DOI: 10.11817/j.issn.1672-7207.2018.03.002

DH36高强度船板钢中碳化物及碳氮化物析出行为

石骁1, 2,吴建中1, 2,郭汉杰1, 2,郭靖1, 2,段生朝1, 2,杨文晟1, 2

(1. 北京科技大学 冶金与生态工程学院,北京,100083;

2. 高端金属材料特种熔炼与制备北京市重点实验室,北京,100083)

摘要:利用碳复型法通过透射电子显微镜研究工业级DH36高强度船板钢在控轧控冷工艺下纳米级碳化物和碳氮化物的析出行为,并针对钢液冷却过程分别对碳化物及氮化物的析出规律进行热力学计算。研究结果表明:钢中普遍存在的析出相为 (Nb,Ti)(C,N)碳氮化物和(Nb,Ti)C碳化物,均为FCC,NaCl型结构,其中(Nb,Ti)(C,N)基本呈立方形,(Nb,Ti)C大多由富Ti的“核”部和富Nb的“帽”部构成;析出粒子均为单相,其晶格常数随Ti与Nb物质的量比的变化而微弱变化;通过统计粒子粒径及分布规律,利用Orowan绕过机制计算得出此类钢中沉淀强化对屈服强度的贡献约为166 MPa;钢中第二相析出的先后顺序为TiN,TiC,NbC,NbN。

关键词:DH36;碳化物;碳氮化物;沉淀强化;析出热力学

中图分类号:TG142.41 文献标志码:A 文章编号:1672-7207(2018)03-0518-11

Precipitation behaviors of carbides and carbonitrides in DH36 high-strength ship plate steel

SHI Xiao1, 2, WU Jianzhong1, 2, GUO Hanjie1, 2, GUO Jing1, 2, DUAN Shengchao1, 2, YANG Wensheng1, 2

(1. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Beijing Key Laboratory of Special Melting and Preparation of High-End Metal Materials, Beijing 100083, China)

Abstract: To study the precipitation of nano-sized carbides and carbonitrides in technical grade DH36 high-strength ship plate steel during the thermomechanical controlled processes (TMCP), carbon replications of DH36 were explored through a transmission electron microscopy. And the precipitation of carbides and nitrides during the cooling process was further investigated thermodynamically. The results show that the common precipitated phases in steels are (Nb,Ti)C carbides and (Nb,Ti)(C,N) carbonitrides, both of which are face-centered cubic of NaCl structure. The (Nb,Ti)(C,N) carbonitrides are mostly cubic, and the (Nb,Ti)C carbides are mainly constituted by Ti rich core part and Nb rich cap part. The precipitates are single phase, and the lattice constant transforms slightly with the alteration of molar ratio of Ti to Nb. Through the statistics of particle size and distribution, a calculation based on Orowan mechanism shows that the precipitation hardening offers 166 MPa yielding strength increase. The precipitation sequence is as follows: TiN, TiC, NbC, NbN.

Key words: DH36; carbides; carbonitrides; precipitation hardening; precipitation thermodynamic

DH36级船板钢属于高强度船体结构用钢,具有强度高,低温冲击韧性佳,焊接性能良好等特点,在造船工业中应用广泛[1-2]。目前,国内外工业级高强度船板钢普遍采用控轧控冷和微合金化有机结合的方法细化铁素体晶粒并析出第二相粒子,以提高其力学性能,此条件下,钢的主要强韧化机制为固溶强化、细晶强化和沉淀强化[3]。在钢中加入Nb,Ti,V等微合金元素,其首要作用是产生溶质拖曳效应,在轧制过程中阻止奥氏体的再结晶行为,为非再结晶区轧制和控制冷却温度的组合过程提供一个很大的温度范围,高效地细化铁素体晶粒;与此同时,此类强碳化物形成元素与C,N结合析出的稳定细小第二相对奥氏体晶界运动具有强烈的阻碍作用,即Zener钉扎现象,不仅抑制了轧制时基体的再结晶行为,而且还能在焊接时有效防止热影响区的晶粒粗化;材料在应力作用下发生塑性变形时,其中的第二相粒子还与位错存在多种方式的交互作用,对位错的运动形成阻力从而产生强化效果,明显提高材料塑性变形时所需要的应力。上述3种微合金化效应均能对钢的强度、韧性、成型性等机械性能产生很大影响。文献[4-11]已经在实验室条件下对Nb,V,Ti,Mo,W,V-Ti,Nb-Ti,Nb-V-Ti等微合金体系析出第二相的晶体结构、取向关系、分布形态以及强化效应进行了报道,研究表明此类碳氮化物基本上具有NaCl型晶体结构,一般与铁素体的错配度低于奥氏体,通过Orowan机制计算,可提供200~400 MPa的屈服强度增量。对于工业级高强度船板钢而言,控轧控冷工艺和特定组织与性能之间的控制和优化关系已有国内外学者做了大量研究[12-16],但对此级别的船板钢在超低硫、氧的情况下,其中析出物的具体种类、大小以及强化作用的综合描述却鲜有报道。因此,本文作者研究了钢中纳米级析出物的晶体结构、晶格常数、物相组成、粒径以及分布形态,并计算了此类粒子产生沉淀强化对屈服强度的贡献值,为更好地控制热加工过程或加工后的第二相析出行为,最后分别对碳化物和氮化物的析出规律进行了热力学计算。

1 实验

工业级DH36高强度船板钢的生产普遍采用转炉冶炼,钢包精炼炉精炼,弧形连铸机浇注,铸坯装炉加热之后开坯并轧制。某钢厂的具体生产工艺流程为:铁水—1 300 t混铁炉—铁水脱硫—150 t转炉—105 t钢包精炼炉—1 600 mm×220 mm连铸机—板坯加热—四辊粗轧—四辊精轧控轧控冷—矫直—冷床—钢板检查—标记入库。

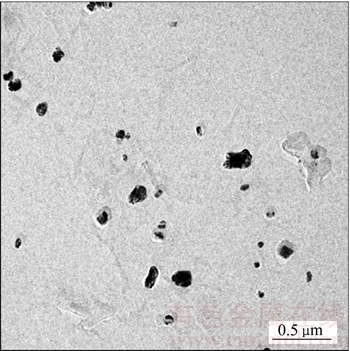

实验所用材料取自该厂厚度为30 mm的交货状态合格板材。用碳硫仪、氮氧仪和化学滴定法准确测定其化学成分,结果见表1。从表1可以看出:S质量分数比国标要求的0.015%降低了约70%,且在C质量分数为0.11%的情况下,全氧质量分数0.001 7%也属于极低水平,故该成分的DH36级船板钢可认为是洁净钢。在热力学方面,低硫、低氧含量可显著减少粗大析出相的平衡析出量,即降低其体积分数,从而减小对钢韧性的损害;在动力学方面,低硫和低氧还可以降低沉淀析出反应的驱动能,使平衡析出温度下降,实际析出温度越低,得到的析出相尺寸就越细小,从而产生更好的强化效果。

表1 DH36试验用钢的化学成分(质量分数)

Table 1 Chemical composition of experimental DH36 steel %

利用透射电子显微镜(TEM,FEI Tecnai F20)对碳萃取复型样品进行观察,并针对部分具有代表性的粒子进行选区电子衍射(SAED)和能谱(EDS)分析,以确定其晶体结构及成分元素的种类和含量。

碳复型法步骤为:将金相抛光试样在4%(体积分数)硝酸乙醇溶液中侵蚀,然后在真空条件下对侵蚀表面蒸镀一层30~40 nm的碳膜,用刀片划成边长为2 mm的正方形,把样品置于8%(体积分数)硝酸乙醇溶液中萃取,将萃取下来的碳膜在乙醇中反复清洗后放入去离子水中使其展开,用铜网捞取,干燥后即为透射电镜样品。

2 实验结果与分析

2.1 析出物的物相及组成

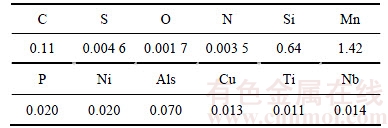

DH36钢中一类典型析出物如图1所示。由图1(a)和图1(d)可见:典型析出物呈较规则的立方体,粒径为100 nm左右,EDS谱显示为富Ti和Nb的碳氮化物,经衍射花样标定,析出物A和B均为 FCC,NaCl型结构,计算得出A的晶格常数a=b=c=0.428 nm,与TiN(a=b=c=0.424 nm)最为接近,半定量结果显示Ti与Nb物质的量比约为9:2;析出物B的晶格常数a=b=c=0.423 nm,也与TiN的符合程度最高,此时Ti/Nb物质的量比约为10:3。实际晶格常数与TiN产生偏差的原因主要有:一是结构中的空位所致;二是已有研究表明[17],具有相同点阵类型的MC或MN相之间可以完全相互固溶,包括金属元素间互溶和C,N元素的相互置换,故点阵常数会随成分的变化而改变。

图1 DH36钢中一类典型析出物

Fig. 1 A typical precipitation in DH36

在单一Ti微合金钢中,根据Ti与其他元素的结合能力,其化合物析出的先后顺序为Ti2O3,TiN,Ti4C2S2,TiC,一般Ti2O3和Ti4C2S2被分离到钢渣内,基体只存在TiN和TiC[18];在单一Nb微合金钢中,一般也只有NbN和NbC[19]。上述4种碳化物和氮化物的常见点阵结构均为FCC,NaCl型[20],结合EDS谱和Ti/Nb物质的量比进行分析,可以认为随着温度的降低,TiN发生相同点阵类型下Nb和C原子的置换行为,最终形成的是(Nb,Ti)(C,N)相。

从图1(b)和(e)可以看出:衍射斑点没有发生分裂,说明析出颗粒是含Nb,Ti,C,N的单一相,进一步证明了上述分析结果,即碳氮化物的形成因素是由于原子的置换而非多相机械混合。原子置换后,Ti与Nb物质的量比的变化会轻微影响(Nb,Ti)(C,N)的晶格常数。

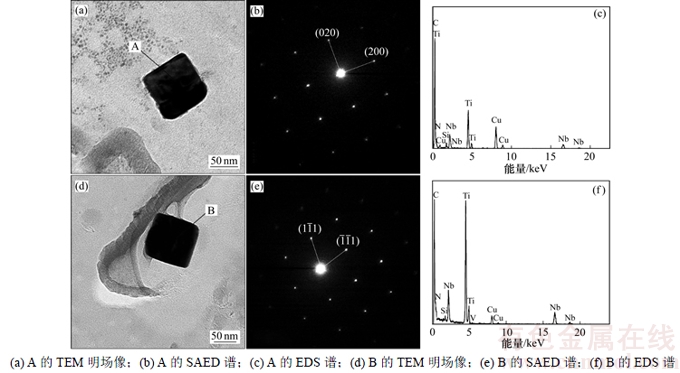

图2所示为TEM下的另一类典型析出物形貌。可见:此类析出物由“核”和“帽”2部分构成, EDS谱显示“核”部和“帽”部的Ti,Nb含量差别很大,而C含量的变化趋势并不显著,经EDS线扫描发现,“核”部的Ti含量明显比Nb的高,而“帽”部正好相反。中心部位的SAED标定结果显示,该物质为FCC,NaCl型结构,计算得出的晶格常数a=b=c=0.432 5 nm,最接近于TiC(a=b=c=0.433 0 nm)。

根据实验结果可以认为:初期首先析出了TiC,随着先析出核周围微区内Nb/Ti浓度比的升高,NbC以TiC边部为核心开始长大,整个过程始终伴随着Ti,Nb原子的置换行为,最终形成了“核”部富Ti、“帽”部富Nb的(Nb,Ti)C析出物。

一般来说,随着温度的降低,形核的全部自由能包括驱动力和能量势垒[5],驱动力源于过饱和溶质的化学自由能,而能量势垒来自形核界面处的界面能和晶格失配造成的应变能。图2(d)中选区衍射斑点的分裂程度十分微弱,说明“核”和“帽”之间存在着cube-cube的取向关系[21],即错配度很低的2个相同晶体结构具有相同的晶向指数和晶面指数,在该取向关系下,形核的应变能和界面能均降到最低[21-22],故富Nb的(Nb,Ti)C更倾向于在富Ti的(Nb,Ti)C核外附着生长。

图2 DH36钢中另一类典型析出物

Fig. 2 Another typical precipitation in DH36

2.2 析出物的分布和尺寸统计

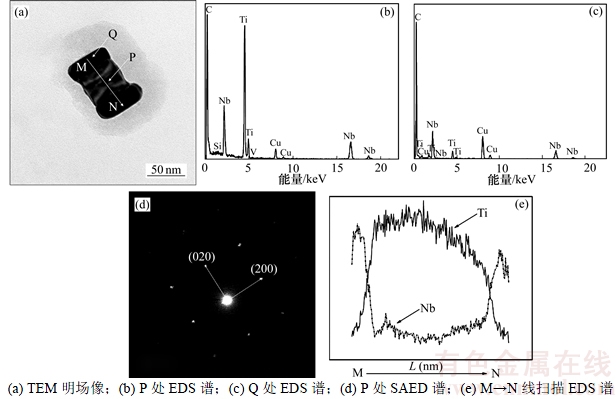

碳复型样品中析出物的分布情况如图3所示。从图3可以看出:尺寸较大的粒子主要呈线状排列分布,小尺寸粒子的分布较为弥散,这与文献[4]中在实验室条件下对Nb-Ti-V微合金HSLA钢应变诱导析出行为的观察结果相同。说明在控轧控冷工艺下,碳化物和碳氮化物优先沿奥氏体晶界形核长大,形成粒径稍大的第二相,随后在晶粒内部析出的粒子粒径较小。

图3 析出物分布

Fig. 3 Distribution of precipitate

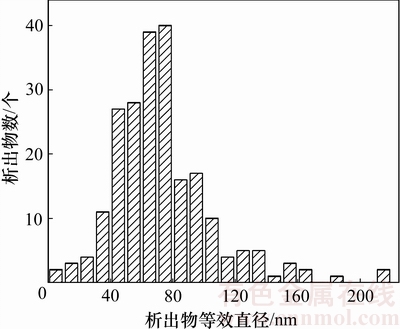

为使析出物的定量计算更精确,随机选取了上述2个不同视场下的明场像照片各15张,用Image-pro软件统计所有照片内的析出物等效直径和数量,结果如图4所示。

图4 析出物等效直径和数量情况统计

Fig. 4 Statistics on size and quantity of precipitates

由图4可知:钢中析出物数量随等效直径的增大整体上呈现出先增加后减少的趋势,约有85%的粒子等效直径在30~110 nm之间,平均等效直径为73.6 nm。在较高温度下的沉淀析出过程完成之后,会立即发生聚集长大,即Ostwald熟化过程,统计得出的整体尺寸变化规律基本符合根据Ostwald熟化理论导出的第二相尺寸稳态分布曲线[20]。

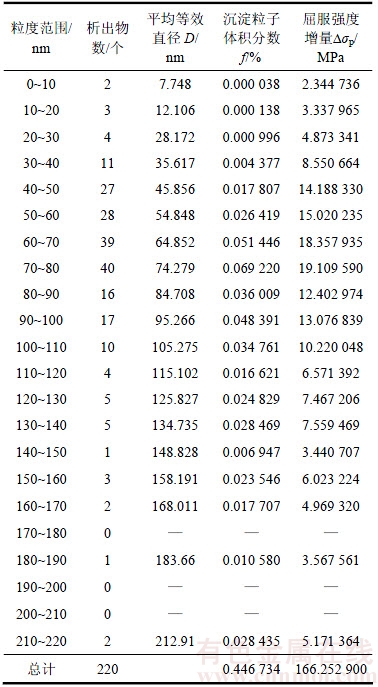

2.3 沉淀强化对屈服强度贡献的计算

金属材料在应力作用下发生塑性变形时,其中的第二相粒子与位错之间存在多种方式的交互作用,并对位错移动形成阻力从而产生强化效果,一般将粒子与位错的交互作用分成2种基本类型,产生不同的强化机制,即切割机制和绕过机制[22]。析出物直径d存在一个临界尺寸dc[20],当d<dc时,切割机制起主要作用;当d>dc时绕过机制占主导。计算表明,当第二相与铁基体的界面能为0.1~1 J/m2时,临界尺寸dc≈1.5~6.0 nm。由图4可知:实验钢中的析出物粒径基本全部大于10 nm,故主要以绕过机制产生沉淀强化效果。

绕过机制的计算采用Ashby-Orowan修正模型[22],析出物的强化增量可通过下式表示:

(1)

(1)

式中: 为屈服强度增量,MPa;i为第i个析出粒子,取值1~N;r为粒子半径,nm;

为屈服强度增量,MPa;i为第i个析出粒子,取值1~N;r为粒子半径,nm; 为剪切系数,对于铁素体取80.26×103 MPa;b为柏氏矢量,对室温下钢铁材料取2.48 nm;f为沉淀粒子的体积分数。

为剪切系数,对于铁素体取80.26×103 MPa;b为柏氏矢量,对室温下钢铁材料取2.48 nm;f为沉淀粒子的体积分数。

采用McCall-Boyd法[23-24]测定弥散型第二相粒子的体积分数,该方法要求在TEM照片上测量已知面积内每个析出物的直径,换算出所有析出物的平均直径,并明确粒子数目。McCall-Boyd法测体积分数由下式计算:

(2)

(2)

式中:A为选取视场的总面积,nm2;N为析出物数;D为析出物平均等效直径,nm。

文献[20]指出,不同尺寸范围析出相的强化增量,其总的强化效果可采用各粒度区间强度累加的方式进行计算。故利用式(1)和式(2)分别将各粒度区间内沉淀强化对屈服强度的贡献进行计算,结果如表2所示。

计算结果显示,DH36高强度船板钢中析出物以Orowan绕过机制产生的沉淀强化对屈服强度的理论贡献值约为166 MPa,占实际总屈服强度(403 MPa)的41%。

表2 不同粒度区间内析出物对屈服强度的贡献

Table 2 Contribution of size of precipitates to yield strength

3 析出热力学计算

根据2.1中的分析结果可知,DH36高强度船板钢中普遍存在的 (Nb,Ti)(C,N)和(Nb,Ti)C析出物是由于相同点阵类型下MN和MC相互固溶而形成的,故本文主要探讨固溶之前TiN,NbN,TiC和NbC化合物的析出热力学。

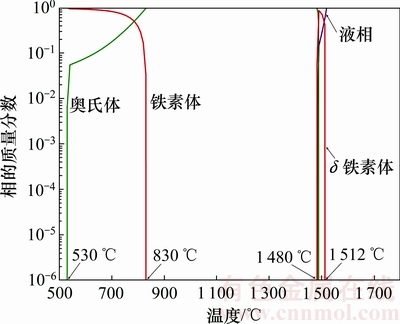

利用Thermo-Calc软件绘制DH36船板钢的平衡态相图见图5。由图5可知:钢液在1 512 ℃开始凝固,首先进入 铁素体区,在经历很小的温度区间到达1 480 ℃之后,液相和

铁素体区,在经历很小的温度区间到达1 480 ℃之后,液相和 铁素体全部转变为奥氏体,奥氏体存在的温度区间相对较大,当温度降至830 ℃时,开始向

铁素体全部转变为奥氏体,奥氏体存在的温度区间相对较大,当温度降至830 ℃时,开始向 铁素体转变。

铁素体转变。

图5 DH36船板钢平衡态相图

Fig. 5 Equilibrium phase diagram of DH36

根据表1中实验钢的化学成分,采用下式[25]计算得出液相线TL=1 786 K,固相线Ts=1 749 K,与Thermo-Calc软件计算结果基本一致。

(3)

(3)

(4)

(4)

式中:w为元素的质量浓度。

3.1 液相中热力学计算

由热力学原理可知,在钢液冷却过程中,碳化物、氮化物在其中的溶解度不断降低,当析出物生成元素的实际溶度积大于平衡溶度积时,发生析出反应。

查阅文献[26],可得到下列热力学数据:

,

, (5)

(5)

,

, (6)

(6)

,

, (7)

(7)

,

, (8)

(8)

其中:T为热力学温度,K; 为吉布斯自由能,J/mol。

为吉布斯自由能,J/mol。

在钢液中,金属元素E与非金属元素F反应生成 的析出反应式为:

的析出反应式为:

(9)

(9)

当反应(9)达到平衡时, ,E和F反应的吉布斯自由能

,E和F反应的吉布斯自由能 与反应平衡常数K的关系可表示为

与反应平衡常数K的关系可表示为

(10)

(10)

式中:R为气体常数;C1和C2为常数。平衡常数K又可表示为

(11)

(11)

式中: ,

, 和

和 分别为析出物

分别为析出物 ,E和F的活度;

,E和F的活度; 和

和 分别为钢液中E和F的质量分数,%;

分别为钢液中E和F的质量分数,%; 和

和 分别为E和F的活度系数。将式(11)代入式(10)可得:

分别为E和F的活度系数。将式(11)代入式(10)可得:

(12)

(12)

故 在钢液中的平衡溶度积可表示为

在钢液中的平衡溶度积可表示为

(13)

(13)

活度系数 和

和 与温度及钢液中各元素的相互作用系数有关。由于DH36船板钢属于高强度低合金(HSLA)钢,各溶质元素的质量分数趋近于0,溶剂

与温度及钢液中各元素的相互作用系数有关。由于DH36船板钢属于高强度低合金(HSLA)钢,各溶质元素的质量分数趋近于0,溶剂 趋近于1,此时二次相互作用系数对活度系数的影响极小,因此直接选用以一次相互作用系数表征的Wagner模型[27]进行计算,在该模型中,各溶质元素的活度系数可表示为

趋近于1,此时二次相互作用系数对活度系数的影响极小,因此直接选用以一次相互作用系数表征的Wagner模型[27]进行计算,在该模型中,各溶质元素的活度系数可表示为

(14)

(14)

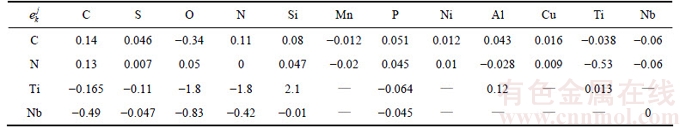

式中: 为溶质元素间的一次相互作用系数,k为多元相中任一溶质组元,j为2,3,…,n溶质组元。钢液中各元素对C,N,Ti和Nb的一次相互作用系数如表3[26]所示。

为溶质元素间的一次相互作用系数,k为多元相中任一溶质组元,j为2,3,…,n溶质组元。钢液中各元素对C,N,Ti和Nb的一次相互作用系数如表3[26]所示。

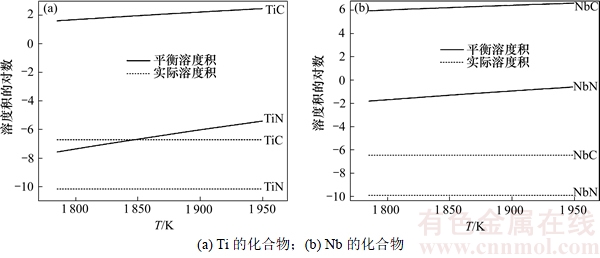

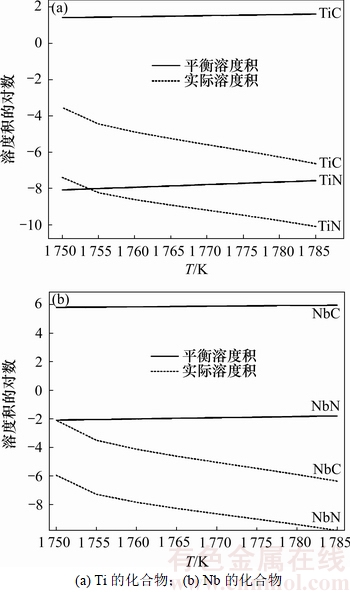

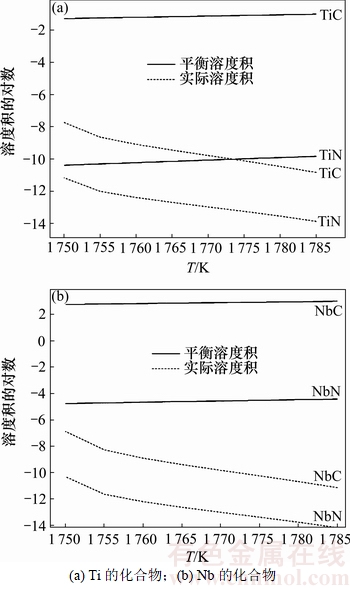

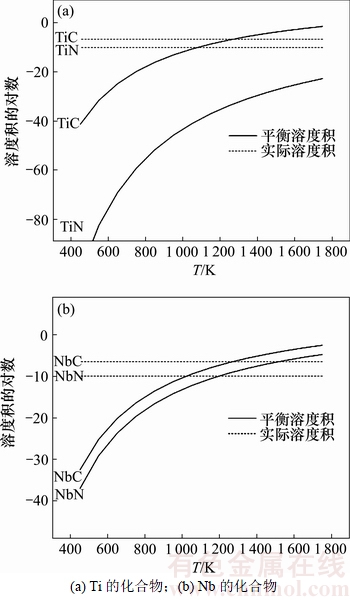

根据表3和式(14)计算得出活度系数fC=1.144 6,fN=1.031 2,fNb=0.833 5,fTi=0.926 7,代入式(13)即可得到钢液中TiN,NbN,TiC和NbC平衡溶度积的对数值,与实际溶度积的对数作图进行比较,结果如图6所示。

由图6可知:在液相线温度(1 786 K)以上时,Ti,Nb的碳化物和氮化物实际溶度积均小于平衡溶度积,未满足析出热力学条件,都不能析出。故在该成分的船板钢液相中,不会生成较大尺寸含Ti,Nb的碳化物或氮化物,这对钢的强度和韧性十分有利,既没有消耗合金元素使其转化为有害相,又没有增加大尺寸非金属夹杂的体积分数。

表3 DH36钢中各元素对C,N,Ti和Nb的一次相互作用系数

Table 3 Interaction factors of elements to C, N, Ti and Nb in DH36 steel

图6 DH36钢在液相中平衡溶度积和实际溶度积随温度的变化曲线

Fig. 6 Curves of equilibrium solubility product and actual solubility product to temperature in the liquid phase

3.2 凝固前沿热力学计算

当钢液开始向 铁素体转变时,会形成固-液两相区。碳化物和氮化物形成元素在凝固过程中产生正偏析,易在凝固前沿液相中富集,导致实际溶度积升高,析出概率增大,此时可假设固相中无扩散,液相均匀混合,固-液界面处于局部平衡状态,文献[28]给出在此条件下,非金属元素及金属元素含量可使用Scheil模型,即式(15)和(16)进行表示:

铁素体转变时,会形成固-液两相区。碳化物和氮化物形成元素在凝固过程中产生正偏析,易在凝固前沿液相中富集,导致实际溶度积升高,析出概率增大,此时可假设固相中无扩散,液相均匀混合,固-液界面处于局部平衡状态,文献[28]给出在此条件下,非金属元素及金属元素含量可使用Scheil模型,即式(15)和(16)进行表示:

(15)

(15)

(16)

(16)

式中: 和

和 分别为固液前沿液相中非金属元素F与金属元素E的质量分数;

分别为固液前沿液相中非金属元素F与金属元素E的质量分数; 和

和 分别为开始凝固时液相中E和F的质量分数,%;KE和 KF分别为E和F的平衡溶质分配系数,由文献[26]可知,在DH36船板钢的化学成分范围内,凝固过程中溶质元素C,N,Ti和Nb在

分别为开始凝固时液相中E和F的质量分数,%;KE和 KF分别为E和F的平衡溶质分配系数,由文献[26]可知,在DH36船板钢的化学成分范围内,凝固过程中溶质元素C,N,Ti和Nb在 铁素体区中的平衡分配系数分别为0.25,0.38,0.6和0.34;Ps为固相分率,其与温度的关系为

铁素体区中的平衡分配系数分别为0.25,0.38,0.6和0.34;Ps为固相分率,其与温度的关系为

(17)

(17)

式中:TF为凝固前沿温度,K;Tm为纯铁熔点,1 809 K;TL和Ts分别为钢的液相线和固相线温度,K。

根据式(15)和(16)计算得出凝固前沿液相中的实际溶度积,再与液相中的平衡溶度积(式(13))作图比较,可得到图7所示结果。

凝固前沿固相中的溶质含量根据Scheil模型[28],可用式(18)和(19)表示:

(18)

(18)

(19)

(19)

式中: 和

和 分别为固液前沿固相中非金属元素F与金属元素E的质量分数。

分别为固液前沿固相中非金属元素F与金属元素E的质量分数。

查阅文献[26]中相关热力学数据:

图7 DH36钢在固液前沿液相中平衡溶度积和实际溶度积随温度的变化曲线

Fig. 7 Curves of equilibrium solubility product and actual solubility product to temperature in liquid phase at solidification front

,

, (20)

(20)

,

, (21)

(21)

,

, (J/mol) (22)

(J/mol) (22)

,

, (J/mol) (23)

(J/mol) (23)

分别代入式(5)~(8),经计算可得:

,

, (24)

(24)

,

, (25)

(25)

,

, (26)

(26)

,

, (27)

(27)

由于碳化物和氮化物的形成元素易在凝固前沿液相中富集,故此时 铁素体相中的溶质含量很低,可认为符合亨利定律,采用1%标准态。根据式(24)~(27)计算得出凝固前沿

铁素体相中的溶质含量很低,可认为符合亨利定律,采用1%标准态。根据式(24)~(27)计算得出凝固前沿 铁素体相中的平衡溶度积,与实际溶度积(式(18)~(19))作图比较,结果如图8所示。

铁素体相中的平衡溶度积,与实际溶度积(式(18)~(19))作图比较,结果如图8所示。

图8 DH36钢在固液前沿固相中平衡溶度积和实际溶度积随温度的变化曲线

Fig. 8 Curves of equilibrium solubility product and actual solubility product to temperature in solid phase at solidification front

由图7和图8可知:当温度处于固-液两相区时,凝固前沿液相中TiN的平衡溶度积和实际溶度积曲线有交点产生,且随着温度的继续降低,实际溶度积开始大于平衡溶度积,具备了析出热力学条件,即该交点为TiN在固液两相区液相中的开始析出温度,通过交点的等式计算可以求出理论析出温度为1 753 K,该析出温度十分接近固相线温度(1 749 K),可以认为是由于凝固前沿钢液中溶质元素富集使局部N,Ti浓度上升,从而在两相区的液相中发生了析出行为,此类析出相的尺寸不会很大[29]。该计算结果与TEM下观察到的一类典型析出物相符,此类析出物点阵常数与TiN非常接近,由于在后续过程中伴随着相同点阵类型下Nb,C原子的置换行为,最终形成了(Nb,Ti)(C,N)相。而在凝固前沿的固相中始终没有发生析出行为。

3.3 固相中热力学计算

当钢液完全凝固后,由相图可知,液相和 铁素体几乎同时全部转变为奥氏体。由于碳化物和氮化物在奥氏体相中的溶解度非常小[25],故可认为熔体符合亨利定律,采用1%标准态,文献[30]直接给出了奥氏体相中的平衡溶度积,如式(28)~(31)所示。

铁素体几乎同时全部转变为奥氏体。由于碳化物和氮化物在奥氏体相中的溶解度非常小[25],故可认为熔体符合亨利定律,采用1%标准态,文献[30]直接给出了奥氏体相中的平衡溶度积,如式(28)~(31)所示。

(28)

(28)

,

,

(29)

(29)

,

,

(30)

(30)

,

,

(31)

(31)

将上述平衡溶度积与实际溶度积结果作图比较,可以判断在奥氏体中第二相的析出可能性,如图9所示。

由图9可知:当温度降至固相线以下进入奥氏体区后,Ti的碳化物和Nb的碳化物及氮化物先后开始析出,析出先后顺序为TiC,NbC,NbN,通过平衡溶度积与实际溶度积对数曲线在交点处的等式计算可以求出理论析出温度分别为1 270,1 267和1 196 K。

析出热力学的计算结果与2.1中的观察现象相互印证,由于TiC先于NbC析出,所以TiC作为先析出相形核,NbC以其为核心在边部附着长大。上述计算已经表明,TiN在同等环境下会首先析出,由于钢中N含量很低,优先生成(Nb,Ti)(C,N)的微小区域已经占用了大量N,故此类析出物的EDS谱未检测到明显的N元素,可以认为最终形成的是(Nb,Ti)C碳化物。最后,理论计算得出NbN的析出温度最低,但此时微区内的N元素几乎已被消耗完毕,微区外的N来不及扩散,所以形成NbN的概率很小,这也是在TEM观察中未能找到富Nb,N的碳氮化物的原因。

图9 DH36钢在固相中平衡溶度积和实际溶度积随温度的变化曲线

Fig. 9 Curves of equilibrium solubility product and actual solubility product to temperature in solid phase

4 结论

1) 工业级DH36高强度船板钢中普遍存在的纳米级碳化物和碳氮化物均为FCC,NaCl型结构,由于在形成过程中始终伴随着相同点阵类型下原子的置换行为,所以最终形成的是单相(Nb,Ti)C和(Nb,Ti)(C,N),其中(Nb,Ti)(C,N)富Ti,基本呈立方体,而富Nb的(Nb,Ti)C更倾向于在富Ti的(Nb,Ti)C核外附着生长,其晶格常数均随Ti与Nb物质的量比的变化而微弱变化。

2) 钢中碳化物和碳氮化物优先沿奥氏体晶界形核长大,随后在晶粒内部析出更加细小的粒子,析出物数量随粒径的增大整体上呈现出先增加后减少的趋势,约有85%的粒子粒径在30~110 nm之间,平均等效直径为73.6 nm;利用Orowan绕过机制估算得出,此类析出物产生沉淀强化对屈服强度的贡献约为166 MPa。

3) 在钢液冷却过程中,TiN在固液两相区的液相中首先析出,析出温度为1 753 K;在奥氏体内,NbC、TiC和NbN均发生了析出行为,析出先后顺序为 TiC(1 270 K),NbC(1 267 K),NbN(1 196 K)。

参考文献:

[1] DEARDO A J. An investigation of the mechanism of splitting which occurs in tensile specimens of high strength low alloy steels[J]. Metallurgical Transactions A, 1977, 8(3): 473-486.

[2] 岳峰, 包燕平, 崔衡, 等. BOF-LF/VD-CC工艺生产高级船板钢纯净度的研究[J]. 北京科技大学学报, 2007, 29(s1): 1-5.

YUE Feng, BAO Yanping, CUI Heng, et al. Study on pureness of high level ship plate produced by process of BOF-LF/VD- CC[J]. Journal of University of Science and Technology Beijing, 2007, 29(s1): 1-5.

[3] 王有铭. 钢材的控制轧制和控制冷却[M]. 北京: 冶金工业出版社, 1995: 1-20.

WANG Youming. Controlled rolling and controlled cooling of steel[M]. Beijing: Metallrugical Industry Press, 1995: 1-20.

[4] HONG S G, JUN H J, KANG K B, et al. Evolution of precipitates in the Nb-Ti-V microalloyed HSLA steels during reheating[J].Scripta Materialia, 2003, 48(8): 1201-1206.

[5] HONG S G, KANG K B, PARK C G. Strain-induced precipitation of NbC in Nb and Nb-Ti microalloyed HSLA steels[J]. Scripta Materialia,2002,46(2): 163-168.

[6] JANG J H, LEE C H, HEO Y U, et al. Stability of (Ti, M) C (M=Nb, V, Mo and W) carbide in steels using first-principles calculations[J]. Acta Materialia, 2012, 60(1): 208-217.

[7] YEN H W, CHEN P Y, HUANG C Y, et al. Interphase precipitation of nanometer-sized carbides in a titanium- molybdenum-bearing low-carbon steel[J]. Acta Materialia, 2011, 59(16): 6264-6274.

[8] YEN H W, CHEN C Y, WANG T Y, et al. Orientation relationship transition of nanometre sized interphase precipitated TiC carbides in Ti bearing steel[J]. Materials Science and Technology, 2010, 26(4): 421-430.

[9] 宁安刚, 毛文文, 郭汉杰, 等. H13钢淬火态碳化物的析出行为及沉淀强化[J]. 过程工程学报, 2014, 14(6): 1041-1046.

NING Angang, MAO Wenwen, GUO Hanjie, et al. Precipitation behaviors and strengthening of carbides in H13 steel during quenching[J]. The Chinese Journal of Process Engineering, 2014, 14(6): 1041-1046.

[10] 傅杰, 李光强, 于月光, 等. 基于纳米铁碳析出物的钢综合强化机理[J]. 中国工程科学, 2011, 13(1): 31-42.

FU Jie, LI Guangqiang, YU Yueguang, et al. Comprehensive strengthening mechanism of steel based on nano-scale cementite precipitates[J]. Engineering Sciences, 2011, 13(1): 31-42.

[11] 李小琳, 王昭东. 含Nb-Ti低碳微合金钢中纳米碳化物的相间析出行为[J]. 金属学报, 2015, 51(4): 417-424.

LI Xiaolin, WANG Zhaodong. Interphase precipitation behaviors of nanometer-sized carbides in a Nb-Ti-bearing low-carbon microalloyed steel[J]. Acta Metallurgica Sinica, 2015, 51(4): 417-424.

[12] PERELOMA E V, CRAWFORD B R, HODGSON P D. Strain-induced precipitation behaviour in hot rolled strip steel[J]. Materials Science & Engineering A, 2001, 299(1/2): 27-37.

[13] 李贞顺. 360MPa级船板钢的组织与性能研究[D]. 济南: 山东大学材料科学与工程学院, 2010: 10-11.

LI Zhenshun. Study on microstructure and property of 360 MPa grade ship plate steel[D]. Jinan: Shandong University. College of Material Science and Engineering, 2010: 10-11.

[14] CHOUDHARY S K, GHOSH A. Mathematical model for prediction of composition of inclusions formed during solidification of liquid steel[J]. ISIJ International, 2009, 49(12): 1891-1827.

[15] 桂赤斌. 高强度钢船体焊接工程技术[M]. 武汉: 湖北科学技术出版社, 2006: 21-52.

GUI Chibin. Welding engineering technology of high strength shipbuilding steel[M]. Wuhan: Hubei Science and Technology Press, 2006: 21-52.

[16] 张豪, 雷运涛, 魏金山. 高强度船体结构钢的现状与发展[J]. 钢结构, 2004, 19(2): 38-40.

ZHANG Hao, LEI Yuntao, WEI Jinshan. Present situation and development tendency of the high strength hull structure steel[J]. Steel Construction, 2004, 19(2): 38-40.

[17] VILLARS P. CALVERT L D. Pearson’s handbook of crystallographic data for intermetallic phases (B)[M]. OH: ASM, 1985: 265-269.

[18] LOU Yanzhi, LIU Delu, Ni Xiaoqin. Precipitates in steels with Ti additive produced by CSP process[J]. Journal of Iron and Steel Research, 2009, 16(4): 60-66.

[19] 徐洋. 钛微合金化钢中铁素体相变及纳米相析出行为与机理研究[D]. 沈阳: 东北大学材料与冶金学院, 2015: 2-12.

XU Yang. Study on ferrite transformation and nano-precipitation behaviors and mechanism of Ti micro-alloyed steel[D]. Shenyang: Northeastern University. College of Material and Metallurgy, 2015: 2-12.

[20] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社,2006: 90-107.

YONG Qilong. Secondary phases in steels[M]. Beijing: Metallurgical Industry Press, 2006: 90-107.

[21] ENOMOTO M. Nucleation of phase transformations at intragranular inclusions in steel[J]. Metals and Materials, 1998, 4(2): 115-123.

[22] 杨王玥, 强文江. 材料力学行为[M]. 北京: 化学工业出版社, 2009: 212-217.

YANG Wangyue, QIANG Wenjiang. Mechanical behavior of materials[M]. Beijing: Chemical industry Press, 2009: 212-217.

[23] 比里西阿G E, 浦迪S M. 体视学和定量金相学[M]. 孙惠林, 马继畲, 译. 北京: 机械工业出版社, 1980: 163-180.

PELLISSIER G E, PURDY S M. Stereological and quantitative metallography[M]. SUN Huilin, MA Jishe, trans. Beijing: China Machine Press, 1980: 163-180.

[24] 马红旭, 李友国. 硅钢中析出物的尺寸分布以及体积分数的测定[J]. 材料科学与工程, 2002, 20(3): 328-330.

MA Hongxu, LI Youguo. Measurement of size distribution and volume fraction of precipitates in silicon steel[J]. Materials Science & Engineering. 2002, 20(3): 328-330.

[25] 王家祈, 黄积荣. 金属的凝固及其控制[M]. 北京: 机械工业出版社, 1977: 9-35.

WANG Jiaqi, HUANG Jirong. Solidification of metal and its control[M]. Beijing: China Machine Press, 1977: 9-35.

[26] 陈家祥. 炼钢常用图表数据手册[M]. 北京: 冶金工业出版社, 2008: 741-761.

CHEN Jiaxiang. Manual of chart and data in common use of steel making[M]. Beijing: MetallurgicalIndustryPress. 2008: 741-761.

[27] 郭汉杰. 冶金物理化学教程[M], 北京: 冶金工业出版社, 2013: 171-176.

GUO Hamjie. Physical chemistry of metallurgy[M]. Beijing: MetallurgicalIndustryPress, 2013: 171-176.

[28] CLYNE T W, KURZ W. Solute redistribution during solidification with rapid solid state diffusion[J]. Metallurgical and Materials Transactions A, 1981, 12(6): 965-971.

[29] 傅杰, 朱剑, 迪林, 等. 微合金钢中TiN的析出规律研究[J]. 金属学报, 2000, 36(8): 801-804.

FU Jie, ZHU Jian, DI Lin, et al. Study on the precipitation behavior of TiN in the microalloyed steels[J]. Acta Metallurgica Sinica, 2000, 36(8): 801-804.

[30] RICHARDSON F D. The thermodynamics of metallurgical carbides and of carbon in iron[J]. Journal of the Iron and Steel Institute, 1953, 175(1): 33-51.

(编辑 赵俊)

收稿日期:2016-10-18;修回日期:2017-01-13

基金项目(Foundation item):国家自然科学基金资助项目(U1560203,51274031) (Projects(U1560203, 51274031) supported by the National Natural Science Foundation of China)

通信作者:郭汉杰,教授,博士生导师,从事冶金物理化学理论以及高端金属熔炼与制备新方法、新工艺等研究;E-mail: guohanjie@ustb.edu.cn