Electrical characteristics and microstructures of

Pr6O11-doped Bi4Ti3O12 thin films

CHEN Min(陈 敏)1, 2, HUANG Ke-long(黄可龙)2, MEI Xiao-an(梅孝安)1,

HUANG Chong-qing(黄重庆)1, LIU Jing(刘 靖)1, CAI An-hui(蔡安辉)3

1. Department of Physics, Hunan Institute of Science and Technology, Yueyang 414000, China;

2. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

3. Powder Metallurgy Research Institute, Central South University, Changsha 410083, China

Received 9 January 2008; accepted 5 May 2008

Abstract: Pr6O11-doped bismuth titanate (BixPryTi3O12, BPT) thin films with random orientation were fabricated on Pt/Ti/SiO2/Si substrates by rf magnetron sputtering technique, and the structures and ferroelectric properties of the films were investigated. XRD studies indicate that all of BPT films consist of single phase of a bismuth-layered structure with well-developed rod-like grains. For samples with y=0.06 , 0.3, 1.2 and 1.5, I—E characteristics exhibit negative differential resistance behaviors and their ferroelectric hysteresis loops are characterized by large leakage current. Whereas for samples with y=0.6 and 0.9, I—E characteristics are of simple ohmic behaviors and their ferroelectric hysteresis loops are saturated and undistorted. The remanent polarization (Pr) and coercive field (Ec) of the BPT Film with y=0.9 are above 35 μC/cm2 and 80 kV/cm, respectively.

Key words: ferroelectric; film; bismuth titanate; doping

1 Introduction

Bismuth titanate layered perovskite films have received much attention because of their potential for technological applications[1-3]. Bismuth titanate, Bi4Ti3O12 (BIT), is a typical ferroelectric material with the spontaneous polarization lying on the a-c plane at about 4.5? to the a-axis and exhibiting two independently reversible components of approximate magnitude of 4 μC/cm2 along the c-axis and 50 μC/cm2 along the a-axis [2]. Generally, the formula of doped bismuth titanate is (Bi2O2)2+(Am–1BmO3m+1)2–, where A means mono-, di-, or trivalent ions, or a mixture of them; B means quadri- or quinquevalence ions, such as Ti4+, Nb5+, Ta5+; and m means integer number (>1). The electrical conductivity, dielectric and optical properties of many doped (Sr, Nb, W, etc) bismuth titanate perovskites based on Bi4Ti3O12 compound have been studied[4-6]. In 1999, PARK et al[2] first reported that ferroelectric lanthanum- substituted bismuth titanate (Bi3.25La0.75Ti3O12) thin films by pulsed laser deposition exhibited a fatigue-free characteristic after 3×1010 read/write cycles. Therefore, this material is considered as a promising candidate for non-volatile memory devices. They suggested that the fatigue-free characteristics of Bi3.25La0.75Ti3O12 thin films resulted from some Bi ions being substituted near the Ti-O octahedron layers by La ions, and that there was some room for improvement by varying the amount of La substitutes, or by substituting other rare-earth ions. Recently, these kinds of materials doped with rare earth elements attract much attention for a large remnant polarization and fatigue-free characteristic[1-3, 6-8]. In order to obtain better properties, a lot of works about Bi4Ti3O12 doped with the rare earth elements such as La, Pr, and Sm have been reported[9-12]. However, the effects of Bi ions substituted by rare earth ions have not been clarified. The authors of this article first reported the work about Bi4Ti3O12 doped with Pr6O11 and the results indicated that the substitution of Pr ion for Bi ion can much improve the ferroelectric properties of Bi4Ti3O12 ceramics[13]. Praseodymium as another rare earth element may be a good additive of Bi4Ti3O12. In the present work, Pr6O11-doped Bi4Ti3O12 thin films were fabricated with rf magnetron sputtering technique, and their structures and electrical properties were studied in details.

2 Experimental

BixPryTi3O12 (y=0.06-1.5) targets were prepared by solid-state reaction of mixture of Bi2O3 (99.9%), Pr6O11 (99.95%) and TiO2 (99.9%) powders. Raw materials of targets were mixed by ball milling with agate balls and ethanol for 24 h. The powders with binder addition were pressed into discs of 50 mm in diameter and about 4 mm in thickness at a pressure of 120 MPa. The discs were sintered at 1 100 ℃ for 2 h in air, and furnace-cooled to room temperature. BPT thin films (about 400-500 nm in thickness) were grown on Pt/Ti/SiO2/Si substrates by rf magnetron sputtering technique. The deposition temperature and ambient oxygen pressure were optimized to be 400 ℃ and 20 Pa, respectively. The as- grown thin films were annealed for 1 h in an oxygen atmosphere at 650 ℃. For electrical measurements, the Pt electrodes of 100 nm were deposited onto BPT films at 400 ℃ through a shadow mask on an area of 2×10-4 cm2. The phase constitutions were characterized by Rigaku X-ray diffractometer (D/MAX-RB) with Cu Kα radiation. The surface morphology was observed by Scanning Electron Microscope (SEM) (JEOL JSM- 6300). The ferroelectric hysteresis loops and the leakage current were measured with the Radiant RT66A Unit. The current—voltage characteristics were measured by means of a dc power supply and a digital multimeter controlled by a computer.

3 Results and discussion

3.1 Microstructures of BPT films

Fig.1 shows XRD patterns of BPT films annealed at 650 ℃. XRD studies indicate that all of the BPT films consist of single phase of a bismuth-layered structure

Fig.1 XRD patterns of BPT films annealed at 650 ℃

showing a highly (117) oriented preferential growth with a minor fraction of (00l) orientation. The results show that Pr-doping does not affect the crystal orientation of the BIT film. According to these results, it is possible to think that the Bi-layered structure is always maintained in BPT and rather insensitive to the amount of Pr. The Bi-layered perovskite structure of BIT can be maintained for such high amount of Pr-doping because the radii of Bi and Pr are very close and some Bi ions are only substituted near Ti-O octahedron layers by Pr ions.

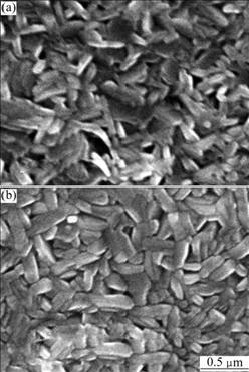

The SEM images of surface morphology of BPT films with y=0.3 and 0.9 annealed at 650 ℃ are shown in Fig.2. The images indicate that the BPT films consist of well-developed rod-like grains with random orientation. The average length and diameter of the grains of the film with y=0.9 are about 350 nm and 150 nm, respectively. This implies that the film with y=0.9 promotes bismuth titanate grain growth greater than the film with y=0.3.

Fig.2 SEM micrographs of BPT films with y=0.3 (a) and y= 0.9(b)

3.2 Ferroelectric properties of BPT films

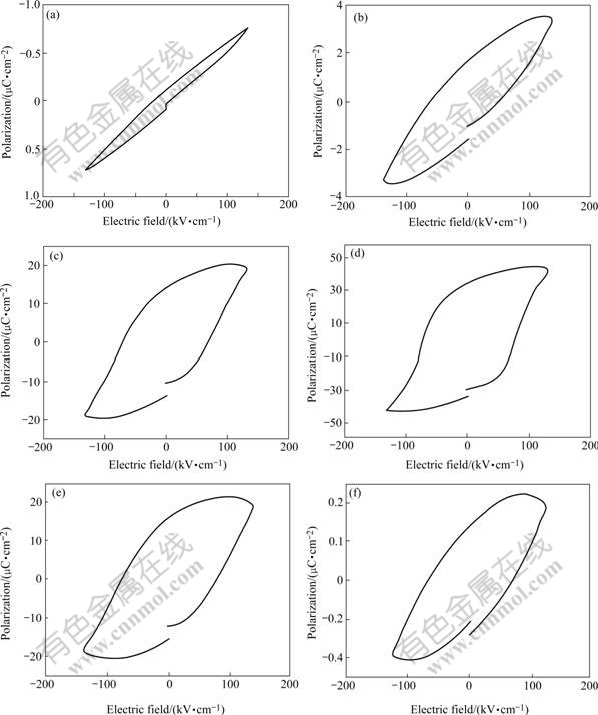

The P—E hysteresis loops of BPT (y=0.06-1.5) films at room temperature are shown in Fig.3. Hysteresis loops of BPT films with y≤0.3 and y≥1.2 are distorted due to leakage current. With y value increasing, the remanent polarization and coercive field of films with y≤0.9 increase, whereas for films with y>0.9, the remanent polarization and coercive field decrease. Well- saturated loops are measured in BPT films with y= 0.6, 0.9. The Pr and the Ec values of the BPT film with y=0.9 are 35 μC/cm2 and 80 kV/cm, respectively. Without controlling the crystal orientation, the Pr of the polycrystalline BPT film with y=0.9 can exceed 35 μC/cm2, much larger than that of the BLT film[2] and comparable to that of the BNTV film[14]. Meanwhile, the Ec is remarkably lower than that of the BNTV film (about 150 kV/cm)[14] and comparable to that of the BLT films[2]. Thus, the BPT film with large Pr and low Ec seems to be more suitable for application as ferroelectric random access memoer(FRAM). The Bi2.9Pr0.9Ti3O12 ceramic prepared by LIU et al[13] showed that the remanent polarization and the coercive were 26 μC/cm2 and 52 kV/cm, respectively. The differences of ferroelectric properties between Pr-doped film and ceramic might originate from the difference of microstructure.

Fig.3 P—E hysteresis loops of BixPryTi3O12 films: (a)y=0.06; (b)y=0.3; (c) y=0.6; (d) y=0.9; (e) y=1.2; (f) y=1.5

NOGUCHI and MIYAYAMA[15], UCHIDA et al[14] discussed the possible origin of good ferroelectric properties of the BTV ceramics and the BNTV films, respectively. They pointed out that V5+ ions substitution for Ti4+ ions caused a decrease in Bi3+ ions content (Bi3+vacancies increasing), and inhibited the generation of oxygen vacancies. However, in the present work, Pr doping is designed to substitute for Bi3+ ions rather than for Ti4+ ions, and the equation of composition is Bi2.9Pr0.9Ti3O12 according to the charge neutrality condition. It is known that the valence of Pr ion is 3+ and 4+, respectively, and Pr6O11 can be divided into two parts by

Pr6O11→Pr2O3+4PrO2 (1)

Three Pr4+ ions should be companied by four Bi3+ vacancies if Pr substituted only for Bi3+ ions. Therefore, it is indicated that Pr4+ ions substitution for Bi3+ ions efficiently suppresses the generation of oxygen vacancies, similar to V5+ ions doping into BIT[14-15], Pr3+ ions substitution for Bi3+ ions, and La3+ and Nd3+ ions doping into BIT[3, 7-16]. Both Pr3+ ions substitution and Pr4+ ions substitution for Bi3+ ions are effective to derive enough ferroelectricity by efficient decrease in space charge density caused by Bi3+-site substitution. This speculation is consistent with experimental results. In fact, the Pr doping into BIT draws out a much larger Pr than that of non-doped BIT and leads to a marked improvement in leakage current properties for BPT films with y=0.6 and 0.9. These experimental results imply that the Pr doping into BIT leads to an efficient decrease in space charge density.

3.3 I—E characteristics of BPT films

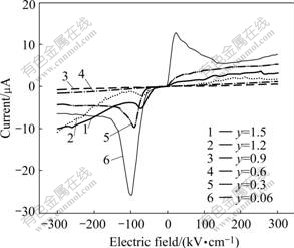

Fig.4 shows current—voltage (I—E) characteristics of BixPryTi3O12 samples. In the same region of applied electric field, the current values of samples with y=0.6 and 0.9 are about 1-2 order of magnitude lower than those of the samples with y=0.06, 0.3, 1.2, and 1.5. The I—E curve of the sample with y=0.06 is not entirely symmetric with the direction of applied field and exhibits current peaks near -100 and 23 kV/cm, so called the voltage-controlled negative differential resistance (VNDR) behavior. I—E curves of samples with y=0.3, 1.2, and 1.5 are asymmetric with the direction of applied field. Near -90, -70, and -65 kV/cm, the samples with y=0.3, 1.2, and 1.5 also exhibit current peaks, respectively, which are lower and broader than those of y=0.06 sample. Both y=0.6 and 0.9 samples exhibit linear current—voltage behavior, as shown in Fig.4.

The voltage-controlled negative differential resistance(VNDR) behavior has been observed in many material systems, such as electroformed metal-insulator- metal(MIM) thin film sandwich structures, amorphous semiconductors and semiconductor quantum devices, and some electrical models have been suggested[16]. The VNDR of the film with y=0.06 can be explained based on the thermal model of filamentary conductivity[16]. Clearly, The I—E curve of the sample y=0.06 is not symmetric when the direction of the applied field is reversed because of polarization response. However, it is difficult to use conducting filamentary model [16] to describe the VNDR of films with y=0.3, 1.2 and 1.5 because it is asymmetric related to the direction of applied field. It is noticed that I—E curves of samples with y=0.3, 1.2 and 1.5 show linear character provided that the current peaks vanish. Therefore, assuming that the conducting filaments exist in these Pr-doped samples and are of characteristic of rectifying like a p-n junction, the VNDR appearing asymmetrically in these I—E curves can be explained. For applied positive field, the conducting filaments manifest high resistance, and the ohmic conductivity controls the I—E characteristics. For negative field, the conducting filaments have low resistance because of their rectifying characteristics and the current increases quickly with the electric field increasing. The larger the current is, the greater the heat effect appears. The conducting filaments are ruptured progressively due to thermal processes, resulting in an eventual decrease in current, then a current peak appears. Once all conducting filaments are ruptured, the I—E characteristic shows ohmic conductivity, that is, a linear behavior. This implies that the origin of conducting filaments should be due to the local structural change caused by Pr doping.

Fig.4 I—E curves of BixPryTi3O12 films

4 Conclusions

1) Pr-doping does not affect the crystal orientation of Bi4Ti3O12film. Experimental results reveal that all of BPT films consist of single phase of a bismuth-layered structure and well-developed rod-like grains with random orientation.

2) Pr-doping results in dramatic improvement in ferroelectric properties of Bi4Ti3O12 film. The remanent polarization and coercive field of the BixPryTi3O12 Film with y=0.9 are above 35 μC/cm2 and 80 kV/cm, respectively. The improvement of ferroelectric properties of Bi4Ti3O12 film is due to both Pr3+ ions and Pr4+ ions simultaneous substitution for Bi3+ ions.

3) For BixPryTi3O12 films with y=0.06 , 0.3, 1.2, and 1.5, I—E characteristics exhibit negative differential resistance behaviors and their ferroelectric hysteresis loops are characterized by large leakage current, whereas for samples with y=0.6 and 0.9, I—E characteristics show simple ohmic behaviors and their ferroelectric hysteresis loops are saturated and undistorted.

References

[1] SCOTT J F. Application of modern ferroelectrics [J]. Science, 2007, 315: 954-959

[2] PARK B H, KANG B S, BU S D, NOH T W, LEE L, JOE W. Lanthanum-substituted bismuth titanate for use in non-volatile memories [J]. Nature, 1999, 401: 682-684.

[3] LEE H N, HESSE D, ZAKHAROV H, GOSELE U. Ferroelectric Bi3.25La0.75Ti3O12 films of uniform a-axis orientation on silicon substrates [J]. Science, 2002, 296: 2006-2009.

[4] CHEN S Y, LAN B C, TASO C S. Effect of titanium substitution on film structure and ferroelectric properties of Sr-deficient Sr0.75bi2.35Ta2O9 thin films [J]. Thin solid films, 2002, 422: 186-192.

[5] BAO Z H, YAO Y Y, ZHU J S, ZHU J S, WANG Y N. Study on ferroelectric and dielectric properties of niobium doped Bi4Ti3O12 ceramics and thin films prepared by PLD method [J]. Materials Letters, 2002, 56: 861-866.

[6] WANG W, ZHU J, MAO X Y. Properties of tungsten-doped Bi4Ti3O12-Sr Bi4Ti4O15 intergrowth ferroelectrics [J]. Mater Res Bull, 2007, 42: 274-280.

[7] SIMOES A Z, QUINELATO C, RIES A, STOJANOVIC B D. Preparation of lanthanum doped Bi4Ti3O12 ceramics by the polymeric precursor method [J]. Mater Chemistry and Phys, 2006, 98: 481-485.

[8] CHANG Y C, KUO D H. The improvement in ferroelectric performance of (Bi3.15Nd0.85) 4Ti3O12 films by the addition of hydrogen peroxide in a spin-coating solution [J]. Thin Solid Films, 2006, 515: 1683-1687

[9] WU D, LI A D, MING N B. Dielectric characterization of Bi3.25La0.75Ti3O12 thin films [J]. Appl Phys Lett, 2004, 84: 4505-4507.

[10] CHEN M, LIU Z L, WANG Y, YAO K L. Ferroelectric properties of Sm-doped Bi4Ti3O12 thin films [J]. Phys Stat Sol (a), 2005, 202(6): 1166-1171.

[11] CHON U, KIM K B, JANG H M, YI G. Fatigue-free samarium-modified bismuth titanate (Bi4-xSmxTi3O12) film capacitors having large spontaneous polarizations [J]. Appl Phys Lette, 2001, 79(19): 3137-3139.

[12] CHEN M, SUN Y H, SU K L, CHEN S, WAN Z M. Dielectric characterization and microstructures of Pr6O11-doped Bi4Ti3O12 [J]. Key Engineering Materials, 2007, 336: 155-157.

[13] LIU Z L, WANG C C, CHEN M, WANG Y, YAO K L. Effects of Pr6O11 doping on the microstructures and properties of Bi4Ti3O12 ferroelectric ceramics [J]. Mater Lett, 2004, 58: 3648-3651.

[14] UCHIDA H, YOSHIKAWA H, OKADA I, MATSUDA H, LIJIMA T, WATANABE T, KOJIMA T, FUNAKUBO H. Approach for enhanced polarization of polycrystalline bismuth titanate films by Nd3+/V5+ cosubstitution [J]. Appl Phys Lett, 2002, 81: 2229-2231.

[15] NOGUCHI Y, MIYAYAMA M. Large remanent of polarization of vanadium-doped Bi4Ti3O12[J] Appl Phys Lett, 2001, 78: 1903-1905.

[16] CHEN M, WANG Y, LIU Z L, DONG L, YANG X S. YAO K L. Electrical characteristics and microstructures of Sm2O3-doped Bi4Ti3O12 [J]. Chin Phys Lett, 2004, 21(9): 1811-1814.

Foundation item: Project (50774034) supported by the National Natural Science Foundation of China; Project (06JJ20005) supported by the Natural Science Foundation of Hunan Province, China; Project (05A055) supported by the Educational Science Foundation of Hunan Province, China

Corresponding author: CHEN Min; Tel: +86-730-8646505; E-mail: chenmin581215@yahoo.com.cn

DOI: 10.1016/S1003-6326(08)60241-1

(Edited by YANG Bing)