文章编号:1004-0609(2012)02-0434-07

Sn-6.5Zn钎料/Cu基板焊点界面特征与

金属间化合物的形成机理

赵国际,盛光敏,邓永强

(重庆大学 材料科学与工程学院,重庆 400044)

摘 要:对255 ℃时Sn-6.5Zn钎料/Cu基板界面反应及金属间化合物的形成与转化进行热力学计算与分析,并利用SEM、EDS、XRD研究分析255 ℃不同钎焊时间条件下钎料/Cu基板界面组织与IMC层形态特征。结果表明:Sn-6.5Zn钎料/Cu焊点界面紧靠Cu基板侧形成CuZn层;CuZn IMC有与钎料中的Zn原子继续反应生成Cu5Zn8 IMC的趋势;在相同钎焊温度条件下,不同钎焊时间对界面厚度影响不大;随钎焊时间延长,Sn-6.5Zn钎料/Cu基板焊点界面IMC层的平均厚度增大,界面粗糙度则由于不同钎焊时间IMC在液态钎料中生长与溶解的差异,呈现先增大而后降低到一个均衡值的变化趋势。

关键词:Sn-6.5Zn钎料;界面;金属间化合物;热力学;粗糙度

中图分类号:TG454 文献标志码:A

Formation mechanism of intermetallic compounds and interface characteristics of joint of Sn-6.5Zn solder/Cu substrate

ZHAO Guo-ji, SHENG Guang-min, DENG Yong-qiang

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The interfacial reaction of Sn-Zn solder/Cu substrate soldered at 255 ℃ and the formation and transformation of intermetallic compounds (IMC) were investigated by the thermodynamic calculation and analysis. The interface of the joint produced at 255 ℃ with various soldering times was analyzed by scanning electron microscope (SEM), X-ray energy dispersive spectrometer (EDS) and X-ray diffraction (XRD). The results show that CuZn IMC forms preferentially within the Cu substrate. The Cu5Zn8 IMC forms by the reaction of CuZn with Zn atoms diffused from the solder. The effect of the soldering time on the interface thickness at the same soldering temperature is slight. With prolonging soldering time, the interface thickness between Sn-6.5Zn solder and Cu substrate increases, and the interface roughness reaches obviously a maximum value, and then decreases to a stable value, which is due to the non-uniform growth and dissolution of dendrite in liquid solder.

Key words: Sn-6.5Zn solder; interface; intermetallic compound; thermodynamics; roughness

随着无铅化进程的日益深入,人们一直在致力于寻找一种性能与成本都能够替代传统Sn-Pb合金焊锡的钎料,但直到目前仍没有形成统一的认识,这也使得目前众多系列的锡基无铅钎料被应用于不同的国家或是不同的电子互联与封装工艺。Sn-Ag-Cu系合金钎焊工艺性能好,并易于得到力学性能优良的焊点,被认为是最具发展前景的无铅焊料并已经得到了广泛应用[1-3],但是,Sn-Ag-Cu系合金熔点较高且添加的贵金属Ag增加了材料成本,使得其应用受到了部分限制。Sn-Zn合金是目前研究和应用的合金系中与Sn-Pb共晶温度(183 ℃)最为接近的无铅焊锡,材料成本低,具有良好的力学性能和抗迁移性,已经得到成功应 用[4-10]。关于Sn-Zn系钎料的特性及应用研究已经开展了大量工作,尤其是关于Sn-9Zn、Sn-8Zn-3Bi等共晶或近共晶钎料的报道较多[4-7]。也有研究表明[8-10],亚共晶Sn-6.5Zn钎料合金具有更为优良的润湿性和焊点性能。

界面IMC形态及生长对焊点性能具有至关重要的影响[11-12]。Sn-Zn系合金钎料作为无铅钎料的一个重要研究和发展应用方向,分析其界面反应及IMC形态特征对研究焊点性能具有重要意义。本文作者对255 ℃时亚共晶Sn-6.5Zn钎料/Cu界面元素反应及IMC形成与转化进行了热力学计算与分析,并分析了焊点界面组织与IMC层形态特征,以期为多元亚共晶新型Sn-Zn系无铅钎料开发提供理论依据。

1 实验

实验用钎料利用纯度为99.99%(质量分数)的Sn、Zn按质量分数比并考虑Zn烧损配比熔炼。熔炼在ZG-001真空感应熔炼炉中进行,抽真空后充氩气保护,熔炼温度550~600 ℃,保温10 min后浇注于预热至约150 ℃的不锈钢模中成型。除利用熔炼过程中的电磁振荡搅拌作用外,对浇注的钎料进行2次重熔以保证钎料成分均匀。对所得钎料利用LAB CENTER XRF-1800扫描型X射线荧光光谱仪进行成分检验,钎料中Zn含量为6.4893%(质量分数)。

为分析Sn-6.5Zn钎料与Cu基板界面反应及IMC的形成特征,依据GB11364—89《钎料铺展性及填缝性试验方法》的要求,将(0.2±0.01) g的钎料置于40 mm×40 mm×3 mm的紫铜板中央并利用市售松香焊锡膏作为钎剂覆盖钎料,然后在SX-12箱式电炉中进行铺展试验。在本试验条件下,通过试验优化设定铺展试验工艺参数为:温度255 ℃,时间2~6 min。对不同保温时间条件下的焊点利用线切割由中心剖开,经打磨抛光腐蚀后利用TESCAN VegaⅡ LMUSEM扫描显微镜(SEM)配OXFORD ISIS300能谱分析仪 (EDS)观察微观组织并分析界面区元素分布。将255 ℃、4 min钎料/Cu铺展焊点依次用400#与800#砂纸水磨至边缘微露出Cu基板后,在丙酮中对试样进行超声波清洗,采用Rigaku D/max-2500 PC X射线衍射仪(XRD)分析界面物相。

2 结果与分析

2.1 界面IMC生成热力学分析

对钎料/基板界面元素反应及IMC形成与转化进行热力学计算有助于焊点组织与性能分析。本研究将工件及炉腔作为一个孤立系统,对钎焊温度为255 ℃时液态钎料与Cu基板间的反应进行热力学分析。

液态Sn-Zn钎料与Cu基板接触时,钎料中的Zn原子与基板中的Cu原子反应形成CuZn IMC层[8-9],反应方程式为

Cu+Zn=CuZn (1)

反应吉布斯自由能可以通过下式计算:

(2)

(2)

式中: 为温度T时的标准反应吉布斯自由能;T为反应温度;

为温度T时的标准反应吉布斯自由能;T为反应温度; 为温度T下的反应焓变;

为温度T下的反应焓变; 为温度T时的反应熵变。

为温度T时的反应熵变。

依据Richards和Tammann提出的分子体积与原子体积总和之差的对比值 与

与 间的关系曲 线[13],推算CuZn IMC

间的关系曲 线[13],推算CuZn IMC (298 K)为-16 728 J/mol;根据Kirchhoff公式计算温度T时的反应焓变:

(298 K)为-16 728 J/mol;根据Kirchhoff公式计算温度T时的反应焓变:

(3)

(3)

式中: 表示物质B的计量数,产物取正值,反应物取负值;

表示物质B的计量数,产物取正值,反应物取负值; 为恒压摩尔热容;

为恒压摩尔热容; 为反应体系中反应物与产物

为反应体系中反应物与产物 的代数和。

的代数和。

标准状态下的反应熵变为反应体系中反应物与产物标准摩尔熵 的代数和,即

的代数和,即

(4)

(4)

则任意温度T时化学反应的熵变为

(5)

(5)

依据文献[14]所提供的金属间化合物热力学性质计算方法,计算二元金属间化合物CuZn和Cu5Zn8的摩尔恒压热容和标准熵,热力学参数计算简化公式为

(6)

(6)

式中:X为待求热力学参数;m和n分别表示组成化合物两元素的原子个数;λ1和λ2分别为元素对金属间化合物热力学性质的贡献值[14]。

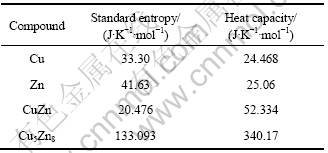

表1所列为参与反应的元素与化合物标准熵(298 K)与摩尔恒压热容,其中元素Cu和Zn有关数值见文献[15],金属间化合物CuZn和Cu5Zn8的有关数值由式(6)计算得到。

表1 298 K恒压下Cu、Zn 及其金属间化合物的标准熵与热容

Table 1 Entropies and heat capacities of Cu, Zn and their intermetallic compounds at constant pressure and 298 K

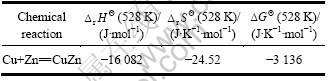

由式(1)~(4)计算钎焊温度T为255 ℃(528 K)时各化学反应的焓变、熵变及反应吉布斯自由能,结果见表2。

表2 Cu-Zn反应焓变、熵变和自由能

Table 2  ,

,  and

and  in reaction of Cu-Zn

in reaction of Cu-Zn

反应(1)的吉布斯自由能 <0,即在255 ℃ (528 K)时,钎料中的Zn原子与基板中的Cu原子生成CuZn IMC的反应能够自发进行。

<0,即在255 ℃ (528 K)时,钎料中的Zn原子与基板中的Cu原子生成CuZn IMC的反应能够自发进行。

在CuZn层靠近钎料侧,IMC Cu5Zn8的形成反应有可能为

5Cu+8Zn=Cu5Zn8 (7)

5CuZn+3Zn=Cu5Zn8 (8)

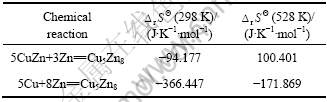

分别计算上述反应528 K时的熵变,利用热力学方法定性推断界面处发生上述反应的自发性及IMC CuZn存在的稳定性,计算结果见表3。

表3 Cu5Zn8 IMC 形成反应熵变

Table 3 Entropy changes in reaction of IMC Cu5Zn8 formation

根据热力学第二定律,孤立系统中的自发反应过程总是向着熵值增大的方向进行。由表3计算结果,界面中IMC Cu5Zn8不能由Cu和Zn原子直接反应生成,其形成过程可以分为两个阶段:基板与液态Sn-Zn钎料接触时,即形成CuZn IMC层;随着反应的进行,基板中的Cu原子持续越过Cu-Zn化合物层向液态钎料中扩散并与钎料中的Zn原子反应,由于Cu原子扩散速度快以及反应初期界面处Zn原子含量较高,与液态钎料接触的CuZn IMC层与钎料中的Zn原子结合形成γ-Cu5Zn8晶核并开始生长。有研究表明,Cu原子在液态Sn基钎料中的扩散速度是Zn原子的1 000倍以上[16],因此可以认为,界面处的扩散是以Cu原子向钎料中的扩散为主导。Cu原子由基体穿越反应层向钎料中的高速扩散及其与Zn原子的反应,使得钎料中的Zn原子难以持续向Cu基体中扩散,界面靠近Cu基体侧形成的CuZn IMC层被保留,但厚度很小。

2.2 界面微观分析

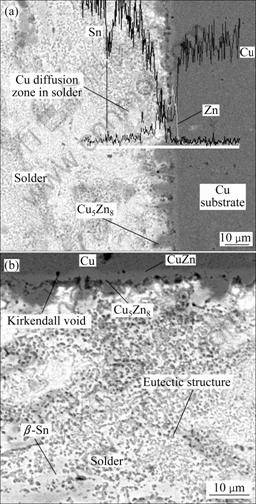

图1所示为Sn-6.5Zn/Cu焊点界面在钎焊温度为255 ℃、时间为4 min时结合界面的SEM像。其中,图1(a)为界面元素扩散线扫描分析结果,图1(b)为界面组织。图2所示为界面焊点的XRD谱。

图1 Sn-6.5Zn/Cu焊点界面的SEM像

Fig. 1 SEM of Sn-6.5Zn/Cu joint interface at 255 ℃ for 4 min: (a) Elements diffusion of interface; (b) Microstructure of joint interface

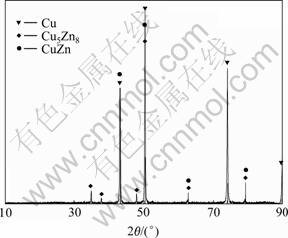

图2 焊点界面的XRD谱

Fig. 2 XRD pattern of joint interface

由Sn-Zn二元相图可知,Sn-6.5Zn合金组织由初生β-Sn相和共晶组织组成,见图1(b)。依据前述热力学分析,结合焊点界面EDS与XRD检测分析结果,并参考Sn-Zn钎料/Cu基板界面反应的研究结果[8-9],可以确定界面处IMC层包括两个组成部分:靠近钎料一侧形成并生长的是IMC γ-Cu5Zn8;Cu5Zn8层与Cu基板间为薄的CuZn IMC层。此外,Cu基板中的Cu原子穿过界面反应层向钎料的扩散过程中,与钎料中的Zn原子结合形成颗粒状的Cu5Zn8[4]分布于靠近结合面的钎料基体中。图1(a)中观察到界面处IMC Cu5Zn8局部呈“笋状”生长,这表明在该工艺条件下IMC在界面处形成与生长的差异增大,局部的快速生长被认为是“笋状”IMC形成的主要原因[17]。有研 究[18]认为,IMC的生长激活能会由于界面具体初始条件的差异而不同,不同的钎焊温度和保温时间对界面初始状态会产生重要影响。钎焊温度为255 ℃、保温时间为2~6 min时结合界面元素扩散线扫描分析结果见图3。

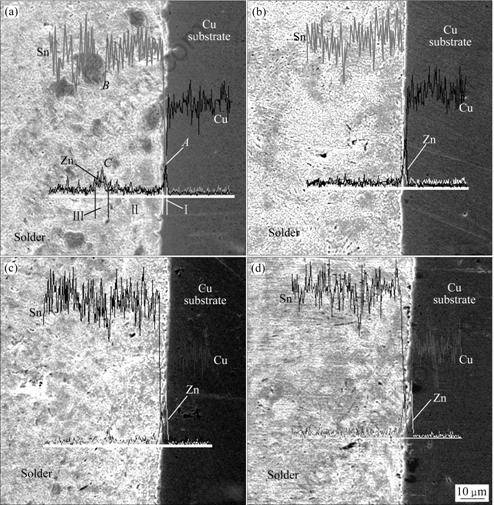

图3 255 ℃时保温不同时间Sn-6.5Zn/Cu焊点结合界面元素扩散能谱线扫描分析

Fig. 3 Energy spectrum line scanning analysis of element diffusion of Sn-6.5Zn/Cu joint interface at 255 ℃ for different soldering times: (a) 2 min; (b) 3 min; (c) 5 min; (d) 6 min

根据界面元素分布能谱线扫描结果可以大致确定基板中的Cu原子向钎料中的扩散距离。具体测量时,以Cu基板中Zn元素分布的陡降线与Cu元素分布的陡升线的交点(见图3(a)中A点)映射到扫描基准线上的点为测量起点,根据钎料中扫描基准线上Sn、Zn、Cu含量的突变位置确定测量终止点(见图3(a)中B点与C点)。由图3可见,钎焊保温时间对基板中Cu原子向钎料中的扩散影响并不明显,不同时间条件下以Cu原子扩散为代表的界面反应区宽度是25~30 μm (见图1(a))。根据元素在界面区的分布与反应特点以及Cu基板中Cu原子向Sn-Zn钎料中的扩散/反应状况,结合前述热力学与接头显微分析结果,焊点界面Ⅰ/Ⅱ/Ⅲ不同区域(见图3(a))的特点分别如下:

Ⅰ区:Sn-Zn液态钎料与基板接触时,首先形成的反应层为Cu-Zn IMC,这是熔融钎料中的Zn原子优先与基板中的Cu原子结合的结果;随着反应的进行,基板中的Cu原子越过Cu-Zn化合物层继续向钎料中扩散,在界面处形成γ-Cu5Zn8的晶核,新相晶核的横向长大形成了覆盖于Cu-Zn-Sn层上的Cu5Zn8层,而不同的温度条件使得纵向长大的晶核形态上产生了差异。当保温时间较短时,Cu5Zn8在横向连成整体后,局部开始有明显的纵向生长(见图3(a)和(b)),各处化合物的生长不均衡甚至局部长成“笋状”[17](见图1(a));当保温时间较长时,Cu5Zn8在整个接触面上的生长趋于均衡,同时,根据Gibbs-Thomson效应,即界面区IMC层外缘的小晶粒能够溶解到液态钎料中,从而促进相邻晶粒进一步生长[19],IMC层逐渐形成典型的“扇贝状”。图3所示的EDS线扫描分析结果也表明,随保温时间的延长,界面中形成的IMC层厚度逐渐增大,而各处化合物的生长呈“扇贝状”并趋于均衡。

Ⅱ区:扩散/反应区位于钎料中,紧靠界面反应层,宽度为15~20 μm。EDS结果表明,该区域为Cu在钎料中的扩散与反应区,由Sn-Zn二元相图可以推断其组织由富Sn相和共晶组织组成。由于接触界面处Zn与Cu的大量反应,扩散/反应区中的Zn原子会由于浓度差异自发地向界面处扩散,使得该区域中Zn元素含量下降;而Zn原子在Sn基钎料中的扩散速度远小于Cu原子的[16],距离反应层较远处的Zn扩散过来的速度较慢。穿越反应层的Cu原子在向钎料中扩散过程中会与钎料中的Zn原子结合,在扩散/反应区中形成粒状Cu5Zn8[4]混杂于共晶组织中(见图1(b));部 分Cu原子穿越该区域后继续向钎料中扩散。Cu原子在Sn基钎料中具有极强的扩散能力[19],加之扩散/反应区中细小的共晶组织存在大量晶界,而晶界处由于具有较高的能量状态和较低的扩散激活能,且原子排列结构也较为松散,有利于原子扩散并可以作为Cu原子向钎料中扩散的通道[20]。Cu原子在钎料中的快 速扩散和反应,使得不同保温时间条件下形成的界面区域尺寸相差不大。

Ⅲ区:扩散终了区的宽度通常为2~5 μm,在元素线扫描结果中主要表现为Sn、Cu、Zn含量的突变。基板中越过Cu-Zn-Sn与Cu5Zn8化合物层以及扩散/反应区的Cu原子会继续向钎料中扩散。远离界面的钎料中,Zn元素含量逐步增大到常规数值,导致与Cu原子反应程度增大,增大了Cu原子在钎料中持续扩散的阻力,所以扩散过来的Cu原子在该区域集中发生了与Zn原子结合成Cu5Zn8化合物的反应,造成该区域在元素分布线扫描结果中表现为Cu与Zn元素含量相对升高(见图3(a)中C处),而Sn元素相对含量明显下降(见图3(a)中B处)。由于扩散终了区的集中反应,邻近区域钎料中的Zn原子会向该区域扩散而导致浓度略有下降。

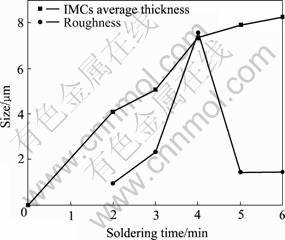

2.3 界面IMC粗糙度分析

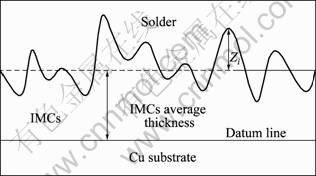

基于焊点界面粗糙度对性能的影响[18, 21-22],本研究参考文献[18, 23]中对微连接焊点界面粗糙度评估方法,对不同钎焊时间条件下Sn-6.5Zn钎料/Cu基板界面反应形成的IMC进行了测量和计算。图4所示为对界面处IMC粗糙度测量示意图。

图4 钎料/基板界面粗糙度示意图

Fig. 4 Schematic diagram of roughness of solder/substrate interface

测量时,根据界面区元素分布能谱线扫描图谱,将Cu基板中Zn元素分布的陡降线与Cu元素分布的陡升线的交点(见图3(a)中A点)映射到扫描基准线上,参考SEM照片中IMC层与Cu基体的颜色差异,画出一条通过映射点并与反应层平行的直线作为基准线;再利用CAD的查面积功能测量出选定长度区域内IMC层的面积,利用面积除以长度来计算所选定区域的IMC层平均厚度,并以该平均厚度线作为粗糙度测量基准线(图4中虚线);利用CAD的测距功能,测量选定区域的IMC峰值到测量基准线间的距离,代入式(9)计算粗糙度:

(9)

(9)

式中:Rrms为粗糙度,μm;N为选定区域测量点的个数;Zi为所测量选定区域的IMC峰值到测量基准线间的距离,μm。为减小测量误差,本研究对不同工艺条件下界面分别选定3个区域,每个区域测量10个点。经测量和计算得到钎焊温度255 ℃、不同保温时间时界面处IMC层平均厚度及粗糙度(见图5)。

图5 钎焊时间对Sn-6.5Zn/Cu界面区化合物层平均厚度与粗糙度的影响(255 ℃)

Fig. 5 Effect of soldering time on interface roughness and average thickness of IMC of Sn-6.5Zn/Cu (255 ℃)

由图5可知,Sn-6.5Zn钎料/Cu基板界面IMC层平均厚度随钎焊时间延长而增大,界面粗糙度则随着钎焊时间的延长,呈现先增大而后降低到一个均衡值的变化趋势。界面IMC层的平均厚度随钎焊时间延长而增大是由原子扩散决定的,而界面粗糙度的变化趋势,也表明界面IMC Cu5Zn8的生长在随保温时间的延长而逐步均衡的同时,发生了端部小晶粒向液态钎料中的溶解,这与Gibbs-Thomson效应[18]符合。由图1和3可观察到,随着保温时间的延长,界面IMC先是逐步长大并粗化,局部甚至生长为“笋状”,界面不平整度逐步增大;而后又逐渐演变为“扇贝状”化合物层,形成较为光滑的界面。目前,关于钎料/Cu基板界面粗糙度对焊点性能影响的研究结果还不够一致,SHANG和YAO[21]研究认为界面IMC层粗糙度增大能显著抑制裂纹扩展,提高焊点的抗疲劳性能;而另有研究表明[18, 22],界面粗糙度增大会导致焊点长时间受热后抗裂纹高速扩展能力下降,且不利于钎料对基板的润湿与铺展。Sn-6.5Zn钎料/Cu基板界面粗糙度对焊点力学性能的影响仍有待于进一步研究。

3 结论

1) 255 ℃条件下Sn-6.5Zn钎料/Cu基板焊点界面的热力学与微观分析表明,Sn-6.5Zn钎料/Cu焊点界面紧靠Cu基板侧形成CuZn层,CuZn IMC有与钎料中的Zn原子继续反应生成Cu5Zn8的趋势。

2) 随钎焊时间的延长,Sn-6.5Zn钎料/Cu基板焊点界面IMC层平均厚度增大,不同钎焊时间对界面厚度的影响不大。

3) 界面粗糙度由于不同钎焊时间IMC在液态钎料中生长与溶解的差异,呈现先增大而后降低到一个均衡值的变化趋势。

REFERENCES

[1] RAO B S S C, WENG J, SHEN L, LEE T K, ZENG K Y. Morphology and mechanical properties of intermetallic compounds in SnAgCu solder joints[J]. Microelectronic Engineering, 2010, 87(11): 2416-2422.

[2] ZHANG L, XUE S B, GAO L L, SHENG Z, ZENG G, CHEN Y, YU S L. Properties of SnAgCu/SnAgCuCe soldered joints for electronic packaging[J]. Journal of Materials Science: Materials in Electronics, 2010, 21(6): 635-642.

[3] 赵国际, 张柯柯, 罗 键. 快速凝固Sn2.5Ag0.7Cu钎料中金属间化合物的形态及对焊点性能的影响[J]. 中国有色金属学报, 2010, 20(10): 2025-2031.

ZHAO Guo-ji, ZHANG Ke-ke, LUO Jian. Micro-morphology of intermetallic compounds in rapid solidification Sn2.5Ag0.7Cu solder alloy and its effects on performance of solder joint[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 2025-2031.

[4] SUGANUMA K, KIM K S. Sn-Zn low temperature solder[J]. Journal of Materials Science: Materials in Electronics, 2007, 18(1/3): 121-127.

[5] EL-DALY A A, HAMMAD A E. Elastic properties and thermal behavior of Sn-Zn based lead-free solder alloys[J]. Journal of Alloys and Compounds, 2010, 505(2): 793-800.

[6] SAAD G, FAWZY A, SHAWKY E. Effect of Ag addition on the creep characteristics of Sn-8.8wt% Zn solder alloy[J]. Journal of Alloys and Compounds, 2009, 479(1/2): 844-850.

[7] 王 慧, 薛松柏, 陈文学, 马秀萍. Ga、Al对Sn-Zn钎料耐蚀及高温抗氧化性能的影响[J]. 稀有金属材料与工程, 2009, 38(12): 2187-2190.

WANG Hui, XUE Song-bai, CHEN Wen-xue, MA Xiu-ping. Effects of Ga and Al additions on corrosion resistance and high-temperature oxidation resistance of Sn-Zn solder[J]. Rare Metal Materials and Engineering, 2009, 38(12): 2187-2190.

[8] WEI X Q, HUANG H Z, ZHOU L, ZHANG M, LIU X D. On the advantages of using a hypoeutectic Sn-Zn as lead-free solder material[J]. Materials Letters, 2007, 61(3): 655-658.

[9] MAHMUDI R, GERANMAYEH A R, NOORI H, SHAHABI M. Impression creep of hypoeutectic Sn-Zn lead-free solder alloys[J]. Materials Science and Engineering A, 2008, 491(1/2): 110-116.

[10] 魏秀琴, 黄惠珍, 周 浪, 张 萌. 亚共晶Sn-Zn系合金无铅焊料的性能[J]. 中国有色金属学报, 2006, 16(12): 1993-1998.

WEI Xiu-qin, HUANG Hui-zhen, ZHOU Lang, ZHANG Meng. Properties of Sn-Zn hypoeutectic alloys as lead-free solders[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 1993-1998.

[11] HO C E, YANG S C, KAO C R. Interfacial reaction issues for lead-free electronic solders[J]. Journal of Materials Science: Materials in Electronics, 2007, 18(1/3): 155-174.

[12] CHOUBEY A, YU H, OSTERMAN M, PECHT M, YUN F, LI Y H, XU M. Intermetallics characterization of lead-free solder joints under isothermal aging[J]. Journal of Electronic Materials, 2008, 37(8): 1130-1138.

[13] 许志宏, 王乐珊. 无机热化学数据库[M]. 北京: 科学出版社, 1987: 141-143.

XU Zhi-hong, WANG Le-shan. Thermo-chemical database of inorganic[M]. Beijing: Science Press, 1987: 141-143.

[14] 陈 锋, 杨章远, 温 浩, 许志宏. 计算金属间化合物热力学性质的新方法[J]. 物理化学学报, 1997, 13(8): 712-715.

CHEN Feng, YANG Zhang-yuan, WEN Hao, XU Zhi-hong. A new method to estimate thermodynamic properties of intermetallic compounds[J]. Acta Physico-Chimica Sinaca, 1997, 13(8): 712-715.

[15] 林宪杰, 许和允, 殷保华, 吴义芳, 邵 军. 物理化学[M]. 北京: 科学出版社, 2010: 466-477.

LIN Xian-jie, XU He-yun, YIN Bao-hua, WU Yi-fang, SHAO Jun. Physical chemistry[M]. Beijing: Science Press, 2010: 466-477.

[16] LEE H M, YOON S W, LEE B J. Thermodynamic prediction of interface phases at Cu/solder joints[J]. Journal of Electronic Materials, 1998, 27(11): 1161-1166.

[17] 劳邦盛, 高 苏, 张启运. 固-液金属界面上金属间化合物的非平衡生长[J]. 物理化学学报, 2001, 17(5): 453-456.

LAO Bang-sheng, GAO Su, ZHANG Qi-yun. Nonequilibrium growth of intermetallics at the interface of liquid-solid metal[J]. Acta Physico-chimica Sinica, 2001, 17(5): 453-456.

[18] MAYAPPAN R, AHMAD A Z. Effect of Bi addition on the activation energy for the growth of Cu5Zn8 intermetallic in the Sn-Zn lead-free solder[J]. Intermetallics, 2010, 18(4): 730-735.

[19] ZURUZI A S, CHIU C H, LAHIRI S K, TU K N. Roughness evolution of Cu6Sn5 intermetallic during soldering[J]. Journal of Applied Physics, 1999, 86(9): 4916-4921.

[20] 袁晓光, 刘彦学, 王怡嵩, 黄宏军. 镁合金表面冷喷涂铝合金的界面扩散行为[J]. 焊接学报, 2007, 28(11): 9-12.

YUAN Xiao-guang, LIU Yan-xue, WANG Yi-song, HUANG Hong-jun. Influence of heat treatment on interfacial diffusion of Al alloy cold spraying coating on magnesium alloy[J]. Transactions of the China Welding Institution, 2007, 28(11): 9-12.

[21] SHANG J K, YAO D. Effect of interface roughness on fatigue crack growth in Sn-Pb solder joints[J]. Journal of Electronic Packaging, 1996, 18(3): 170-173.

[22] ZURUZI A S, CHIU C H, CHEN W T, LAHIRI S K, TU K N. Interdiffusion of high-Sn/high-Pb (SnPb) solders in low-temperature flip chip joints during reflow[J]. Applied Physics Letters, 1999, 75(23): 3635-3637.

[23] YU D Q, WANG L. The growth and roughness evolution of intermetallic compounds of Sn-Ag-Cu/Cu interface during soldering reaction[J]. Journal of Alloys and Compounds, 2008, 458(1/2): 542-547.

(编辑 李艳红)

基金项目:重庆市自然科学基金资助项目(CSTC 2007BB4111);重庆大学大型仪器设备开放基金资助项目(2010063010)

收稿日期:2011-03-07;修订日期:2011-07-20

通信作者:盛光敏,教授,博士;电话:15923026226;E-mail: msheng@cqu.edu.cn