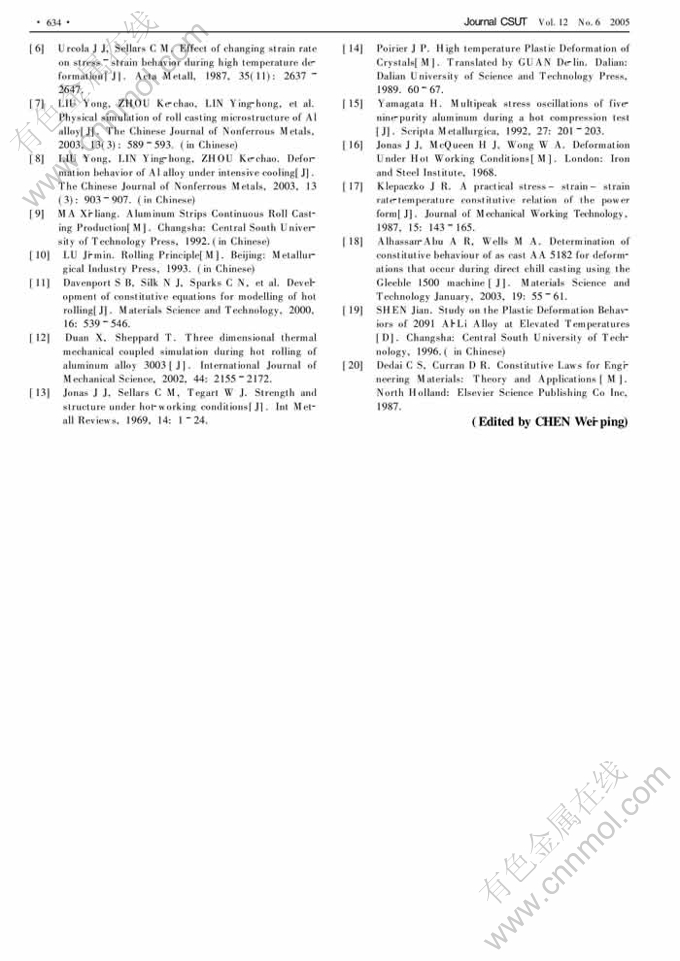

Abstract: The rheological behavior of aluminum alloy and its influencing factors in physical simulation of continuous roll casting process were studied by using a Gleeble-1500 thermal-mechanical simulation tester with a set of special clamp system. The relationships between the flow stress and the strain rate in the deformation process of simulating roll casting experiment were obtained. The results show that four different characteristic stages exist in the temperature range of the whole rheological process. The first occurs when the temperature is higher than 600℃,which belongs to the creep deformation stage; the second occurs when the temperature lies in the range of 500-600℃, and it can be regarded as the high temperature and low stress level deformation stage; the third occurs when thetemperature decreases to the range of 300 -500℃, it is considered to be the middle stress level deformation stage;the last occurs when the temperature is less than 300℃and the strain rate is less than 1.00 s-1, it belongs to middle stress level deformation stage. But when the strain rate is larger than 1.00 s-1, it belongs to the high stress level deformation stage. And the relative constitutive models suitable for the four different stages of continuous roll casting process were established through multivariate linear regression analysis of the experimental data.