Effects of heat treatment on microstructure of directionally solidified Ti-45Al-8Nb-(W, B, Y) alloy

DING Xian-fei, LIN Jun-pin, ZHANG Lai-qi, CHEN Guo-liang

State Key Laboratory for Advanced Metals and Materials,

University of Science and Technology Beijing, Beijing 100083, China

Received 31 December 2009; accepted 27 April 2010

Abstract: The effects of heat treatments on typical microstructures of directionally solidified (DS) Ti-45Al-8Nb-(W, B, Y) (molar fraction, %) alloys prepared by the Bridgeman method were studied. Two typical DS microstructures including full lamellae with cellular growth morphology and massive structure with dendritic growth morphology were examined. The results show that the heat treatment of 1250 °C for 24 h + 900 °C for 30 min+air cooling can efficiently eliminate the B2 phase in the DS alloys and change the massive structure of the rapid DS alloy into lamellar microstructure. Columnar lamellar colonies with widths of 150-200 μm and 50-100 μm respectively were observed in intercellular and dendritic arm regions. The heat treatment of 1 400 °C for 12 h+900 °C for 30 min+air cooling could simultaneously remove the B2 phase, massive structure and solidification segregations from the DS alloys, however, it caused severe growth of grains.

Key words: TiAl alloy; directional solidification; heat treatment; microstructure; segregation

1 Introduction

High Nb containing TiAl alloy is one of the most potential materials for lightweight high-temperature structural applications due to its excellent strength, oxidation resistance and creep properties at elevated temperature[1-3]. However, poor room temperature ductility and fracture toughness restrict its further applications on turbine engines and aerial materials[4]. Directional solidification (DS) technique can efficiently promote its room temperature applications by developing the preferential property with better combination of yield stress and ductility. Previous studies showed that two favorable microstructures of TiAl alloys are expected to be achieved by the DS technique, one is polysynthetic twinned crystals (PST) with the lamellar orientation aligned parallel to the tensile axis[5-7], which is usually achieved by using a seeding technique and difficult to be controlled; the other microstructure consists of columnar grains with full lamellae[8], which amends the off-axis properties of the PST crystal and can be achieved without any seed. The second microstructure is more available in practice of engineering. Nevertheless, influenced by the peritectic solidification and subsequent solid-state transformations during DS process, heat treatment is a necessary step to adjust the microstructure of the DS alloy.

High concentration of β-formation elements such as Nb can result in the appearance of β-segregation in DS microstructure as well as in the conventional as-cast microstructure[9]. It is indicated that elongated B2 (ordered β phase) particles can also appear in the intercellular or interdendritic regions[10-11]. B2 phase contained in the TiAl alloys is known to be detrimental to the tensile ductility[12]. In order to improve the ductility of the DS alloy, B2 phase and other unfavorable factors such as massive structure created by a rapid DS process and various segregations should be eliminated from the DS microstructure. Fortunately, proper heat treatment is an efficient way to solve the problems.

This work gives a preliminary study on the effects of heat treatment on the microstructure of a DS Ti-45Al-8Nb-(W,B,Y) (molar fraction, %) alloy. Two regimes of heat treatment were examined on the typical DS microstructures with cellular and dendritic morphologies, respectively. The microstructural changes in the grain structure and the segregation were discussed.

2 Experimental

The DS alloy bars with chemical composition of Ti-45.27Al-7.89Nb-(W, B, Y) (molar fraction, %) with dimensions of d 6.5 mm×100 mm were prepared by the Bridgman furnace under the condition of GL=3.8×103 K/m. In order to achieve columnar structures, DS bars with columnar growth morphology were selected. Two bars with growth morphology of cell at a growth rate (v) of 20 μm/s and two bars with dendritic morphology at a growth rate of 200 μm/s were examined. These DS bars were sectioned transversely in the middle and the back-halves of them were cut longitudinally. One quarter of each bar was sealed into quartz tubes under the protection of high-purity argon.

Recent studies[13-14] of the heat treatments for as-cast Ti-45Al-8Nb-(W, B, Y) alloys showed that after heat treatment of 1250 °C for 24 h+900 °C for 30 min + air cooling (HT1), B2 phase can be completely eliminated from the as-cast microstructure, furthermore, both B2 phase and Al-segregation can be removed after heat treatment of 1 400 °C for 12 h+900 °C for 30 min + air cooling (HT2), Lamellar microstructures were eventually achieved after HT1 and HT2. So heat treatment regimes of HT1 and HT2 are chosen and experimented separately on the microstructure of the DS alloys.

After heat treatments, the alloys were taken out and consequently processed by grinding and polishing for standard metallographic investigations with another quarter of bar. Microstructure analyses were conducted with field emission scanning electron microscopy (FEM) employing back-scattered electron (BSE) imaging. Compositions of various microstructural constituents were determined by energy dispersive analysis (EDS) using an EDS analyzer equipped to the FEM. After being etched in a solution of 5%HF+10%HNO3+85%H2O (volume fraction), an optical microscope (OM) was used to characterize the microstructure.

3 Results

3.1 Original microstructure before heat treatment

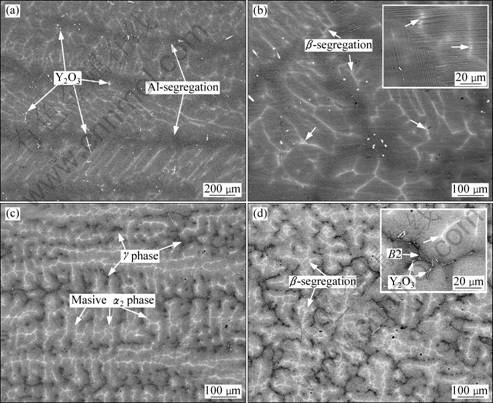

Figs.1(a)-(d) show the microstructures of the DS Ti-45Al-8Nb-(W, B, Y) bars at growth rates of 20 and 200 μm/s, respectively. The insert images show the high-magnitude microstructures. The growth direction is from left to right in longitudinal sections (the same to Fig.2 and Fig.3). The growth morphologies of cell and dendrite are clearly recognized separately. Few Y2O3 particles are formed irregularly and exhibit white contrast in BSE images in Figs.1(a) and (d). These particles dropped into the melt during DS process due to

Fig.1 BSE images of DS Ti-45Al-8Nb-(W, B, Y) bars: (a) Longitudinal section, v=20 μm/s; (b) Transversal section, v=20 μm/s; (c) Longitudinal section, v=200 μm/s; (d) Transversal section, v=200 μm/s

the thermal impact and convection applied to the crucible coated by yttria. Dark grey regions show Al-segregations where Al is rejected by primary β phase. Majority of β-segregation exists in the cellular or dendritic regions with collateral shape at both growth rates (Figs.1(b) and (d)), some elongated B2 particles appear in the interdendritic regions (Fig.1(d)). At a growth rate of 20 μm/s, fully lamellar microstructure with a mean interlamellar spacing of 1-2 μm is observed. Massive α2 and γ phases are found in dendrite and interdendritic regions, respectively, at the growth rate of 200 μm/s (Figs.1(c) and (d)).

3.2 Microstructure after heat treatment

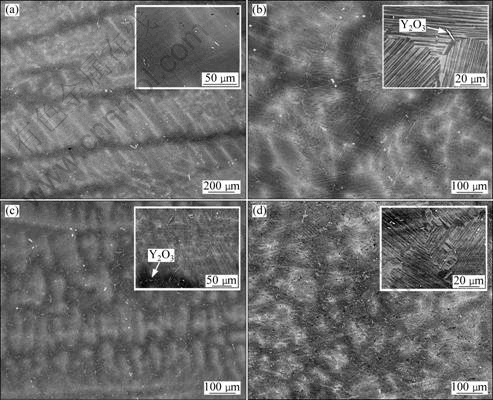

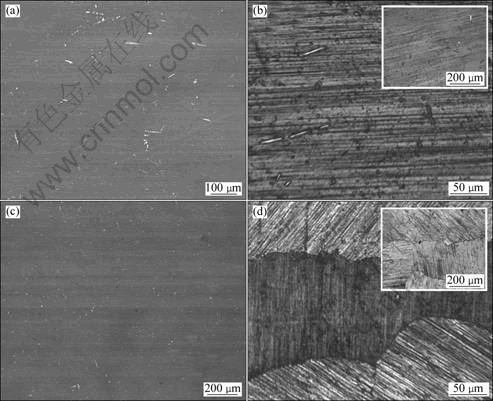

Figs.2 and 3 show the BSE and optical images after heat treatments of HT1 and HT2, respectively. From the BSE images, it is found that Y2O3 particles cannot be dissolved or eliminated by the heat treatments, so further study on the improvement of crucible or coating technology should be conducted necessarily in order to decrease the impurity of the DS alloy.

Figs.2(a) and (c) show that the white segregations with collaterals shape diffuse obviously, but the dark grey regions of Al-segregation do not change at all. High-magnitude images of transversal sections in Figs.2(b) and (d) clearly show that B2 phase completely dissolves into the α2-lath with lamellar structure and makes it coarse even to a shape of small block at grain boundaries. Massive α2 and γ phases in the rapid DS alloy are all substituted by lamellar structures as shown in Figs.2(c) and (d), and the orientation of the lamella is not changed when it goes across the Al-segregation region. The mean interlamellar spacing increases to about 2 μm, just a little higher than that before the heat treatment HT1. The columnar grains are found covering the intercellular regions or appearing at the centers of the dendritic regions, and their widths can reach to 150-200 μm and 50-100 μm, respectively.

BSE images in Fig.3 show that homogenous microstructures except for some Y2O3 particles are all achieved after HT2 is applied on both slow and rapid DS alloys (Figs.3(a) and (c)). Lamellar boundary is hard to be identified in BSE images, but it is easy to be observed in OM images (Figs.3(b) and (d)). The pictures and inserts respectively show the optical microstructures of the longitudinal and transversal sections. Long time exploration at high temperature results in the growth of grains apparently. The microstructure with more coarse columnar grains in the slow DS alloy changes into structure with an aligned orientation. That is to say, the width of a grain is up to the diameter of the bar. The interlamellar spacing is about 3-5 μm. However, the heat treated rapid DS alloy has a lamellar microstructure with coarse and irregular columnar grains, the width and

Fig.2 BSE images of heat treated DS Ti-45Al-8Nb-(W, B, Y) bars after HT1: (a) Longitudinal section, v=20 μm/s; (b) Transversal section, v=20 μm/s; (c) Longitudinal section, v=200 μm/s; (d) Transversal section, v=200 μm/s

Fig.3 Microstructures of heat treated DS Ti-45Al-8Nb-(W, B, Y) bars after HT2: (a) BSE image of longitudinal section, v=20 μm/s; (b) OM image, v=20 μm/s; (c) BSE image of longitudinal section, v=200 μm/s; (d) OM image, v=200 μm/s

interlamellar spacing of which are about 200 and 2 μm, respectively.

4 Discussion

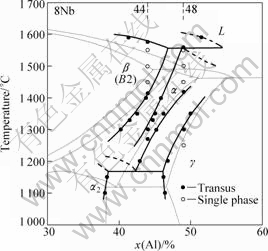

The heat treatment HT1 is located in the solid phase region of α+γ where the temperature is between the points of eutectoid and α-transformed (tα=1 335 °C). Fig.4 shows the 8Nb-TiAl (molar fraction, %) quasi-phase diagram[15]. Heating provides energy to improve the diffusion rate of W and Nb atoms. Thus, these elements can overcome the activation barrier to decompose the metastable β phase. But the diffusion of Nb and W elements just occurs around β phase at the highest temperature of HT1, as shown in Fig.2. After HT1, B2 phase was efficiently eliminated from both the intercellular/interdendritic regions and the cellular/ dendritic arms regions. Dissolving of B2 is followed by the discharging of Ti and Nb and the absorbing of Al, which results in the growing up of α2-lath and reducing of γ-lath, and even makes the α2-lath into a small block of α2 phase. More coarse α2-lath is directly precipitated from the region with high concentration of Ti and Nb when HT1 is applied on the rapid DS alloy.

At the edge of cell/dendrite or in intercellular/ interdendritic region, Al-segregation appears during DS

Fig.4 8Nb-TiAl quasi-phase diagram[15]

process and consequently induces α-leading solidification, which induces the formation of γ phase directly solidified from the liquid if the cooling rate is high enough. Because α-leading solidification has a wide range of composition, all connected melt in this range will be theoretically solidified into the uniform orientated α phase, and eventually transformed to the aligned lamellar (γ+α2) microstructure with the orientation relationship  The orientation of α phase cannot change during HT1, so the orientation of lamellar boundary cannot change. In the cellular region, β-leading solidification results in growth and existence of a few grains with different lamellar orientations. After the heat treatment of HT1, these grains emerge together into larger lamellar colonies. Coarse α2-lath and small block of α2 promote the generation of grain boundaries. In the dendritic region of the rapid DS alloy, columnar grains with aligned lamellar orientation can be achieved. Peritectic reaction and transformation take place in the outer area of the region whereas the solid-state transformation of β→α occurs in the inner area during DS process. Therefore, the lamellar colonies with different orientations form after HT1.

The orientation of α phase cannot change during HT1, so the orientation of lamellar boundary cannot change. In the cellular region, β-leading solidification results in growth and existence of a few grains with different lamellar orientations. After the heat treatment of HT1, these grains emerge together into larger lamellar colonies. Coarse α2-lath and small block of α2 promote the generation of grain boundaries. In the dendritic region of the rapid DS alloy, columnar grains with aligned lamellar orientation can be achieved. Peritectic reaction and transformation take place in the outer area of the region whereas the solid-state transformation of β→α occurs in the inner area during DS process. Therefore, the lamellar colonies with different orientations form after HT1.

The highest temperature of heat treatment HT2 is above α-transformed point (Fig.4). In order to ensure the B2 phase is not recreated after HT2, the heated temperature must not reach the solid phase region of α+β. All elements segregations were eliminated by diffusion, so that the lath boundary in lamellar structure can be hardly identified in BSE images but can be seen clearly in the OM images.

Resulted from non-equilibrium solidification, more Al-segregation occurs in the interdendritic or intercellular regions at higher growth rate during the DS process. During the heat treatment of HT2, high temperature α phase merges into a bigger one, and the holding time at α phase region greatly affects the size of lamellar colonies. For the DS alloy with growth rate of 200 μm/s, the composition range of interdendritic region changes from γ-leading to β-leading solidification by the diffusion of Al. Different orientations of α phases in dendritic and interdendritic region result in different lamellar orientations eventually, then microstructure with inhomogeneous coarse columnar grains is obtained after HT2. In the DS alloy with growth rate of 20 μm/s, the composition variations in cellular and intercellular regions are all through out the α phase region. Long time holding at this temperature provides a chance of forming a combined α phase and consequently transforms to aligned lamellar microstructure, which is greatly distinguished from the result of heat treatment HT2 applied on the as-cast alloy[12], microstructure consisting of equiaxed grains is achieved. One reason is probably that, the DS alloy with cellular growth morphology has a homogeneous composition along the growth direction and slight transversal composition fluctuations, which can be completely eliminated after the heat treatment of HT2. A combined α phase at high temperature could be formed and even transform into a single crystal, which potentially gives a way to fabricate PST crystals of TiAl alloys.

In a word, the HT1 heat treatment can dissolve B2 phase in the DS high Nb-containing TiAl alloys and change the massive structure into the lamellar microstructure. Columnar grains with different sizes are observed in different locations of the growth morphology. The HT2 heat treatment can simultaneously remove the B2 phase, massive microstructure and solidification segregations from the DS alloys. Coarse column-grains and even a single crystal are observed in the microstructures of heat treated DS alloys.

5 Conclusions

1) By means of the heat treatment of 1 250 °C for 24 h+900 °C for 30 min+air cooling, B2 phase in DS Ti-45Al-8Nb-(W, B, Y) alloy was efficiently eliminated, and the massive structure of rapid DS alloy also transformed into lamellar microstructure. Columnar structures with width of 150-200 μm and 50-100 μm were achieved in intercellular and dendritic arm regions, respectively. The dissolving of B2 results in the coarsening of α2-lath and eventually the tendency to initiate grain boundaries.

2) By means of the heat treatment of 1 400 °C for 12 h+900 °C for 30 min+air cooling, the B2 phase, massive structure and solidification segregations were simultaneously removed, but the grains with severe growth was observed. Microstructure with inhomogeneous and coarse column-grains was obtained after the heat treatment applied on the rapid DS alloy with dendritic growth morphology. A single crystal with a uniform lamellar orientation was even achieved after the heat treatment applied to the DS alloy with cellular growth morphology.

References

[1] LIN Jun-pin, XU Xiang-jun, WANG Yan-li, GAO Jing-feng, LIN Zhi, CHEN Guo-liang. Effect of forging on microstructure and tensile properties of Ti-45Al-(8-9)Nb-(W,B,Y) alloy [J]. Journal of Alloys and Compounds, 2006, 414(1-2): 175-180.

[2] CHEN G L, LIU Z C, LIN J P, ZHANG W J. Strengthening mechanism in high Nb containing TiAl base alloys [C]//HEMKER K J. Structural Intermetallics 2001. Jackson Hole, WY, USA: TMS- Miner Metals & Mater Soc, 2001: 475-481.

[3] YOSHIHARA M, MIURA K. Effects of Nb addition on oxidation behavior of TiAl [J]. Intermetallics, 1995, 3(5): 357-363.

[4] XU X J, LIN J P, WANG Y L, GAO J F, LIN Z, CHEN G L. Microstructure and tensile properties of as-cast Ti-45Al-(8-9)Nb-(W, B, Y) alloy [J]. Journal of Alloys and Compounds, 2006, 414(1-2): 131-136.

[5] GUPTA A, WIEZOREK J M. Microstructural evolution of PST-TiAl during low-rate compressive micro-straining at 1 023 K in hard and soft orientations [J]. Intermetallics, 2003, 11(6): 589-600.

[6] ASAI T, HIRATA S, TAKEYAMA M, MATSUO T. Microstructure in Ti-48at.%Al PST crystal subjected to creep deformation [J] Mater Sci Eng A, 2002, 329: 828-834.

[7] ZHANG Yong-gang, HAN Ya-fang, CHEN Guo-liang. Intermetallic compound structural material [M]. Beijing: Defense Industry Publishing House, 2001: 716-719. (in Chinese)

[8] JOHNSON D R, CHIHARA K, INUI H, YAMAGUCHI M. Microstructural control of TiAl-Mo-B alloys by directional solidification [J]. Acta Materialia, 1998, 46(18): 6529-6540.

[9] CHEN G L, XU X J, TENG Z K, WANG Y L, LIN J P. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale [J]. Intermetallics, 2007, 15(5-6): 625-631.

[10] KIM J H, KIM S W, LEE H N, OH M H, IUI H; WEE D M. Effects of Si and C additions on the thermal stability of directionally solidified TiAl-Nb alloys [J]. Intermetallics, 2005, 13(10): 1038-1047.

[11] JUNG I S, JANG H S, OH M H, LEE J H, WEE D M. Microstructure control of TiAl alloys containing β stabilizers by directional solidification [J]. Materials Science and Engineering A, 2002, 329-331: 13-18.

[12] LEE H N, JOHNSON D R, INUI H, OH M H, WEE D M, YAMAGUCHI M. Microstructural control through seeding and directional solidification of TiAl alloys containing Mo and C [J]. Acta Mater, 2000, 48(12): 3221-3233.

[13] XU Zheng-fang, XU Xiang-jun, LIN Jun-pin, ZHANG Yong, WANG Yan-li, LIN Zhi, CHEN Guo-liang. Effect of heat treatment on S-segregation of microstructure for as-cast high Nb containing TiAl alloy [J]. Journal of Aeronautical Materials, 2007, 27(3): 28-32. (in Chinese)

[14] XU Zheng-fang, XU Xiang-jun, LIN Jun-pin, ZHANG Yong, WANG Yan-li, LIN Zhi, CHEN Guo-liang. Elimination of β phase segregation in as-cast high Nb containing TiAl alloy by heat treatment [J]. Journal of Materials Engineering, 2007, 9: 42-46. (in Chinese)

[15] CHEN G L, ZHANG W J, LIU Z C, LI S J, KIM Y W. Microstructure and properties of high-Nb containing TiAl-base alloys [C]//KIM Y W. Gamma Titanium Aluminides 1999. San Diego, CA, USA: TMS- Miner Metals & Mater Soc, 1999: 371-380.

[16] YAMAGUCHI M, JOHNSON D R, LEE H N, INUI H. Directional solidification of TiAl-base alloys [J]. Intermetallics, 2000, 8(5-6): 511-517.

热处理对定向凝固Ti-45Al-8Nb-(W, B, Y)合金组织的影响

丁贤飞,林均品,张来启,陈国良

北京科技大学 新金属材料国家重点实验室,北京 100083

摘 要:研究两种热处理制度对Bridgeman法制备的典型定向凝固Ti-45Al-8Nb-(W,B,Y)(摩尔分数,%)合金组织的影响。两种典型的定向凝固显微组织分别为胞状生长形貌全片层组织和枝晶状生长形貌块状组织,对其热处理发现:热处理1 250 °C,24 h+900 °C,30 min+AC能有效消除其定向凝固合金中的B2相,并将快速定向凝固时产生的块状组织转变为片层组织,在胞状间及枝晶臂上分别获得了宽度为150-200 μm和50-100 μm的柱状晶。热处理1 400 °C,2 h+900 °C,30 min+AC能同时消除B2相、块状组织及凝固偏析,但造成了晶粒的严重长大。热处理能有效改进定向凝固合金的显微组织。

关键词:TiAl合金;定向凝固;热处理;显微组织;偏析

(Edited by FANG Jing-hua)

Foundation item: Projects(50771013, 50871127) supported by the National Natural Science Foundation of China

Corresponding author: LIN Jun-pin; Tel: +86-10-62332192; Fax: +86-10-62333447; E-mail: linjunpin@skl.ustb.edu.cn

DOI: 10.1016/S1003-6326(11)60673-0