Ce元素对Mg-Gd-Y-Nd-Zr合金组织与热变形行为的影响

张新明1, 2,赵凤景1, 2,邓运来1, 2,唐昌平1, 2,张国义1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 教育部有色金属材料科学与工程重点实验室,湖南 长沙,410083)

摘要:采用Gleeble-1500D热模拟机,对Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr(x=0和0.2%,质量分数)合金进行热压缩变形实验(实验温度为375~525 ℃,应变速率为0.01、0.1和1 s-1,最大变形量为50%),并对合金的塑性变形行为以及变形后的组织进行研究。研究结果表明:合金在变形温度为375 ℃、应变速率为0.01 s-1条件下开始发生动态再结晶;随着变形温度的升高或应变速率的降低,再结晶体积分数逐渐增加,再结晶晶粒粒径逐渐变大;添加Ce元素可提高再结晶体积分数,减小再结晶晶粒粒径;固溶过程中出现的“椭球状”Mg12Ce粒子对再结晶有粒子激发形核(PSN)作用;这2种合金在375~525 ℃下的变形表观激活能分别为191和212 kJ/mol。

关键词:Mg-Gd-Y-Nd-Ce-Zr合金;热压缩变形;变形激活能;再结晶;粒子激发形核

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2012)03-0890-10

Effects of Ce addition on microstructures and hot deformation behaviors of Mg-Gd-Y-Nd-Zr alloy

ZHANG Xin-ming1, 2, ZHAO Feng-jing1, 2, Deng Yun-lai1, 2, TANG Chang-ping1, 2, ZHANG Guo-yi1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410012, China

Abstract: Simulation experiments of constant-strain-rate hot-compression for Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloys were carried out with the conditions of temperatures of 375-525 ℃, strain rates of 0.01, 0.1, 1 s-1 and a maximum deformation reduction of 50% by Gleeble-1500D thermal simulators. Then, its plastic deformation behavior and microstructures were investigated. The results indicate that the dynamic recrystallization starts to occur under the condition of 375 ℃ and strain rate of 0.01 s-1; and the volume fraction of recrystallization and recrystallized grain size increases gradually as the temperature increases or strain rate decreases. Addition of Ce increases the recrystallization volume fraction, and decreases the recrystallization grain size; the ellipsoidal Mg12Ce particles occurring during solution can accelerate recrystallization by the mechanism of particle stimulated nucleation(PSN). The apparent activation energy of two alloys at 375-525℃ are 191 and 212 kJ/mol, respectively.

Key words: Mg-Gd-Y-Nd-Ce-Zr alloy; hot-compression; activation energy; recrystallization; particle stimulated nucleation

镁合金是现有的最轻结构材料,具有密度低、比强度和比刚度高等优良特性,在结构件的应用中有很大的潜力[1]。但镁合金是密排六方金属,滑移系数目少,塑性变形能力差。细化晶粒可以有效地改善镁合金的塑性变形能力,提高镁合金的强度和延展性。目前主要采用大变形塑性加工工艺如等径角挤压方法[2]细化晶粒。利用等径角挤压法加工镁合金,能够在不改变样品横截面面积的同时使挤压材料承受很大的塑性变形,且挤压后的镁合金具有极小的晶粒结构和良好的力学性能[3]。但等径角挤压法也存在一些不足,如不能生产大粒径的细晶金属材料,生产效率低,成本高等[4]。因此,研究新的再结晶方法对镁合金研究非常重要。粒子激发形核(PSN)现象已经得到广泛研究。研究普遍认为,粒径超过1 μm且分布距离适中的硬粒子可以对再结晶产生粒子激发形核效应[5],通过粒子激发形核效应提高再结晶形核率,可减小再结晶的晶粒粒径,得到细小均匀的组织,提高合金的力学性能。Ce是一种有效的晶粒细化剂,添加Ce元素可以生成1种粒子,这种粒子可以促进热变形过程中的动态再结晶形核且抑制再结晶晶粒的长大[6]。目前,对AZ系列镁合金中添加Ce元素已有大量研究,但很少见到将Ce元素添加到Mg-Gd-Y-Zr合金中的研究,尤其是Ce元素对Mg-Gd-Y-Zr合金组织和热变形行为的影响尚未见报道。为此,本文作者主要研究Mg-5.5Gd-4.5Y-1Nd- xCe-1Zr(x=0和0.2%,质量分数) 2种合金(分别命名为A和B合金)的组织和高温塑性变形行为,以期通过添加Ce元素得到一种粒子,从而在热变形过程中产生PSN效应,得到细小均匀的晶粒组织,为改善变形镁合金的组织性能提供依据。

1 实验

实验材料采用自行熔炼的Mg-5.5Gd-4.5Y-1Nd- xCe-1Zr(x=0和0.2%,质量分数)合金。合金用电阻炉在铁坩埚里熔炼,熔炼过程中采用自制熔剂进行保护,Gd,Y,Nd,Ce和Zr分别以中间合金的形式加入。将样品在Gleeble-1500D热模拟机上进行热压缩试验,试样长×宽×高为10 mm×20 mm×25 mm,实验温度分别为375,425,475和525 ℃,在1 min内升至设定温度并保温5 min,应变速率为0.01,0.1和1 s-1,应变量均为50%。压缩过程中采用石墨和机油进行润滑,试样压缩后立即淬火。在试样上平行于压缩方向取样,选中间区域进行显微分析。金相组织的观察在XJP-6A型立式光学显微镜上进行,用于金相组织观察的试样采用体积分数为4%的硝酸酒精溶液进行腐蚀,腐蚀时间为20~30 s,扫描电镜(SEM)组织观察在Quanta-200型扫描电镜上进行,采用D500-X线分析仪分析合金的相组成。

2 实验结果与讨论

2.1 显微组织观察与分析

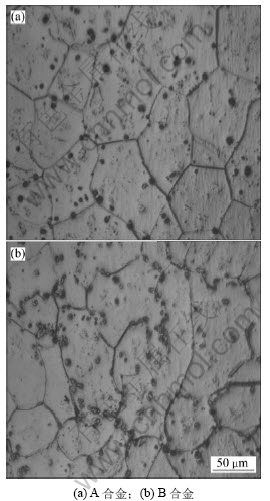

图1所示为Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr(x=0和0.2%,质量分数)合金的固溶态显微组织。从图1可以看出:2种合金的晶粒粒径基本相同,平均晶粒粒径约为47 μm,这说明Ce元素对合金的晶粒粒径没有明显影响;晶界及晶内分布着大量块状粒子,粒径约为3 μm,主要沿晶界分布,其中在B合金中出现一种“椭球状”白色粒子,粒子粒径为3~5 μm,主要沿晶界分布。

图1 Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr(x=0和0.2%,质量分数)合金的固溶态显微组织

Fig.1 Microstructure of Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloys as solid-soluted

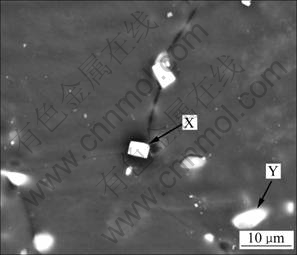

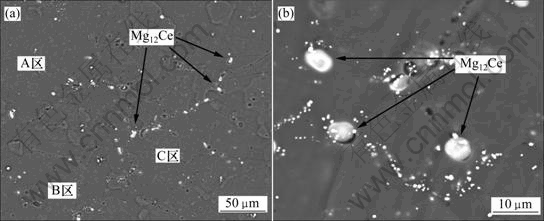

图2所示为Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金的固溶态SEM照片。从图2可见:分布在晶界附近有块状粒子和“椭球状”粒子,分别对2种粒子进行能谱分析,结果见表1和表2。块状相为含Y量相对较高的富稀土粒子,它并不含Ce元素,Ce元素主要存在于“椭球状”粒子中。

图2 Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金的固溶态SEM照片

Fig.2 SEM image of Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr alloy as solid-soluted

表1 图2中X点的能谱分析结果

Table 1 Sprectrum results of point X shown in Fig.2

表2 图2中Y点的能谱分析结果

Table 2 Sprectrum results of point Y shown in Fig.2

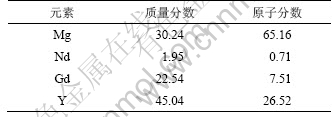

图3所示为A和B 2种合金的固溶态X线衍射谱(XRD)。综合图2的能谱分析,并通过图3(a)和(b)图对比得白色“椭球状”相为Ce含量相对较高的Mg12Ce粒子[6-7]。

2.2 热压缩实验结果分析

为研究这些粒子对再结晶的作用,对合金A和B进行热模拟实验,试验温度为375,425,475和525 ℃,应变速率为0.01,0.1和1 s-1,变形量为50%。平面应变压缩试验时的名义真应变如式(1)所示,名义平均应力(即压头对试样所施加的平均应力,如式(2)所示。

图3 Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0,0.2%, 质量分数)合金的固溶态XRD谱

Fig.3 XRD patterns of Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloy as solid-soluted

(1)

(1)

(2)

(2)

其中:h为试样变形后的瞬时厚度;h0为试样变形前的厚度,取10 mm;F为压缩载荷,可由热力模拟试验机测得;w为压头宽度,取8 mm;B为压头长度。

由于试样在压缩时将发生一定的宽展,因此实际的应变量将略大于名义应变量,而实际的平均应力将略小于名义平均应力。Sellary等通过实验与计算提出修正后的应力与应变计算公式,以表示实际的应力-应变关系[8],即

(3)

(3)

(4)

(4)

(5)

(5)

其中:f为修正系数;b为试样在压缩过程中的瞬时宽度,用西斯公式[9]计算,即

(6)

(6)

(7)

(7)

其中:c为宽展系数,由实验确定,c=0.35~0.48,取0.35;Δh为压下量。

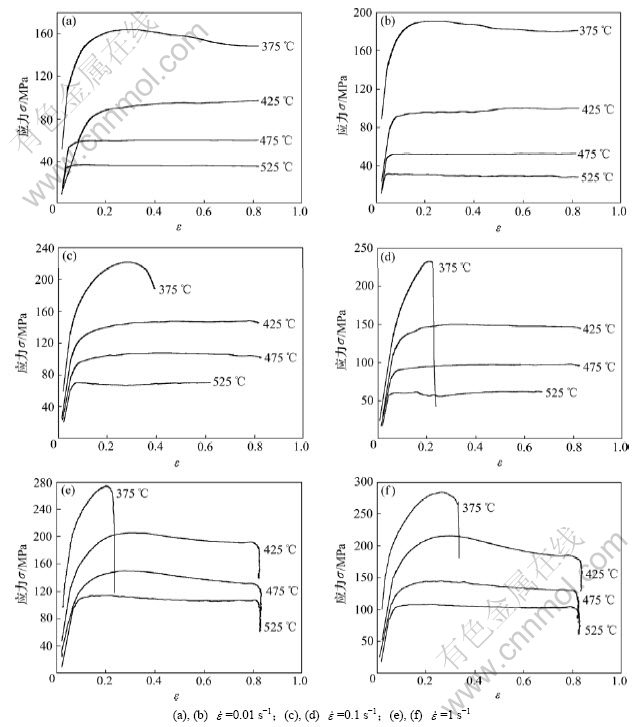

图4为合金A和B的真应力-应变曲线。由图4可知,在压缩变形的初始阶段主要是弹性变形,应力-应变曲线呈直线关系,符合胡克定律;随着变形量的继续增加,流变应力逐渐增加,到达峰值后逐渐降低进入稳态流变阶段,此时,加工硬化和动态再结晶产生的软化达到平衡;但在低变形温度为375 ℃的条件下,应力-应变曲线在达到峰值应力后下降趋势明显比其他温度下的应力高,并且在高应变速率0.1和1 s-1条件下样品被压断。这是因为镁合金是密排六方晶体结构,滑移系数目较少,塑性较差,因此,在塑性变形过程中,加工硬化起主要作用;另外,镁合金的低温成型性受单个晶粒的塑性各向异性的限制,在变形过程中,这种多晶体的晶粒之间的应力不相容,从而导致合金的过早断裂[10]。在温度425~525 ℃下,由于非基面滑移系的启动和动态再结晶的发生,流变应力展现出较好的塑性和加工软化作用。

图4 Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0和0.2%,质量分数)合金的真应力-应变曲线

Fig.4 True stress-strain curves of Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloys

温度对流变应力有重要影响。从图4可知:在同一应变速率下,真应力随压缩温度的升高而降低,这是因为随着温度的升高,原子运动更剧烈,临界切应力减小;变形温度在动态再结晶的产生和数量上起关键作用,随着温度的升高,动态再结晶的数量增加,引起的软化程度增大,这两方面共同作用导致合金的真应力降低;在同一变形温度下,材料的真应力随应变速率的增大而增大。这主要是因为位错产生的数目与应变速率成正比,因此,位错强化作用增强;而且由于时间短,动态回复和动态再结晶进行的不充分,软化作用变弱,合金变形的临界切应力提高,导致流变应力增大[11]。

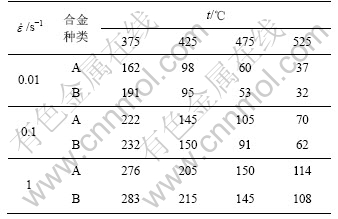

表3所示为Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0和0.2%,质量分数)合金在不同变形条件下实测峰值的流变应力。从表3可知:在低温下(375和425 ℃),A合金的峰值应力比B合金的低,而在高温下(475和525 ℃),B合金的峰值应力比A合金的低。这是因为在低温变形过程中,这2种合金组织中主要产生孪晶,动态再结晶(DRX)被抑制,且Ce的原子半径比Mg的大,Ce的化合价与Mg的化合价相差较大,因此,Ce在

表3 Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0和0.2%,质量分数)合金在不同变形条件下实测峰值的流变应力

Table 3 Measured peak flow stress of Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloy under different deformation conditions Mpa

Mg合金中产生一定的固溶强化作用,从而导致B合金的峰值应力比A合金的高。而在高温下(475和 525 ℃),变形组织中主要发生DRX,由于添加Ce元素形成的Mg12Ce粒子能够激发再结晶形核和抑制再结晶晶粒长大,因此B合金中的DRX体积分数比A合金的高且再结晶晶粒粒径比A合金的小,因此产生的软化效果比A合金好,因此B合金的峰值应力比A合金的低。

一般来说,金属材料热变形可视为原子扩散运动过程,引入变形表观激活能(Q)概念,热变形的温度与应变速率可采用带激活能项的Zener-Hollomon参数Z描述,如式(8)所示。在低应力水平下,Z参数与σ之间符合幂函数形式公式,如式(9)所示;高应力水平下,Z参数与σ之间符合指数函数形式公式,如式(10)所示;Sellars等[12]提出的半经验公式,Z参数与σ之间符合双曲正弦函数关系式,如式(11)所示。

(8)

(8)

或

或  (9)

(9)

或

或  (10)

(10)

或

或 (11)

(11)

其中:Q为表观激活能;T为热力学温度;σ为流变应力;R为气体常数,R=8.314 J/(mol·K);Ap,np,AI,βI,AH,αH和nH均为与σ和T无关的材料常数,np和nH可称为硬化指数,βI可称为硬化系数,常数αH满足:αH=βI/np。

Li等[13]认为双曲正弦函数更适合镁合金[13],尤其在高温条件下,双曲正弦函数拟合Z参数与σ间的关系得到的线性相关系数最高,这说明热变形过程是一个热激活过程。激活能可由如下公式求得:

(12)

(12)

其中:第1项为斜率 的平均值,第2项为斜率

的平均值,第2项为斜率 的平均值。

的平均值。

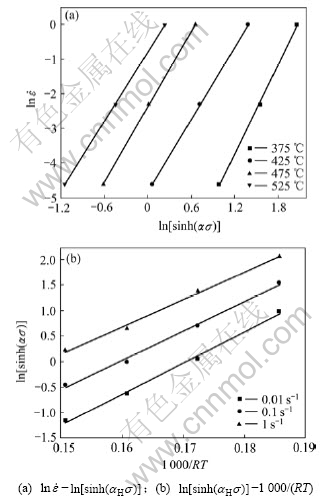

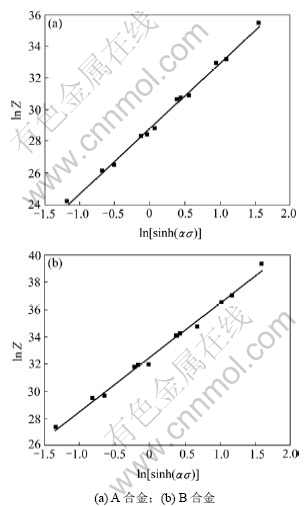

图5所示为Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金高温塑性变形过程中峰值应力、应变速率与温度的关系。由图5可知:相关量之间保持很好的线性关系,得到的线性相关系数都超过0.99。计算得到变形表观激活能:对Mg-5.5Gd-4.5Y-1Nd-1Zr, =191 kJ/mol;对Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr,

=191 kJ/mol;对Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr, =212 kJ/mol。这2种合金的激活能均比镁合金的自扩散激活能高。

=212 kJ/mol。这2种合金的激活能均比镁合金的自扩散激活能高。

图5 Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金高温塑性变形过程中峰值应力、应变速率与温度的关系

Fig.5 Relationship between peak stress/strain rate and temperature of Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr alloy during plastic deformation at high temperature

热变形激活能Q是衡量塑性变形难易程度的1个重要参数。在一般情况下,固溶态合金的热变形激活能较高。原因有2个方面:一是Gd和Y在镁合金中都有较大的固溶度,固溶体中的位错容易被这些溶质原子钉扎,使得位错的滑移和攀移受阻;二是固溶体中的位错在运动时会遇到阻力,因此,位错脱钉及运动需要的激活能均增加。B合金的激活能比A合金的高,这是因为B合金中添加了Ce元素,Ce在α-Mg基体中能够钉扎位错,有固溶强化作用,同时镁的层错能 (尤其是基面层错能)低,其扩展位错宽度大,很难从位错网中解脱,也很难通过交滑移和攀移而与异号位错抵消。Ce原子的加入提高了变形激活能,导致动态回复变得更加困难,使合金更有利于发生动态再结晶[14-15]。

图6所示为3种合金Z参数与流变应力的关系图。由图6可得应力指数nH和常数AH,将其代入式(11),得出2种合金用双曲正弦函数表示的流变应力方程:

对Mg-5.5Gd-4.5Y-1Nd-1Zr 合金,

对Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金,

图6 Z与流变应力的关系

Fig.6 Relationship between Z and flow stress

2.3 热压缩试样显微组织观察与分析

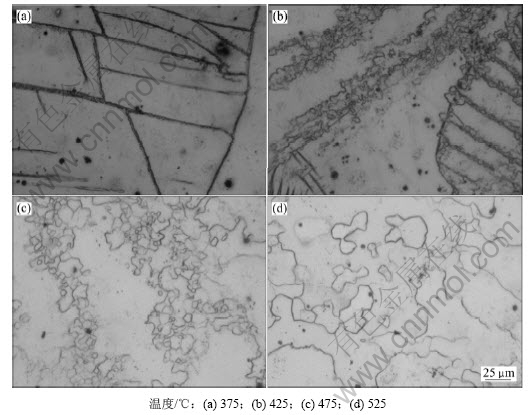

图7所示为Mg-5.5Gd-4.5Y-1Nd-1Zr合金热压缩的变形组织。从图7可知:合金在应变速率为0.01 s-1时的各个温度下均发生了动态再结晶,且再结晶体积分数及再结晶晶粒粒径随着变形温度的升高逐渐增大。在较低温度(375和425 ℃)下,在试样中发现典型的孪晶以及少量的动态再结晶。动态再结晶主要分布在晶界处及部分孪晶里面。这是由于镁合金在低温下的滑移系数小,塑性变形和动态再结晶只发生在一些取向占优势的晶粒中,且动态再结晶难以继续进行,因此,在位错滑移难以进行的晶粒中有孪晶[16]。孪晶界和晶界附近易出现位错塞积,形成缠结的位错墙,从而形成位错胞,位错墙逐渐转变为亚晶界,位错胞状结构也就转变成亚晶粒,随着应变的增大,亚晶界进一步转变为晶界,从而在原始晶粒的晶界处和孪晶里面形成具有链状结构的再结晶晶粒[17-18]。

图7  =0.01 s-1时Mg-5.5Gd-4.5Y-1Nd-1Zr合金热压缩的变形组织

=0.01 s-1时Mg-5.5Gd-4.5Y-1Nd-1Zr合金热压缩的变形组织

Fig.7 Microstructures of Mg-5.5Gd-4.5Y-1Nd-1Zr alloy by hot compression at  =0.01 s-1

=0.01 s-1

在中温(475 ℃)下,孪晶基本消失,动态再结晶主要在晶界上发生。动态再结晶与交滑移的产生有很大关系。根据Friedel-Escaing交滑移机制[17],交滑移主要是在原始晶界附近被激活,该处的应力高度集中,位错的交滑移使基面上的螺型位错转变为1个新基面上的螺型位错和2个非基面上的刃型位错,由于这种刃型位错位于非基面上,该面的层错能很高,因此,位错易攀移。位错由于交滑移和攀移造成的重排而在原始晶界处生成了小角度网络,小角度边界附近不断吸收位错而导致新晶粒的形成。在高温(525 ℃)下产生的是不连续动态再结晶,不连续动态再结晶与位错有关而与孪晶没有太大关系,新晶粒是由形核和长大形成的[19]。此时原子扩散和晶界的迁移作用增强,动态再结晶晶粒变粗大,但分布更均匀,高温作用促进动态再结晶晶界的迁移,从而使动态再结晶逐渐取代母相晶粒。

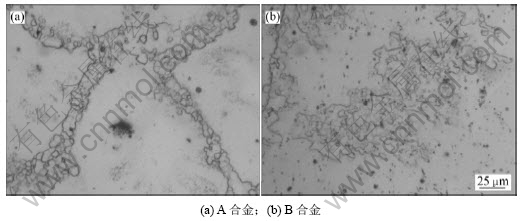

图8所示为Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr(x=0和0.2%,质量分数)合金热压缩的变形组织。由图8可知:经过压缩变形后,富稀土粒子仍然弥散分布于合金中;A合金中的再结晶晶粒主要沿晶界分布,B合金中的再结晶除在晶界上形成之外,还有少量在第二相粒子周围形成;B合金的再结晶晶粒粒径比A合金的稍小。这说明第二相粒子对再结晶有粒子激发形核(PSN)效应,并且能够细化再结晶晶粒。PSN效应在含高成分稀土元素的镁合金中经常可以观察到,当粒子粒径超过1 μm,且在压缩过程中不变形时便可以通过粒子激发形核效应而加速再结晶[20]。

图9所示为Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金热压缩变形组织的SEM照片。如图9(b)所示,压缩变形后Mg12Ce粒子仍然呈“椭球状”,粒径为3~5 μm,且粒子弥散分布,粒子间距离较远,说明这些粒子符合PSN形核的条件,因此,可以产生粒子激发形核效应,这在文献[6]中也得到证实。如图9(a)中的箭头所示,在Mg12Ce粒子周围发生了再结晶,而在Mg12Ce粒子比较少的A,B和C区则没有或者很少再结晶晶粒。

图8 Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0和0.2%,质量分数)合金热压缩的变形组织( =0.1 s-1,475 ℃)

=0.1 s-1,475 ℃)

Fig.8 Microstructures of Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloys by hot compression at  =0.1 s-1 and temperature of 475 ℃

=0.1 s-1 and temperature of 475 ℃

图9 Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr合金热压缩变形组织的SEM照片( =0.1 s-1,525 ℃)

=0.1 s-1,525 ℃)

Fig.9 SEM images of Mg-5.5Gd-4.5Y-1Nd-0.2Ce-1Zr alloy by hot compression at  =0.1 s-1 and temperature of 525 ℃

=0.1 s-1 and temperature of 525 ℃

粒子激发形核是许多含大粒子的工程材料的主要形核方式。高密度位错易聚集在这些粗大的Mg12Ce粒子处形成缠结的位错墙,位错墙组成位错胞,随着变形过程的进行,位错墙逐渐转变为亚晶界,这些小的位错胞状结构也跟着演变成亚晶结构,亚晶界逐渐转变为晶界,因此,亚晶粒逐渐转变为再结晶晶 粒[18, 21]。另外,Mg12Ce粒子对再结晶晶粒的长大也有抑制作用,因此,B合金比A合金的再结晶体积分数高,且B合金中的再结晶晶粒粒径比A合金中的小。如图9(b)所示,在Mg12Ce粒子周围分布着大量弥散分布的高密度小粒子,这些小粒子对回复前期位错胞壁和后期亚晶界的移动都有钉扎作用,导致回复形成的亚晶粒粒径和亚晶界错配角很小,若不能达到临界值,则不能形成大角度晶界,再结晶形核就会被抑制,只有大粒子影响区的局部储存能产生的驱动力大于小粒子的局部钉扎阻力和再结晶形核的临界驱动力之和时,再结晶才能形核和长大[22],这可能也是B合金中的再结晶晶粒尺寸比A合金中的小的原因之一。

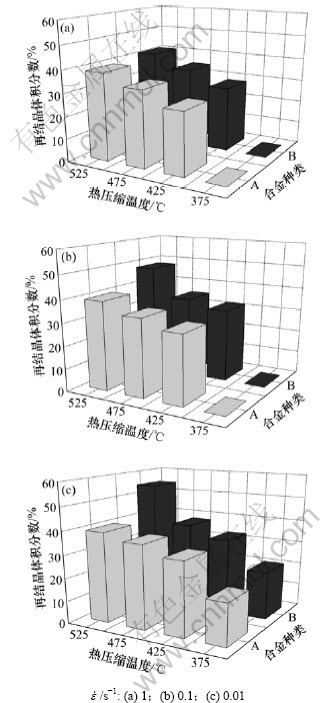

图10为A和B合金热压缩变形组织中的再结晶体积分数。由图10可知:在375 ℃时,A和B合金压缩组织在应变速率为1和0.1 s-1时没有发生动态再结晶;在0.01 s-1开始发生再结晶;在各个变形制度 下, B合金热压缩变形组织中的再结晶体积分数都比A合金的高,且温度越高,2种合金的再结晶体积分数相差越大,这也证实添加Ce元素后形成的Mg12Ce粒子对变形组织中的动态再结晶有粒子激发形核效,且粒子激发形核效应大于Zener钉扎对再结晶形核的抑制作用,因而,B合金热压缩变形组织中的再结晶体积分数比A合金的高。

图10 Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0和0.2%,质量分数)合金热压缩变形组织中的再结晶体积分数

Fig.10 Volume fraction of recrystallization in hot compression structure of Mg-5.5Gd-4.5Y-1Nd-xCe-1Zr (x=0 and 0.2%, mass fraction) alloys

3 结论

(1) A和B合金在425~525 ℃下的变形表观激活能分别为191 kJ/mol和212 kJ/mol。

(2) 随着变形温度的升高或应变速率的降低,A和B合金中的再结晶体积分数逐渐增加,再结晶晶粒尺寸逐渐增大。

(3) A和B合金在375 ℃、应变速率为0.01 s-1的变形条件下开始发生动态再结晶,添加Ce元素可提高合金的再结晶体积分数,降低再结晶晶粒尺寸。

(4) 在Mg-5.5Gd-4.5Y-1Nd-1Zr合金中添加Ce元素生成了一种“椭球状”Mg12Ce粒子,该粒子对再结晶有PSN作用,能够激发再结晶形核和抑制再结晶晶粒长大。

参考文献:

[1] LIU Jian, CUI Zhen-shan, LI Cong-xing. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B[J]. Computational Materials Science, 2008, 41(3): 375-382.

[2] YANG Xu-yun, Miura H, Sakai T. Recrystallization behaviour of fine-grained magnesium alloy after hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1139-1142.

[3] Watanabe H, Mukai T, Ishikawa K, et al. Low temperature superplasticity of a fine-grained ZK60 magnesium alloy processed by equal-channel-angular extrusion[J]. Scripta Materialia, 2002, 46(12): 851-856.

[4] 罗许, 史庆南, 刘韶华, 等. 材料等径角挤压法发展新趋势[J]. 上海金属, 2009, 31(3): 54-58.

LUO Xu, SHI Qing-nan, LIU Shao-hua, et al. The new trend of ECAP in materials[J]. Shanghai Metal, 2009, 31(3): 54-58.

[5] Wang X J, Wu K, Zhang H F, et al. Effect of hot extrusion on the microstructure of a particulate reinforced magnesium matrix composite[J]. Materials Science and Engineering A, 2007, 465(1/2): 78-84.

[6] Huppmann M, Gall S, Müller S, et al. Changes of the texture and the mechanical properties of the extruded Mg alloy ME21 as a function of the process parameters[J]. Materials Science and Engineering A, 2010, 528(1): 342-354.

[7] Peng Q M, Wang J L, Wu Y M, et al. The effect of La or Ce on ageing response and mechanical properties of cast Mg-Gd-Zr alloys[J]. Materials Characterization, 2008, 59(4): 435-439.

[8] 牛济泰. 材料与热加工领域的物理模拟技术[M]. 哈尔滨: 哈尔滨工业大学出版社, 1999: 153-157.

NIU Ji-tai. The physical simulation technologies of hot processing and materials[M]. Harbin: Harbin Institute of Technology Press, 1999: 153-157.

[9] 傅祖铸, 罗春晖. 有色金属板带材生产[M]. 长沙: 中南大学出版社, 2000: 27-29.

FU Zu-zhu, LUO Chun-hui. Nonferrous metal plate and strip production[M]. Changsha: Central South University Press, 2000: 27-29.

[10] Cottam R, Robson J, Lorimer G, et al. Dynamic recrystallization of Mg and Mg-Y alloys: Crystallographic texture development[J]. Materials Science and Engineering A, 2008, 485(1/2): 375-382.

[11] 张志高, 夏长清, 乔翔, 等. Mg-8Gd-3Y-0.5Zr耐热镁合金的热压缩变形行为[J]. 矿冶工程, 2009, 29(5): 105-108.

ZHANG Zhi-gao, XIA Chang-qing, QIAO Xiang, et al. Hot Compression deformation behavior of Mg-8Gd-3Y-0.5Zr magnesium alloy[J]. Mining and Metallurgical Engineering, 2009, 29(5): 105-108.

[12] Sellars C M, McTegart W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[13] LI Li, ZHANG Xing-ming. Hot compression deformation behavior and processing parameters of a cast Mg-Gd-Y-Zr alloy[J]. Materials Science and Engineering A, 2011, 528(3): 1396-1401.

[14] JIN Neng-ping, ZHANG Hui, HAN Yi, et al. Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature[J]. Materials Characterization, 2009, 60(6): 530-536.

[15] 姚素娟. Mg-Gd-Y(Sc)合金的制备技术和高温性能研究[D]. 长沙: 中南大学材料科学与工程学院, 2009: 55-61.

YAO Su-juan. Preparation technology and high temperature properties of Mg-Gd-Y(Sc) alloys[D]. Changsha: Central South University. School of Materials Science and Engineering, 2009: 55-61.

[16] Zhao X, Zhang K, Li X G, et al. Deformation behavior and dynamic recrystallization of Mg-Y-Nd-Gd-Zr alloy[J]. Journal of Rareearths, 2008, 26(6): 846-850.

[17] 陈振华, 严红革, 陈吉华, 等. 镁合金[M]. 北京: 化学工业出版社, 2004: 210-212.

CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, et al. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004: 210-212.

[18] Yang Z, Guo Y C, Li J P, et al. Plastic deformation and dynamicrecrystallization behaviors of Mg-5Gd-4Y-0.5Zn-0.5Zr alloy[J]. Materials Science and Engineering A, 2008, 485(1/2): 487-491.

[19] Chino A, Kado M, Mabuchi M. Compressive deformation behavior at room temperature -773 K in Mg-0.2 mass% (0.035at.%)Ce alloy[J]. Acta Materialia, 2008, 56(3): 387-394.

[20] Yang Z, Li J P, Zhang J X. Effect of homogenization on the hot-deformation ability and dynamic recrystallization of Mg-9Gd-3Y-0.5Zr alloy[J]. Materials Science and Engineering A, 2009, 515(1/2): 102-107.

[21] Ihara K, Miura Y. Dynamic recrystallization in Al-Mg-Sc alloys[J]. Materials Science and Engineering A, 2004, 387/389(15): 647-650.

[22] 宋晓艳, Markus R, 张久兴. 含有两尺寸组粒子分布的多相材料再结晶的研究[J]. 金属学报, 2004, 40(10): 1009-1017.

SONG Xiao-yan, Markus R, ZHANG Jiu-xing. Recrystallizion in multi-mhase materials containing particles with a two-class size distribution[J]. Metal Technology, 2004, 40(10): 1009-1017.

(编辑 邓履翔)

收稿日期:2011-05-31;修回日期:2011-07-15

基金项目:国防基础科研项目(A0420110401)

通信作者:张新明(1945-),男,湖南常德人,博士,教授,从事铝及铝合金的组织、织构理论与塑性加工技术研究;电话:0731-8830265;E-mail: xmzhang@csu.edu.cn