Mechanical and electrical properties of In-Bi solder at Bi2212 superconductor interface with annealed Ag spray layers and Ag precoating layers

Seung-Yong SHIN, Ji-Hyun LEE, Hai-Woong PARK

Department of Materials Engineering, Korea University of Technology and Education (KUT),

Chunan, 330-708, Korea

Received 18 June 2008; accepted 10 March 2009

Abstract: The electrical properties of solder contact layers between Cu-Ni shunt metal and tube type Bi2212 superconductor that is applied in superconducting fault current limiter were studied. The contact properties of the solders are improved not only by Ag precoating layers, but also by the pre-sprayed Ag layer and subsequent Ag precoating layers. The annealed Ag sprayed layers onto Bi2212 superconductor prior to Ag electroplating work as protecting layers for the superconductor from plating solutions. The contact angle of the electroplated Ag layer is 42.91? and decreases to 15.25? and 5.88? with Ag sprayed layer and additional Ag electroplated layers. The Ag sprayed layer with suitable annealing prior to Ag electroplating improves contact strength of the Ag electroplated layer by about 12% due to denser microstructure of the Ag electroplated layers.

Key words: SFCL; Bi2212; Ag electroplating; Ag spray process

1 Introduction

Since the discovery of superconductors, various industrial applications have been developed using a superconducting bulk materials. In particular, BSCCO superconducting tube is considered as an appropriate material for superconducting fault current limiter(SFCL), which is utilized in an electrical power application for protection of power grid[1-2]. As the demand for power has increased recently, additional generators and power grids are required to be inserted in power distribution and transmission systems [3].

As SFCL, the jointing technology between super- conductor and shunt metal is very crucial. The joint area should have good contact properties at the interface between superconductor and shunt metal to maintain good electrical properties. In this perspective, In-Bi solder is one of the good representatives as the lead-free solder which has a low processing temperature of 110- 120 ℃[4-6].

In the case of the joint formation between ceramic-type superconductor and metal, the contact strength can be improved by applying metallic precoating layers on the superconductor substrate. Metallic layer between the solder and the substrate is known to raise the wettability of the solder and thus increase the joining strength[7-9].

In this study, Bi2212 superconductor substrate was either directly electroplated by metallic Ag or sprayed by Ag suspended liquid prior to metallic Ag electroplating. The coated substrates were annealed at different temperatures and then followed by In-Bi soldering. The aim of the present work is to investigate the effects of different metallic Ag coating processes and annealing temperatures of Ag precoating layer on the contact properties of the In-Bi solder with Bi2212 superconductor.

2 Experimental

The powders of the Bi2212 superconductor were mixed by ball-milling. The mixed powders were compacted at static pressure of 4.83 MPa by press. They were formed in size of 20 mm×5 mm. The specimens were then compacted by CIP (Cold Isostatic Press) to increase their density and sintered at 840 ℃ for 8 h in oxygen environment.

Metallic Ag was coated on the surface of Bi2212 superconductor by electroplating. In the electroplating system, 99.95% Ag plates were used as the anode and Bi2212 specimens were used as the cathode. The electrolyte solution was continuously stirred by magnetic stirrer to keep uniform concentration of the solution and was held at 30 ℃. The Bi2212 specimens were electro- plated by Ag prior to In-Bi soldering.

In this work, silver particles were made in the distilled water with stainless plates cathode and Ag plates anode by electrolysis method. The nano scale oxide or hydroxide silver in the solution was to react as an ionic condition which results in better connectivity.

Fig.1 shows the schematic diagrams of the interfaces for the multi-layered superconductor solder contact. Ag layers were formed by either electroplating technique or spray process.

Fig.1 Schematic diagrams of interface of Ag precoating layer and Ag spray process layer

The pretreated specimens were soldered by In-33.7Bi. The qualities of the soldering joints of the specimens were evaluated by the shear strength and the microstructures at the interface between the shunt metals and the superconductor substrate. Fig.2 shows the specially designed zig for shear strength test of the solder contact between superconductor pellets. Universal testing machine(UTM) and specially designed holder were used to measure the shear strength.

Fig.2 Schematic diagram and picture of shear strength test

The microstructures of the electroplated surface between Bi2212 and In-Bi solder were examined by SEM. The obtained shear strength values were correlated with the microstructure of the specimens.

3 Result and discussion

In this study, two sets of experiments were conducted to study the effects of metallic precoating layers on the joint properties of In-Bi solder with Bi2212 superconductor. The annealing effects of Ag electroplated precoating layers were investigated and the effects of Ag sprayed layers prior to Ag electroplating on the contact properties were also evaluated. The annealing effects were evaluated with annealing temperatures.

3.1 Effects of Ag sprayed layers

In order to study the effects of sprayed Ag layers prior to Ag electroplating on the contact properties, 3 sets of experiments were conducted. The Bi2212 superconductors were coated with Ag by 1) electro- plating process, 2) spraying process, and 3) spraying followed by Ag electroplating process. The Ag coated samples were annealed at 250 ℃ for 2 h in air environment and then furnace cooled.

Fig.3 shows the SEM microstructures of the annealed Ag layers coated by electroplating process, spraying process and both spraying and electroplating processes. In the case of Ag spraying process, the suspended Ag nano particles were uniformly distributed throughout the sample. As seen in Fig.3(c), the electroplated Ag layer surface with prior sprayed Ag layers showed more dense structure and better connected grains than the sprayed or electroplated Ag layer (Fig.3(a)).

Fig.3 SEM microstructures of annealed Ag coating layers: (a) Electroplated Ag layer; (b) Sprayed Ag layer; (c) Sprayed followed by electroplated Ag layers

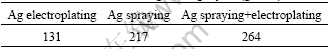

After Ag electroplating, the peel tests were conducted to compare the contact properties of each Ag precoating layers. Table 1 shows the peel test results of Ag electroplated samples. The contact strength of the Ag precoating layer with Ag sprayed layer was about 2 times that of single Ag electroplating layer. This contact property increase was due to finer coating microstructure by Ag sprayed layers.

Table 1 Peel test values for Ag coating layers (g/mm2)

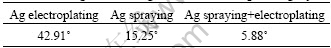

The contact angles on the Ag coated surface were measured in order to compare the wettability of the coating layers. Table 2 shows the measured contact angles for the Ag coating layers prepared by 3 different processes. The contact angle for the sample sprayed by Ag suspended liquid and then electroplated by Ag decreased to 5.88? from 42.91? of Ag electroplated surface. This sharp decrease of contact angle is directly related to the improvement of the wettability of Ag coating layer.

Table 2 Average contact angles at surface of Ag coating layers

Table 3 shows the shear strength of the Ag coated pellets prepared by 3 different Ag coating processes. The shear strength for the sample having 2 different Ag coating layers increased by 29% compared with that of the single Ag electroplated sample. This result indicated that the Ag spray process by suspended nano-scale Ag particles prior to Ag electroplating is more effective to have good contact properties than the single Ag electroplating process.

Table 3 Shear strength of Ag coating layers

3.2 Annealing effects of Ag precoating layers

In order to study the annealing effects on the contact properties of Ag coating layers, the Bi2212 superconductor pellets were coated by spraying of Ag suspended liquid followed by electroplating of metallic Ag. The precoated Ag layers on Bi2212 samples were annealed at 250 ℃ or 700 ℃ for 2 h in air environment and then furnace cooled.

Fig.4 shows the SEM microstructures of the Ag layers annealed at 250 ℃ and 700 ℃, respectively. In the case of 700 ℃ sample shown in Fig.4(b), the surface microstructure is more denser and finer than that of 200 ℃ annealed case. The denser surface of Ag coating layer at higher annealing temperature can give better grain connectivity and thus leads to better coating properties.

Fig.4 SEM microstructures of annealed Ag surface layers coated by spraying process followed by electroplating process: (a) 250 ℃; (b) 750 ℃

The qualities of the soldering joints of the specimens were evaluated by the shear strength at the interface between the shunt metal and the Bi2212 sample. The superconductor surface was pretreated by Ag spraying/electroplating followed by annealing at different temperatures. Then the specimens were soldered by In-33.7Bi. The shear strength of the sample annealed at 700 ℃ is 6.12 MPa, which is 12% higher than that of the sample annealed at 250 ℃ (5.46 MPa).

4 Conclusions

The contact properties of the solder joints between Bi2212 superconductor pretreated with Ag coating layers and shunt metal were evaluated. In the peel test for the Ag coated layers, the Ag electroplated layer on the Ag sprayed layer showed about 2 times of peel resistance value that of the single Ag electroplated layer. This peel resistance increase is due to the finer coating microstructure for the sample prepared by Ag spraying and then by Ag electroplating.

The shear strength of the sample having 2 different Ag coating layers showed 29% increase compared with that of the single Ag electroplated sample. This strength increase is attributed to the wettability improvement for the sprayed Ag layer which showed contact angle decrease from 42.91? to 15.25?.

The annealing process for Ag sprayed sample improved surface density. As the annealing temperature increased from 200 ℃ to 700 ℃, the surface microstructure became denser and finer. The improvement of the surface density gives better grain connectivity and thus leads to better coating properties.

References

[1] OH S Y, KIM H R, JEONG Y H, HYUN O B, KIM C J. Effects of heat-treatment on critical current of BSCCO-2212 superconductor [J]. Physica C, 2007, 463/465: 464-467.

[2] CHEN M, PAUL W, LAKNER M, DONZEL L, HOIDIS M, UNTERNAEHRER P, WEDER R, MENDIK M. 6.4 MVA resitive fault current limiter based on Bi-2212 superconductor [J]. Physica C, 2002, 372: 1657-1663.

[3] HODGE J D, MULLER H, APPLEGATE D S, HUANG Q. A resistive fault current limiter based on high temperature superconductors [J]. Applied Superconductivity, 1995, 3: 469-482.

[4] LEE H Y. Lead-free solder alloys [J]. J Korean Int Surf Eng, 2002, 35: 218-231.

[5] LEE C C, CHOE S. Fluxless In-Sn bonding process at 140 ℃ [J]. Materials Science and Engineering A, 2002, 333: 45-50.

[6] CHUANG R W, LEE C C. High-temperature non-eutectic indium-tin joints fabricated by a fluxless process [J]. Thin Solid Films, 2002, 414: 175-179.

[7] YAMAMOTO N, IMAIZUMI T, SAWA K, TOMITA M, MURAKAMI M, HIRABAYASHI I. Contact characteristics for bulk superconductors [J]. Physica C, 2004, 412/414: 662-667.

[8] CHANG T C, HSU Y T, HON M, WANG M C. Enhancement of the wettability and solder joint reliability at the Sn-9Zn-0.5Ag lead-free solder alloy—Cu interface by Ag precoating [J]. J Alloys and Compounds, 2003, 360: 217-224.

[9] UELTZEN M, MARTINEK I, SYROWATKA F, FLOEGEL-DELOR U, RIEDEL T. Soldered Ohmic contacts to superconductors for high-current applications [J]. Physica C, 2002, 372/376: 1653-1656.

[10] JANG J H, KIM S H, SHIN S Y, LEE Y C, KIM C J, HYUN O B, PARK H W. Influence of Ag precoating of Bi2212 superconductor-In base solder soldering [J]. J Kor Inst Surf Eng, 2006, 39: 57-63.

[11] MURRAY J L, BENNETT L H, BAKER H. Binary alloy phase diagrams [M]. American Society for Metals, 1986: 34.

[12] LIN J, HUANG L W, JANG G Y, LEE S L. Solid–liquid interdiffusion bonding between In-coated silver thick films [J]. Solid Films, 2002, 410: 212-221.

[13] PARK D K, KIM Y J, AHN M C, YANG S E, SEOK B Y, KO T K. A study on the short-circuit test by fault angle control and the recovery characteristics of the fault current limiter using coated conductor [J]. Physica C, 2007, 463/465: 1188-1192.

[14] WEI Z L, TNAG D, O’KEEFE T. Nano-structured silver coating on copper prepared in an ethanol-based solution [J]. China Particuology, 2005, 3: 271-274.

[15] JANG J H, KIM C J, HYUN O B, PARK H W. Characterization of the interfacial properties between In-Bi solder and bulk Bi2212 with metallic precoating layers [J]. Physica C, 2007, 463/465: 455-459.

Corresponding author: Hai-Woong PARK; Tel/Fax: +82-41-560-1360; E-mail: hwpark@kut.ac.kr

DOI: 10.1016/S1003-6326(08)60386-6

(Edited by YUAN Sai-qian)